-

Posts

5,200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Kortes, Thank you for the tutorial on the sail making, I really like the results. Michael

-

An update, I have reworked the lines for the umpteenth time I revisited all the pictures that I have and further correspondence with Roger. I did cut out all the 23 stations in 3/16 basswood and will now need to revisit those and reshape most of them The keel will need to be remade so at some point i will use the old keel for a freelance model. The stem would be the only thing that could be reused so it will be better to start over. I am going to build this, now that all the information matches. and here is a PDF of the plans. new lines march 25.pdf So now I am going to take a break away from the desk and do some cutting. Michael

-

Hi Dan just catching up, superb job as usual, Those funnels looked like they were a lot of work, nicely done! Personally I am not a fan of laminating thin sheets of styrene and have had some issues in the past with blistering caused by temperature changes, likely caused because I was not able to get a complete surface adhesion even though the liquid cement capillaries a long way. Michael

- 238 replies

-

- leviathan

- troop ship

-

(and 2 more)

Tagged with:

-

Doris....I would not expect anything else now! You are gifted there is no other word for it. I do enjoy your updates. Michael

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

I'm beginning to understand why a large number of the boat builders of the late 19th century and early 20th Century used half models then lofted on the floor from the model.......just sayin' I have been going to bed cross eyed for the last week. why do I feel a spell in the workshop at the wood-bench with planes and chisels might be in my future? Michael

-

Mark if you can only get Plaster of Paris, in my experience you can mix it in small batches and soak strips of J cloth or cheese cloth to add to the strength. just build up a few layers it will take longer but will give you the strength and integrity you need. and wait afterward until it is completely dry before using it for its intended purpose. Michael

-

The planking is looking really nice Keith. The series of circles is a great idea I have not seen that before. Michael

-

Mark looks like you are on your way. I would agree with Druxey, and as LH suggested put the brass master back in before making the jacket. If you know someone in the medical profession perhaps get a line on the same plaster that is used for plaster casts, which is basically the same stuff that Evergreen use for the landscape work make the plaster jacket the same way that you made the mold only make it so that it is 90 degrees and when it is slipped over the two halves it automatically holds them together. Michael

-

Kortes, thank you for clarifying, this log for me I am a bit short on grasping things sometimes, and missed the information in the earlier post. Keith It is good to know that someone was paying attention to the fine print and not just drooling over the pictures 😉 Thank you Kortes for taking the time to put this build log together after the fact. There is a certain benefit to being able to follow along at a measured pace. Michael

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

MONTAÑES by Amalio

michael mott replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

You must have the best vacuum system in the world..... not a speck of dust! Michael -

