-

Posts

3,980 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by KeithAug

-

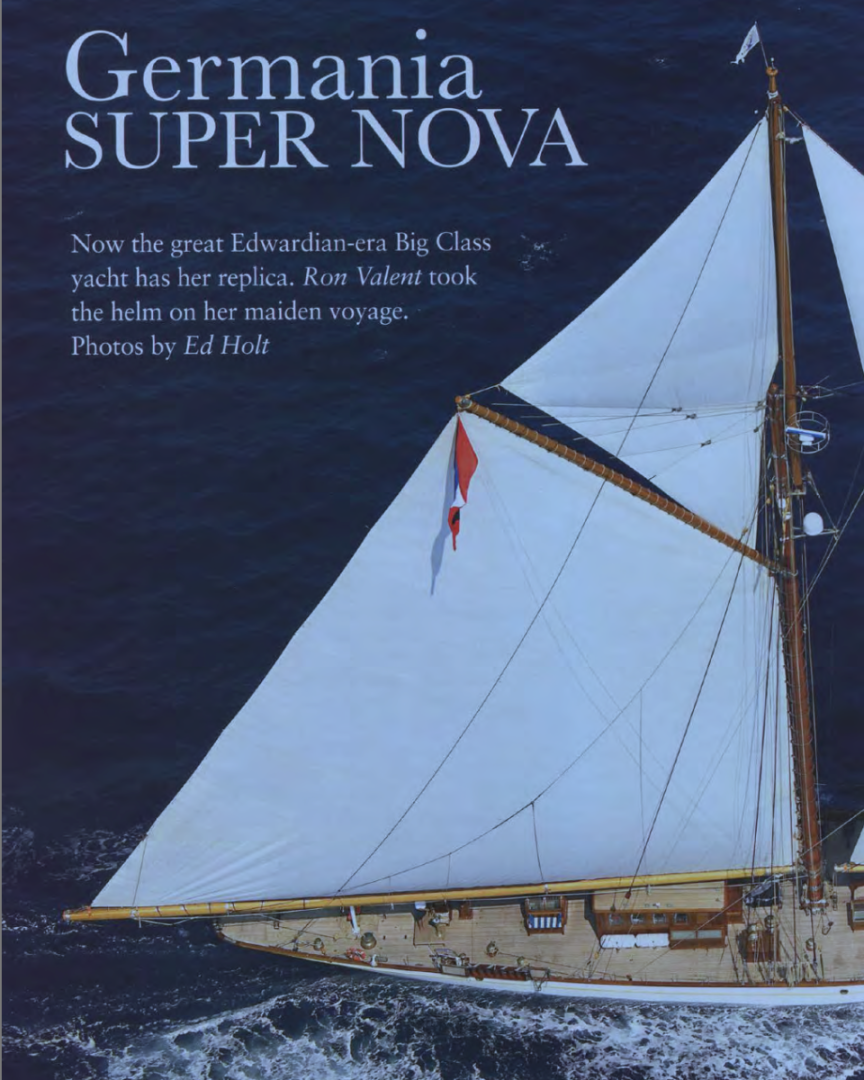

Hakan - I think good practice isn't always achieved - i was thinking of this shot of Germania when I made the comment. I hope you are keeping ok?

-

Bit of both Dan, also they are often just dumped in a jumbled mess on the deck. There are so many and given the mast height they are so bulky that hanging all of them from the belaying pins would probably be impractical. At the scale I am modelling it becomes virtually impossible.

-

Accurate Triangle metal square

KeithAug replied to michael101's topic in Modeling tools and Workshop Equipment

Hmmmm! Best not to upset the admiral. -

Accurate Triangle metal square

KeithAug replied to michael101's topic in Modeling tools and Workshop Equipment

It was easy, she just flipped over the pan. -

Enough of this speculative chat about the future and back to the job in hand - But thank you all for your contributions. Time to tidy up some of those loose ends. Those of you with long memories will remember that many many months ago I made the pin rails for the foot of the masts. With the blocks installed around the masts the pin rails could be glued in place. As you might imagine tying off the halyards was a bit of a pain ( I marvel at the patience of all you fully rigged ship builders). The fore mast starboard side. I then coiled the tails. Fore mast port side. Main mast starboard side. Main mast port side. Fore mast port looking forward. You may also remember that I only completed the fore and aft standing rigging to ease access for the sail and halyard installation. Now it is time to move on to the abeam standing rigging. But first I needed a few more shackles to attach the turnbuckles. Luckily my storage system for long ago made parts is working well. You may remember the turnbuckles. The 16 turnbuckles were then attached to the rails with the afore mentioned shackles. I think I need a break from rigging.

