-

Posts

9,703 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Had the guys over to the shop. Tale of two Winnies. One is mine and the other is Mikes (stuntflyer).

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks guys. There will be a barge but I am taking a break from Winnie for a bit. I am going to catch with with making inventory of blocks and rope once I get back and maybe start work on Speedwell. I also have to write the last chapter and cut parts for folks.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just a wee bit high on the angle. Make the bottom of the cathead flush with the bottom edge of the molding. That should adjust the angle a bit.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You have done a masterful job on her. I think I had as much fun watching you build her as you had building her. Beautiful work.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

You are welcome. I will be the first to admit that I take forever to design and produce these projects. I cant rush through them. So many kit mfgs seem to announce the availability of new kits every few months. That is something I can never do. This next project will be a bit of wait. Hopefully worth it. POF projects have triple the parts and more complexity. I prefer quality over quantity any day. I am also trying out some new design features to make it easier to build. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you so much guys. Its always a bit weird when you finish project that took years. I cant believe its done actually. writing the last chapter today.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you all for the kind comments. I wasnt planning on it. I dont think I have enough room in my shop for all the wood that I will need for those. They would also be ridiculously expensive. I will make the plans available however in short order. It would be best to have some uniqueness to everyones presentation as well. It will nice to see how everyone displays theirs.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Almost 5 years to the day....she is finally finished. Always a bit anti climactic. Thank you all for following along all these many years. For those of you building her, I hope you are having as much fun with it as I did. Well here goes the final pics. The top picture is of course of the Winnie contemporary model which inspired me as well as the Amazon. I hope I did them justice. Everyone should build a Georgian style model of an English frigate at least once in their lifetime.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

