-

Posts

1,931 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hamilton

-

Amazing detail - and so clean at such a small scale! Can i ask what you're using for a blackening agent (Maybe you've noted this further back in the log so sorry for repeat....) - I used to use Blacken-it, but no one seems to carry it up here any more....someone said it had been discontinued....I have another product that does not do a very good job at all.....looking for something that actually works! Thanks for the update Ron hamilton

-

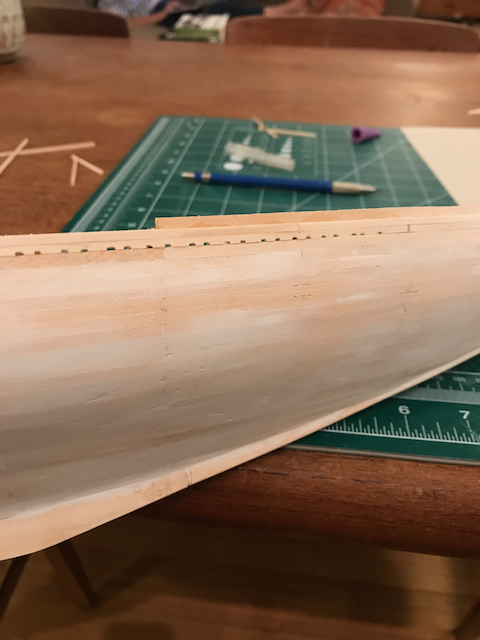

So I've completed the bulwarks. They went reasonably well. One issue was that the height of the top of the waterways did not exactly match up with the bottom of the second 3/32" x 1/16" bulwark strake. At points, then, it seemed that the scuppers would have to be filed into the top of the first strake and the bottom of the second one at different points. I could, I suppose, have simple planked the transom and then drilled the scuppers out by hand - a tedious job, but one that would have resulted in more even scuppers. As it is, I went for the easier solution - the result is that on both the port and starboard side, there is a little step in the scuppers of the quartedeck about half way along. It's not totally unsightly, but it may prove to be annoying enough that I'll remove the bulwark planking and redo it, this time drilling the scuppers out (though with this technique they won't be the right shape....arghh!!) Anyway, here are some photos. Apart from the issue with the scuppers, it's pretty rough looking at the moment. I'll spend a couple of days thinking about the bulwarks and cleaning them up a bit and then seeing how I feel about them overall before I decide whether to move on or redo them....bye for now. hamilton

