-

Posts

5,198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

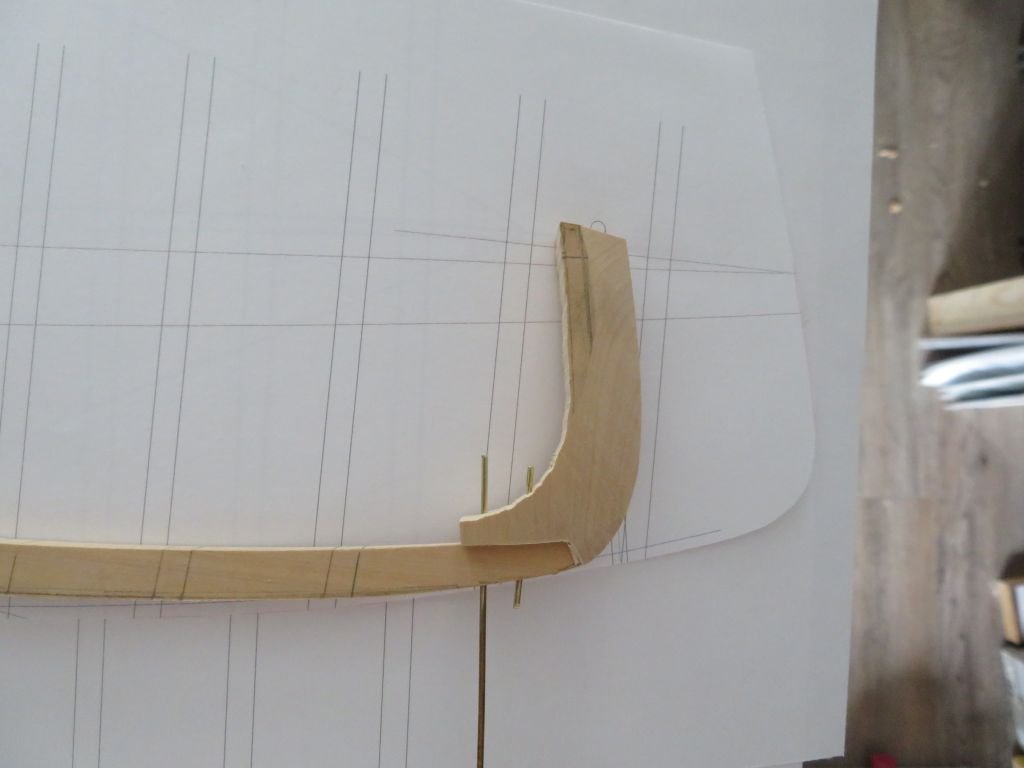

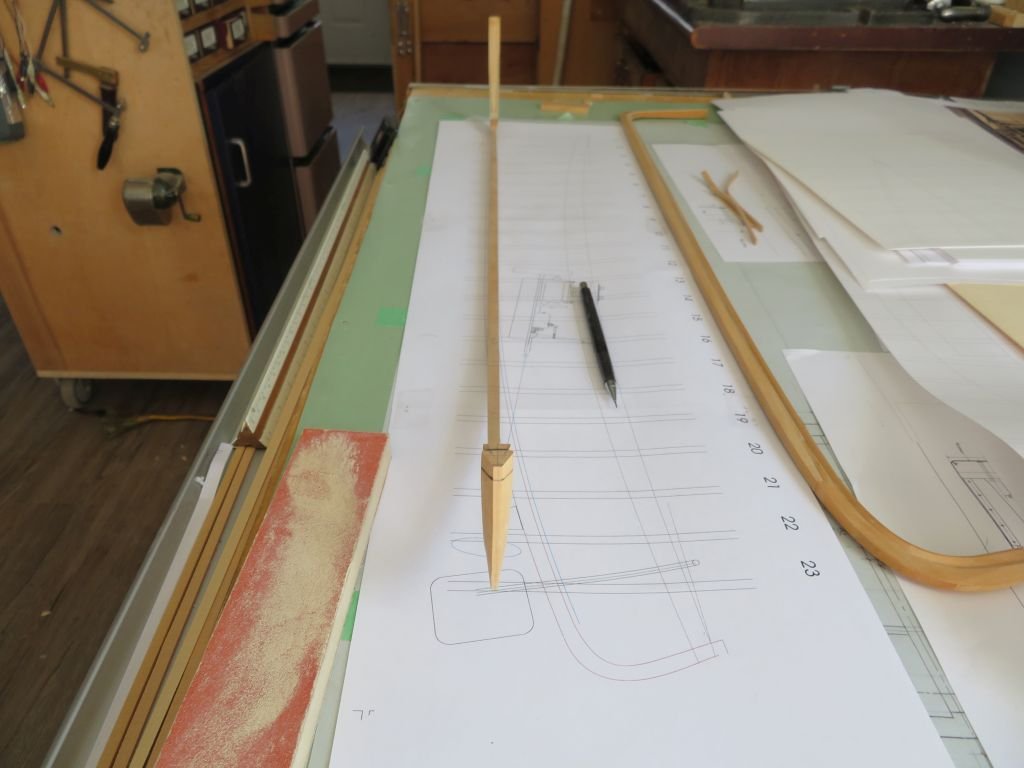

I am so glad that my little model shop is air conditioned, it was 31C here today and anything above 20-22C I find uncomfortable. Finished rough shaping the stem today so now I can concentrate on the frames and floors. I am quite happy with it Her is a comparison between the first keel and stern and the new one, Although I do like the overall shape of the first Perhaps I can build a freelance model on it at some later date or lifetime.😉 Michael