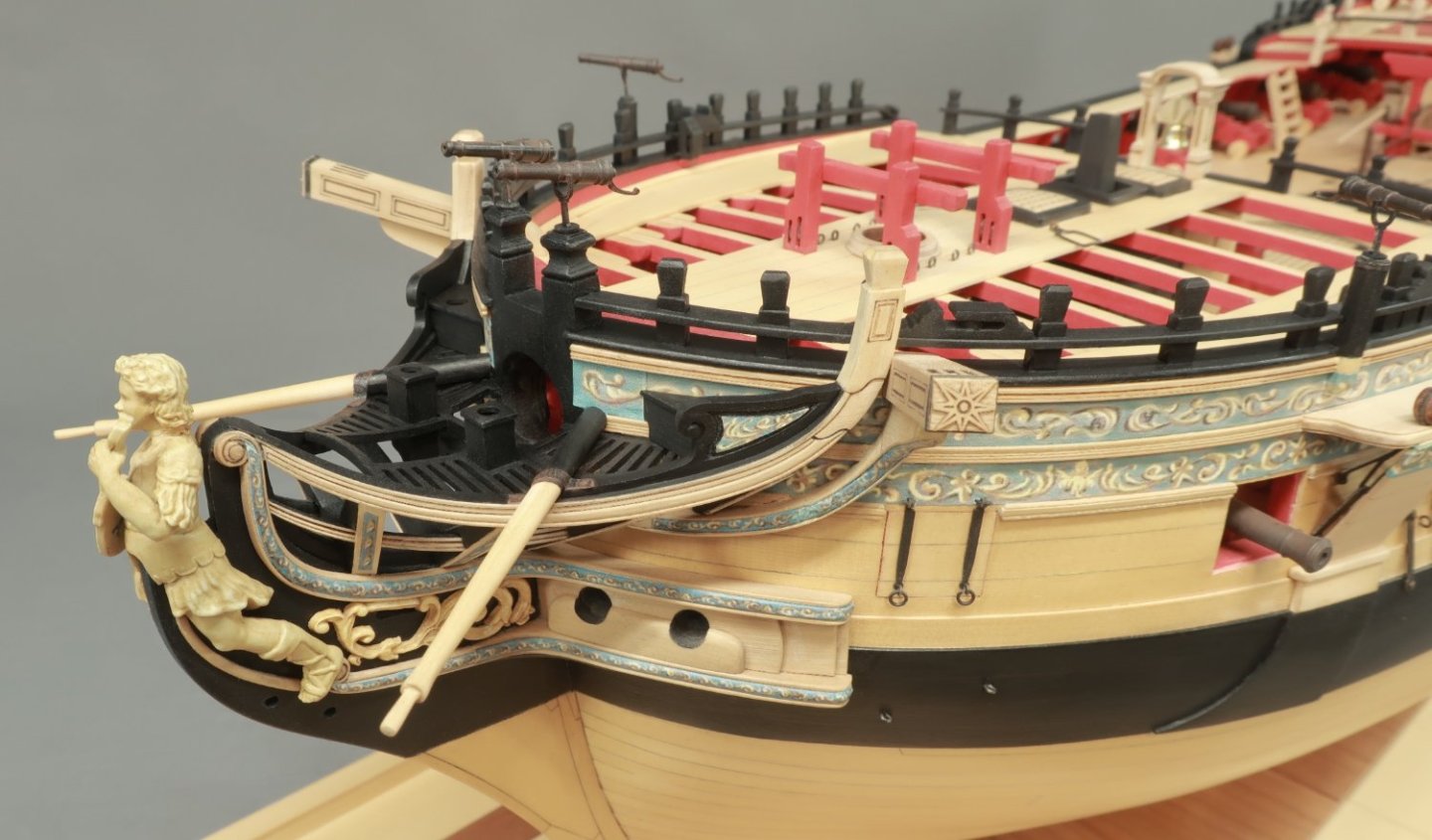

The bumpkins will be laser cut for you. They will be square. You will first need to sand the same tapered shape into it while keeping it square. It is cut from 1/8" stock and the forward end tapers much smaller. So first just match that taper as a square shape. Then round it off. BUT...you cant place them in a drill or lathe. They also have a slight downward curve to them. See this image of Amazon. Heres an image of the Minerva model. And the Winnie model which has the straight bumpkins....But I dont like that as much. I am going with the curved bumpkins like those on Minerva. You guys can go with straight if you like. Just use a 1/8 x 1/8 strip of boxwood or cherry. I am also going to leave the outboard end natural as shown on Minerva rather than paint them all black. Note the solid black false rail on Minerva above with no friezes. You may like that as well....so many possibilities. I also want to point out the wire rail shown on Minerva above. The Amazon doesnt show it and neither does the Winnie model. I am leaning toward not adding it. The run of this rail when viewed from the side sometimes doesnt follow the shear. It ruins the night smooth run and curve of the shear when you look at the model. I suspect it did have the rail but since I am not kitchen sinking this model it is optional. Many contemporary models dont show this feature as you can see. I also suspect they they left it off the models for the same reason that I am. But These pictures of the contemporary model of Minerva should be more than enough to guide you should you want to add them. The next pictures you see of my model will be of her all finished.....I am guessing by about noon tomorrow if I can get out of bed early enough.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Before I forget. Friezes for head timbers and head rails...I will also put in downloads area. It has the templates for shaping the cathead supports as well. headtimberfriezes.pdf

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

No not at all. I have only ever seen one contemporary model with those. Most didnt have anything. Its just as I have shown it. That is a more modern convention of showing it. But you could if you want to.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

