-

Posts

1,931 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hamilton

-

Good to hear from you Tim! I've just come back to town from our annual cottage vacation....now back to work! I'm on a list for surgery on my hand, but I'm still able to do most things, including tying my shoes! My left middle finger is becoming like a second index.... I'll check in on your Cutty Sark - in the meantime, take care! hamilton

-

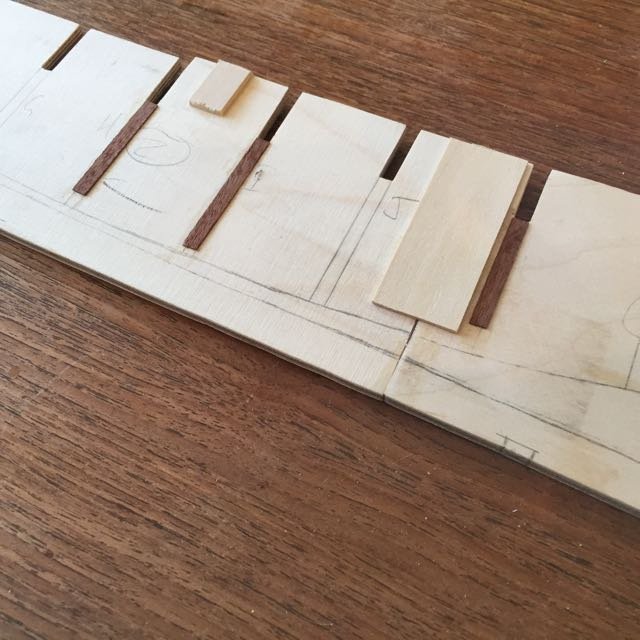

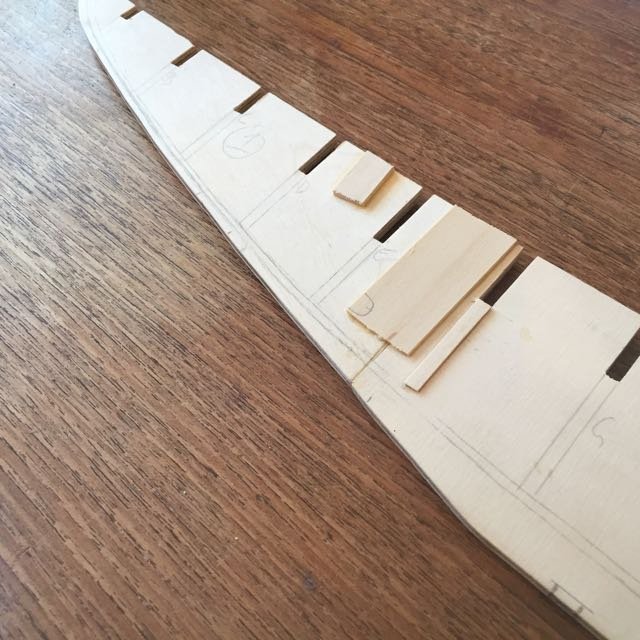

OK - another small update.... In the last few days I've been fine-tuning the centre keel and bulkheads - only the top of the latter for now, though some early tests have shown that there's a bit of shimming and trimming that needs to be done along the edges....I also fit the two parts of the "great beam" atop bulkhead "H" - made some patters for these pieces and cut them from 3/32" basswood sheeting. They are not very elegant, as can be seen from the photo below, but once they were fit on the bulkhead I took some time working on the top edges to ensure that the aft (lower) part was even with the quarterdeck bulkhead tops and then that top of the forward (higher) part was 1/16" above the lower part. Final work will be done on this once the deck planking is complete.... I also made a couple of templates for the upper edges of the stern filler blocks - not very exciting, are they....anyway, they'll come in handy in a couple of days when I'm shaping these. My main work has been on the rabbet joint. The photos below show how unpretty the work is....I scored the rabbet line with a #11 blade and then used a #10 blade to remove the wood....not the best instrument but as I don't have any gouges or chisels, it had to do....eventually I'll invest in more appropriate tools for this job! In any case, though it's a bit messy it's nothing some wood filler and a lot of paint won't hide when it comes down to cases. That's all for now. We're leaving for a couple of weeks to go up to a place called Hornby Island in the Northern part of the Salish Sea (Straight of Georgia) - I might do some maintenance on the Corel Flattie that I have stashed up there at a friend's cabin but no other modelling....hope to have the framework of the Bluenose complete by then and ready to move onto the planking when we get back....bye for now hamilton

