-

Posts

5,938 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by BANYAN

-

Stunning Denis; those standoff shots in particular make the model looks so life-like (colour and atmosphere). Nice work mate, that detail really pops; especially like the little things like the brass handrails etc. cheers Pat

-

Nice work again on those 25s Greg; that ship sure had some close range fire power. 28 of this miniscule things; not just cross-eyed but a bit of a headache also I'd guess? cheers Pat

-

Poochiie, have a look in the sites database of articles for a good article on this subject and many others that can assist you. http://modelshipworldforum.com/ship-model-materials-and-tools.php cheers Pat

-

Nice work Dave and thanks for the pointer to Tom's work, but to find it please? cheers Pat

- 742 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

Very nice job on the 20mm cannon / guns Greg, even if only a 6 of them, that is very well detailed and came up a treat. cheers Pat

-

Your promised a nice addition, and probably a surprise or two left, and you haven't disappointed Looking really good mate. cheers Pat

-

Cruizer-class Brig-Sloops of the Royal Navy

BANYAN replied to molasses's topic in Nautical/Naval History

Some great reading here, thanks BW and all contributors. cheers Pat -

Nice progress Ulises, those pin racks look good (and solid ) cheers Pat

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

That is a great bit of detailing Greg, looks really good and I like the idea you have for hanging a float plane from it. cheers Pat

-

Found your log this morning cog; sorry to be late to the show. Looks like another very highly detailed model in the making here. Those turret enhancements look great Make room in the front row for me too please cheers Pat

-

I agree with Gunther; whatever you thinks looks best in situ. cheers Pat

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

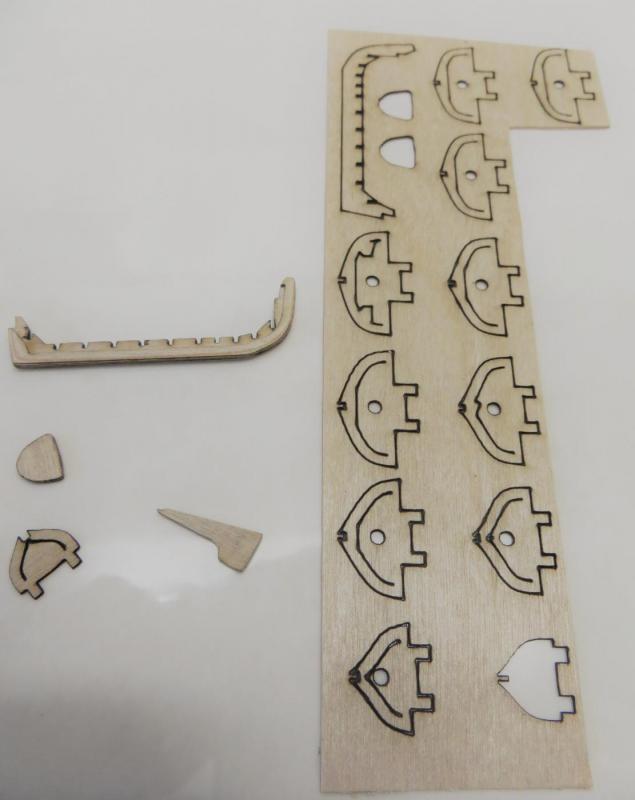

A small update, the frames/temp bulkheads have now been fitted in a basic jig. The longitudinal temp stiffener has yet to be glued and will be done after I straighten a couple of the frames. The eagle eyed will note a couple of frames not quite aligned; some of this is due to camera angle. Gluing in the longitudinal stiffener will help keep them in place vertically, but first I need to fix/redo at least one of the frames. This system works quite well and was well laid out by Dave when he did the artwork as I did not need to do much filing for fit at all. The holes in the temp bulkhead (which will be broken away later) were for a toothpick to pass through to assist with alignment, but at this scale almost impossible to utilise and too fiddly. Sorry all, I forgot the ruler again but this is only about 80mm long (just over 3") overall. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Persistence pays off Denis, those nets will look great on the model..... and a couple of spares to boot cheers Pat

-

Hi and a very Happy New Year Rusty, nice progress. The links work but on PC at least, the thumbnails are not showing? cheers Pat

- 310 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wow!!!!!! that is going to be one very nicely detailed model if this is any indication Wefalck. cheers Pat

-

Another beautiful model John; she looks great. Particularly nice to see another model that is not mainstream and preserves the history of these vessels. cheers Pat

- 745 replies

-

- francis pritt

- mission ship

-

(and 1 more)

Tagged with:

-

Much easier Greg Denis, the idea/concept was developed by Chuck who does this with his small boat series; Dave has just adapted it a little to serve his needs (and the lucky soul has access to a laser cutter) Thanks for all who looked in and gave a 'like" cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Hi again folks; hope you all had a happy and safe festive season. I have made a start on the two remaining boats to complete my build; the yawl and the skiff. I am doing these part-time between the yard chores and HMCSS Victoria. First, I would like to thanks DaveRow who has kindly designed the laser templates and cut the boat templates for his build but provided me with a spare set; many thanks Dave. These are great, and make assembly a lot easier. The template is 0.6mm thick so the keel is a lamination of 4 layers which creates a natural rabbet. The rudder and transom piece are 2 x lamination but the remainder of the pieces will be single. I don't think I would have achieved this level of detail without the template. i will stage a ruler in my next set of shots to give a better idea of scale. cheers Pat

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Great to see you back Remco and to see that lovely model of yours again. cheers Pat

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Nice to see you back at this model Wefalck; look forward to seeing her evolve. cheers Pat

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.