-

Posts

9,717 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Drillbitsunlimited.com And home depot or Lowes for MinWax wipe-On Poly satin finish Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The carriages on the contemporary model in the Rogers collection is very similar except for the super tiny trucks. I pretty much used the plan I showed which is a really good fit and more traditional. But there are many many variations. I would love to see someone have a go at the more wacky concepts used on revenue cutters. There are plenty.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

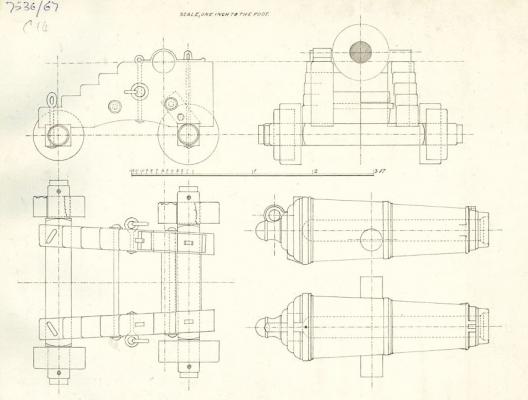

Most of the revenue cutters had them this wayafter 1800 or even a weirder looking carriage. This was the most normal.. Here is a plan detail of ZAZ6992 which actually says its for carronades on revenue cutters circa 1812. Its a little weird but its one of those things that make it interesting. This is from the NMM collection.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes I did...and a simple sanding stick. I started with a square stick of boxwood 3/64" x 3/64". It actually goes pretty quick once you get into it. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you very much I decided to make one carronade with all of the details. This way I could find out what is in store for me. Now I can more comfortably finish up the remaining 11 guns. I will describe how with a step-by-step once I get started. But for now..here is what the completed gun looks like. I also finished making the belaying pins. They were made from boxwood. I dislike the brass belaying pins available because they are just the wrong proportions. With only about 16 pins needed I decided to make my own. If you are a heavy handed rigger....someone who likes to pull theit rigging lines super tight like a guitar string then you should probably stick to the brass. Otherwise give this a try. I just chucked up a thin boxwood strip in my dremel and went to work. The same method was used to make the quoin handle for the carriages. Image is below. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

Chuck replied to rafine's topic in - Build logs for subjects built 1801 - 1850

Looks great Bob... One Note however. The 5 hole deadeye should be the other way around. ...but that has long since been corrected. It was mistakenly flipped at some point on my plan and I never noticed. I am referring to the deadeye itself......the holes are correctly aligned but the grooves in the deadeyes should go the other way around.....just letting everyone know. But either way it looks fantastic. Well done. Chuck- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That is looking really sharp. Well done John. Chuck

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Yupp, Thats how I do it. Then the slot is rounded off into the holes so the sheave actually looks rounded. To finish it off I use a sharp pencil to darken the sheave.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

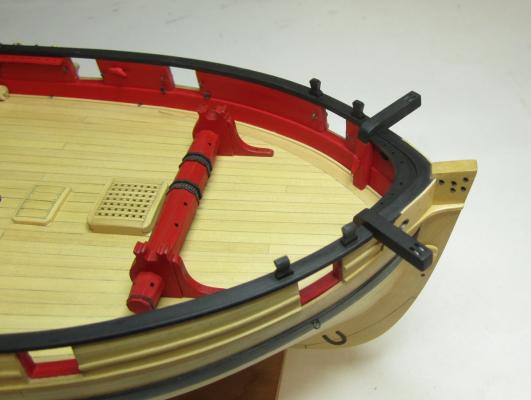

Today I finished up the bulwark details. All of the cleats and the pinrails have been added. I also made the catheads. These warrant special note. These were made in two pieces. They were shaped from a 3/16" x 3/16" strip. Care was taken to shape the inboard leg of the cathead to fit snug against the bulwarks. It had to be shaped to fit around the waterway and spirketting. The top portion had its two sheaves simulated in the usual manner. The cap rail was then notched out to accept the cathead and the two sections of the catheads were fit together ahead of time. After the notched cap rail was ready...the two parts were tweaked until they fit well. Only then were they glued together and painted. Hopefully sometime this week I will begin putting the gun carriages together or maybe make the belaying pins. I dont need that many belaying pins for this model so why not make them from scratch as well. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