-

Nice work overcoming the early problems you experienced - I'm building the Syren too, but my kit was purchased a few years back or more and all seems well in order - templates fine and plywood in good shape (though I've read elsewhere about scale issues with the carronades.....). Anyway, I'm also in agreement with Doug and Bill regarding the framing - this part of the build requires some sensitivity and trying to work with grains in opposite directions would be tricky and frustrating. I had the sills and lintels on for a long time before picking up a sanding block - mostly because I thought it would be incredibly tedious to sand these down....in the end it went quite quickly with 100 grit sandpaper... One other piece of advice - when you install the gunport frames try to keep them flush with the lintels and sills on the inboard side - it is much easier to sand outboard than in inboard.... hamilton

-

Thanks Mark and Bill! Bill - that's good advice! My main concern is about the fragility of the pieces....they're quite thin, and cutting them will be quite tricky I think using my bandsaw - the only tool I have for such things.....I'm going to put a 1/8" blade on it to facilitate the process....My plan was to make multiples of all the frames so as to have backups at the ready, so maybe I'll cut a couple from ply and a couple from basswood and try my luck! Thanks again for the tip - I'm pretty sure I have some 3/16" basswood sheeting lying around too....but I can't recall.... hamilton

-

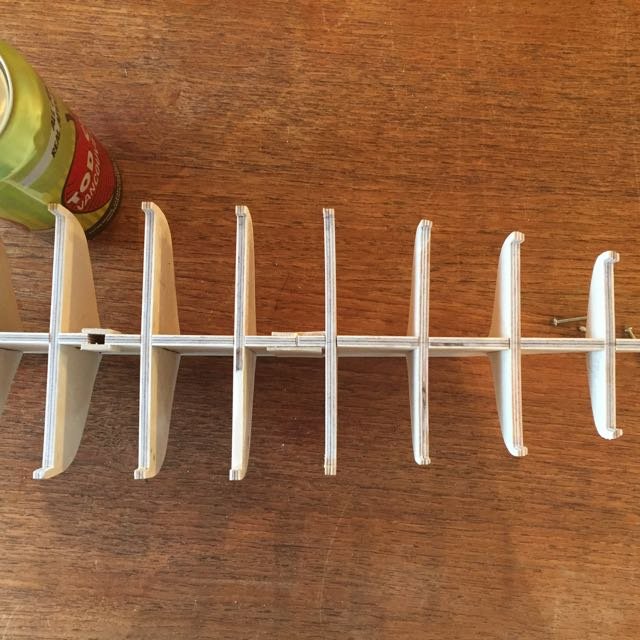

Hi Doug: I cannot believe the poor quality of the material you were sent! I bought this kit a few years ago and have just turned to building it - the laser cut parts were from a good quality ply, though still quite fragile. I'm at about the same stage as you - I had attached the stern frames, but snapped them all off when trying to reposition stern frame "C" - I gouged my finger with a scalpel blade and in the chaos broke off all the frames - I too now have to make new ones! Anyway, I'll follow along with interest hamilton

-

Off to a promising start Ben - I've always been interested in this kit - but went with the Syren instead. Looking forward to following your build and comparing notes hamilton

- 18 replies

-

- niagara

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Grant: Late to the party here - this is some really incredible and exacting work - the metal work is especially impressive to me! hamilton

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

-

Hi Steve: A lot of hair-raising work here - these parts must be extremely sensitive and prone to breaking....but the results are really great. hamilton

