-

Posts

1,528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by VTHokiEE

-

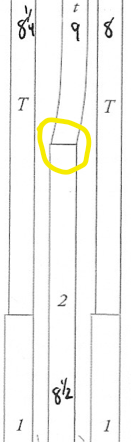

So I have run into a slight problem reading the plans (currently available here: http://www.admiraltymodels.com/Tips.html) and I am hoping that some advice from the forum can help me determine the best way to proceed. The top timber on frame 3 aft casts forward to make the side of a port. In the sided frame dimensions this top timber is marked as 9" and the second futtocks is marked as 8 1/2". I added the second futons and was preparing to deal with the top timbers (I've honestly am not certain how to approach shaping this yet which has not helped motivate me to work faster) when I saw that in the sided frame dimensions image it doesn't appear as if the toptimber extends past the second futtocks as shown in the next picture (which it would have to if it were indeed 1/2" thicker). So then I started looking at pictures of the finished frame and it looks like the second futtocks is the same thickness as the floors (10 1/2"). Right now I think I need to remake the second futtocks thicker but since this is counter to the sided dimensions I was hoping that some could advise? Thank you!

-

I place drops down (or on the plank) for a small section (how big is up to you) and then press that down and secure it. I then add a few more drops (I usually use a pipette type applicator) and press the next section of the plank down slowly working my way across the entire plank. I think attempting to glue too much at once may not end well.

-

In a word - slowly. I have 7/12 frames completed (and hopefully correctly 🙂 ) and have broken ground on the 8th. Life took me for a bit of ride out of the shipyard at the beginning of the year (nothing bad) and as much as I wish I could spend more time on the build life and the temperature in my garage are currently against me. I'll keep slowly working away at it though but I figure no one really wants to see pictures of 3 (and ultimately 8 ) more fairly similar frames - ha.

-

Some builders (cough, cough myself included) separate this into two pieces of line. You tie off the first line and then glue a coil, that was created off ship, on separately.

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

USF Confederacy by Rustyj - FINISHED

VTHokiEE replied to Rustyj's topic in - Build logs for subjects built 1751 - 1800

Congratulations!- 149 replies

-

- confederacy

- frigate

-

(and 1 more)

Tagged with:

-

Wow just saw your log - what a great job so far. I really like what you did with the floor; I wish I had done that on mine but it was my first rodeo so I stayed pretty true to the kit.

- 29 replies

-

- first build

- Chesapeake Bay Flattie

-

(and 2 more)

Tagged with:

-

If I'm looking at the same hole it is for the Bowsprit 'Iron Hoop" placement (PE-12 and PE-13) in the instructions I have on hand.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Do you mean Mamoli instead of Caldercraft?

-

Festool shop vacuums - a quieter option

VTHokiEE replied to druxey's topic in Modeling tools and Workshop Equipment

I went through that dizzying process, finally settled on a model, and unfortunately they raised prices in the new year and priced me out when I was ready to buy :-(. I eventually came up with a different plan but someday I hope to get one of these (and hopefully be able to be more lax on the ear muffs). -

It has components that you sand down to fit from what I’ve seen (I own a set but I haven’t used it yet). I do know that Blue Ensign has used them on many of his 1:64 builds (including his Alert which is a similar style ship). I would also assume it can be used at 1:48 since that is primarily what Chuck’s kits are.

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

I think this link works: https://syrenshipmodelcompany.com/laser-cut-ship-model-fittings.php#!/Pintles-&-Gudgeons-Laser-Cut-Mini-Kit-1-16-wide-straps/p/65643912/category=5764789

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

Can you use the pintels and gudgeons kit from Syren for fixing the rudder?

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

I’ve seen it mentioned that you wouldn’t want to plank an entire side first as it may create some twist to the assembly. I can certainly see how that has potential with some out skeletons but I would think the amount of reinforcement here would prevent that though. I would do a belt (or less) on each side at a time so that I could keep them in alignment from side to side better, but that may simply be a personal preference.

-

I think there is confusion about underway; I believe you meant in action and moving while an alternate definition might be in the process of being built. I’m curious if you could add the link to the description of the gallery? I think there are text sections that can be used to describe the completed work.

-

Do you use these, comments?

VTHokiEE replied to Dave_E's topic in Modeling tools and Workshop Equipment

Making a custom version of the last one can be useful for rigging. I picked up that version and it was simply too big. I use it for other random things now.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.