-

Posts

3,173 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Did Aubrey talk about the tiller and accompanying rigging that would have complemented a wheel? Your earlier drawings would put the tiller and cabling somewhere in the great cabin...

- 346 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well, Tom says he wants to build according to the book, so I suspect Sophie will have a wheel..😀

- 346 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Definitely Historic Ship Models by Wolfram Zu Monfeld.. Considering they are free, any number of the instruction books available at ModelExpo would be my 2nd choice.. Particularly the one's by Chuck Passaro.. They are like tutorials that would apply to any number of ships besides the kit they are written for. A good example is the US Brig Syren Look down the page for the 20 part instructions. You will find similar if not as detailed, instructions for all Model Shipways kits.. They are not just instructions for the kit in question, they provide a lot of basic kit building and rigging information.

-

Very nice look of the rudder! You may have it finished by the time you read this, but have you considered faking the Pintles and Gudgeons? The method is to pin the rudder to the stern post, then use card or tape to simulate the straps.. One of my pins is not as well hidden as it should be.. Do you see it?

-

202mm x 64mm = 12,928 = 508.97638 inches = 42.4 feet, which sounds realistic for a beam of 30 feet..

- 346 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

What was the reason given for his dissatisfaction?

- 346 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

1:98 HMS Victory plans

Gregory replied to Rgpracer's topic in Building, Framing, Planking and plating a ships hull and deck

For future reference, if you know the measurements for the full size ship, you can divide that by the same dimension of the model and get an approximation.. Or Divide the full size dimension by the scale and see what you get. A length I see for Victory is 186 feet on the gun deck.. Divide by 98 and you get 1.897 feet or about 22.7 inches. So if your victory model is close to 23 inches on the gun deck, I would consider it close to 1:98.. Close enough that it is unlikely to be another common scale, such as 1:72 or -

2mm Sounds a bit thick for the amount of bend in that area. You might try thinning it down to at most 1.5 mm. Try soaking the strip before bending it in place, then let it dry before gluing.. Also note that it may tend to split more depending on the direction of the bend. Start your bend, and if it looks like it wants to split, try bending in the other direction.

