-

Posts

9,704 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Dont forget that you will need to get 3 packages of grating strips (with camber) along with the jig. It is available in Yellow Cedar, Cherry or Boxwood. You will probably need more cedar planking sheets to mill strips for the bulwarks as well. Check out the materials list below. Materials List for Winnie fourth.pdf

-

Absolutely Beautiful Bob.... Wonderful work on those sails. Time for you to start the Winnie next...LOL!!! Chuck

- 87 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The monograph chapter is already available. I just have to finalize the 12 chapter 4 packages I have already laser cut. I am trying!!!! Aside from this I woke up this morning with 26 items out of stock!!! I am having a record breaking month of sales once again during this pandemic and its rather impossible to catch up. I am trying my best and shooting for the weekend. Have to create the part in my online store so you guys can place an order. Chuck

-

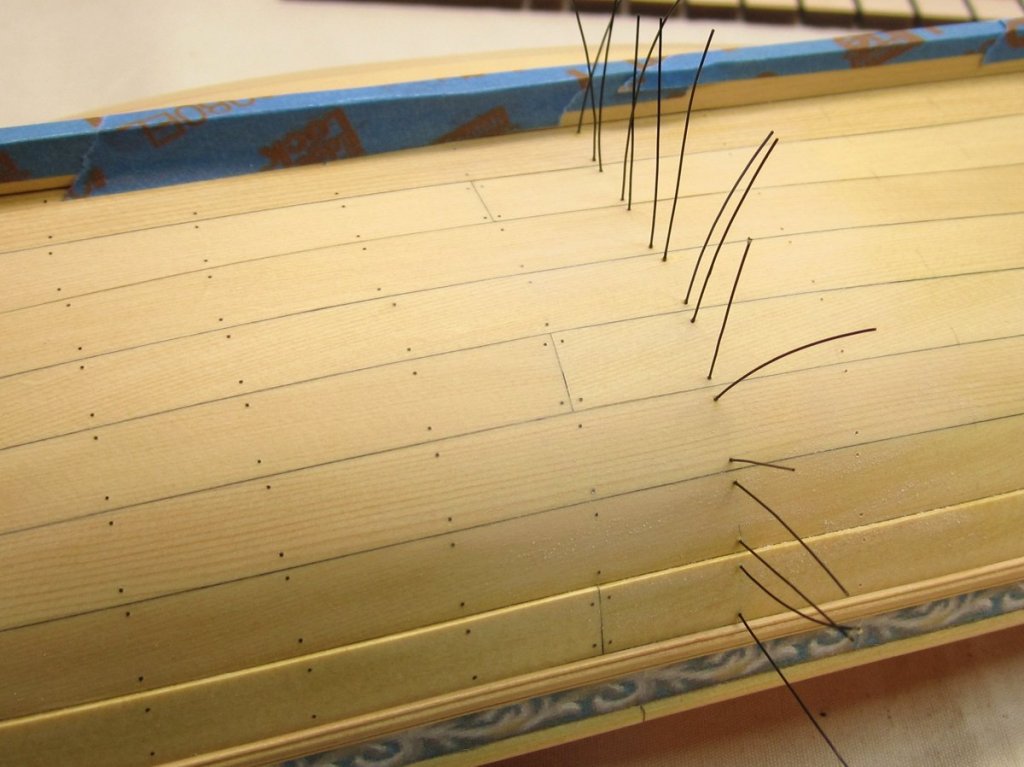

Chapter four is below. It isnt completely finished as I still have to complete my planking of the gun deck. But its 98% there. Since I will chapter four parts ready in a few days I wanted to post it ahead of time. I will update it as soon as I finish. But happy reading and dont hesitate to ask me any questions. Chapterfour.pdf - Chapter Four Chuck

-

To try and remove the cupping, wet the top of the concave side only thorougly. Then set it down with the concave side down. Place some weights on it. It should remove some of the cupping depending on how severe it is. You can also iron it. some folks prefer to place the concave side up after wetting. I dont think it matters and i have done both. The important thing is adding weight while it dries. There are many videos online that show the process. If its a hot sunny day this can be done outside on your driveway or sidewalk. This works well with plywood also. Whenever I see some boards cupping in my stacks of boards I try to flip them upside down and place them on the bottom of the stack. This also works but takes a lot of time. If you dont catch the cupping early it is very hard to remove it. Catch it as it starts and flip it over and it will correct itself before setting for good.

-

That is a very good start. Looks like a lot of fun to build.

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

I would go with the boxwood or pear. all that stiff is painted either red or black. Like the contemporary model. Picture this with the addition of gun carriages painted red also.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Is that pear on the right? Looks dark for boxwood. The cedar would compliment the carvings and friezes better and tie in with them. The holly may be too light. But using Pear would keep it all consistent. I personally like the decks the same color as the hull planking but thats just me. You need to thing about how the deck fittings would look against the deck planks if you use pear and and paint most of the fittings down the deck. Its a tough decision. One I anguish over all the time.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just use a straight razor blade to slice it flush. Works the best. I use CA to glue them in the holes. But seriously you dont have to use any glue at all. If your hole is the correct diameter and you get a good tight fit. Then when you apply the wipe on poly and it dries it will act like additional glue. You can simply sand the hull to after you use the straight razor to make the line flush. Use a fine grit say 320. Its a very simple process. Your treenails may have started out as #78 bits but my guess is they were made much larger by whatever awl you used or the pencil. They look way too large. Thats the issue. With cedar the wood is soft and prone to enlarged holes. Also....Not that big a deal if you dont add treenails at all. Its a real nice look. Much preferred over a poor job of treenailing. Run more tests before you even touch the model.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You did a great job on that planking. It would be a real shame to ruin that with an odd treenailing job. I wouldnt just put them at the butt joints. That looks awful. It only looks right if the treenails are to scale and placed where they would be. The sample board you made is definitely too large. That would really be a mistake in my opinion. I would not go larger than a #78 drill bit. You might want to try using brown mono-filament. You can even use black....I would go with 10 pound stock and nothing larger than 12 lb fishing line. They would be nice and neat. A brown line looks very good and I have seen one Cheerful hull done that way and it looks great. Otherwise the treenails can get too large with irregular shape. The other very good option is to not show treenails at all. That planking looks so good it would be a shame to ruin it with an odd pattern or large treenails. It would look fantastic as it is right now.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

No not at this time. Maybe a lot later down the road. It would be too huge for me to rig. But plans for rigging her may be done way way down the road. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Blocks would have been 8" long and at that scale they would be??? 3/32" long I believe. I know its challenging but I would also consider making the ring bolt smaller in the carriage. That would help. It looks to be about 8" round considering the block size in the photo. Maybe try with thinner gauge wire. Chuck

-

Ripping Planks - what I've learned from others

Chuck replied to glbarlow's topic in Modeling tools and Workshop Equipment

Yupp, thats how I do it. I dont use a push stick or any blocks. I just use my hands. Maybe some would see this as unsafe but i feel I get more control actually with my hands touching the sheet being milled. For me its the safer way to go. With thinner sheets....like 1/32” sheets where I am ripping 1/32” x 1/32” strips, I will use two or three clamps on the fence to keep the wood down on the table. The thin sheets want to bend and buckle and more clamps seem to do the trick as a hold down. Its really not hard to do and just takes a bit of practice getting comfortable. -

Yes that looks very good indeed. Well done.

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

They look OK....the length wont affect things. But yes they are the typical funky shape for commercial ones being very bulbous on the tops. I am more worried about you not being able to get the rope coils over the top of those because they are so close together. But it will probably be OK. I think you should use the longer ones. They are much better than the shorter ones.

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.