-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

NAIAD 1797 by Bitao - 1:60

michael mott replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Dear Bitao for you kindness, and inquiry. I am well and staying safe with my wife Judy, here in a rather cold chilly winter season. My hand has recovered from the surgery, and I am close to finishing an old project that I have been fiddling with since 2004, I am looking forward to getting back to work on my Skipjack Launch within the coming month[s]. There is a lot of interesting detail to sort out on the launch. One of the things that I am contemplating is to complete the launch in a similar way to the way that some of the classic ship models are presented. One side showing the construction of the internal elements and the other showing the external finishes. Michael -

NAIAD 1797 by Bitao - 1:60

michael mott replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Bitao, I have just been catching up with your new build! The work that you do leaves me basically speechless, your ability to solve complex constructions using non traditional methods with creative ways is a great contribution that adds to our collective knowledge. Your strive for continually improving your skills is inspiring. I admire your willingness to start over with work that you are not happy with, in order to reach the desired result that seek. All the best in the new year and thank you so much for sharing a greater level of detail in your methods and tooling, How we work is often as valuable for learning as seeing the end results. Humbly Michael -

Hakan First I am glad to hear that you are healing well and that your injury to your hand minimal. Second the push stick on the right is the only kind that I will use, I do not however add the piece with the screws at the back. I cut them out of MDF in a few different thicknesses from 1/8th (3mm) to 1/2 (12mm) and as they wear I make new ones or re-cut the bottom edges. I have never used the type on the left as I think they are dangerous. My saw is a 10 inch Unisaw that was 3HP and has been down powered to a 1/2 HP with mostly 8 inch hollow ground plywood blades. I like the large surface and solid cast iron top that the rigid Unisaw has. I also use zero clearance inserts cut from 3/8 (10mm) MDF I add the leveling screws which are 10x24 grub screws. Michael .

-

Yes you are correct Roger, the fins were for doing exactly what you are suggesting.. There were even attempts to use some preheating of the air with some of the developments of the air locos. Albeit a bit counter productive in some cases as it negated the reason for using air in the first place, to avoid explosions in mines. Michael

-

There is room But I am a complete Luddite when it comes to electronics. Locoremote has a number of different set ups including built in speakers and for adding ones own speakers. Perhaps once I have the current unit up and running with a bog standard 6-12 volt unit I would be able to swap it out for the other unit. As it is the battery and electronics will slide out on a tray through the opening hatch on the front. the large clamp has two bolts that are long and capped at the inside end, by undoing them the plate that is behind the oval opening and the clamp can be rotated through 90 degrees to be removed to access the inside of the tank which is 3 inches in diameter. Then the rechargeable batteries can slid out on their tray. Michael