-

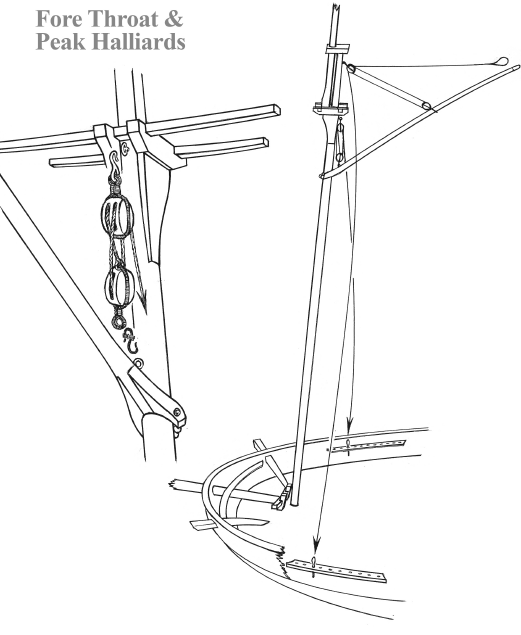

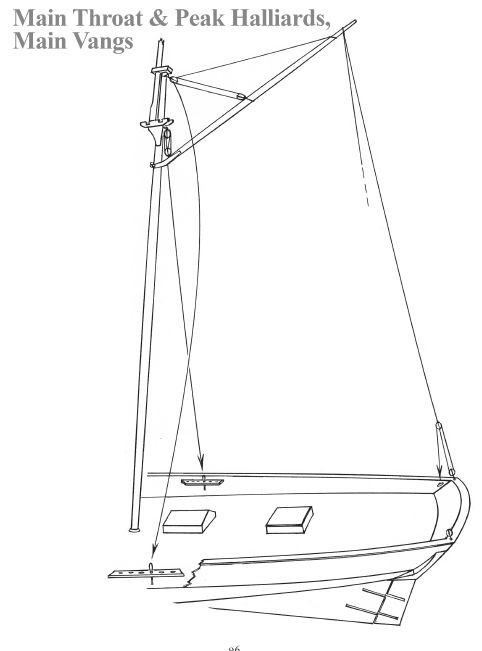

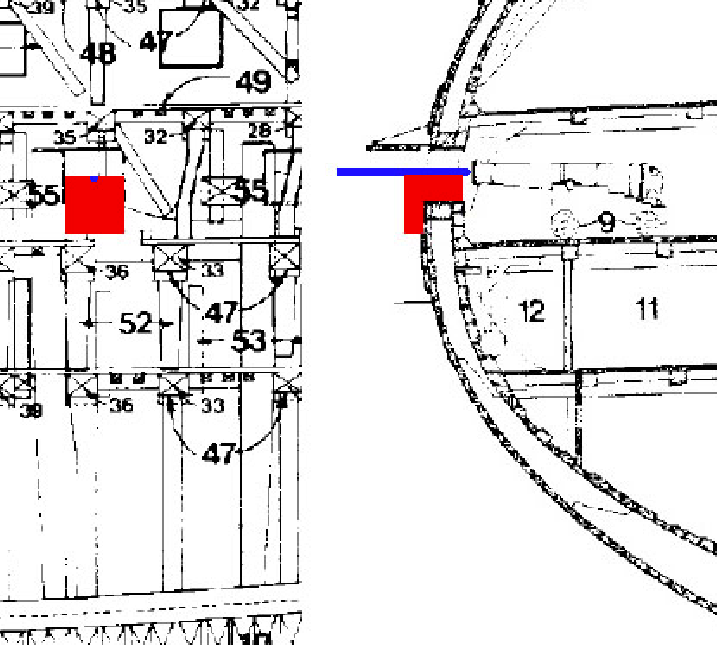

Has anyone referred you to Petersson's Rigging Period Fore and Aft Craft? One has to keep in mind that the author simply documented what he observed on a contemporary model. While the information appears to be accurate in many respects, some problems have been pointed out, here and there. Here are his diagrams of the the throat and peak halyard rigging for " .. a typical American schooner." Along with all the other information you have been provided, this should be of some help..

- 164 replies

-

- Model Shipways

- Finished

-

(and 1 more)

Tagged with:

-

Yes, they are Bob Smith..

-

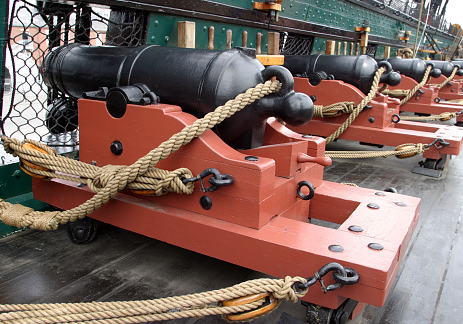

I don't think the quoin would have been used to raise and lower the gun, rather it was moved into position after the fact.. I would go with what looks good..

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Accurate copper plating

Gregory replied to allanyed's topic in Building, Framing, Planking and plating a ships hull and deck

You did a great job with what the kit provided.. What is the actual size of those plates? -

Accurate copper plating

Gregory replied to allanyed's topic in Building, Framing, Planking and plating a ships hull and deck

I see coppering as a personal preference as to how you want the model to appear.. How many people outside of our community are going to look at a coppered model and say " Oh, those copper plates are too thick and out of scale.. " ? -

Accurate copper plating

Gregory replied to allanyed's topic in Building, Framing, Planking and plating a ships hull and deck

I wasn't suggesting the overlap was not used, in fact, it would seem to be essential, similar to the principals in laying shingles.. I was just questioning the usefulness/ appearance or lack thereof, when modeling.. -

Accurate copper plating

Gregory replied to allanyed's topic in Building, Framing, Planking and plating a ships hull and deck

How relevant is the thickness if you don't overlap? The overlap is not apparent in the images of the Cutty Sark and Constitution presented earlier.. Plus, there are various thicknesses available. I saw one that was .025mm. It doesn't appear to be listed in the specs, but if you ask, you will get a good answer from the seller/manufacturer.. -

Accurate copper plating

Gregory replied to allanyed's topic in Building, Framing, Planking and plating a ships hull and deck

Copper foil tape is available in 1/4 - 1.5 inch diameters. Those who are so inclined, can adjust the size.. -

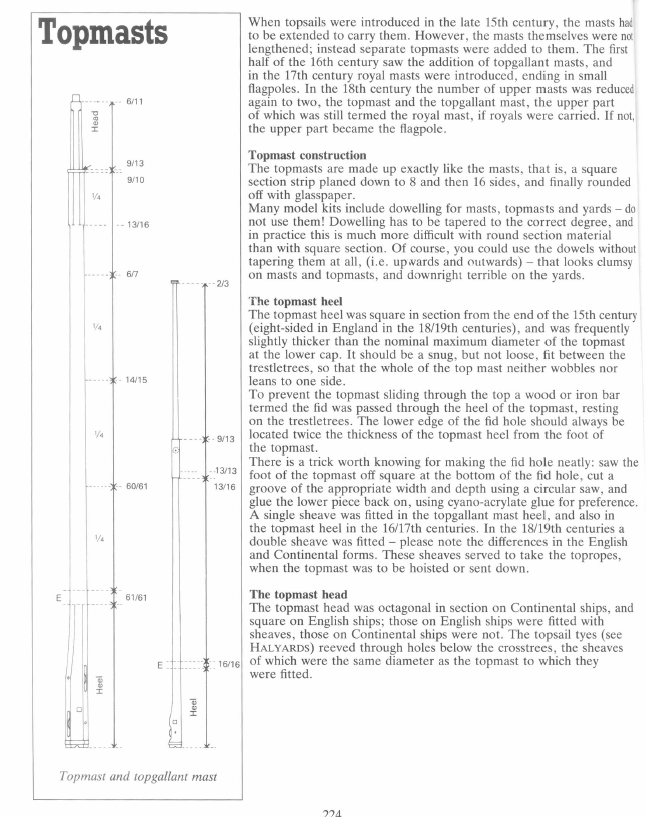

Topmasts and Topgallant masts vs Lower Mast

Gregory replied to Tommy Vercetti's topic in Masting, rigging and sails

Historic Ship Model by Mondfeld has a lot of general information .. Can be a good place to start. Here is an example .. Topmasts and topgallants were for the most part made from single timbers and not built up like lower masts.. -

You might find this to be of some help:

-

A critique of the works of Nicolaes Witsen

Gregory replied to Philemon1948's topic in Nautical/Naval History

No money in it.. -

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.