-

Posts

3,534 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by amateur

-

Took some time to find and afternoon with enough spare time.... Today I finished the two aft double guns. Now only the single gun left. Jan

-

The last breechloading gun the Dutch Rijksmuseum has in its collection is dated 'before 1740'. The others are muzzle loading, or much older. Jan

- 9 replies

-

- swivel guns

- cannon

-

(and 1 more)

Tagged with:

-

As the others said: good to see you back in the workshop! Did you finish your cross stich project? Jan

- 161 replies

-

- pegasus

- victory models

-

(and 1 more)

Tagged with:

-

New Here and Cant Identify a Model Ship I Inherited

amateur replied to TroyFlores1994's topic in New member Introductions

Hi, hope you don’t mind me telling it... These type of odels used to be highly popular in Europe around the fifties. They took a ship type (in this case: clipper/tall ship), placed a name and a date on it that drew attention. Some of them very nice models, some of them a bit crude, none of them a real model of an existing ship. In your case the name refers to a type of sjip: a Spanish frigate, the model inspired by an 1880 english clipper. Take it for what it is: a decorative piece and a remembrance of your granddad. Jan -

All derflingers are build according to the same plan: a plan drawn by RolfHoeckel , a German wirter on historic ships. The plan is drawn somewhere around the forties, and is notquite historically accurate. the internet is full of it (eg here https://www.westfriesmuseum.info/critical-look/ ) there is definitely a knighthead in that position,, just as Mark shows. Whatever Dikarmade f it,it is not a galley for sure: ships in that period had there galley amidships, and is was just a brick box, nothing fancy. Jan

-

But he will not be able to reach under the details already there. resulting in non-treated areas around the tiny stuff. Don't know whether that is a good idea.... Jan

-

I you write 'tragedy', but the pictures do not look like tragedy..... Jan

- 146 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

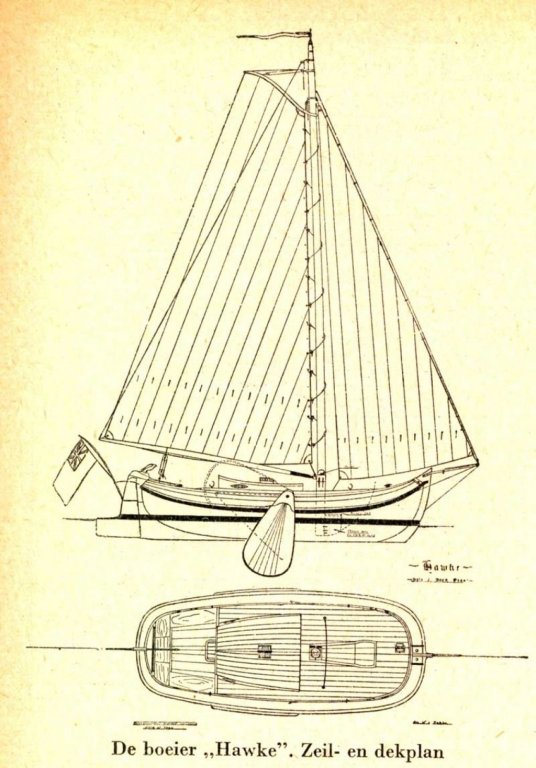

Nope, it is a schouw. One of our other famous flat bottomed ships. Not in the least as beautiful as a boeier. a Schouw is build from six large curved boards, with a flat sterns. jan

-

and with respect to the curvature: perhaps I overestimated the curvature in Kortes picture, but This is what I referred to: Straight for the lower half, curved only the upper half starting some distance above the iron ring that holds it. I guess the love for curves did play a role in this design. Jan

-

Hello Keith, There is absolutely no boeier there. That is a small 'schouw', probably a tourist visiting Amsterdam, or a local owning a boat that he uses to sail on the Amstel. Boeiers are sailing ships for the larger (mostly inland) waters. The moats in Amsterdam are/were a bad place for sailing ships: you can't get into those without the help of a motor (or rowing/poling), and a boeier can't be rowed. The moats are for transportation purposes: getting your goodies from the harbor to your warehouse. And a boeier is not suited at all for any kind of transportation. So no: no boeiers or any other larger sailing ships ever were in the Amsterdam moats. Therefore a fairly large amount of the bridges have always been fixed bridges (apart from a couple of the bridges over the river Amstel, and the canals connected to the Amstel. And believe me: a boeier will never be able to pass a bridge as low as the one you showed . Jan

-

Hi all, did some googling, and there is no answer. Its tradition. I think Kortes (or Sperwers builder) slightly overdid: in most cases the lower half is not curved, and the upper part is, to such an extent that the cap is at 45 degree angle to the waterline (more or less) I guess that it goes back to the 15th centyry, when also mastheads had a curved upper part (as far a I know: just to please the eye) nothimg to do with bridges: the lowered mast is higher , and the flagpole is not fixed, and can be removed) Jan

