-

Posts

339 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rob S

-

- 395 replies

-

Great kit Cleat! Looks like you are well on the way. This forum has recently been reorganized but used to have this great planking resource that really got into the details. I do remember one planking constraint where no plank should be tapered below 20% of the non-tapered plank width... so in those cases, the stealers come in. It looks like you are employing many of the techniques (e.g., creating bands, measuring the band length for each bulkhead, etc.) from the resource. You may be familiar with the resource I’m referencing, but in the meantime will try to find a link to it. Rob S

- 13 replies

-

Looks good Robert! The deck staining turned out very well. As you get into planking, you may want to consider sanding down the forward and rear facing corners of your forward and aft bulkheads, respectively. This provides more bulkhead surface for your planks to adhere to rather than just the bulkhead edge. This is especially truce in the more forward and aft bulkheads.

-

- 395 replies

-

What a beauty she is! Great log;appreciate the multi-media

- 358 replies

-

- occre

- santisima trinidad

-

(and 1 more)

Tagged with:

-

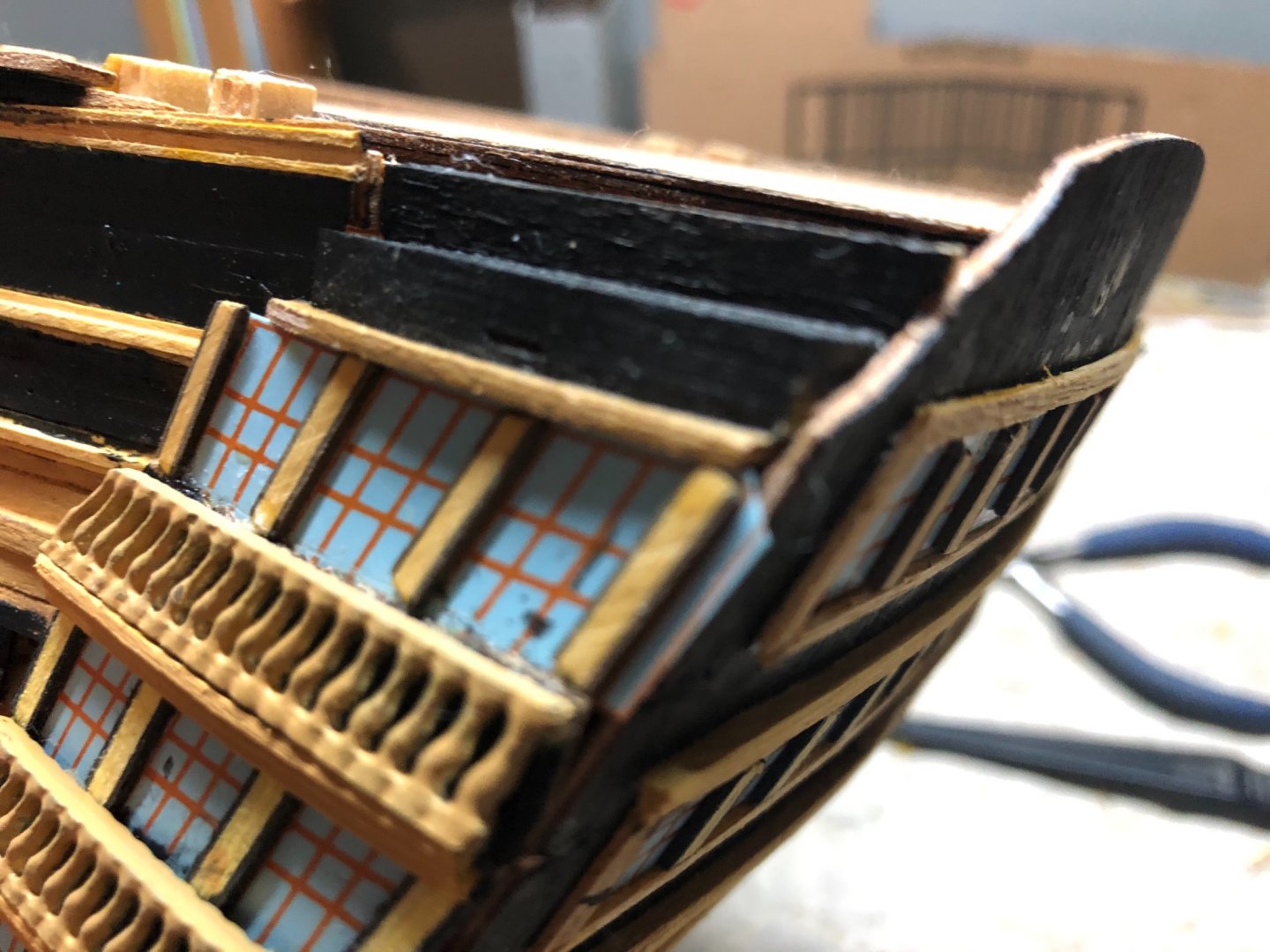

Working the bow stanchions and finding it difficult to modify the 10mm x 2mm x 2mm walnut laths to show the detail (e.g., Timber Heads). I’m amazed at the abilities of those able to implement this level of detail. Also need to do some cleanup on some of the paint.