-

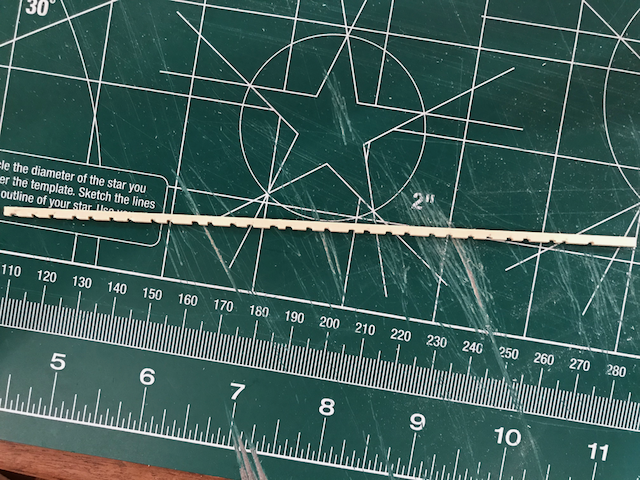

So I'm now moving on to the bulwark planking and there are a couple of things to note - as other logs have noted. First is that, in line with the main deck, the bottom edge of the first strake of bulwark planking should be flush with the top of the waterways. The scuppers will be cut into the bottom edge of this strake - I will use my Microlux table saw to do this. Second, in line with the quarterdeck, this same strake should be flush at the upper edge with the waterways of the quarterdeck. The next strake up on the quarterdeck has the scuppers cut into it as with the first strake in line with the main deck. Third, planks of 1/16" thickness are used for the first 3/16 scale inches of the bulwarks, followed by a 1/32" x 1/8" plank just below the level of the main rails. My model as built is such that, to use a single strake that both contains the main deck scuppers and comes into line with the waterways of the quarterdeck, 3/32 x 1/16" planks will be used. 2 strakes of 3/32" planks will be used to make up the full 3/16" width of the thicker planking strakes and will contain the scuppers. Then a single strake of 1/32 x 1/8" planking will be used for the remaining height of the bulwarks. I am debating about whether to cut the small 1/32"-3/64" cove into the thicker bulwark strakes just below the level of the 1/32" ones, or whether, as I see others have done, simple to paint a thin line of yellow along the outer bulwarks at this level. I might do some tests to see how things look before committing to anything. Anyway, I'll start on this tonight and see how far I get....photos later hamilton

-

Thanks Per - I took a page from your build log in doing the transom! I've cleaned this area up now, though the inboard planking is very rough - fortunately it will be hidden in the end.....hope you're enjoying the weekend hamilton

