-

Posts

5,961 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Not far to go now John - Christmas pressie to yourself??? She is starting to look liker a working boat now. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Not a good thing Mark - back to hand cutting for a while...or can HMS Visa find some room after Xmas spending? cheers Pat

-

They would be small at that scale OC; but to me the driver would be the quality of the kit part. If it holds definition and shows the correct detail, stay with it; otherwise... cheers Pat

-

Quite a bit of detail even in the funnels - this should make into one very nice model Greg. cheers Pat

-

Good to see this little lady again Rusty; I hope you are enjoying making sawdust again? cheers Pat

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Dave, I am sure you'll get the hang of it if you are used to AutoCAD. There are a few 'quirks' with the program I am still trying to get to grips with but I am coming from a "know nothing' background; your experience will help a lot. My biggest errors were not using 'blocks' so I have far too many entities, and using the wrong line tools ending up in far too many nodes. cheers Pat

-

That's a pretty good result Ulises. cheers Pat

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Nice work John, the blocks appear very nicely to scale. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

That looks really good Dave; I might have to have a look at that myself. let me know when you get to the Yawl and Gig, as I have to do those yet - a set of dxf files for those would be useful if you don't mind sharing? cheers Pat

-

My, you have been busy Greg. That is looking good; quite the complex ship but I suppose it had to be with all that armament. cheers Pat

-

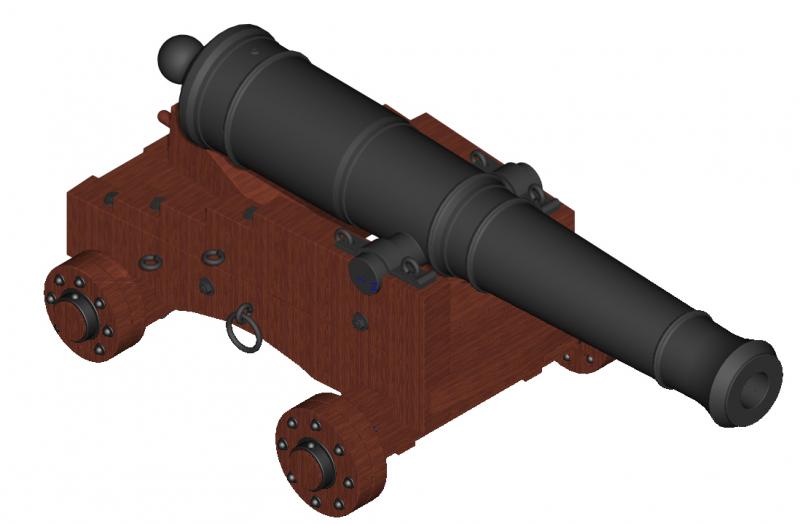

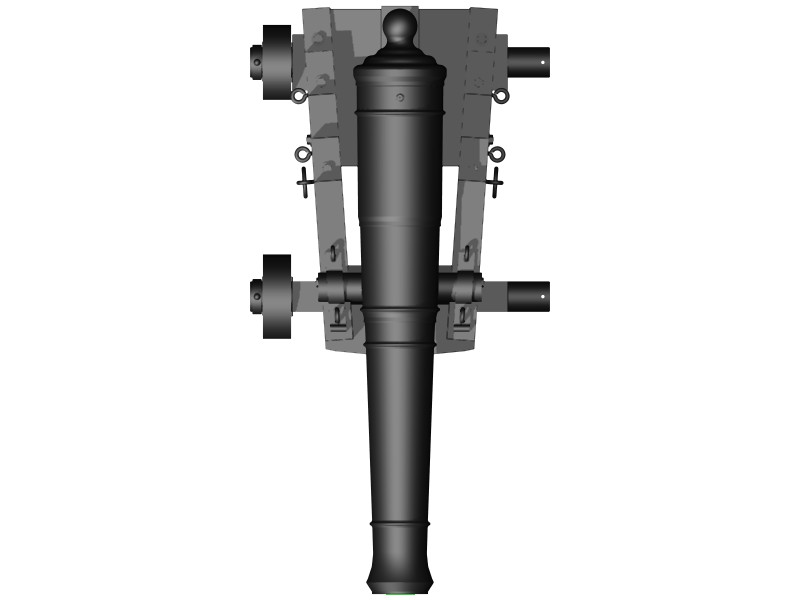

Hi folks, another update - Ron talked me into it I played around with some materials and the result is shown below - still a few minor errors to correct - but largely there. Next job - work out how to apply all of this to reflect the cannon and carriage design for the HMCSS Victoria. That part will not be so easy Mark - don't say I don't do as I am told - off to prepare for the hangover cheers Pat

-

Looks good OC, great work with the paintbrush to get such an even looking finish - I hope the missus didn't mind you 'borrowing' the hairdryer cheers Pat

-

Thanks for looking in Doc, Ron, Carl and Mark, and for the many likes. Ron, I will have a poke around the menus to see what I can do with materials. I am doing this following a Tutorial so I don't want to get too far ahead of myself. I am only a couple of hours (hangovers allowing) to starting that process but it can't do much harm 'exploring" - I hope cheers Pat

-

Well, a bit more practice and some progress with my TurboCAD 3D project. Here are a few basic renders of the progress I have made to date. Hopefully within a couple of weeks I'll be able to show a couple of advanced renders. Things will slow for the next few days as my younger boy is getting married this Saturday and I hope to send him on his honeymoon with a 'hangover' - I know, I'll be in trouble with the daughter-in-law cheers Pat

-

Many thanks Michael - off to the shed tomorrow cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Thanks again Michael; I missed this otherwise would not have cluttered you log as much This looks a very usable and ergonomic solution. cheers Pat

-

Hi Chris, the biggest 'must do' for me is power outlets - never have enough of them- plus one at the front of the bench to plug in those hand held tool so that the cords are more easily managed/kept away from the work piece. cheers Pat

-

Thanks Michael, that is very helpful. That would be very useful if you go ahead with a design using commonly available materials; I for one would value it. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

Michael, I think having two of those little beauties (third hands) is excessive; to save you the embarrassment I am happy to take the second one off your hands (all puns intended) Seriously though, they look great. I purchased a GRS third hand (soldering station) but yours, especially with the machine clamps look very usefull for rigging as well as many soldering set-ups. Would you mind posting a pdf of the mechanical set-up of the arm version (how you make it grip the bar yet remain adjustable etc)? I am not keen on grub or thumb screw option and I really like what you have done here. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.