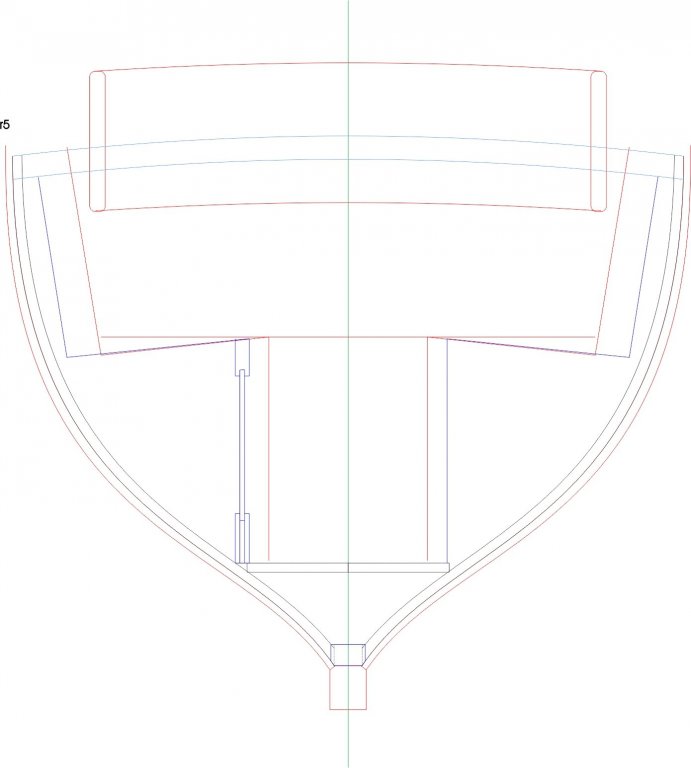

Hello Druxey I can see why you would think that. My thinking and awareness have been so close to the drawing and what line represents what, that clarity for others is sometimes assumed. the following drawing now modified shows the red outer line as the outside of the lower rub rail, (the top rub rail is left off the plan) the next black line shows the outside of the sheer strake and the top edge of the planking, the red dashed line is the inside of the planking. The 2 sets of numbers are large ones are rib numbers, and the small ones are station numbers ( I am probably not following traditional convention ) This shows the elevation of the rub rails at rib 5 and the position on the profiles. The sheer strake is outlined in blue on the profiles. I had to adjust the line of the rub rial on the plan because it was sticking out way too far when I transferred that line to the profile I am really not trying to confuse you all. I have no idea how the draftsmen of the early three mast fully rigged ships did it, nor the members who have produced new books full of drawings of those same types of ships. My Hat is off to those of you who have done that. Being able to use different colors has been helpful to me. Now all I have to do is keep the colours consistent on all three views.....I'l get there. A last comment is that working in a cad program Autocad Lt 2000 and, switching to Corel draw 7, can sometimes be a bit of a spot for confusion because they function differently. I get used to one because I can do some things more easily in it, and other things more easily in the other... I'll stop there..... Michael

-

Hi Mark Thanks I see what you are saying and thanks for spotting that. I have been working back and forth from the plan to the profiles and in the beginning I worked a lot with the waterlines. I shall revisit the issue and clean it up. I have found this work to be very time consuming but in the end it will have all been worth it I feel. Michael

-

HMCSS Victoria 1855 by BANYAN - 1:72

michael mott replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Pat the model is looking really sharp! realyl great work at that scale. Michael- 1,021 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Tell me you have help! my goodness you work fast and accurately that deck looks fantastic, and then the hull.... Michael

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

Hi Dave, it is great to see that you are jumping in with both feet. Michael

-

I understand how you are feeling Rob, A friend of mine passed away this morning. Michael

- 1,208 replies

-

- great republic

- clipper

-

(and 1 more)

Tagged with:

-

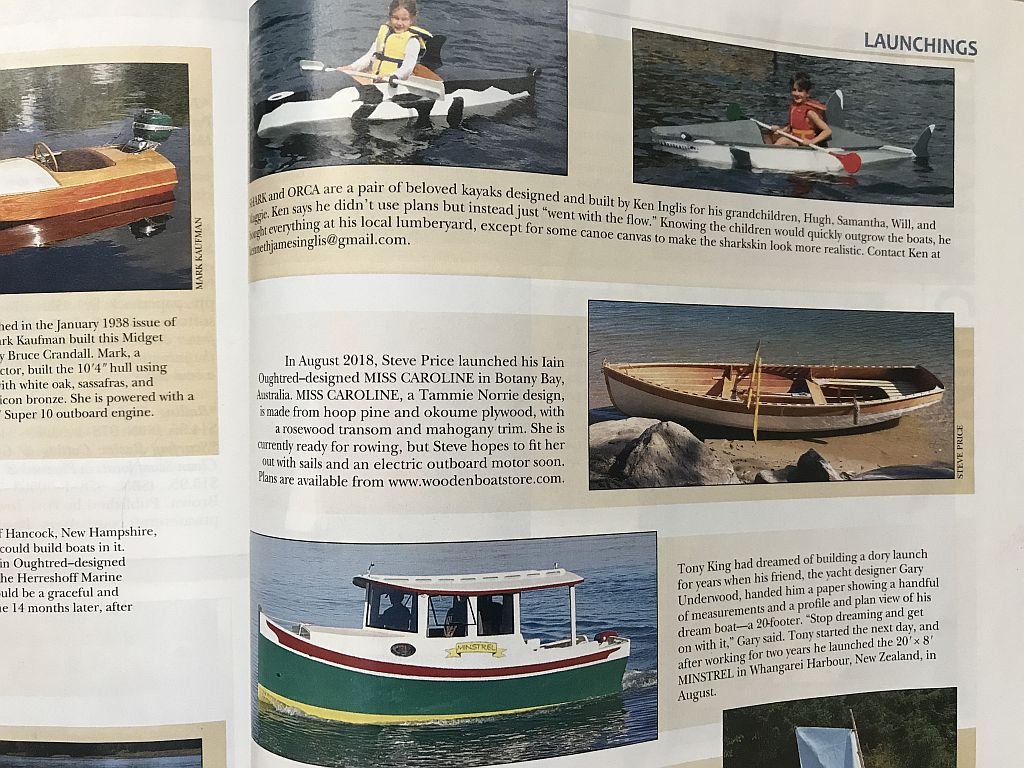

15' Dinghy by Bedford - FINISHED - 1:1 scale

michael mott replied to Bedford's topic in Non-ship/categorised builds

Now I'm guessing that this might be too big of a coincidence to be different boats Steve Looks like MSW is way ahead of Wooden Boat Magazine in the information department about this beauty. Your boat is absolutely gorgeous Steve. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.