-

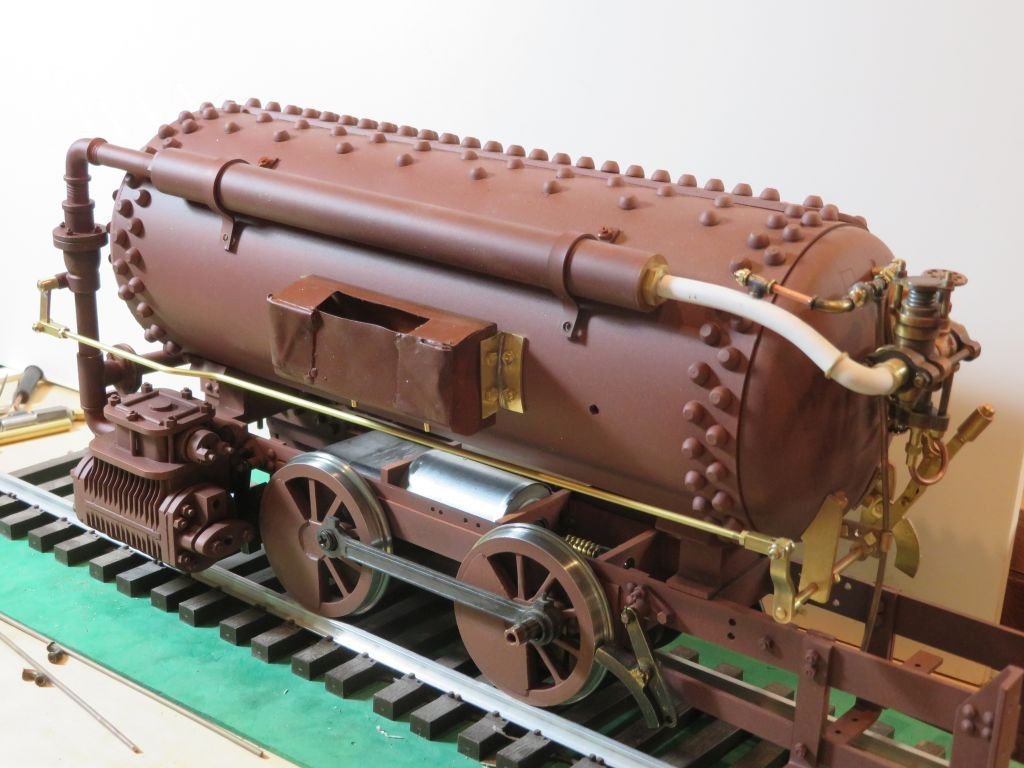

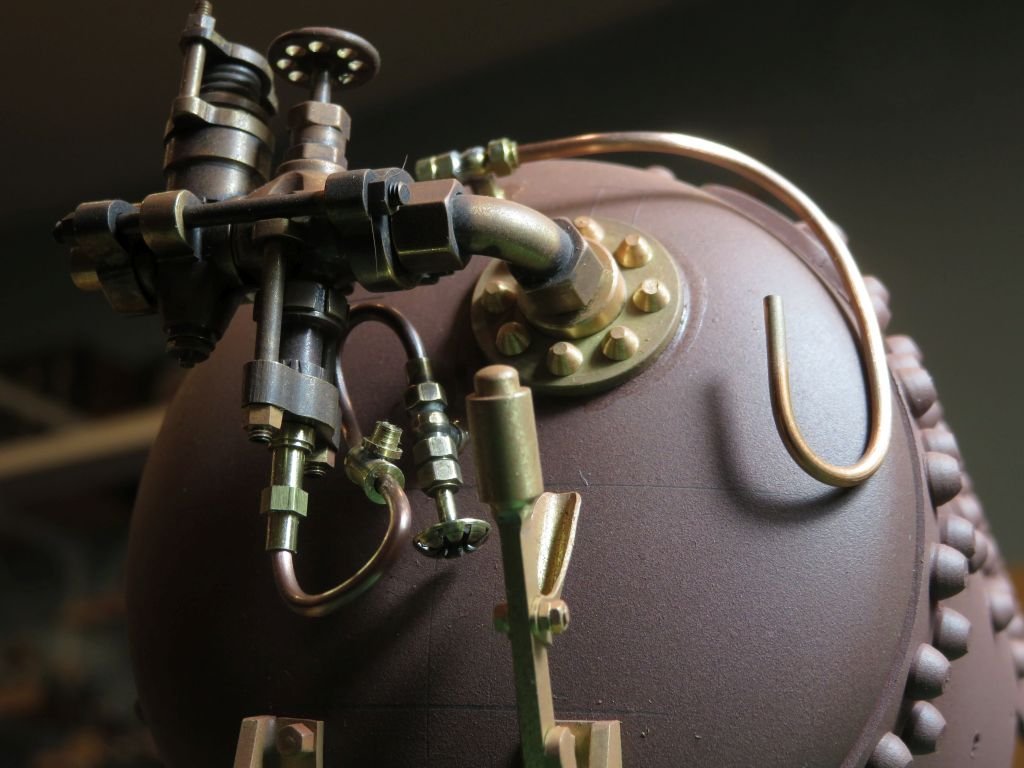

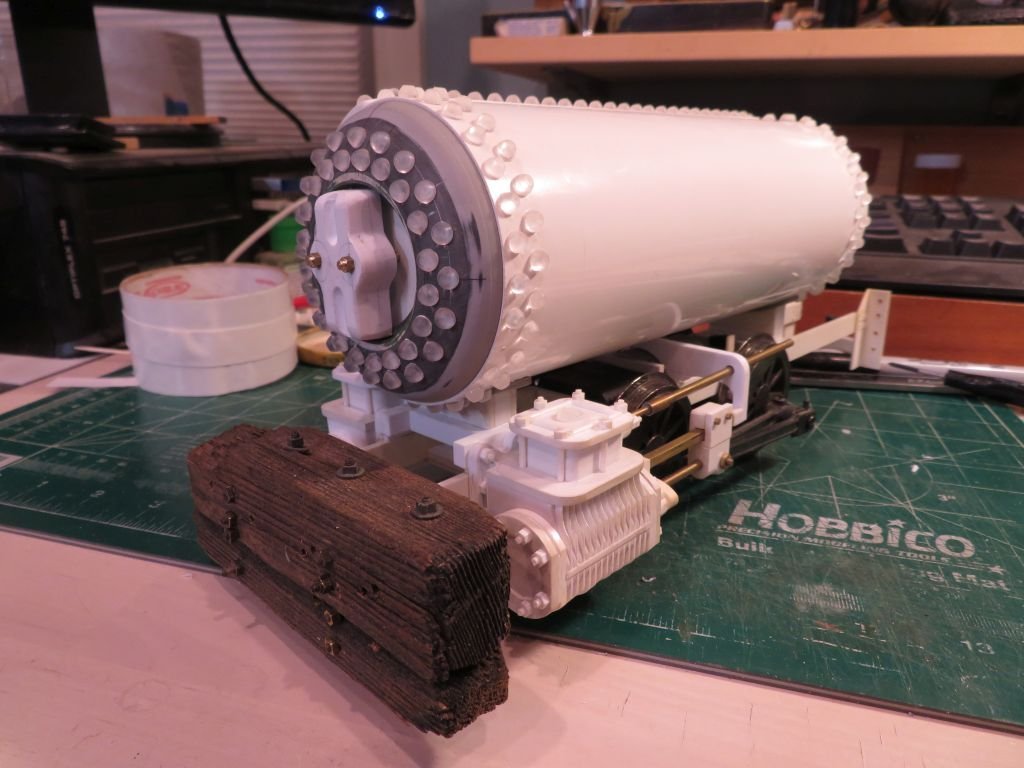

First a merry Christmas to everyone A watercolour after Walter phillips I feel this captures the current Christmas feel. As it is evident T have not been working on the model boat stuff lately, after the surgery an a spell of doing nothing model related, once the healing had progressed enough That I could do some work it was confined to using the lathe and mill. I had an old project that I had started in 2004 and was inspired to do a bit of work on it. This picture will give you an idea of where this is going. Around 2009 I had it set up with a plastic frame this was worked around an Aristocraft 0-4-0 chassis, but the plastic was sagging so i recently opted to rework it all. The little fiddly parts were slowly worked on, and although the loco model is compromised regarding the proper gauge etc I decided to press on and try to complete it. As much as possible things work. The next picture shows the forward reverse lever and the brake lever. all the nuts and bolts are made by me except the 00x90 ones. Rivets are 1/16th. A couple of week were spent sorting out how to make these wire handle valves . The wire shape was a tricky bit of folding. They are not exact but I am ok with that. The back of the loco has a fair bit of fiddly bits and the sequencing of assembling the parts is a challenging. This odd looking bit of brass is the main valve to let air out of the tank. and fitted to the back of the loco, along with the pressure relief valve. on each side of the loco are sand boxes with a bunch of piping and odds and ends of unions and elbows. the copper pipe is 1/16th diameter, an early Christmas present was a Badger sand blasting kit. The current state of the loco minus the buffer beams at the moment. The brakes actually do work here is a short video of them earlier Happy new year everyone. Michael

-

Lovely work as ever Keith. I like the way you have the quick tool holders set up at the back of the lathe, slotting them onto the wood holders makes good sense. Michael

-

I too received the Christmas Catalogue in the mail the other day, made for an enjoyable read, The "magpie" in me "wanted" the whole lot of those miniature tools. They do look wonderful and are really well made, I do use one of the older miniature wooden planes that they had a while back. O am with Bob on this one regarding the versatility and use of the older larger stable cast iron tools and tops. I recently cut a load of 1mm x 4 mm yellow cedar planks for Walrus Guy using my old 10 inch unisaw with a narrow kerf 200 tooth 8 inch blade and My old second hand 20 inch band saw with a 1/2 inch blade. That said I realize that