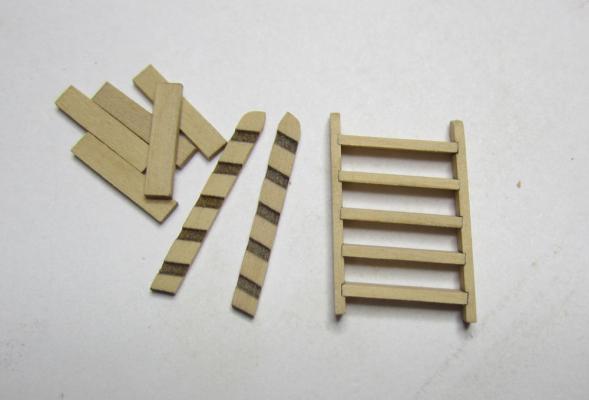

Thank You.... Its just a matter of slowing down and taking your time. Not rushing is a huge part of it. I think everyone can do the same but I see so many folks running through their projects like they are in a race. Should parts not fit correctly...throw them away and do it again. It took me about 2 hours to paint the stern after making the seats and adding the cleats. It took me about 1 hour to just paint one ladder after making it. Many thin coats being careful not to get any dust on it. Sanding carefully when imperfections and brush strokes take place. The key in my mind is to just slow down....my best advice for any model builder. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

At some point it does get ridiculous. Again I reiterate how I wanted this to be a scratch/semi-scratch project. But it all depends on how much demand there is for the pesky parts nobody likes to build from scratch. I have basically kept all of the laser cutting files for each element of the project just in case. If a lot of folks want these to be available I will certainly add them to the list of parts available. I use the laser cutter like anyone else would use any other tool. So its easy enough to do. Mike is in my local club for example...so I usually cut double the amount and I will give him some ladder kits tonight when I see him. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Making ladders now. They are usually very annoying to make in any scale. I quickly drafted some laser cut plans. Makes it much easier. I laser etched slots to take each step. Note the angle to the completed ladder. It follows the sheer of the deck fore and aft and therefore is askew. Otherwise it would look funny. These will be painted red. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes there would have been a discharge hole through the counter but it is rarely modeled. You can absolutely choose to show it if you want. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just a small update. I worked on the inboard stern details. The seats are completed. Card templates were made first using the plans as a guide. Then they were tweaked to get a nice tight fit with the parts. Cleats were added...these are all laser cut Syren cleats (5, 7, and 9mm). All that was needed to do was sand them a bit to shape and then add a piece of wire as a pin. Then they were glued into place. I decided to paint these bulwark red also to match the many contemporary models I have seen. Finally....the horse was added for the boom sheet. This was just a small piece of wire bent to shape. Two small washers laser cut from paper were added to finish it off nicely on each end. They were painted to look like metal. I should have dusted the model better before taking the pics....next time I will now continue my way forward along the bulwarks adding eyebolts, cleats, ladders and pin rails. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

Chuck replied to rafine's topic in - Build logs for subjects built 1801 - 1850

Nicely done......have fun with the serving machine....after a while you will wonder what all of the fuss is about. Serving is easy enough and it adds a great deal to the models look. Yours is certainly looking good.- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That is looking so nice. Very clean and precise. Can you place a ruler along side for a better grasp at just how large this model is? Thanks Chuck

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

That would be a bit risky.....i wouldnt do it...you would have more control just doing it by hand. Chuck

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cutter Cheerful by iosto - 1/4" scale

Chuck replied to iosto's topic in - Build logs for subjects built 1801 - 1850

Looking good!!! Wonderful.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.