- 190 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

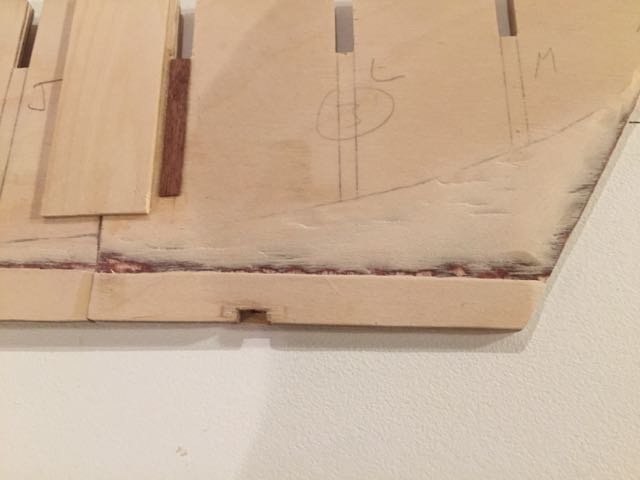

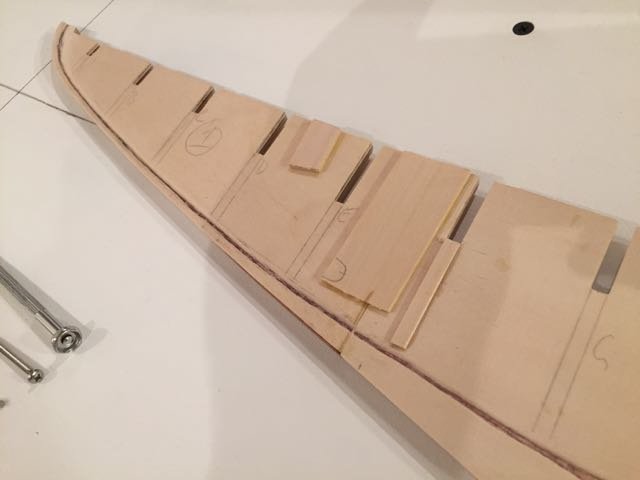

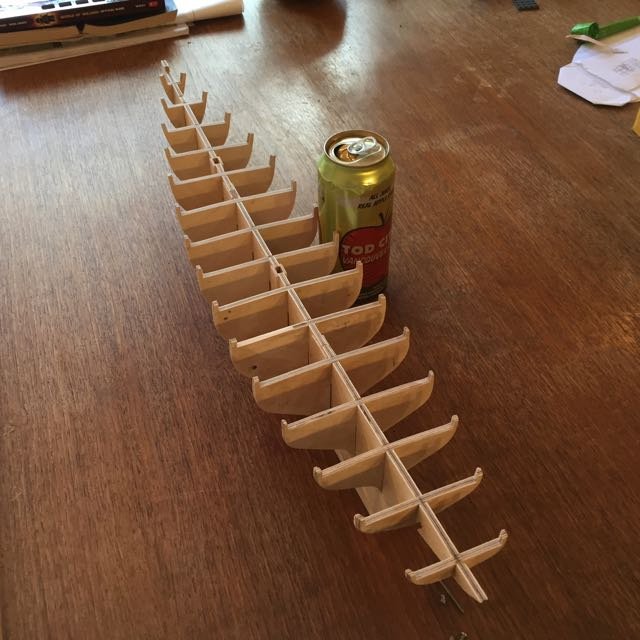

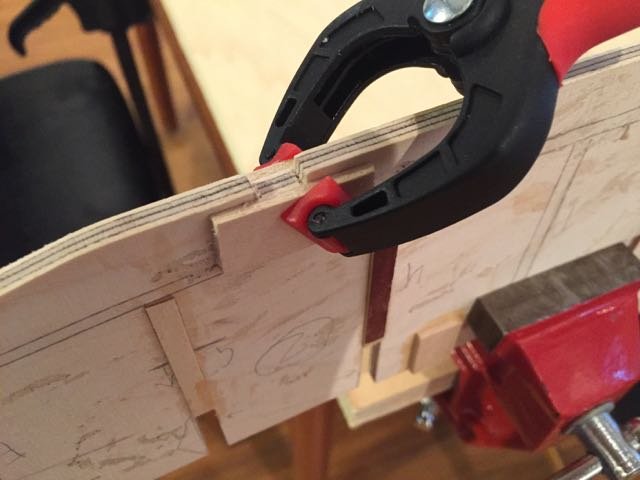

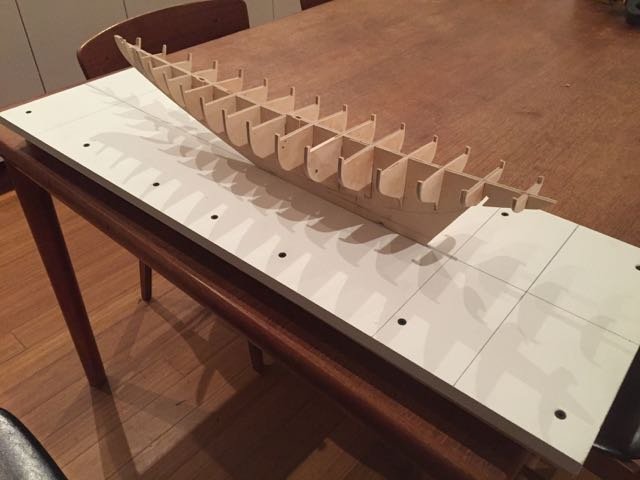

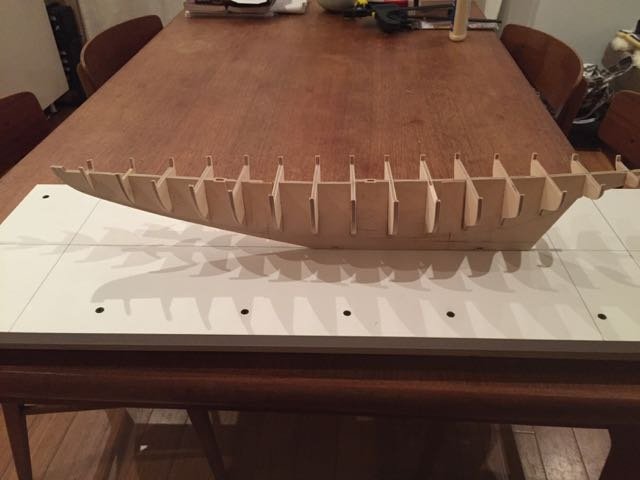

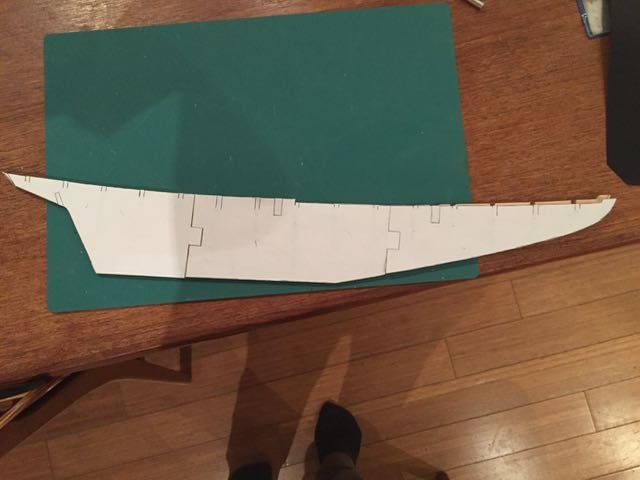

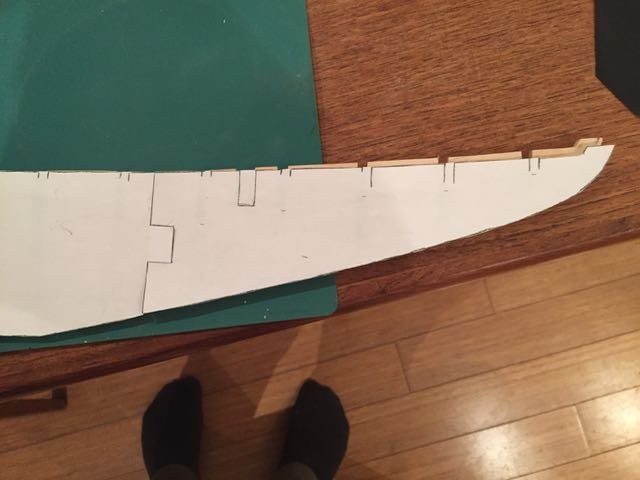

OK - time for a real update - I finally feel like I've made some progress on the Bluenose after starting on her last September! I should mention that while working on the stern of the Syren on Thursday evening, I ended up putting an extremely deep gash in the upper joint of my left index finger. I had positioned the outside stern frames about 1/64" too high and was trying to wrench them free (stupidly) by levering their seams with a scalpel blade.....the blade slipped and I ended up slipping, tearing the entire stern framing off, nicking an artery and spurting blood all over the place, and spending several hours in the ER getting stitched up and consulting with plastic surgeons about tendon and nerve repair. Fortunately, my tendon is fine - good movement, though painful still. The nerve is damaged on the inside, and may need surgery - I'm going for a consult at a hand clinic on Friday and they'll tell me then whether it's worthwhile to operate. Long story short - Syren is now on hiatus while I work on Bluenose....eventually I'll cut new stern frames (I have plenty of 3/16" ply from the Bluenose build)....but for now.... After remaking the keel parts to correct for the issues I experienced before, I spent quite a bit of time refining the individual keel pieces and re-fitting the bulkheads. Having done this before it went pretty fast - here are a couple of shots of the centre keel with shims installed to fit the bulkheads snugly, as well as reinforcements for the keel joints and mast mortices. You'll notice on the bow shot that the lower edge of the forward keel piece is a little all over the place - this has since been corrected with some sanding and thin shims. Here are a few shots of the bukheads dry fit.... I also spent a bit of time making a building board adapting the design given by David Antscherl in TFFM Vol. 1. For the Bluenose, I used a 5/8" sheet of MDF, painted