Jim Rogers

NRG Member-

Posts

1,381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Rogers

-

I developed and wrote Technical Documentation for the Navy for several years and I applaud your effort. In order to improve the process you should do a walkthrough after a certain number of steps. Locate someone that has the kit and has not started yet and use your process ONLY to do the build. It would be better if this was their first build. If this is their first build no bad habits have been developed yet. This is the best way to get proof of process and identify and fix issues. Remember a plan never survives first contact. Good luck.

-

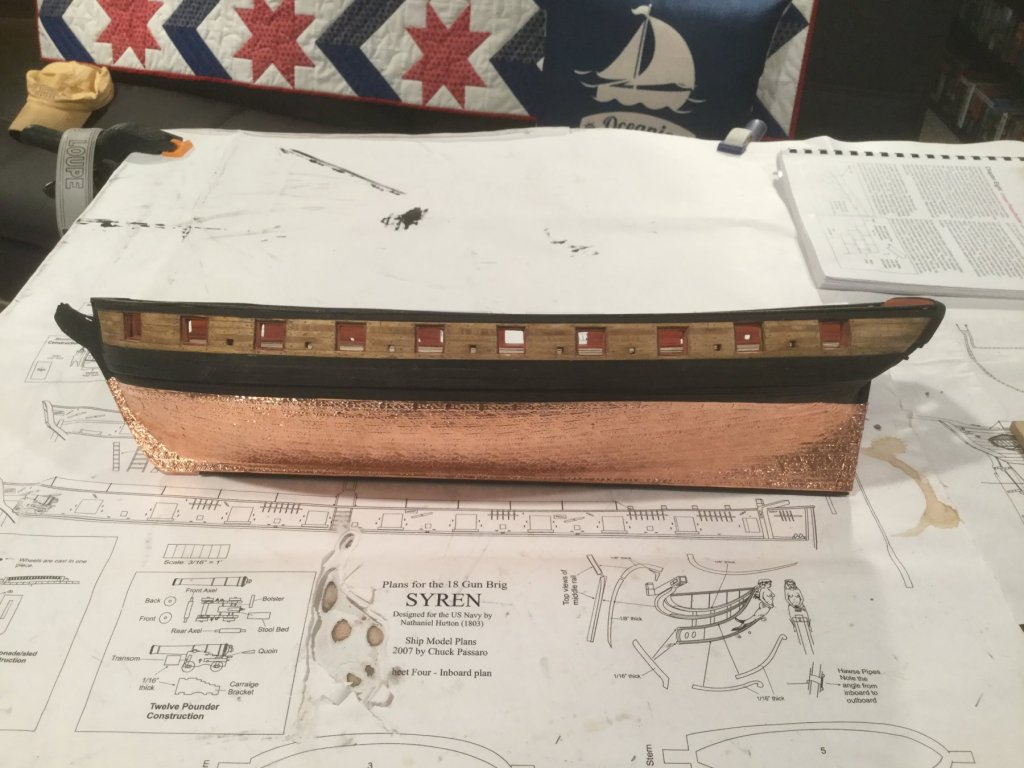

I used about 3/4 of the roll. I started doing individual plates but couldn’t keep it exactly lined up so I removed it all, maybe 10 plates. So I did 6 inch sections. The pattern makes individual plates uneeded in my opinion. For the keel I just folded the section of plate over. I drilled and pegged the false keel over the plate. For the dressing band I did both Port and starboard patterns on each plate. Looks great. I bought individual plates from Model Shipways for the dressing band but (1) they were fat and chunky, (2) looked phony (3) you had to glue them on so probably messy. I wish you would have mentioned the waterway issue about two weeks ago. I am not tearing every out to fix it. Nobody knows but me anyhow so what the heck. Any time you get some time off you are more than welcome to come over to the Goat Locker Shipyard and Rock n’ Roll Emporium.

-

Gluing Planks When Wet

Jim Rogers replied to mikiek's topic in Building, Framing, Planking and plating a ships hull and deck

As far as clamps go anything that will work. Different places on the Model require different length, shape and number of clamps. You can use a piece of wood and one clamp to hold three or four strips in place. Rubber bands work also. -

Revive thickened epoxy resin

Jim Rogers replied to vaddoc's topic in Modeling tools and Workshop Equipment

Doing it whilst the Admiral was away shows great wisdom on your part. -

I tried to build three of these. I always steam bend but this was just to tight and the wood kept splintering so I shifted to plastic. The plastic bent fine but then the notches in the bulkheads broke out ....I’m still picking the pieces out of the wall. As I recall Ken W had some good pictures of one of these builds in his Rattlesnake Log.

-

Semper Fi Norman and welcome aboard. 25 year Navy Vet here.

-

I love Sapele Wood and it is georgous when finished. Good choice for pin rails. I built my Stereo System shelves in the Goat Locker out of Sapele with an Ebony Highlight.

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

This is just me but I would just go ahead and redo the Standing rigging while you are at it using the new Syren rope. My reasoning for this is that the Standing Rigging is basically the backbone of all the rigging and it is 10 years older than the new running rigging and the age difference may cause an issue in a few years. My 2 cents.

-

I don’t believe you have me on your distribution list. I see you are a Scuba Diver also. I got certified in 1973 and have well over 1000 dives. I had to give it up a couple of years ago when I became insulin dependent. I dove with Diabetes for years but throwing insulin into the mix is a whole new deal. The Admiral and I had an epic final dive. The San Fransisco Maru, 165 feet , Truk Lagoon. Two man Japanese Battle tank on the deck of the San Fransisco Maru

-

The no place to attach decking issue you ran into I used to run into every build. Now I install balsa wood in between all bulkheads all the way to the outside. This gives me a more solid model, and more surface area to glue deck and hull planking. Actually makes it easier to fair the hull as you get a good eyeball view. You should be able to sand the CA. Didn’t you buy a set of the AL scrapers? You should be able to make your own scraper from a thin piece of metal. You don’t really need and edge on it just remember to always PULL it towards you. You can do the same with a single edged razor but angle the blade away from you otherwise you are going to gouge your deck. You’ll get it fixed. I learn something new every build.

-

Model Shipway Ratline tool

Jim Rogers replied to fnkershner's topic in Modeling tools and Workshop Equipment

I don’t understand the need and they seem like more hassle then they are worth. I enjoy working the lines on the build. But that is just me -

Just my opinion and It may not have any impact on your situation but certain species of wood when kiln dried resist holding a steam bent shape ( Redheart as an example). Steam bent wood may take days to fully dry naturally and as it dries it tries to straighten back out. I have had this issue in my own builds. I leave mine in a plywood form and hit it with a heat gun to assist in drying, then steam it again followed by drying. It is a pita problem to solve.

- 8 replies

-

- deformation

- ribs

-

(and 1 more)

Tagged with:

-

Heat sealing iron question

Jim Rogers replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

I steam bend. Instead of using screws to form a hull jig I cut a solid one out on my jig saw and epoxy it to a chunk of wood. Then you clamp it to the front of the jig, hit it with steam and wrap,it around the curve and clamp the back. Let it set for a couple of hours. I can do ten sticks at a time. I have a “travel” jig that I can clamp five pieces to in order to keep the strain on the form. You can also do lateral bends for top rails with this method . For a lateral bend I lay the wood next to the form and use a nail to hold it tight against the form, steam the hell out of it start the bend nail, a little more nail etc. you may need a clamp to keep the work piece held down. Works great. The steamer is a clothes/cleaning steamer available online for about $30. You can also speed dry using a heat gun.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.