I am very lucky to have those tools, and I have had the table saw for 45 years and the band saw for 20 years. My old workbench I have had for 45 years as well. In My view the low angle block planes by Veritas are the best value for money that you can buy for much of the work we do. with regards preparing wood to thickness for our models. Also a good sharpening system for keeping them razor sharp. I am not trying to persuade anyone from purchasing some beautiful Model tools, But do think about the reality of what they are intended for. And if anyone is thinking of sending me a Christmas present I would like the tiny chisels. cheers Michael

-

Great looking progress since the last time I stopped by. Michael

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

At David Antscherl's prompting, I have just finished transferring all my notes and pictures in this thread along with the relevant questions and answers. to a word Document. Although this thread was chronological I can now sort out the various areas into their subject groups and properly organize them into a potential Monograph about this restoration, which might be of use as a book type document it will take a bit of time because there are 26,000+ words and lots of pictures. I do have high resolution images of pretty much all of the images, which were reduced in size for the forum. Just one more project to add to the many that are waiting. A couple more weeks and I should be back pushing a chisel into a keel for Skipjack the open launch. Happy Thanksgiving to all the Canadian folk out there. Michael

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Dear Kortes , I am not sure how I missed the rest of your build from about page 6 onwards, But have just spent some very enjoyable time catching up., What a treasure of not only beautiful workmanship and skill, but your step by step sequences are most valuable. It is amazing what can be done with simple common materials. That anchor is a testament to your skill and tenacity. The final display Cabinetry sets of the model very well. Congratulations again on a fantastic model. Michael

- 306 replies

-

- schooner

- la jacinthe

-

(and 1 more)

Tagged with:

-

The post op appointment went well stitches removed, looks a bit ugly at the moment will be able to get it wet again in a couple more days. Doc was pleased with the progress and my feedback regarding the lack of pain. There is a little bruising that will subside over time. I told him that i was using my fingers and he was pleased told me to keep doing it, I confided that I would lay of the WWF boxing for a while yet though, Made him laugh during these stressful days for the medical profession. Cheers Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.