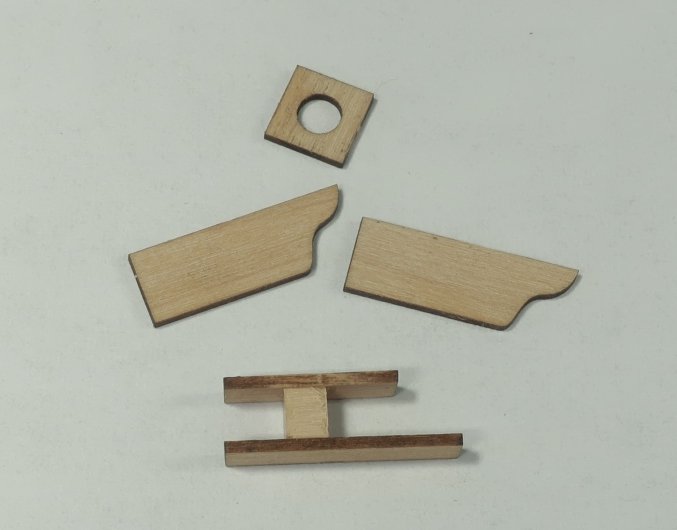

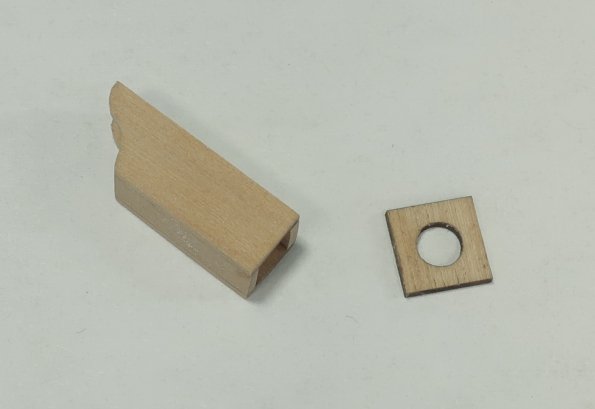

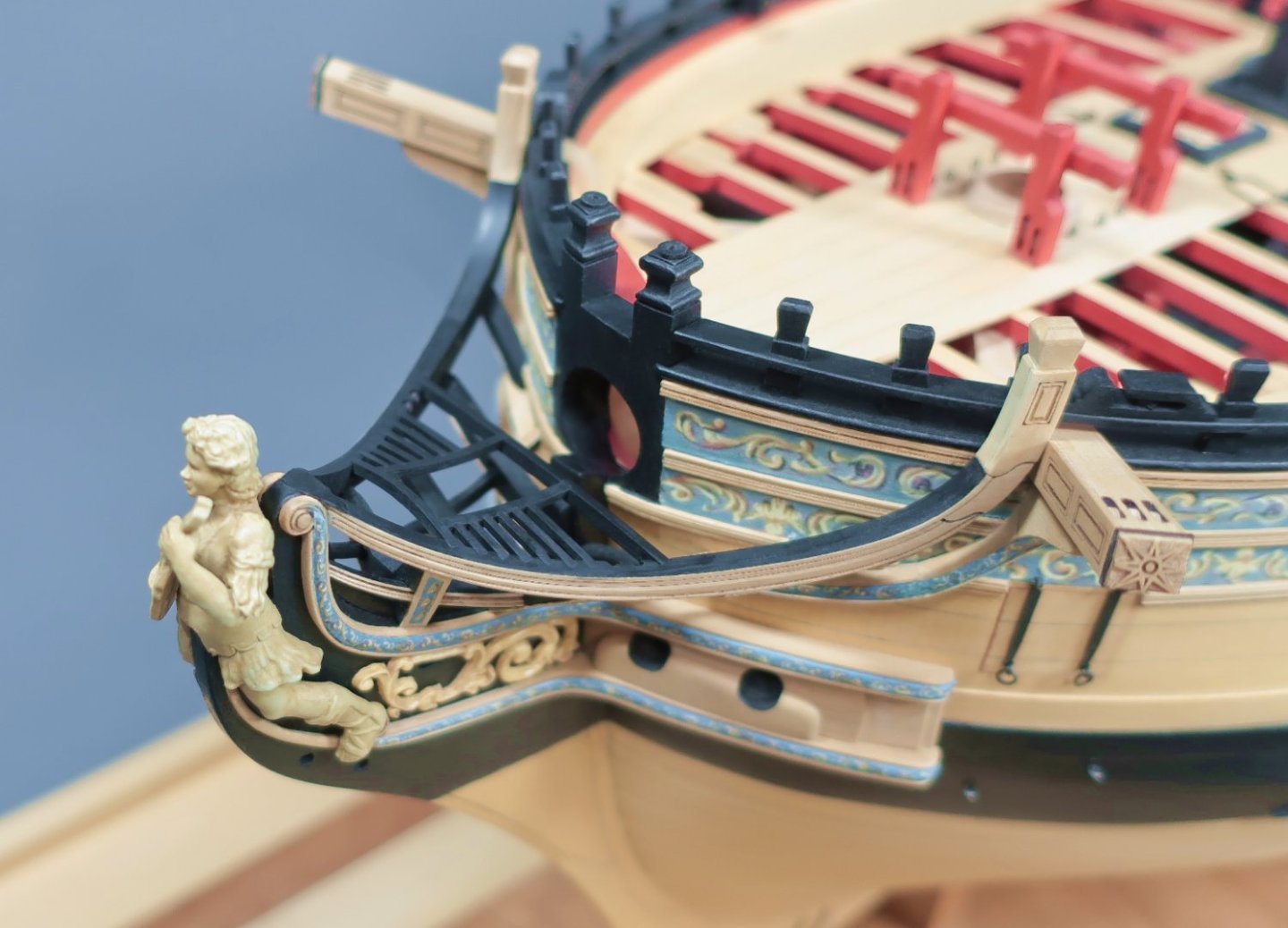

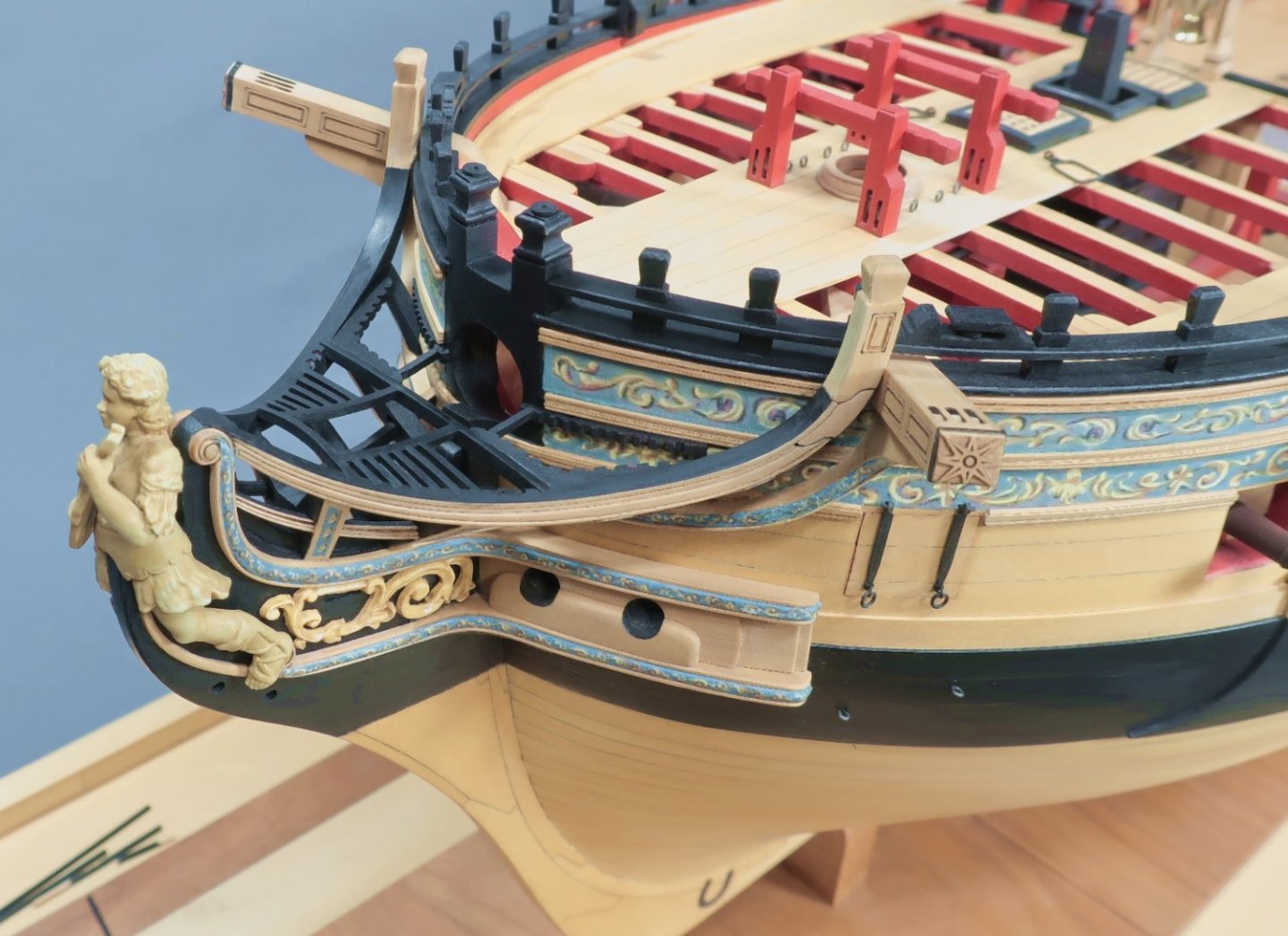

Thank you guys Moving along... Next up I made the false rails. These are pretty easy to make. Just sand them a bit to prep for painting. Test the fit on top of the main rail. There is a small circle or disc laser cut on the veneer sheet you will get. That is the tiny button for the scroll on the false rail. Paint it all black (or not) and add the freeze. Glue it into position. You can paint it black or keep it natural. That is up to you. There are many color combinations seen on contemporary models. You may also opt NOT to use the frieze here and just paint it all black. Its all about what you like best. Then it was time to assemble and add the aft seats. Those are the pair of seats in the corners between the false rail and hull. These can be tricky and I suspect everyone will have their own best way to make and position these. Here is what I did. I assembled them first and then painted them black before gluing them into position....BUT It was important to first test the fit of the top of these seats on the model so I could finalize its shape. Once I knew it would fit between the false rail and hull, I could tell how long to make the front face of the seat. These parts are laser cut but you will no doubt have to tweak them to fit your model. Then I glue the front face on the seat leaving the top with an ever so slight overhang. Note the filed out area where the molding would be and the main rail. This was all filed into the front face while off the model. I kept testing and tweaking for a good fit. Then I painted them black and glued them into position. I was careful to line them up so they looked even port and starboard. Dry fit both in position before gluing. ALL THAT REMAINS....is to do the bumpkins at this point and the model is all done. At least I think it will be, always feels like I am forgetting something. Anyway...by tomorrow it should all be completed. Any questions???

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thats a challenging little fitting to make. But really rewarding. You did an excellent job.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