-

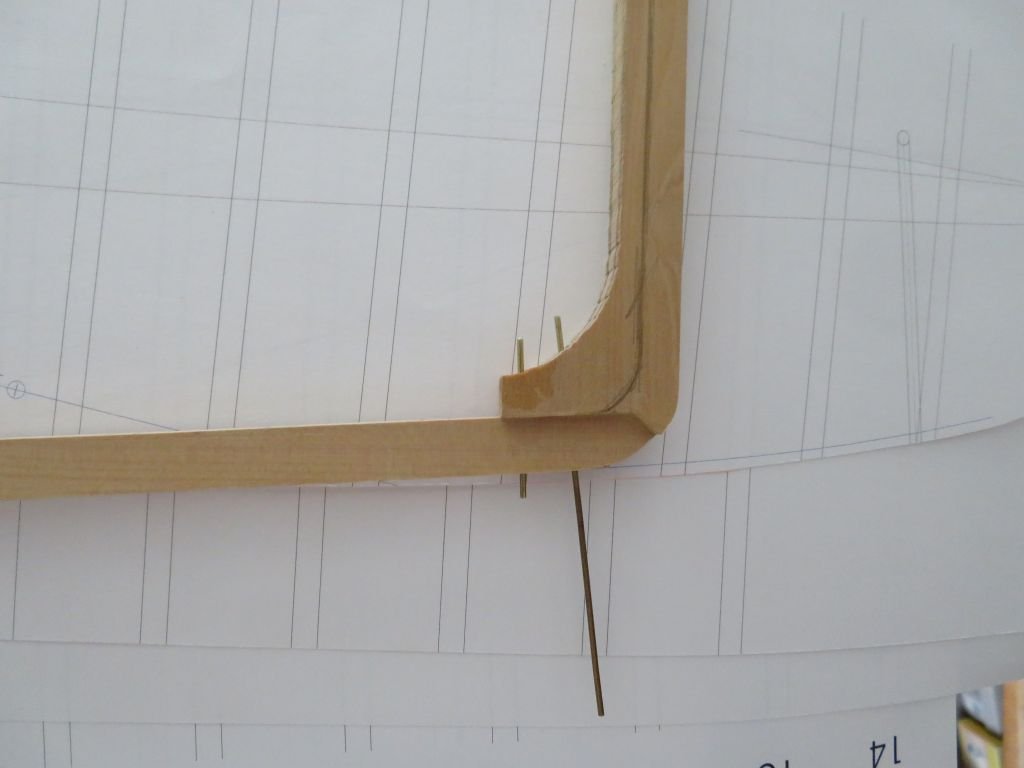

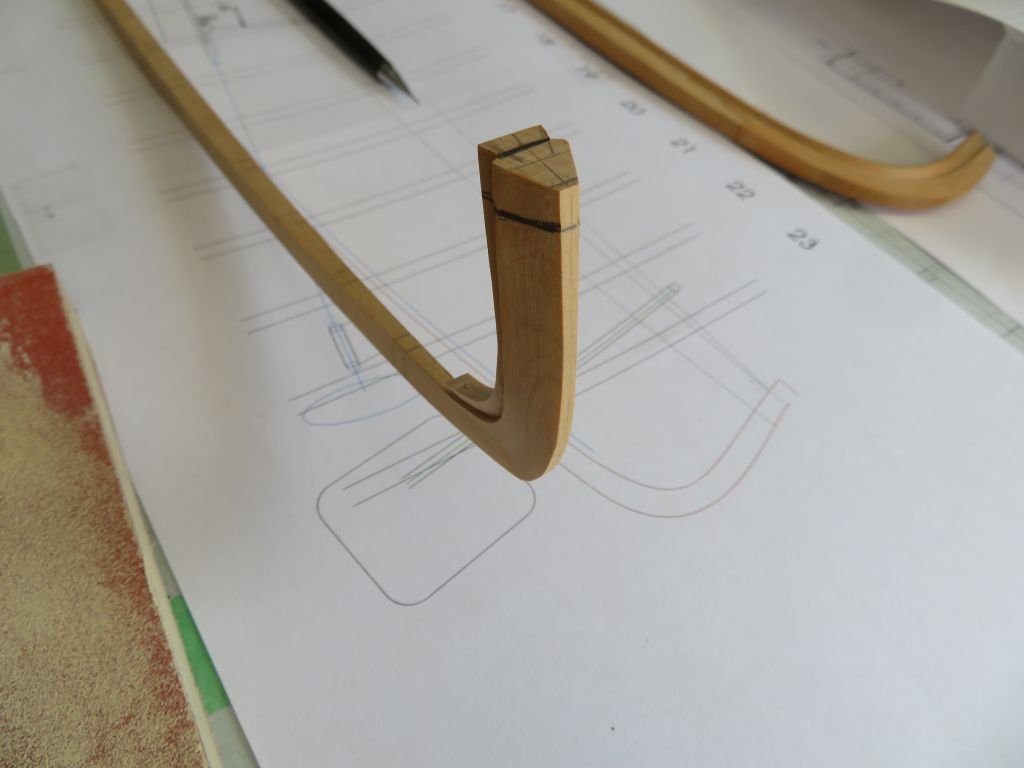

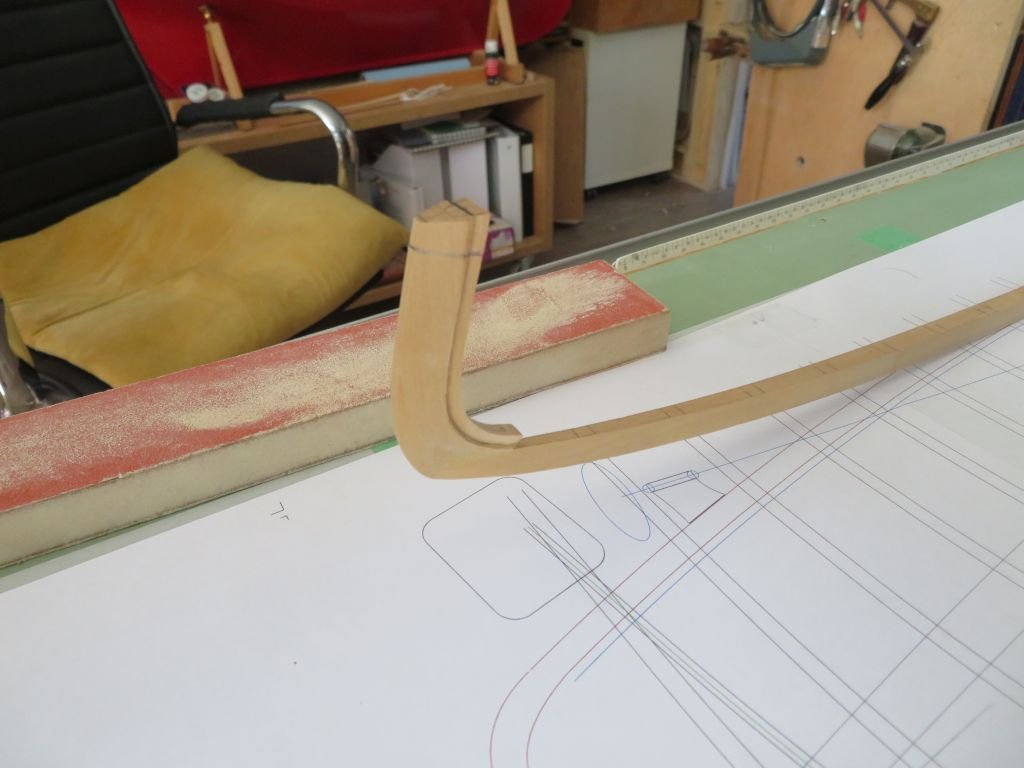

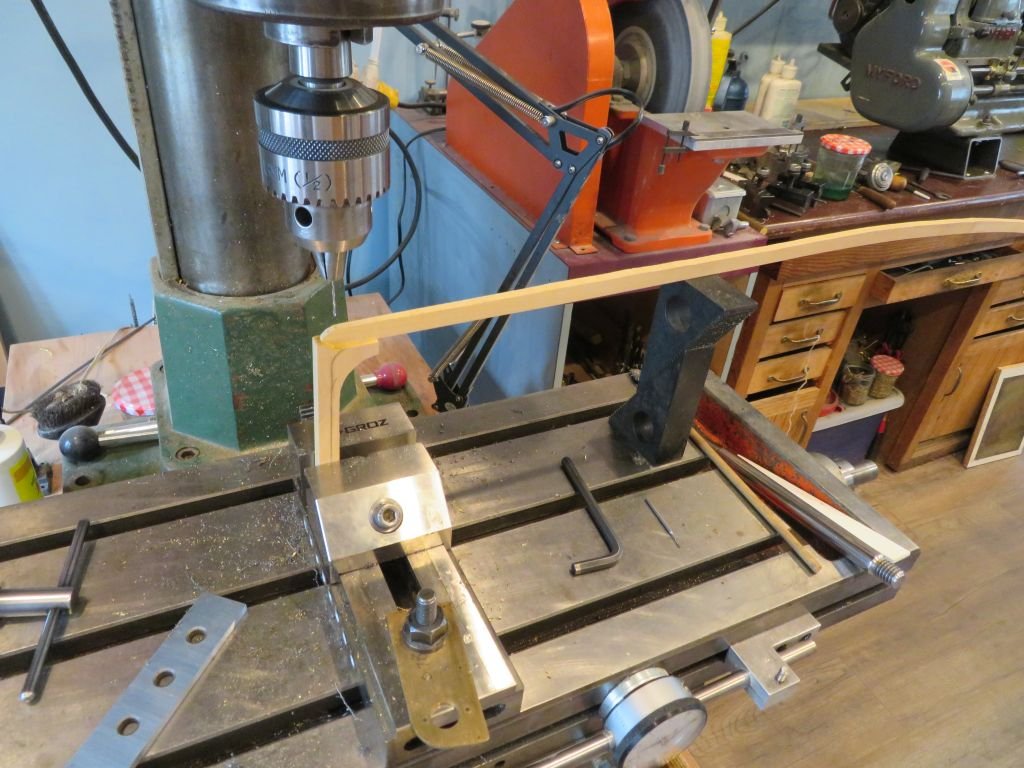

Worked on a bit of carving the stern today. first I set up to add the (bronze drift bolts) brass .046" dowels these were angled differently from each other, similar to a dovetail Then using riflers to rough shape, along with some careful #11 exacto work the stern is done far enough for the moment. Tomorrow the stem. And as an aside I was able to book my second Covid Vaccine for Friday the 5th June, this afternoon, when I logged onto the AHS site there were only 21,000 ahead of me with a wait time of 26 minutes till it was my turn to book. Michael

-

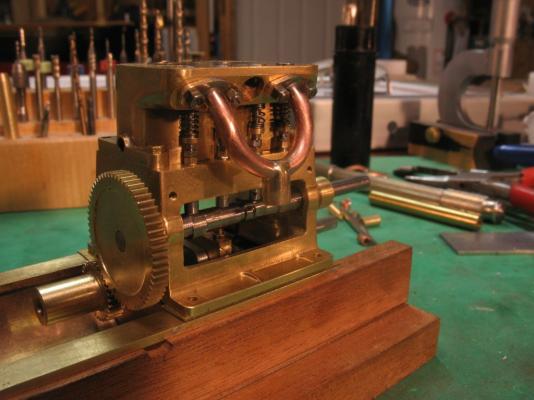

Thank you for sharing this work, what a delight to find out that it is a music box. Exquisite looking work. Michael