-

Thanks, I can follow your line of reasonimg. as for looks: I don’t like the completely enclosed versions, the open and straight are better, but the B-version is my favorite. What is uours: from the beginning your working sketches used the A-version. Jan

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

No, that was not the point I did not understand. I meant to say that when I look at that painting, I am struggling to see the back-end of the ship, so I don't understand how you conclude from that painting that there is not stepping in the superstructure. Even more: the superstructure just behind the paddle wheel does step back... Is there anything in the aerials made during the excavation that does give a clue in where the superstructure stood on the deck? Jan

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Actually, I don't see how you can conclude on the stepping back aft based on an artist impression of the from side..... having said that: I like the stepped back version more thatn the other one. Although a profit maximizing owner perhaps disagrees.... Jan

- 599 replies

-

- sidewheeler

- arabia

-

(and 4 more)

Tagged with:

-

Those are very nice birds! I like your attention to the very small details. just a question: you showed us a drawing in your fist post, but that drawing does not have this level of detail (at least not in the versions I know) Where did you get all the additional detail: from an other drawing, or did you just eyeball those on the basis of pictures?? Jan

-

I guess that Smit Rotterdam had those copper coloured props. Still looking for a pic.... (which turned in something else due to heavy use, so: 'do you build 'as new', or 'at the end of her life'. Here is 'new', unfortunately in BW-photography Pic found here: http://www.hobbyjan.nl/site/index.php?id=109&pagina=1 jan

-

Hi all, I need to clean my desk, and to make some pics, but today the unthinkable has happened: I tied the last knot on my rigging. Now, I need to make some sawdust for the remaining stuff: I still need: - guns - gunport lids (including hinges, rings and ropes) - lanterns - anchors - anchorrope - anchor buoys - flags Not on the home stretch by far.... Jan

- 139 replies

-

- corel

- prins willem

-

(and 1 more)

Tagged with:

-

Hi Doris, I would happily believe anyone that tells me that you fotoshopped a real gun into your last picture Your mastery, not only of card, but also of paint is astonishing. Jan (pm to myself: scan the dictionary for more superlatives )

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

New here. Possibly in over my head.

amateur replied to NicholasJ's topic in New member Introductions

Don't panic: it is like a lego box, but a slightly more complicated one Buying second hand is a bit of a risk: the box already being opened can result in either missing, or damaged parts. Buying a kit that is already started, is also a risk: you start out with the problems an other person made. Having siad that: step 1: check the contents of the box (check it against the instruction booklet, which I hope is there, otherwise you have a BIG chalenge) step 2: read the instruction booklet (not hust the first step, but all of it, at least twice). You can also do this as step 0 Step 3: try to imagine where everything has to go (more or less) step 4 buy you some basic tools and materials. a small hammer, couple of pins (you know the long shapr ones, the missus uses when creating a new dress). Clothing peggs can be usefull as well as clamps. Buy something like a couple of sharp knives (the X-acto will do, don't forget the spare blades, as you will snap and damage a couple when going along). for glue: white wood glue, gives you plenty of grip, and plenty of correction time. Some modellersfiles (not the heavy metal workers version), and sandpaper (course and fine). Accept the fact that you will come to the point that your tools don't suffice, and buy when needed. No need to set up a full scale modellers workshop before starting your first. Don't set your standards too high. I don't know what you paid for this kit, but be prepared to think "ah well, it was only just for fun, and I had some fun trying". The 'next will be better thought' will never leave you, however high quality you will ever reach With respect to the model itself: it looks as if the frames are already glued to the keel. If so, make sure that the keel is straight, and than the frames are perpendicular to the keel. And then you are off, onto a whole new road: read the booklet, and sees what comes next. Remeber: it is very tempting to do things not in the order the booklet shows, but they are there (probably) for a reason. In all cases: don't forget to think ahead. What comes next, and how am I going to do it. In case of doubt or emergency: stop working, and give us a shout and a picture. Jan -

Angling that part can be disrupting..... I should have done the same:cutting and glueing. I didn’t dare to do the steps jan

- 10 replies

-

- v108

- digital navy

-

(and 1 more)

Tagged with:

-

Admiralty model query

amateur replied to iMack's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Bob, Although I admire your knowledge and your equipment (guess you also use it for models, bur couldn’t find anything of that work here at msw), I wonder whether you make things more difficult than necessary: you can draw ideal lines, but I guess (never tried myself) that slightly less ideal would also work. The final fairing is done when frames are set up in the model so the use of a simple pencil and ruler and a basic set of curves should do for a beginner. I have even seen an admiralty type of model without lofting, using just station lines. Also Mccaffery uses such a method for his small-scale models: he cleverly builds up a layered block, and shapes it as if it were a solid hull modell. Requires some thinking and preparation, but it works without any curves or dawing let alone drafting. Jan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.