- 395 replies

-

- 395 replies

-

- 395 replies

-

- 395 replies

-

- 395 replies

-

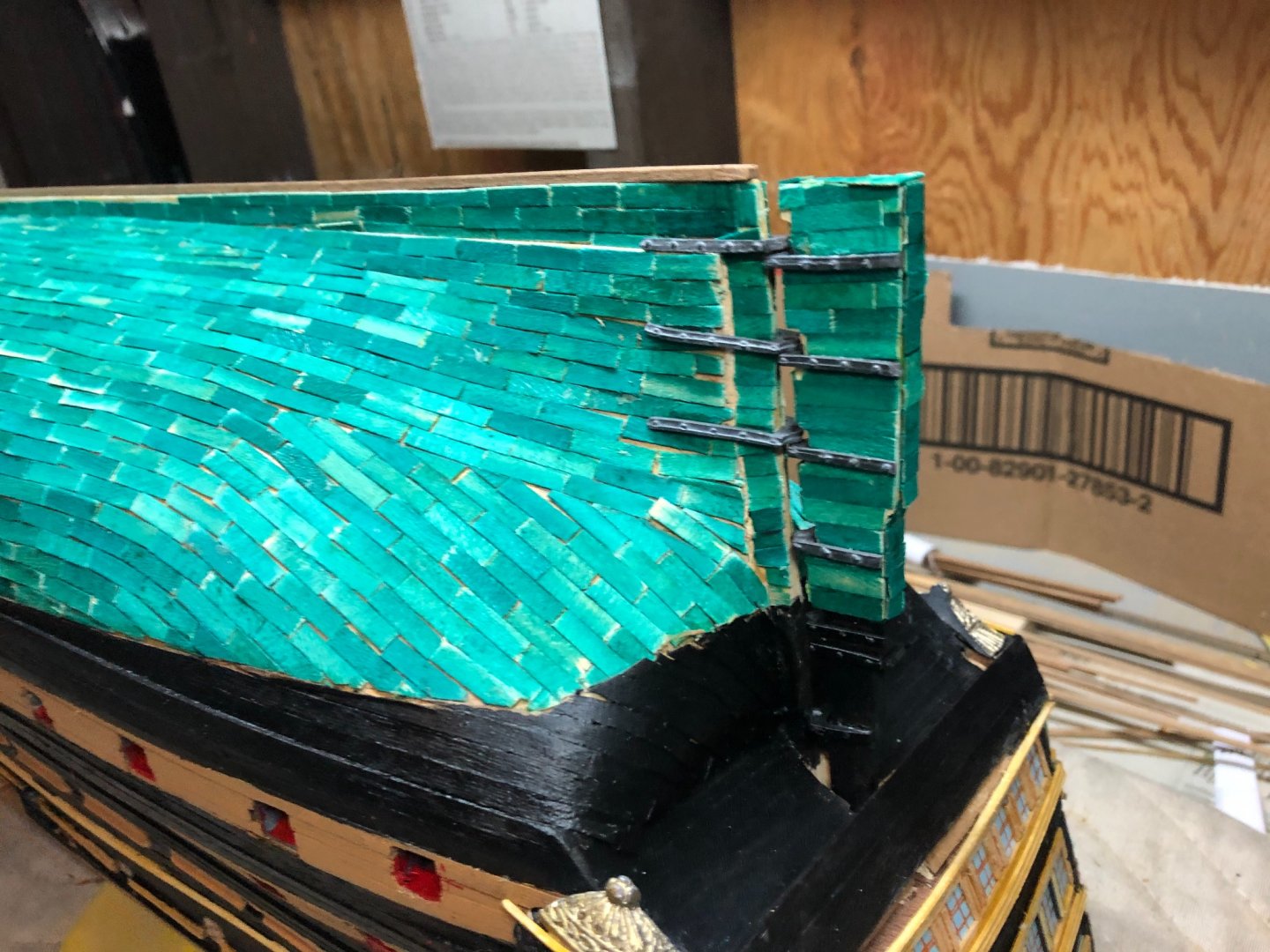

Setting the rudder. The lead pieces provided are brittle and subject to breakage. Slow, but steady going.

- 395 replies

-

Taking an opportunity to prep for the next stage by painting the beakhead bulkhead with associated round houses as well as finishing the rudder before installing it. Also noted the transom had some missing planking that I’ve add to both port and starboard sides. You can see the build progression. I will also be filling in some of the missing planking/deck area on the poop deck after removing the upper part of the aft bulkheads that show above the poop deck. I also need to fill in some planking that is missing at the transom/ship hull interface. So lots of ‘little’ things going on and still to do on the transom area before transitioning to the forward part of the ship.

- 395 replies

-

- 395 replies

-

Dave - I appreciate all the detail you’ve provided during your planking exercise. Your Bounty looks very nice. While I’m a bit late to the party, I experienced many of the issues you have during the planking of my Vic. As time went on, I assembled a ‘soaker’ tube from PVC piping and ends and used it in conjunction with my plank bender. Also, your second planking will cover up some of your earlier errors:) I look forward to following along on your journey!

-

Beautiful work! She looks fantastic!

- 55 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Merry Christmas to you as well Diablo! Happy New Year! Appreciate your kind words on my build. In truth, my transom is coming together more because of your progress/pictures than of the Mamoli instructions! I am nearing the end of my build as I only intend to go to a 'hull down' type of finish rather than the full up, rigged model. Takes up much less room. Of course, I might change my mind later:)