-

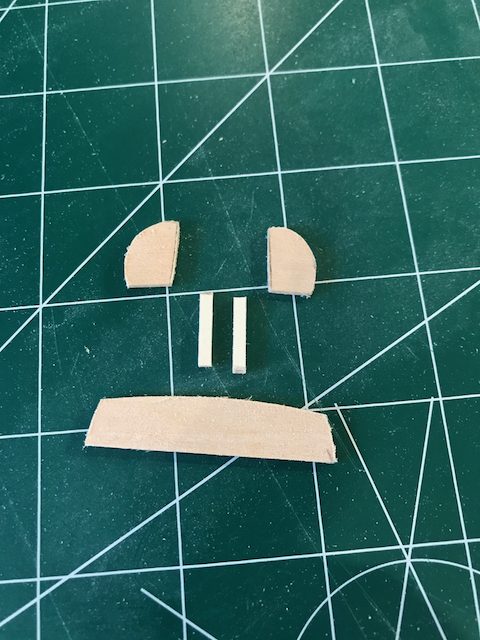

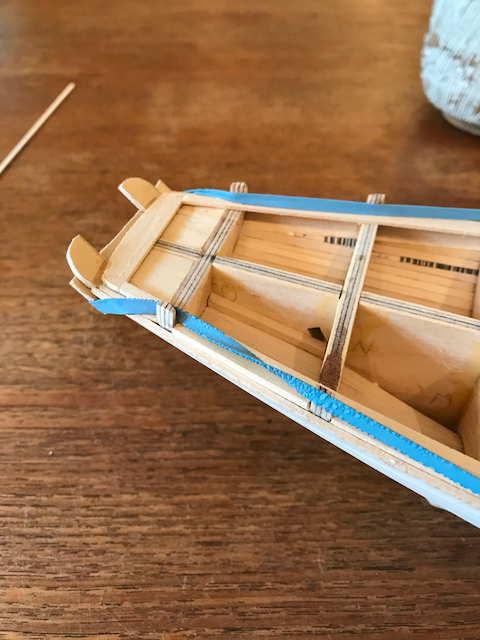

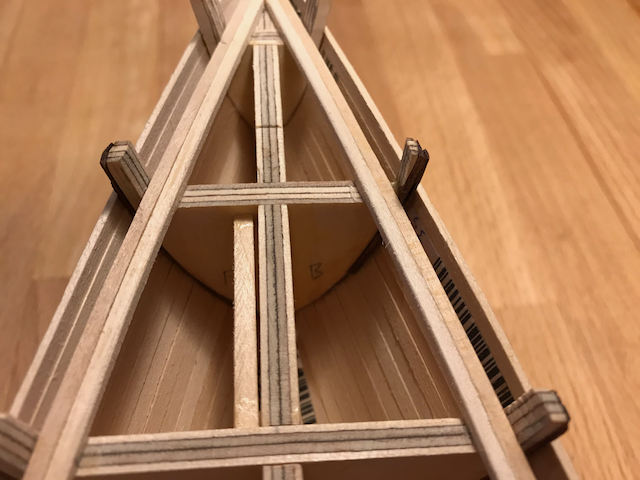

Hello all: So after installing the outer waterways between the bulkheads, I've now reinstalled the hull planks I removed up to the top of the waterway on the main deck and below the waterway level on the quarterdeck. At this point I wasn't sure what to do next - the bulwarks, the deck planking or the transom framing/planking and installation of the forward blocks for the hawse pieces/knightheads....I looked through many of the BN logs here on MSW, and found a lot of different approaches. The one that made most sense to me was to complete the transom framing and forward hawse blocks prior to both bulwark and deck planking. In the process I also completed the transom framing. This process was much more straightforward than I thought it might be. The transom framing was a little tricky, but I used a piece of scrap wood strapped across the transom with an elastic to get the right angle for the outer pieces, and then used a batten clamped to these once the glue was set to get the proper angle for the inner "stanchions". Other than that is was just shaping and test fitting the aft and forward blocks, which are now installed and ready to act as a decent landing place for the bulwark planks. The plans suggest incorporating the extensions of bulkhead "A" into the forward block, but I decided against this, since the inner part of the extension would have been exposed and presented a harsh texture contrast with the basswood block. So in the end, I sawed off the extensions and installed these pieces as single blocks. I used 3/32 x 1/6 planks for the transom - the photos show it in an unpolished state - I'm going to sand it down and clean it up tomorrow. The inner transom planking looks quite messy (no photo), but since it will be pretty much entirely covered over by the main rail I'm not too worried about it..... Photos follow - enjoy! Next it's on to the bulwark planking (not looking forward to filing out all those scuppers!), then the deck and finishing the hull, which I'm really looking forward to. Bye for now hamilton

-

Thanks for the vote of confidence Mark! A quick update to say that I've finished installing the outer waterways, having removed the upper hull planking. The job is not entirely finished yet - I have to clean things up a little bit here and there, fair the outer edges of the waterways and re-install the hull planks. Then I can finally move forward - I'm going to do a bit of stern framing and install the solid piece forward for the hawse holes & knightheads. Then it's the transom planking, bulwarks and deck planking....it's be nice to have the interior structures covered up! Here are some photos - I'm happy with the overall results though they are not absolutely perfect..... hamilton

-

Thanks Grant: I ended up going with option 1 and removing the upper 2 strakes of planking from the hull - in the end this was going to be way less finicky and frustrating than trying to get pieces to fit exactly in weirdly shaped spots....I have a bunch of 1/8" square strips that I'm using for the purpose and managed to get through about half of the job last night. I hope to finish this evening, but there's a chance I won't get to the "bench"....we'll see - thanks again and bye for now hamilton

-

Just took a look at some other BN logs and noticed that the smarter builders followed the instructions and installed the outermost waterway before doing the planking.....I'm wondering about either removing the top two hull planking strakes and then installing them, or leaving it as is and trying to fi pieces in to the gaps.....the first option might be easier in the long run, since I would be able to fair the outboard edges of the waterway planks while with the second option it'll be a lot of finicky trial and error for each of a couple of dozen small strips.....have to give it some thought.... hamilton