with 5 coats of matte white paint with 2 1" x 2" spruce battens for support. I took a while locally sourcing some 4-40 machine screws - just small enough for my 3/16" keel. I've never mounted a model ship using internal nuts, so it took some thinking how to go about it, particularly given the size of the nuts relative to my keel. I filed down the hexagonal nuts roughly square and fit them as you see in the photos below. To drill the holes I clamped some 3/32" basswood to the side of the keel to avoid blowing out the ply, and then very gradually opened up holes to fit the 4-40 machine screw - first pricking the centres of the carved out part with an awl, then using a 3/64" drill in my pin vice, then a 3/32" bitt in my power drill, then a 1/8" bit. Here are the results, the nut attached with epoxy. I then used to some 1/32" x 3/32" basswood strips to cover the outside edges of the slots where the nuts were installed, and sanded them down very flat - the nut shows through slightly, but the painted hull should not show them, so all will be well. And here are a couple of shots of her skeleton (bulkheads still dry fit) on the building board. Thanks for stopping by and any and all comments, questions or (constructive) critiques are welcome. hamilton

-

Sorry for the (extremely) late reply Eddie - but thanks for following along - though there hasn't really been much to follow! I've been travelling quite a bit since the beginning of the year - San Diego, Ottawa, Rome, the Netherlands and Germany in the past 5 months.....it's been fun, but it'll be nice to spend some time at home! And then we're off to cabin country at the end of this month, so I'm trying to pack some modelling into the next few weeks! So I finally got back to the BN today after many months of dust gathering....The work today involved re-cutting the keel pieces, which I did (for I think the fourth time) on the bandsaw. I cleaned them up with some files and belt/disc sander and found.....that they had the same problem as before! While the aft two keel pieces seemed fine, the forward one was out of line with the plans. Instead of taking new templates and cutting entirely new pieces, though, I just fidgeted with the joint between the foreward and centre keel pieces until all of them lined up - required