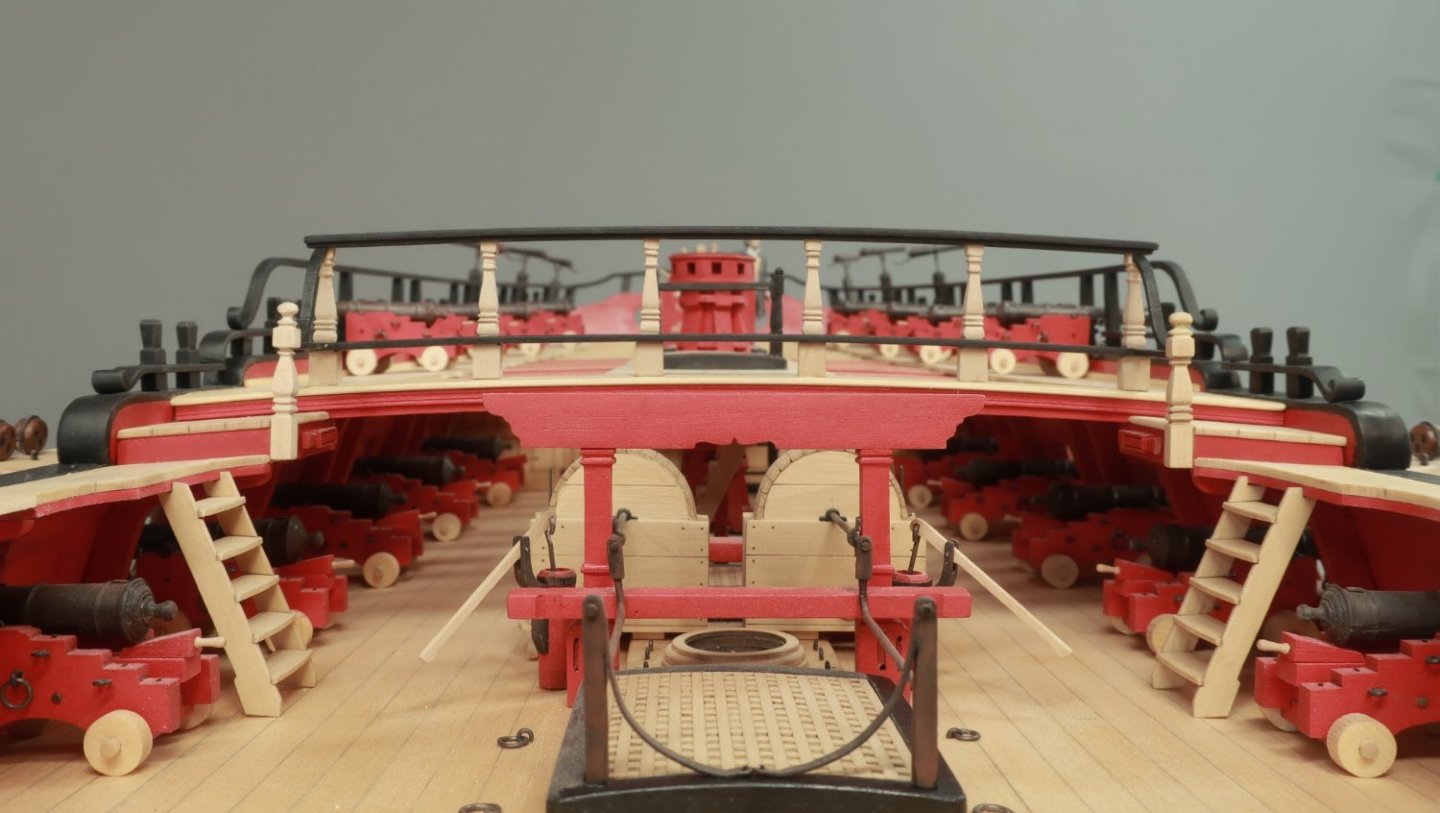

The forward seats... Here is a look at some contemporary models. On the Winnie model, note the poop shoot. It has slipped down over the years and hasn't been repaired. But its a nice feature usually never shown on a model kit. On Minerva you can see the two seats from above The top of the seat should be about 14" high off the grating. Thats about 5/16" so remember that. Maybe slightly less but not much. To make the seats its real easy. Cut a very small length of scrap wood strip. A 1/8" x 1/8" strip. Cut it very very short...maybe just 1/8" long. Its just to use so you can keep the seats squared up. Glue the two thinner sides onto this small 1/8" square as shown. Note how on one side the tops are flush. This will be the top of the seats. Then glue the other sides on. Easy peasy!!! At this stage paint the tube inside and out black and then glue on the top. Glue it onto the model. Make sure you face it the correct way. Look at those contemporary model pictures again of the poop shoot. Remember to keep the top of the seats about 5/16" above the gratings. Get them both to match. Also note that in that same photo I added a 3/64 x 3/64" strip against the outside face of the seat. This helps hold it into position. Dont worry about the dust at this stage. Sand any rough spots and touch up the paint. Then add those final two battens on each side. Use the curved ones that we used earlier. You should have plenty left over. At this stage start to clean everything up and repaint. Keep it neat and tidy. Here is an overall shot since these close ups are brutal. I have lots of cleaning and dusting and repainting to do once its all done. Next up the false rails and aft seats on the head gratings!!! Getting close now.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

By the way ....here is a PDF of the head grating layout. 8.5 x 11. headgratinglayout.pdf

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The head grating battens are complete for now. I added them all between the knees and the hull. These were just 3/64" x 3/64" strips. They were painted black ahead of time and cut to length. Then glued into position with the slots. I sanded them gently with 600 grit sandpaper and touched up the paint. Next will be the forward pair seats. Once these are done I can add the false rail and the two remaining seats of ease. Its hard to photograph all these pieces painted black but I am trying my best.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