-

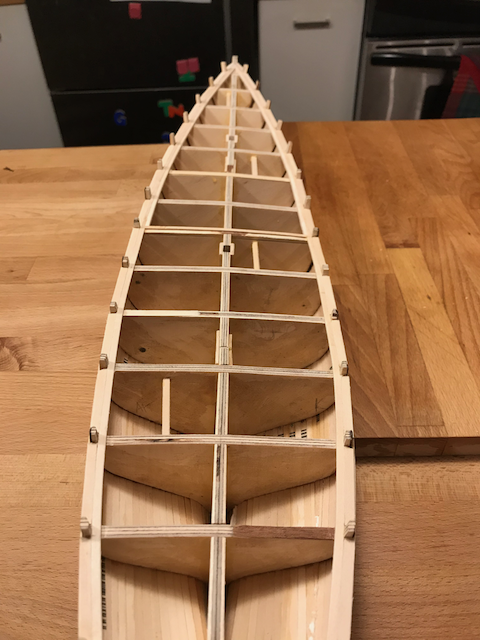

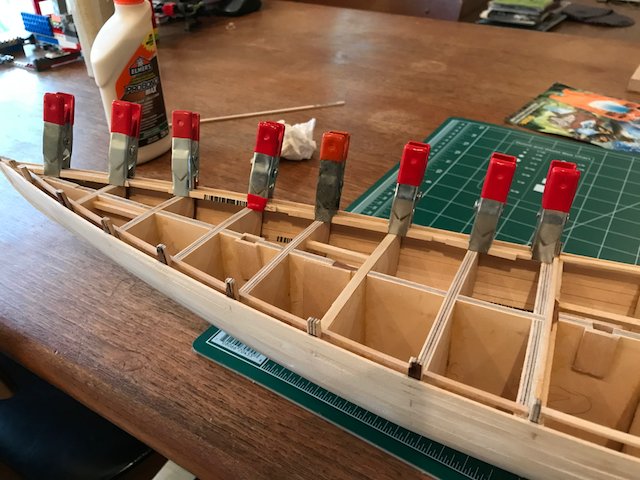

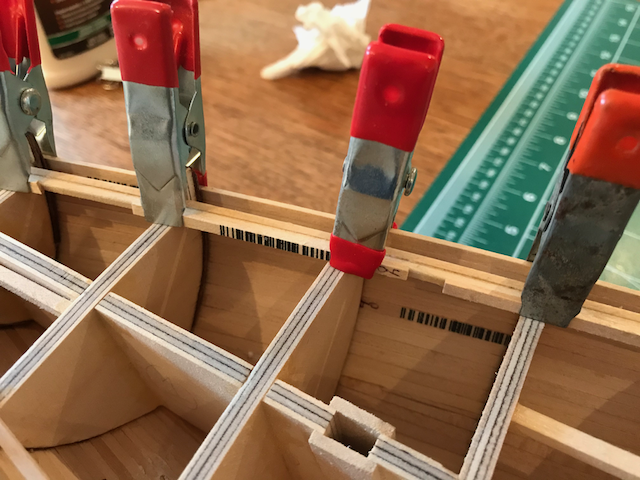

2 updates in less than 24 hours! Have to say it's very nice to be back at the bench! Anyways, it's a rainy Sunday here, so not a bad time to install the inner waterway planks. These are fashioned from 3/32 x 3/32 strips, slightly chamfered on the inner edge to fade down to the thinner deck planks. This was achieved by clamping the strip, cut to measure, to an old piece of MDF and carefully working at it with a file and a sanding block. The effect is barely noticeable, but it feels good to have it done. The photos below show some 1/8" pieces of scrap basswood being used as braces for the clamps so as not to mar the waterways themselves. After I installed them I noticed (why is it always after that I notice?) a bit of unevenness in the milling of the two waterways - especially on the port side, there was a lip between the two pieces. This was straightened out using a #10 x-acto blade and some fine sandpaper. These will be finished grey eventually, so the colour contrast won't matter at all. Here are the results. The next step before moving onto the transom & bulwark planking will be to install some filler pieces between the bulkhead extensions....this seems like it might be a tricky operation, so any tips from past MS Bluenose builders would be appreciated.....Enjoy the photos and bye for now hamilton

-

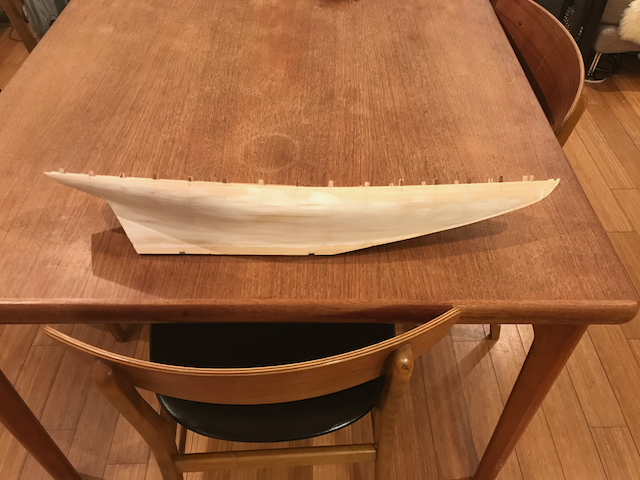

Thanks Grant and Mark! It's been too long, for sure...I have occasionally lurked around here on MSW admiring others' work from a distance, but now it is probably time to jump back into the fray. Here, as promised, are a few shots of the hull - it is very difficult for me to get a decent shot of it....just using my phone, of course....should probably invest in a decent camera...Enjoy! Next step will be to complete the waterways - one 3/32" x 3/32" strip i/b on the main deck and then filler pieces to go between the outer waterway and the hull planking.....that's for tomorrow. Bye for now hamilton