-

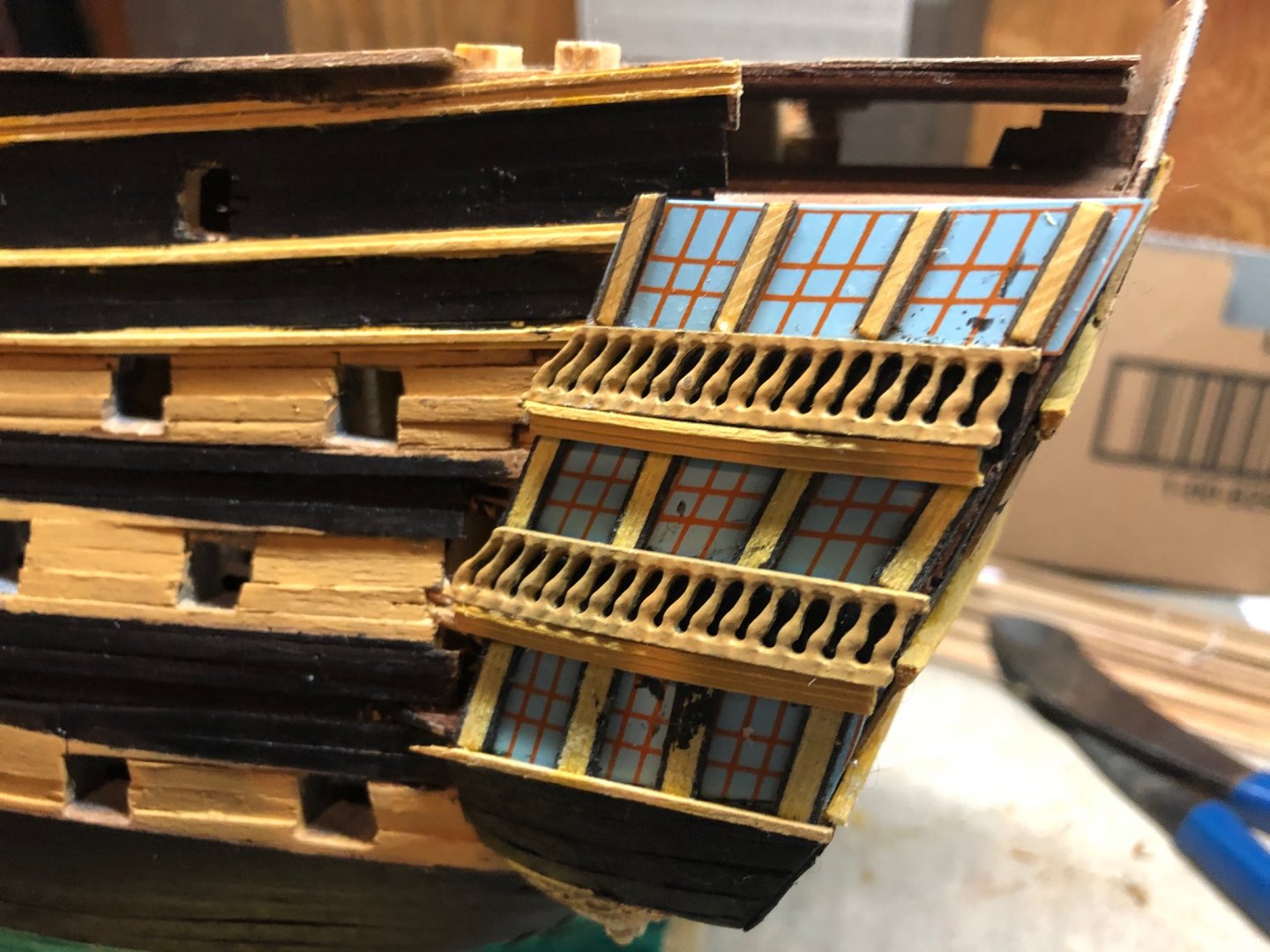

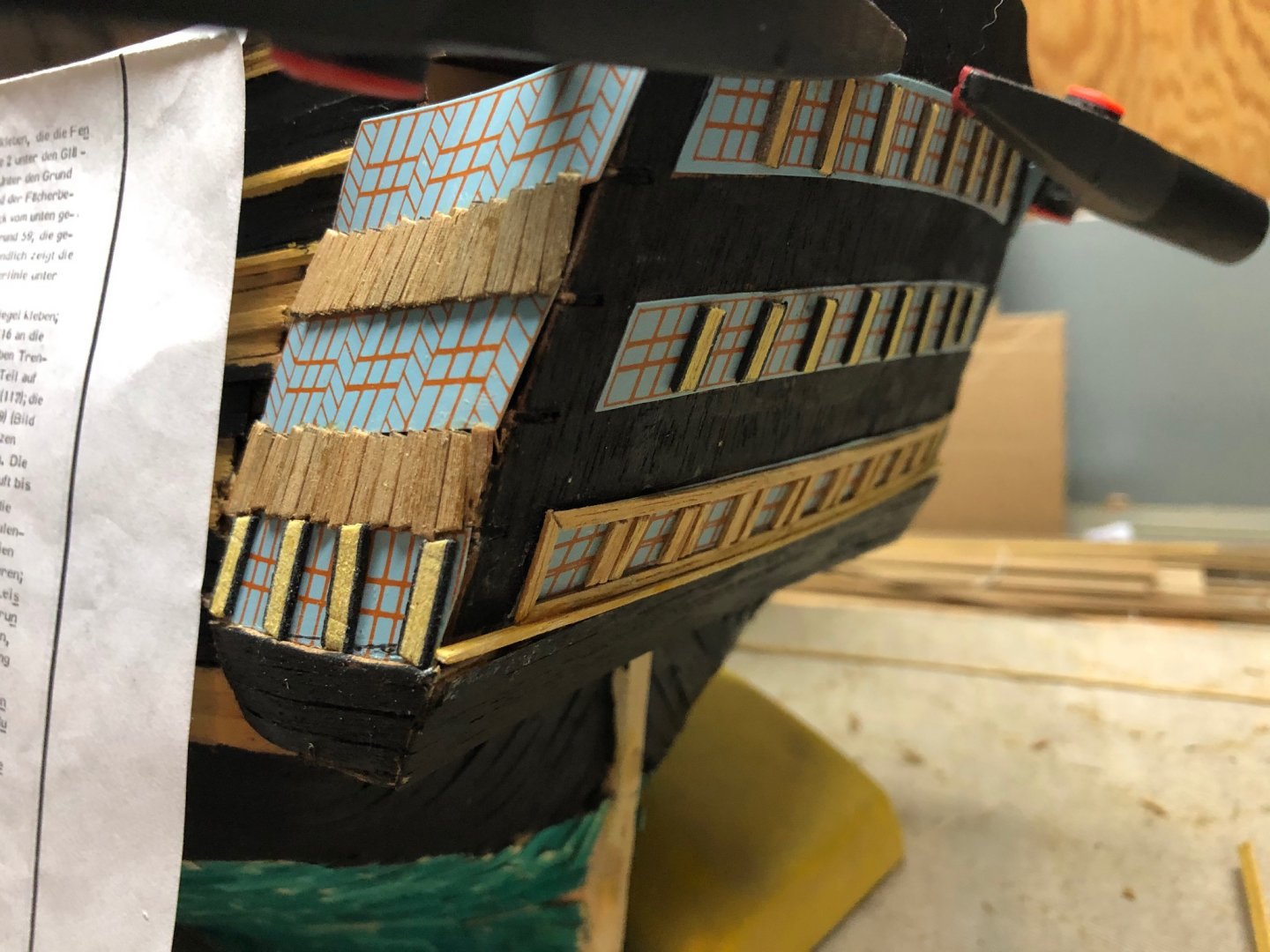

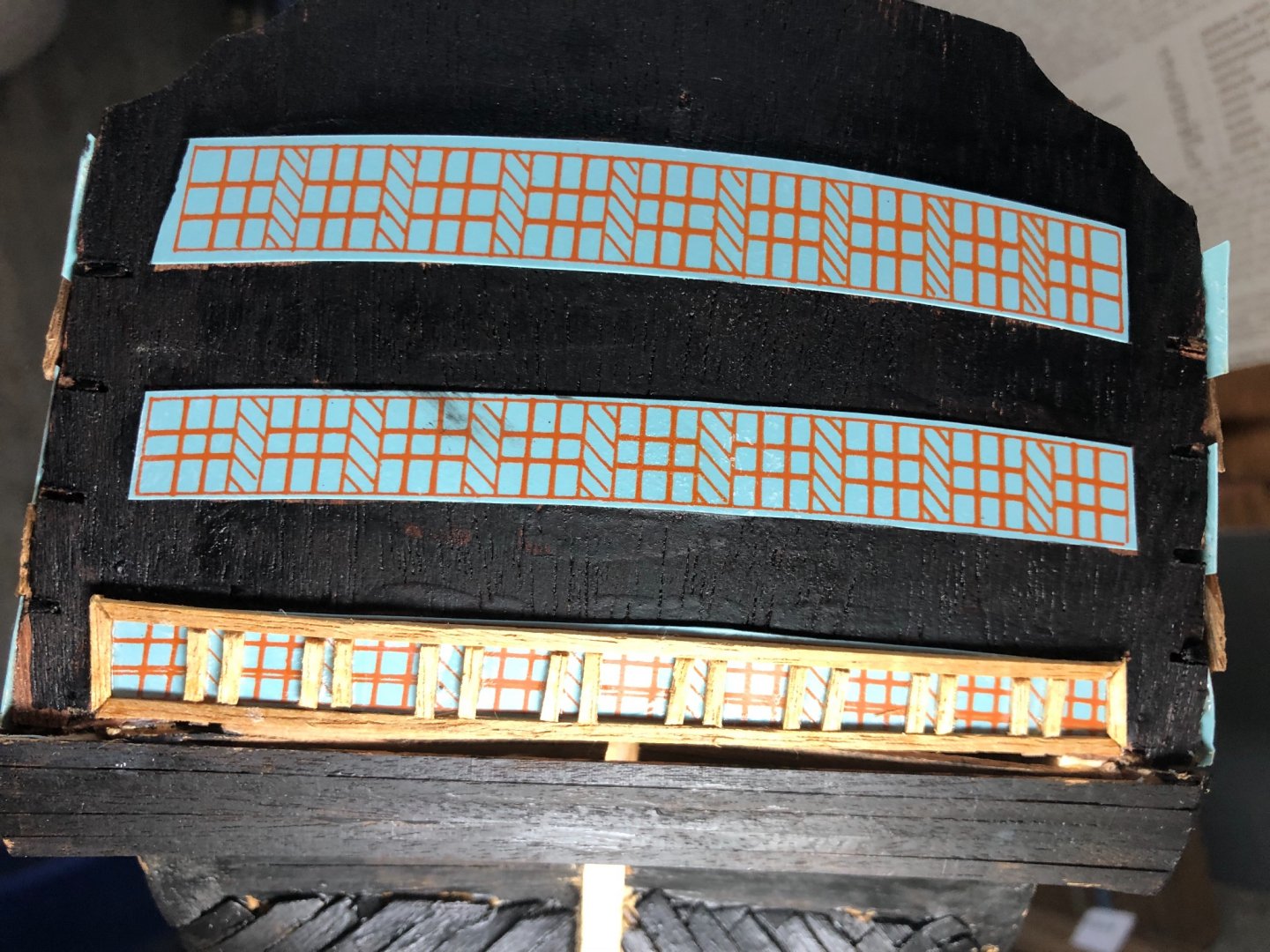

Transom framing coming along. After shaping molding to better align with the transom surface, I still find it difficult to hold the pieces in place while the glue sets. You can see my mish-mash of tools used to keep the piece in place. Sometimes successful, other times not. Had a slight mishap with wet black paint but was able to get most of it off. You can see the remnants on the port side of the transom.