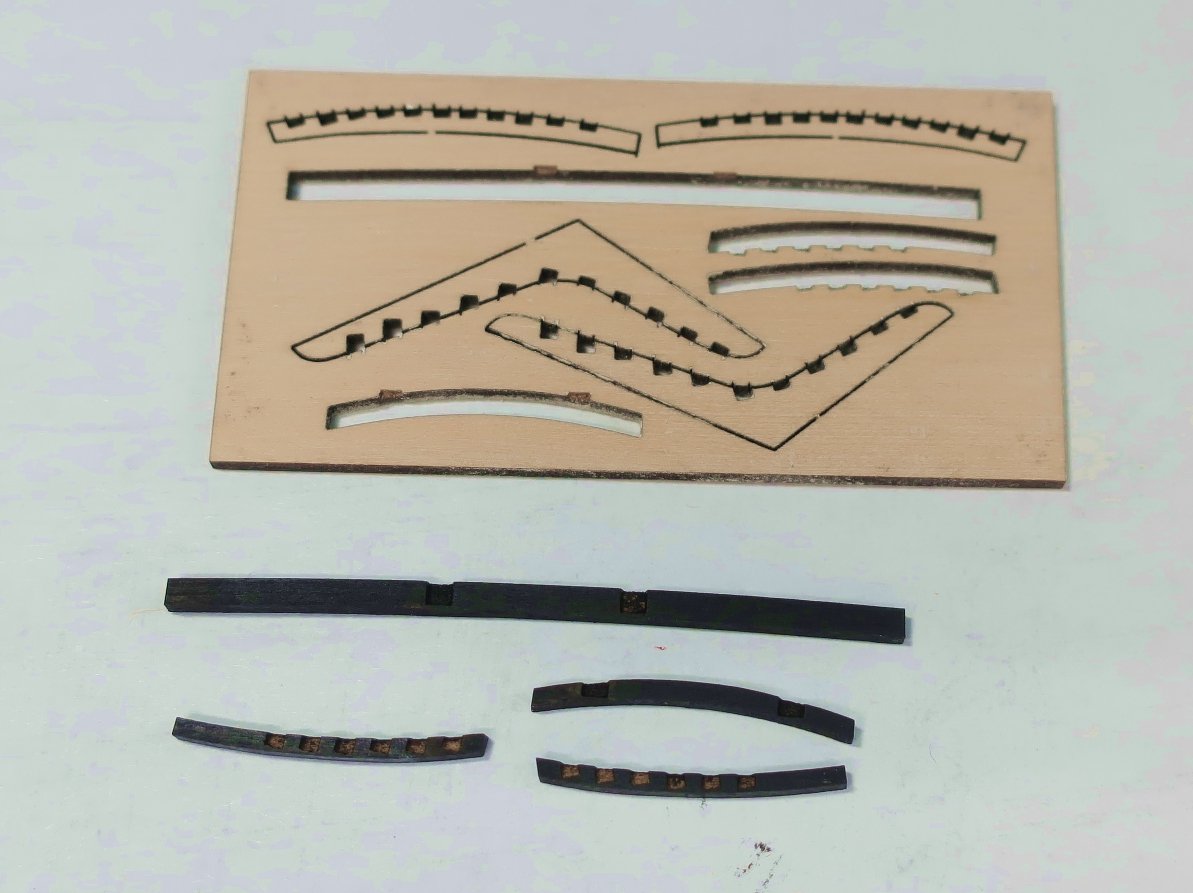

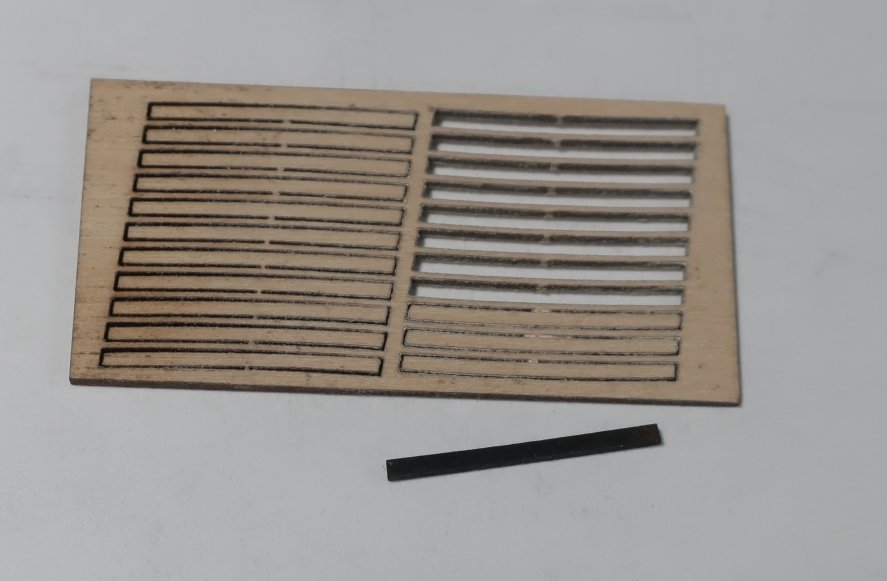

For the head gratings, you have to be methodical. I started by lightly sanding the initial for pieces and painting them black. These are 1/16" thick. Each of these pieces is laser cut slightly longer than you will need because everyone's model will vary a bit. The first two pieces are the two cross beams with a camber or roundup on them. These are the two that run port and starboard. Sand them to length a little at a time taking equal amounts off both sides until they fit snug in the notches of the main headrail. Dont make it so tight that it spreads your rails apart. Make it fit just right. Then the two pieces that run fore and aft can be added next. I recommend a dry fit of these four pieces before you glue them in permanently. Make sure you have the notches facing the correct way. Study these photos. Because next we will be adding the smaller gratings pieces. When you have these last two pieces in dry-fit only. Examine them to see if they are running straight with the center line of the hull and that they are both centered. Dont worry about the dust...you will be screwing up the paint job. Once you glue them in permanently you can give the top a light sanding with 600 grit sandpaper. Then touch up the paint. But dont worry about it being perfect yet because you will be sanding and painting more with each step. Next up are the smaller 3/64" thick battens which are also laser cut for you. These are laser cut really long because you have to cut them to fit your model exactly. I painted them black first. They have a slight curve as you can see. I inserted one end into a notch in the head gratings and then marked the length I needed as it spanned across to the other side. You will only be added the first six on each side at this point. Those last two wont be added until after we put the seats in position later. Carefully measure and cut all six grating battens and dry fit them first. Then glue them in with yellow glue or tite-bond. Brush away any excess glue to keep it neat. Once dry you can lightly sand the joints and paint. It should look like this at this current stage. Then go back to the 1/16" sheet and remove the two knees with all the notches in them. And also remove the long curved pieces with notches. These can be painted black ahead of time as well. Yes, even the bottom side. The knees will be put in position first. The longer leg of the knee sits along the main headrail. You will no-doubt have to adjust the angle of the knee so it fits your model properly. Both legs should sit firmly against the