Jim Rogers

NRG Member-

Posts

1,381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Rogers

-

When to attach sails to a model

Jim Rogers replied to gthursby's topic in Masting, rigging and sails

I do all my standing rigging then a yard at a time starting with the lowers. I go fore, main, mizzenmast. Then the next yard up. Gets kinda tight as you go up but it allows you nice runs. Have lots of tweezers and rigging tools on hand plus a bucketful of patience. Have fun. -

Gonna have to pick one of those up.

-

A band clamp without the corners employed would work the same as rubber bands. It would apply equal pressure around the hull and in some cases would be easier to apply. You just need to find one small enough to use.

-

Cedar dust is my nemesis. I have been to the emergency room twice because of it with severe breathing issues. Figured out what was causing the issues after the second trip. I now wear a mask and I use a shop installed vacuum system with a cyclone separator. The issue as stated previously is that the ports on our hobby machines are not a standard shop machine size. People ALWAYS accuse me of having my shop “too clean”, even the photos I posted on the forum had the same quotes. You can’t be to clean when it comes to good dust management. I usually vacuum the surrounding area when I complete a cutting job. I worked in the Ordnance field for over 45 years and being clean and tidy is just second nature.

-

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Bloodwood/Redheart. I am also going to use it for interior framing. Not going to paint the bulwarks just apply a finish.

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

In order to make Deck planking easier and to add strength I basically built a solid hull. Made fairing easier and lots of area to glue too when planking.

- 90 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Peter she looks great. You should be proud. I have used a wipe on Poly, a wipe on finish called “The Good Stuff” which I love and a spray on poly. The problem on when to apply is tricky because the build is not complete and sometimes, dependent on which you choose, you must sand off to glue on parts. And the flip side the finish does protect the paint. I would finish the hull now and again it is a beaut.

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Makes sense and also why I have never seen them before as they would be attached just prior to raising the anchor and then stored.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I have had zero luck with Wood Project Source and Lumberyard. I ordered Ocooch and I am happy with their product. Woodcraft should be a good source for woods used commonly for building boxes and furniture. Rockler also has wood available. I am having problems getting a hold of Costello Boxwood and Holly. I am going to drive over to Edensaw next week and see if the have any Holly. I’ll have to mill it myself but at least I’ll have it.

-

Jesse what are those lines you attached to the anchor lines and what is their purpose/function?

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Very nice planking job and good thinking on the mast holes.

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Mike that ship and case are beautiful. Put a nice oak apron on it and get a set of nice turned legs. Repurpose some old Queen Anne legs.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

Put a set of legs on the case and make it a stand up display. It will look great. Very nice job.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

I would be real careful with a low flame as a disaster would just be a micro second away. The hair dryer or heat gun is probably your best option. Time and distance is the key. You really only need just a smidgen of pliability to get the job done.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

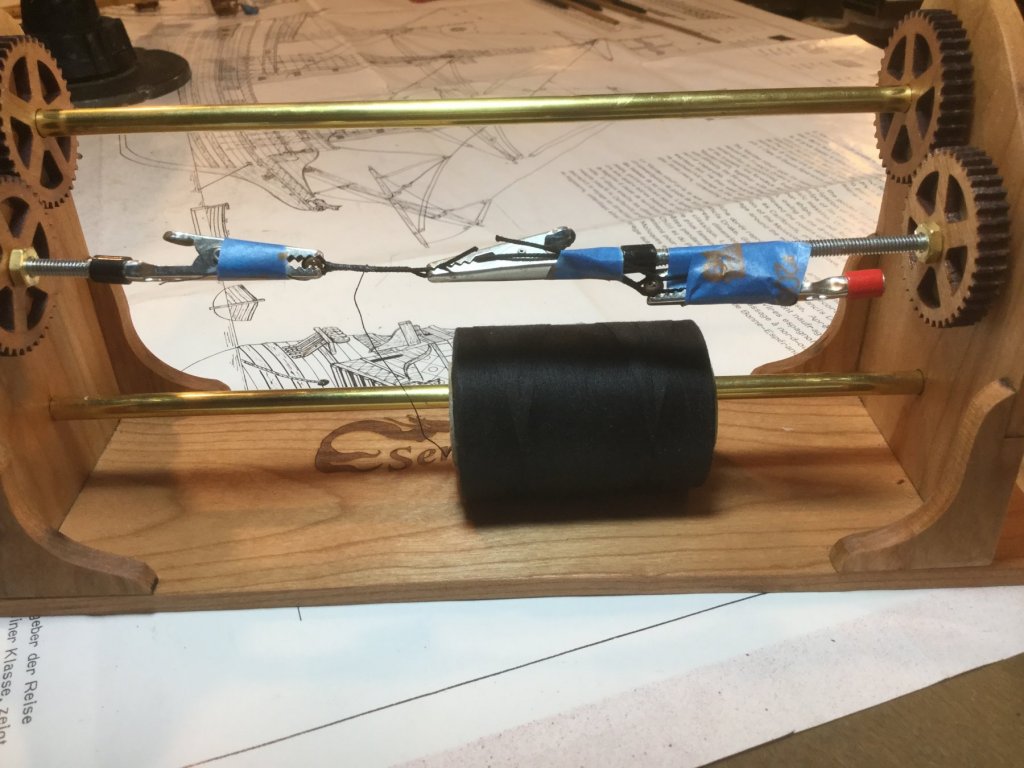

- 11 replies

-

- block seizing serving

- serv-o-matic

-

(and 1 more)

Tagged with:

-

Jet or Dewalt scroll saw

Jim Rogers replied to Anguirel's topic in Modeling tools and Workshop Equipment

I don’t see how there could be $500 worth of difference between these two saws. Personally I would get the Dewalt and use the $500 towards a Mini Milling machine. You could explain to the Admiral how you saved money by getting two pieces of equipment for the price of one.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.