-

My wife has banned mirrors. We could start a list of pros and cons for each option. - Cangarda is the patriotic choice for a Michigan resident.😀

-

Yes I agree that Ena is the more beautiful yacht and the deck embellishments are far superior. The thing that is drawing me towards Cangarda is this:- I think it would be fun to include details of the engine room with the skylights open to allow viewing. Ena's engine room is below the main cabin and therefore not visible. However I have a couple of months before i decide finally.

-

SD 14 by RN77 - Marcle Models - CARD

KeithAug replied to RN77's topic in - Build logs for subjects built 1901 - Present Day

This looks different. You have sparked my interest. -

Hi Bob, yes i had seen that video - quite alarming really. I'm not really too sure why it happened. Yes I was going to email Rutherford's boatyard to see if they could help with the hull lines. I found some fairly reasonable plans on the internet, unfortunately the only real omission was the hull lines. Hakan, Yes she meets my "elegance" criteria. I'll add her to my search list.

-

Keith - yes I have looked at Ena but I am also looking at this:-https://www.sandemanyachtcompany.co.uk/yacht/618/pusey-and-jones-126-ft-steam-yacht-19012009. As yet i haven't found the hull lines anywhere.

-

Veszett, Thank you, if they are off the internet I think I can find them. I see the building of a modern replica is being considered - https://www.superyachtnews.com/owner/britannia-replica-to-rule-the-waves-again. In my case it might be worth waiting and building a model of the replica which should have a more comprehensive photographic record. Hakan - yes, i love the boats built in the early part of the 20th century. For me they epitomise elegance and beauty. I am thinking about building a display model of a steam yacht if I can find a subject with enough detail.

-

Veszett, Yes I looked at her some time ago the plus is that the plans can be bought, the minus is that there are not many decent photos of the deck detail. Have you found any?

-

They are all magnificent, unfortunately I don't think I have enough time left (or display space) to build many more of them. I think I misused my youth on work, i should have been born rich. I note Germania makes a few appearances in the video. I am currently wondering what to build next. My hope is to finish Germania before Christmas so I am looking round for another project. Thank you for the compliments.

-

Keel klamper alternative

KeithAug replied to zamboknee's topic in Modeling tools and Workshop Equipment

I must be missing something because I have never used a keel clamp. I just tend to knock up a support cradle from scrap wood and have never felt the need for anything better. As far as the Stanley vice is concerned I have one and wouldn’t recommend it for anything but the very smallest boats - nothing more than a few inches long. -

However if I look long enough i will find the answer! There are a pair of stays and they are obviously "running" stays that can be slackened on either side depending on which tack the boat is on. i hope the crew remember to tighten the stays or they may loose the fore top mast. it seems a bit of a worrying arrangement to me.