inside of the main rail and also the cross piece of the head. Note how it sits against the inside edge of the main rail. Do you see how it slopes down rather than sit flush with the top of the main rail. THIS is very important. You see, there is the other curved piece with notches that will sit against the hull. Those notches will have more battens running from them to its corresponding notch in the knee. You want the platform created by these battens to have a nice flow into the hull. You dont want them slopped up or down. Remember this when you place the curved piece against the hull. As designed, I intended for this piece to fit directly under the fancy molding as shown in the photos. Does this make sense? Its real important but may vary on your model. You may have to place it lower...every model will vary slightly. In that same photo you can see that I started added the battens between it and the knee. I did the first two. The inner two lengths. I added these first because I wanted to show you guys that these two battens will/should run parallel to the center line. This is yet another important piece of the puzzle and when you add the notched curved section along the hull be conscious of this. You want that first notch to line up directly across from the one on the knee so those first two battens are straight with the center line. Makes sense??? Plan the placement of those curved and notched pieces against the hull carefully. One end of this curved and notched piece is longer than the other. I did this purposely so you would know which side should be the aft end closest to the catheads. The longer end is towards the cathead. Tomorrow I will continue adding the remaining battens. Then its onto the seats of ease. Speaking of seats of ease.....until tomorrow then. You should ask questions if you have them when doing this part. There are lots of little details to remember about the placement of these pieces. Read through the instructions a few times.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chris’ wonderful figures being prepared for painting by a good friend of mine and master miniature painter Larry Friedlander. I am so excited about this. Thank you Chris for the best scale figures I have ever seen. It is so good not have a mini that looks like a cartoon. These are so realistic. bases are removed so they can be used on a model or diorama. then primed and ready for paint. This guys work is amazing and you will love it. I will try and keep you guys posted. One of Larry’s figures below to show you the kind of work he does.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.