-

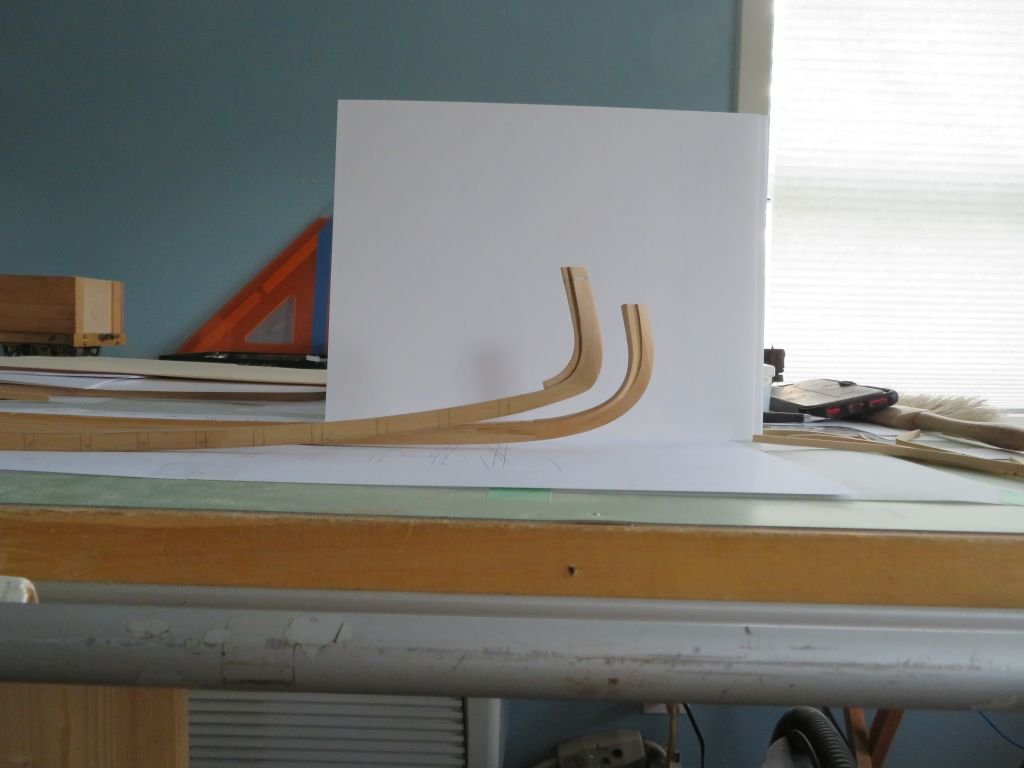

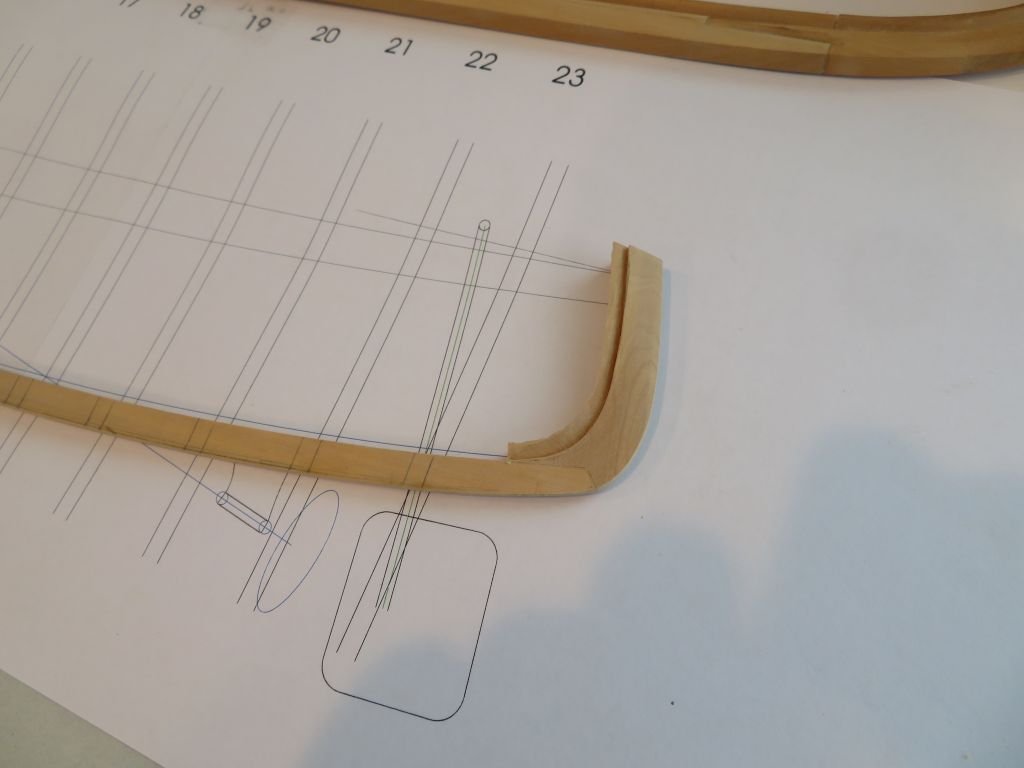

Thank you all for the visit and appreciation. The vast amount of Sanding was an overstatement to be clear. It turned out to be far less work than anticipated. After checking that the shape was in the ball park. I worked on tapering the fore and aft portions of the keel ready for the stem and stern timbers. Some thicker blocks were roughed out to profiles and glued to the keel tomorrow when the glue has properly set I will add some 1/16th dowels to reinforce the joints before shaping them. That's about it for today. Michael

-

Thank you for you kind words. There is a place on this forum for showing other work that is not ship related like this post I also enjoy other forms of model work,so there is a place for you to show us you other work. regards Michael

- 257 replies

-

- young america

- Finished

-

(and 1 more)

Tagged with:

-

Bitao, Thank yo again for sharing your work with us. Not only are you skills well refined but also you have speed and stamina to boot. My question is what to you do with the completed work do you have a place to display them, and if so can you show us other work you have completed? regards Michael

- 257 replies

-

- young america

- Finished

-

(and 1 more)

Tagged with:

