-

Posts

9,703 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

I am really not sure what you are asking. It depends on what I am using it for. For planking sheets used to rip planking strips ....yes I will cut cherry or AYCedar that way. But other types of wood may be different. But on Cherry and AYC that is the best way to get grain free clear strips for planking....

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Its getting crazy now…yellow cedar used to cost me $10 per bf. As of this week after placing an order it has shot up to $19 per bf. This is for the primo stuff which we need. You can buy garbage Cedar wood cheaper but would have to throw half of it in the fireplace. boxwood and pear is way up there in the USA. Its actually cheaper for me to order a few hundred pounds of pear from Europe and have it shipped to me than buy it in the states. Its nuts. I havent raised my prices for my products yet over the last six years but sadly after the wood prices almost doubled now…I may have to. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very nice save. That is a very tricky part of the build. A square tuck is always a challenge and yours looks really good.

- 113 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ihave no idea...but let us know how your experiments work out.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I use either regular copy paper with my ink jet or when I want to go really thin so you cant see the paper at all I use tissue paper. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes...they work great BUT.....BUT, the adhesive is very strong and it isnt easy to reposition and slide them into place nicely. Thats why I prefer to use a glue stick which has an open time and lets you slide them around. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That is better answered by the others. But every part or nearly so is laser cut.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Slow and steady…they will fit. You just have to get the knack for it.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

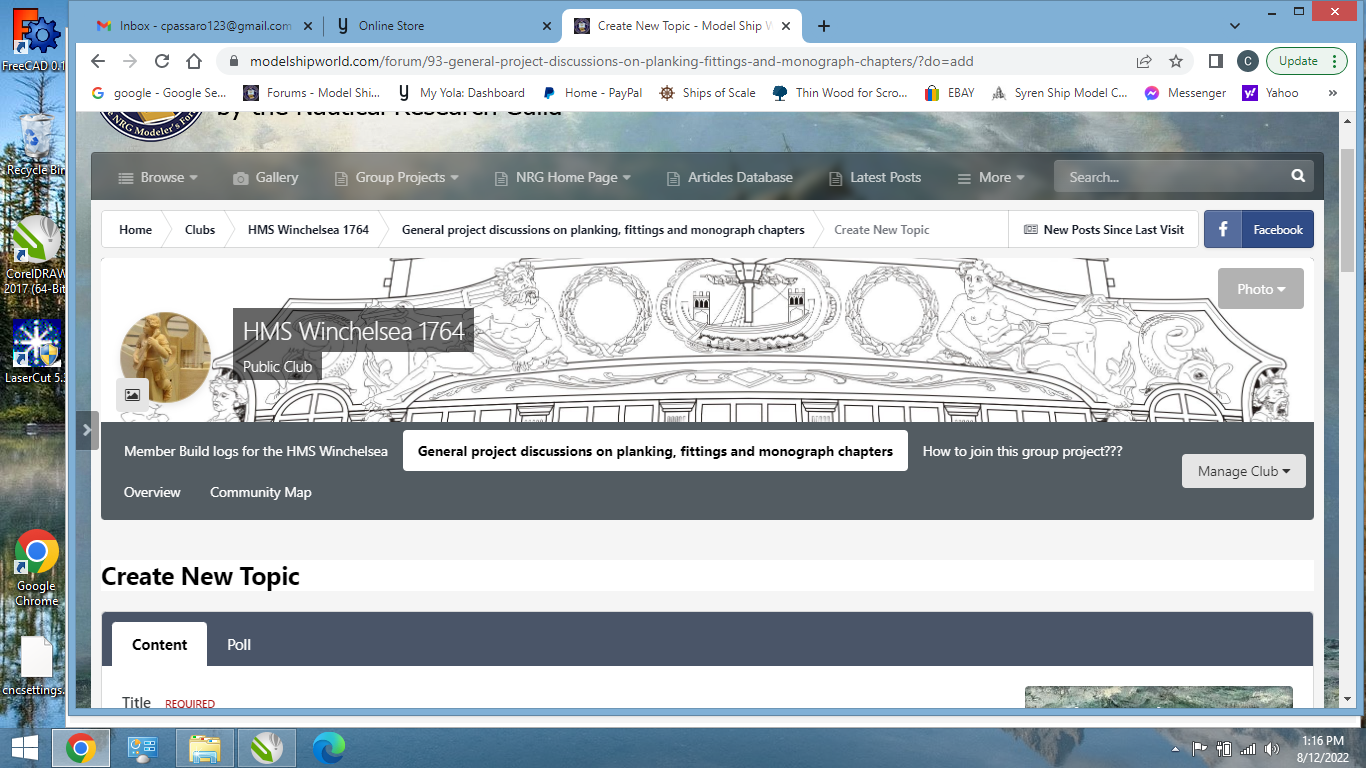

https://modelshipworld.com/forum/93-general-project-discussions-on-planking-fittings-and-monograph-chapters/ That link above takes you to a tab that can be found above the build logs.......see it highlighted in white below in this screenshot. There seem to be a lot of folks who have forgotten about this areafor the group or recently joined and didnt see it mentioned on the "how to join this group" topic. So browse anything you might have missed and feel free to join any of these IMPORTANT discussions. Also start new ones if you need to because its easier to find a discussion on a particular Winnie topic here than hunting through all of those build logs. This area is being way under utilized as a source. Chuck

-

Looking good....dont forget to simulate the caulking between deck planks. You are well on your way.

- 113 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Some of you guys are way overthinking these stern set ups. The best way to line things up and get things level is to work from the other side. View the stern frames and fillers from the outboard side. One step at a time working from the inside two stern frames placing the fillers and frames in position. Use the template to mark the heights ahead of time. I see so many errors in your placement you will certainly have issues with the way you are proceeding. Just attach each template to each stern frame to establish the heights for the sills and fillers. Then proceed to place each filler and sill between them working from the inside out.... Place the number 3 filler first and then the sills above and below it... Then proceed to #2 and #4 And lastly 1 and 5. Getting a visual from the outboard side at each step. Chuck

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks exceptional…really nice work

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That will happen sOmetimes. But you recovered nicely. Onward and upward as they say.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks nice...one thing I do recommend is that the blue paint on the stern transom shouldnt be used at full brilliance or saturation. Its too bright and blue....Before you add anything else I do recommend that the blue paint there be toned down with just the smallest amount of white mixed in to it to lighten it up. Iamof course suggesting some white mixed with the blue on your pallet before you paint. Just a smidgeon....it helps a lot. Chuck

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great Ben....how did I miss this post. Wonderful progress. Chuck

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.