-

Hello there - if anyone's still there! I see that it's been 2 years since I started this log - lots has happened since then - my youngest has started school; I've stepped down (gratefully and after 8 years of service) as the chair of my department at the university; I've still only got about 45-50% use of my left index finger, though it's manageable as injuries go; I've built a small cabin; published a book and spent some time asleep. And yes, there has been progress on the BN. I think my finger injury last summer, combined with an incredibly difficult year at work, took the wind out of my modelling sails - I've still only dabbled at the Syren since July 2017 and it sits now with the bulwarks partially planked. In the last couple of days, though, I've returned to the BN, finished the lower hull planking and mapped out the next phases of the build. Part of the malaise has been being stuck at points of the build that can be quite tedious - the hull planking. In the case of the BN, I have also been quite slapdash about the planking, particularly below the waterline, since the hull will be finished. The thing had been sitting in a closet with only a few stealers to complete before it was done, but somehow, after putting my boys to bed each night, I found that I didn't have the energy, patience or alertness that is necessary for good results. But now I hope I can gather some momentum since I'll now be moving onto what I find to be more satisfying parts of the build. I have no photos to post at the moment, but will do later this evening - in any event, I've slathered the hull in modelling paste and am waiting for it to dry so I can sand it smooth. More later hamilton

-

I built this same 1:100 Amati one several years ago and gave it to a close family friend as a birthday gift - she still has it displayed in her living room and it's nice to see it when we go visiting. Small but nice looking! hamilton

-

Looking good Ferit - I've made that exact same mistake cutting the shrouds!! Probably two or three times! I feel your pain....but keep it up - she's looking gorgeous hamilton

-

Tim! Sorry for the very late response....the holidays have been and gone and I'm just getting back to looking in on MSW in a serious way. Still no work on the Blunenose since last official update....It's sitting in the closet covered in an old shirt, and now that a new semester has begun it's hard to say when I'll get back to her. I'm hoping to be able to eke out some time at the "bench" this winter, but it's hard to say.....Most nights I am just too knackered to commit to it and since I don't have an ongoing modelling set up half the hurdle is pulling stuff out and setting stuff up....so we'll see if I can recoup the energy required to do a half-decent job. As for finger push-ups.....not in my future....the finger is not really improving too much, unfortunately, except for wagging at people every once in a while. I has not interrupted my modelling so far, but when I come to rigging, I'm fearful that the fine motor skills of my middle finger (which I'm now using as a surrogate index) will not be up to snuff....we'll have to see..... bye for now hamilton

-

Well well well! It's nice to see you at this beautiful build again. Ferit! Hoping there's much more to come hamilton

-

Just as a follow up question - might it be possible to get a wood list for a Swan framing package - just for future reference? I've ordered the plans, but I'm not sure if they come with a wood list or not and this would be very useful to have when I come to this project some time in the far future..... hamilton

-

Thanks OC - things have been so busy at work that I've not had a chance to get back to the BN or my other build (the Model Shipways Syren) for quite some time....I'm hoping that over the holidays I'll be able to dedicate some time to modelling, but at that time there are, of course, so many other obligations....I'm missing the work a lot these days and will hopefully get back to it soon....... hamilton

-

Nice to see you picking this up again Collingwood! She's looking very fine indeed hamilton

- 455 replies

-

- slightly modified

- greyhound

-

(and 1 more)

Tagged with:

-

Whoa! This is sad news....I bought (and have yet to start on) the Echo cross section, and am right now about to head over hoping that Swan plans are still available for a future build.....a great service to the community and it will certainly leave a gap that no amount of wood filler can correct..... hamilton

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.