a bit of extra filing and the addition of two small skims on the forward joint of the centre keel piece, and now everything connects and lines up well....I won't post photos, since you've kind of seen them already! These keel pieces still need quite a bit of attention. I need to cut the templates off at the rabbet line and the bearding line and mark those on the starboard side and also make port-side templates to mark these lines to port. I'll then assemble the keel, cut the rabbet joint and taper the cutwater. Fortunately, the bulkhead pieces I made last Fall are still serviceable, but I'll need to make adjustments on the new keel to fit them properly. Then I'll have to adjust the stern end of the aft keel piece so the sternpost fits snugly - though this won't be installed until after the hull planking is complete. At that point, I should be able to install the bulkheads..... I have to say it's been nice to get back to this build! I've taken almost the entirety of 2017 so far off of modelling -- there simply hasn't been any time and I found also that I needed a hiatus to reignite my interest! Anyway, hopefully there will be some decent progress to show here over the next few weeks. Bye for now hamilton

-

rigging sizes and proportions in Lees

hamilton replied to hamilton's topic in Masting, rigging and sails

Thank you Russ! That makes sense. The heading in Lees says "proportionate rigging sizes" and doesn't clarify that it's circumference - but I should probably have guessed! Thanks once again hamilton -

Hi there: I've been doing a bit of planning for a future build (Corel's HMS Bellona) and have been consulting James Lees' Masting and Rigging of English Ships of War to flesh out the vaguer aspects provided by Brian Lavery's Anatomy of the Ship HMS Bellona and correct or improve upon Corel's design. One thing that has struck me as strange is the proportion that Lees gives for lower stays - "1/2 the diameter of the appropriate lower mast" (p. 185). This would mean a main stay that would be almost 5mm and the forestay 4mm (based on information obtained from Lavery)!! On a 1:100 model that seems way too thick....is Lees off base here or am I missing something? Any wisdom any of you can provide would be most welcome. Thanks a lot in advance! hamilton