-

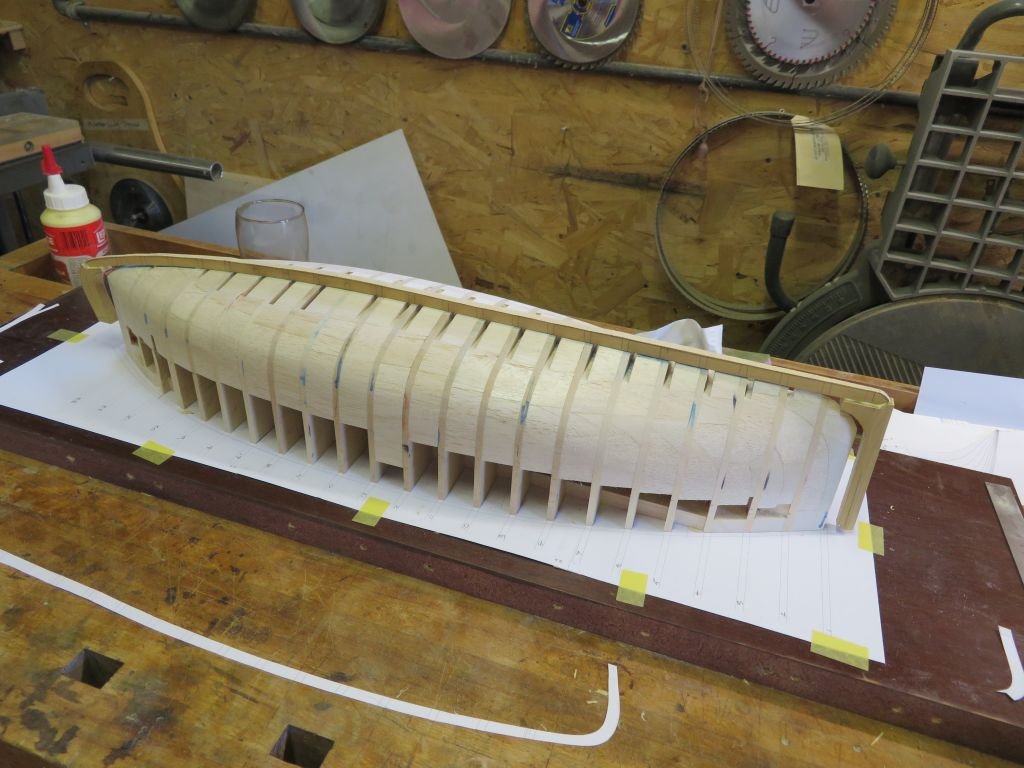

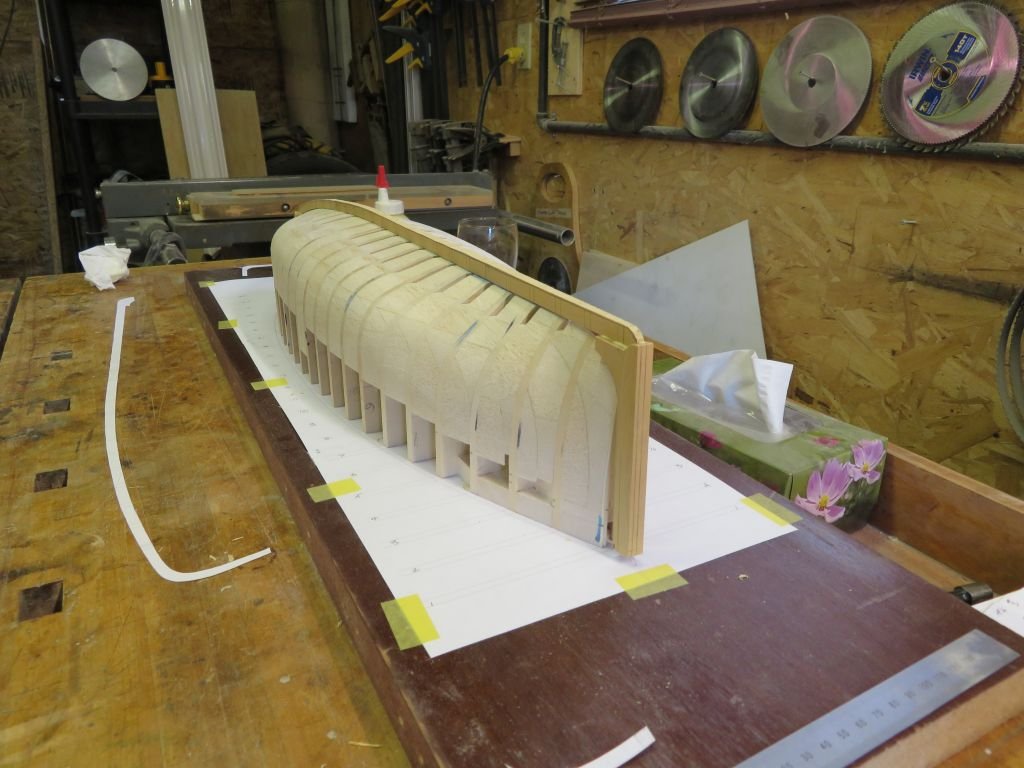

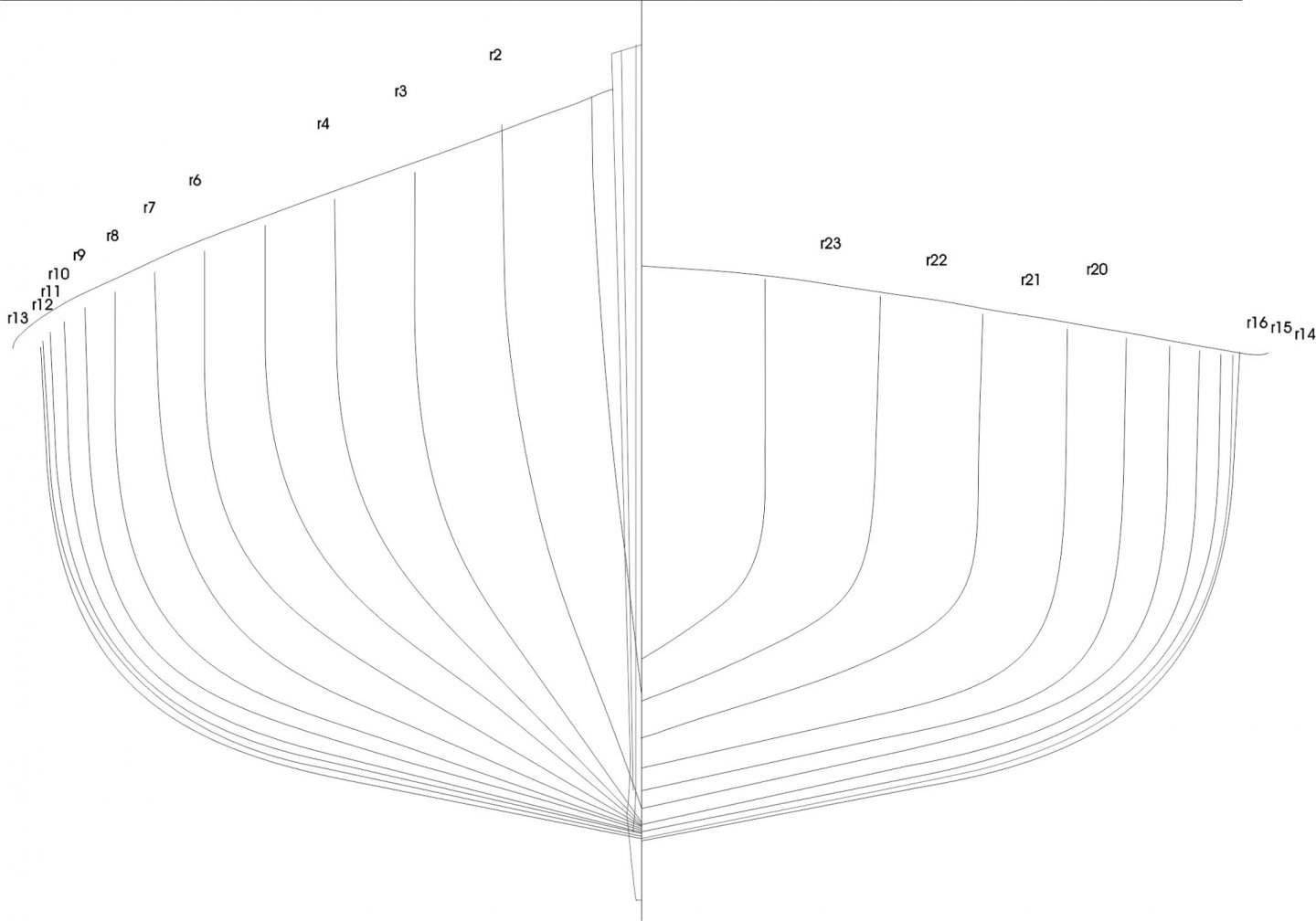

So the last couple of days have been part of my usual dance one step forward three back, I call it "the shipbuilder's waltz" Basically what I realized was that with some of the changes to the lines and the body lines and plan needed to be redrawn accurately for the subtraction of the thickness of the ribs and planks. Unlike Druxey I did not have the confidence to set in the frames or ribs into the form and I also needed to refine it a little here and there. Lots of work redoing sets of templates because now it is all of a block. here are the results, of the drawing. Tomorrow feels like a big sanding day. Michael

-

Druxey, I'm guessing that you have the back of the chisel set to a mirror finish so that you can facilitate vertical cuts with ease, by looking at the lined up reflected image. Michael

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Translucent planking! very impressive. Michael

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

