-

Posts

5,951 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Great idea and good results. Thanks for sharing. cheers Pat

-

Nice technique with soldering that ring into place Michael. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

BANYAN replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Sorry there has not been an update for a little while, I am back at the PC drawing up the plans, and continuing the research. I am going to have to ensure a quality build noting the experience and abilities of the build followers cheers Pat- 1,013 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Wow what a comeback Glenn, I had been missing your updates. Those skylights are stunning. I will be making some for my Victoria project in the coming year and wish I had CNC. I have the mill but I don't think I would use CNC enough to get value-for-money; may need to investigate a little further noting the great results you achieve. You truly are the master of metal; those 'charley nobles' look great, and a neat construction technique. I am learning so much from following your build log; many thanks! cheers Pat

-

A Lorch Micro-Mill that never was ...

BANYAN replied to wefalck's topic in Modeling tools and Workshop Equipment

Now that you have almost completed your prototype, I'll send over my 'Lanco' for you to adapt Very nice work Wefalck; that will be a very useful mini-machine and a fine addition to your wonderful workshop. cheers Pat -

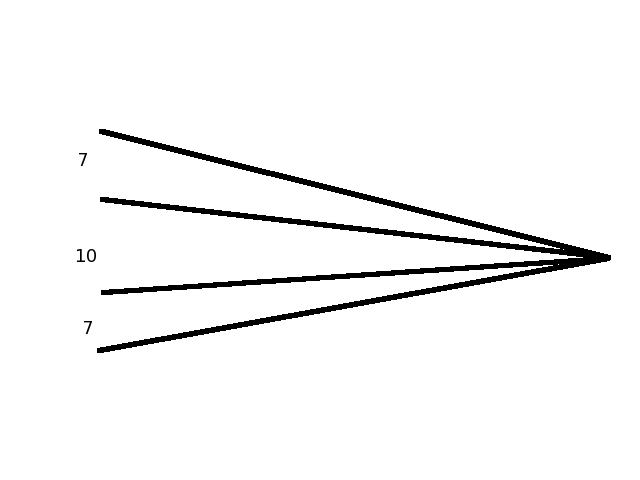

JT here is a rough copy of such a fan someone posted on this site I think (sorry cannot recall who). These are the proportions by which to reduce square stock to get an octagon (the 10 is the meat that remains). Simply place the square stock on the fan so that the edges of the stock meet the outer edges of the '7' fan lines, then mark the wood with the other lines. The lines should be ruled with a straight edge back towards the centre to reflect the angle of taper rquired. For some yards, not direct to the centre but to the point of transition from straight octagonal to taperered round. These then give you the guide lines to which you reduce the square stock with plane, chisel, file or.... Note: the square stock should be reduced to the appropriate thickness before starting, such that the width of the meat [10] ends up wide enough, that after rounding, is the correct diameter of the round - this takes a little calculation. Always better to err on 'bigger' so that you can reduce; harder to add Once you have the round, even in taper, it is relatively easy to maintain it with further sanding. cheers Pat

-

Adapting what we have in accordance with our skills is the key Dave - I see a very nice capstan cheers Pat

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Nice work Michael, those stays especially are looking very good. cheers Pat

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

CNC and Laser cutter in one - that seems an awfully useful machine Christi - great pick-up mate. I hope it lives up to its claims and you get good use out of it - it certainly looks promising. Does it require any specialised software? cheers Pat

-

Major milestone completed with the running rigging Dave, she is certainly looking great! cheers Pat

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Not far to go now John - Christmas pressie to yourself??? She is starting to look liker a working boat now. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Not a good thing Mark - back to hand cutting for a while...or can HMS Visa find some room after Xmas spending? cheers Pat

-

They would be small at that scale OC; but to me the driver would be the quality of the kit part. If it holds definition and shows the correct detail, stay with it; otherwise... cheers Pat

-

Quite a bit of detail even in the funnels - this should make into one very nice model Greg. cheers Pat

-

Good to see this little lady again Rusty; I hope you are enjoying making sawdust again? cheers Pat

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Dave, I am sure you'll get the hang of it if you are used to AutoCAD. There are a few 'quirks' with the program I am still trying to get to grips with but I am coming from a "know nothing' background; your experience will help a lot. My biggest errors were not using 'blocks' so I have far too many entities, and using the wrong line tools ending up in far too many nodes. cheers Pat

-

That's a pretty good result Ulises. cheers Pat

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.