- 395 replies

-

- 395 replies

-

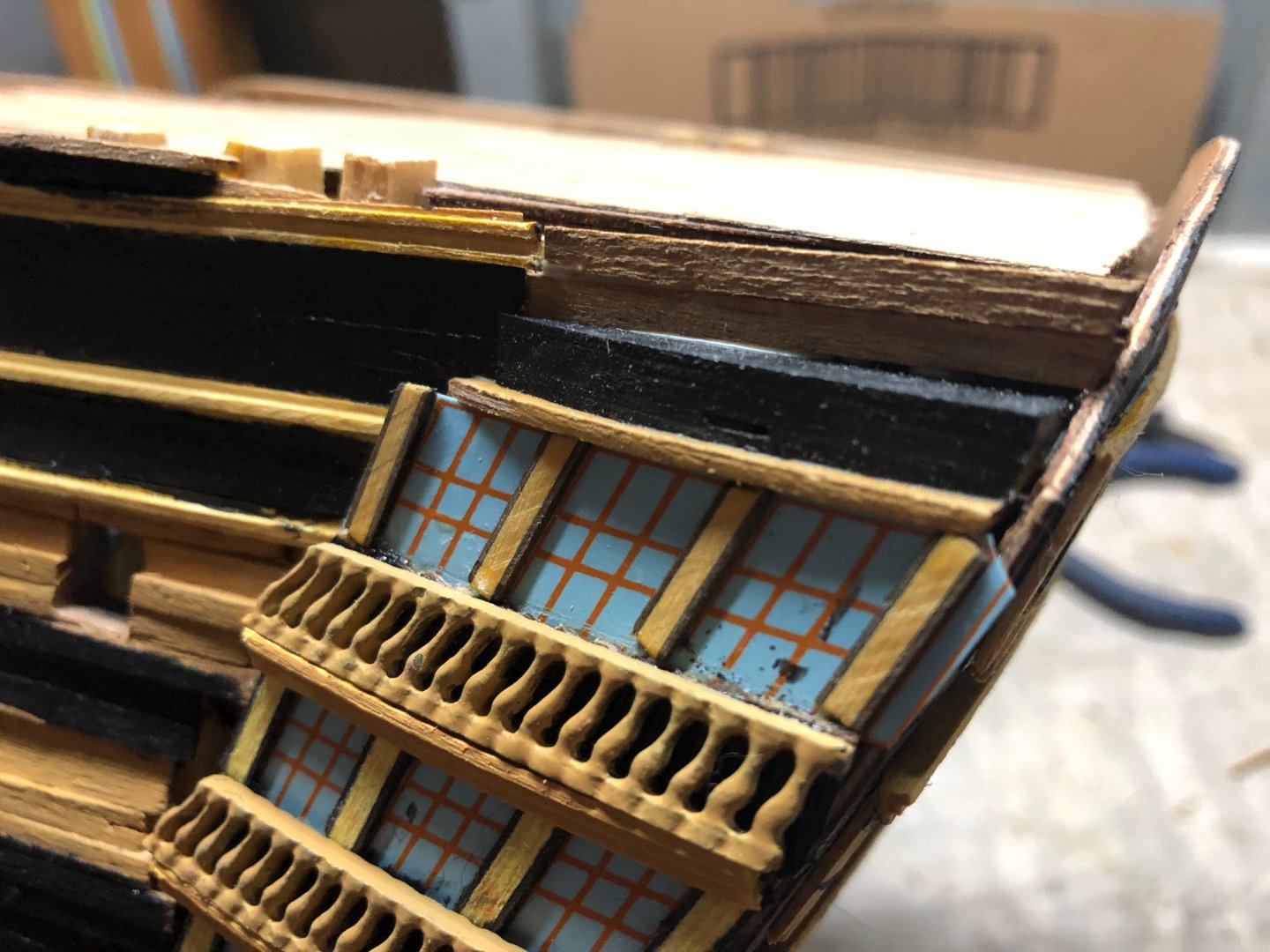

Continuing transom finishing. Still working to understand the directions, but glad I have some Victory source material to aid with what pieces go where. Also painting the metal railings yellow ochre. I’ve shaped a molding piece for later inclusion above the lower windows. The metal railings will go above the piece.

- 395 replies

-

Assembling the lower transom window framing with 1x2mm laths. I’ve decided the wider (2mm) side of the lath will be placed against the windows rather than the thinner (1mm) sides. This seems consistent with the instructions however the material then covers up some of the window markings. The same size lath is to be placed under the the bottom framing next before putting the inner planks between the windows.

- 395 replies

-

Just starting the transom finishing of the stern windows after a short break. The window material is a plastic base vs. the wood framing so I’m using a ‘super glue’ variant for the window/framing bond. I just wish the glue worked as well bonding the material as between my fingers and the wood!? There is a slight radius on the transom and to aid the bonding process, I actually soaked the wood and used my plank bender to set a slight ‘bend’ in the 1x2mm planks and then secured it in my plank bender apparatus while they dried to maintain the radius. That helped with the actual placing and bonding as it is easier to hold the frames in place while the glue sets when the planks align with the surface.

- 395 replies

-

Thanks for the kind words Bill! I don’t really know what happened with Y.T. All I know is one day he was here and then he wasn’t.

- 395 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.