It has been a while but after chatting with Druxey yesterday I am thinking that I might have to do some work on this model. One of my problems is with such a long interval between the last work on both the engine and the hull and my ham fisted approaches to model boat building at time mostly because I am not primarily a model boat builder but more a generalist. Each discipline has all sorts of methods and procedures that are time honored, and not knowing or understanding many of these is one of my reasons for shifting to a different type of model when some challenges rear up. I feel a bit like a coward sometimes and put off the needed work to solve the challenge. Eventually I come to the realization that the best way forward it to jump in with both feet. I have just reread this build to bring myself back up to speed with what I was doing and what I was thinking. It does not change the challenges though. So where to go today.... a coffee and breakfast first, then bring the hull back down off the top shelf and decide on the next move. Michael

-

Druxey, thanks for directing me to your build during our chat this afternoon. The planking at .015"thick really is a wonderful bit of modelbuilding. I think I wore out the like button on my laptop this evening. you have given me a number of clues for proceeding on my model of Skipjack, and I am going to switch wood for the frames. The photographs really give the impression that this is a much larger model that it is, and having seen it in your hands puts it all into perspective. now that I am caught up I can follow along, with your beautiful work and tutorial. Michael

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Just catching up, I have to agree with all the previous comments about what a fantastic job you are doing on this model. The rigging certainly does look like a herculean job and not for the feint of heart, well done! Michael

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Keith doing a bit of catching up myself. As much as I enjoy the pictures of the amazing brass-work, I also like the drawings and the way you sort out how to make these tiny pieces on paper with a pencil. Michael

-

Very nice Keith, sometimes it is easy to forget how small a lot of these details are, because you have executed them so well. Michael

-

Thank you Craig for your kindness in thinking of me. What a lovely image, looks like it might be starting to liven up a bit judging by the water. Michael

- 2,215 replies

-

Looks like a nice day for a sail Michael. I have to say that I miss sailing the full size models, I am hoping that I get invited out for a sail this summer at the lake that I used to live at. Michael

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.