-

Thanks Jond - I've been out of it for a while now, so it'll be nice to be back at the bench when my plate clears....have not even had much time to drop in on some of my favourites - including your massive Bluenose! Promise I will soon! hamilton

-

Thanks Mark & Per: It is good to be back (even in such a small way....) Hope to be able to carve out some time also to check in on your work, too! hamilton

-

Thanks for dropping by Keith - yes, there are so many things that can go wrong at this stage - distorted plans, shaky hands, bad cutting....I could (and do!) drive myself crazy checking things against as many sources as I can and I'll still find time to second guess myself and/or get it wrong!.....anyways, today I made my "good" templates - double checked against plan 1 and 2 of the MS sheets, and against my previously assembled keel to see if the error still showed up as prominently in this final template as it did on the rough ones I made last night - it did! I think I've made these templates at least 4 or 5 times - I really hope this is the last! I'd love to actually get started with this build! Now I have to follow Grant's suggestion above to debond the keel parts already assembled. I'm not sure when I'll have a chance to cut the new keel pieces - as I've mentioned before I'm a dining room table modeller living in the Pacific Northwest and I have to do all my cutting out on the front patio and only when it's nice and dry - the rain has let up for a couple of days but it's supposed to come back tomorrow evening and through the week. There's a well-known Vancouver joke (though maybe it's shared by our neighbours in Washington State) - how do you know it's Monday in Vancouver? The rain stops.....anyway, I'll get the bandsaw out again soon enough.... hamilton

-

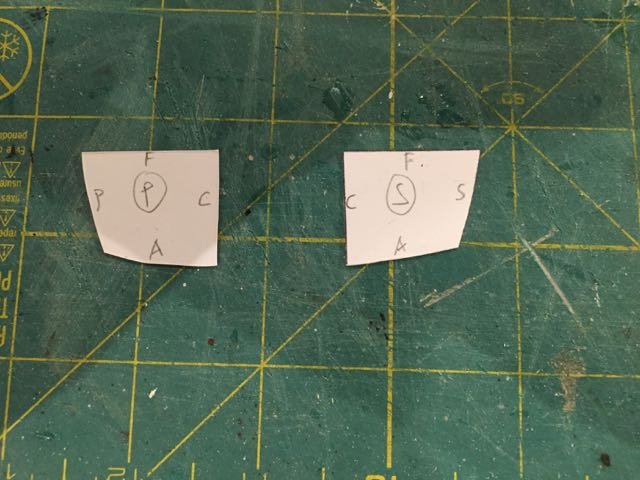

Well, my last update to this topic was way back in October.....and my contributions to MSW in general have been pretty lax (the occasional brief comment or like)....above and beyond that the last time I spent any time modelling was back in December! Crazy!! I have not taken a break for this long since I started. But with Syren stalled at the beginnings of the gunport framing (to be picked up again soon) and with the weather improving, I thought I'd think to Bluenose once again..... Tonight I made some new templates of the centre and foreward keel pieces from the MS drawings - two sets of templates were made - one from sheet one (which shows outlines of the laser cut parts) the other from sheet two (which shows sheer and plan views of the framework and planking). The templates were made quite quickly and were a bit rough - but they were really just meant to allow me to identify where my errors were in cutting the pieces the first time. My earlier guess ended up being right - there were two errors that compounded one another - first in the cutting of the forward piece and second in finessing the joint between the forward and centre pieces. Here's a photo showing the cumulative error: And here's a closeup: So as predicted it's back to the drawing board with the keel. I hope to do the debonding of the currently assembled pieces over the next few days - I'll then salvage the aft piece, make more careful templates of the centre and foreward, recut them and assemble the centre keel once again. Since I've already cut the bulkheads, I imagine that once this business gets done the framework will come together quickly. Bye for now hamilton

-

Hi Peter: It's been a while since I checked in and your America looks great! The sails are beautiful and thanks for the tutorial above!! Very helpful - I will definitely be consulting it next time I try to make sails! As for the block you mention above for the tack - the one on the long line connected to the gaff. That block is actually for the topsail sheet - I think it must have been put in place to allow the operation of the gaff topsail from a single location on deck (i.e., the foot of the mast) - though I'm no expert.... great work - looks like you're close to the end.... hamilton

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.99dd7c13e29644b8d36b1b6405964052.jpg)