-

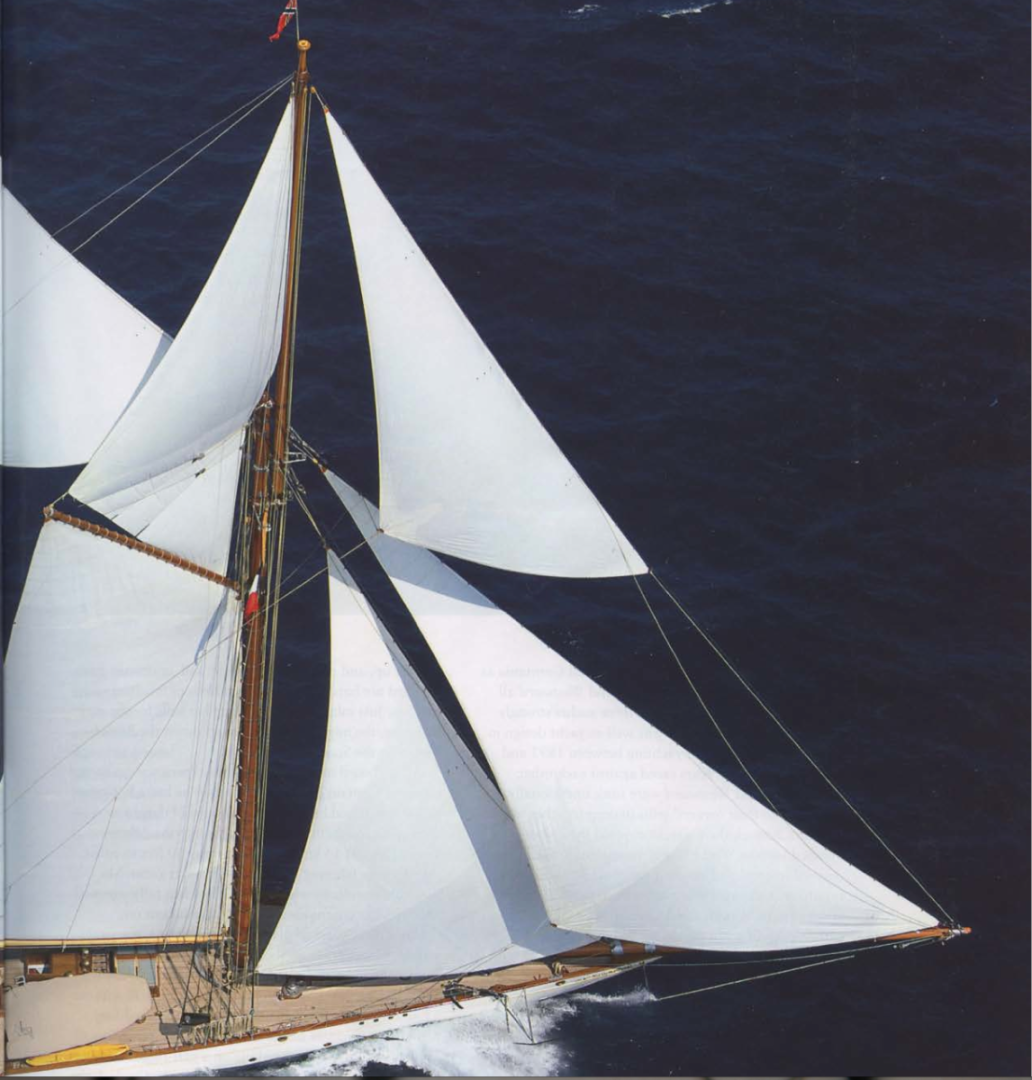

They have even managed to make tacking the fishermans complicated on Germania. I don't think you have spotted the unusual way the between mast stays are rigged. It is like the final video you posted in 2073. Now why would they do that? I have added insta360 to my Farther Christmas wish list. It is brilliant.

-

Thank you for your two interesting and informative contributions, i learned a lot and i am sure they will be of interest to quite a few visitors to my build. The camera work in the second video is fascinating. I assume a drone was employed with some sort of fancy lens. Were you the operator? The video also reminded me that I haven't hd chilli for a while and I love chilli. Steve - I have a lot of photos of Germania that supports your point. The coloured photos are of Germainia Nova while the black and white is the original.

-

I am sure I have seen someone post a picture of a Byrnes saw set into a work bench with the top flush with the bench surface. If I had the space I would do this to overcome the limitations of the relatively small table. p.s. Does everyone keep the blade guard on? I found it was constantly in the way and removed it a long time ago ( I take a lot of care - famous last words!).

-

Andrew, I haven't seen the film but I will look out for it on Netflix or similar. I agree there is something special about a schooner under full sail. Phil, I agree that a squall would be worrying. They seem to sail Germania most of the time with a much smaller sail (Photo) so I guess they are worried too. I don't like Germania as much with this rig. She seems a little "squat" to me. Sadly not Tom - we don't get a lot of visitors beyond family and close friends. The most important and valued audience is of course my friends at MSW. Thank you Keith, Brian, Steve, Pat, Andrew, Phil, Eberhard, Valeriy and Tom, your interest and kind remarks are as ever much appreciated. Also thanks to everyone who have visited and or liked my work.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.