-

Posts

3,135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Might be because water and water based products have a tendency to raise the grain of the wood.. Also something to think about when painting, if the wood hasn't been sealed..

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Focus Stacking

Gregory replied to Dennis P Finegan's topic in Photographing your work. How to do this.

After reading your post, I took a closer look at a Panasonic FZ80 I had my sights on for a camera upgrade. Turns out it has 'focus stacking' and calls it 'post focus'.. It has two different modes that I haven't fully explored, plus I have a lot to learn about optimizing all the features on this camera, but for now, I'm pretty much going with the automatic basic settings.. Anyway, here is my first experiment in ' focus stacking .. This is a shot using the auto-focus feature of the camera.. I think the 2nd gun from the front was what the camera focused on. Here is a shot using the " post focus " feature. Rick mentioned it takes a ' short movie'. One second of 30 frames to be exact, where it shifts the focus from front to back, then merges them into one image. Processing only takes a few seconds. I have a lot to learn about using the camera, but this feature shows some promise for taking better pictures of model ships. -

Cured CA is plastic, so it could get brittle under the same conditions any plastic would. Sunlight would probably be the biggest influence.. Next up, would be extreme temperature.

-

These come from Amazon. Happened more than once when I was refining the process.. I used a thin grinding disk to rough up the inside edges. I use high RPM and move the piece slowly.. I realize there is more at risk when using limited kit parts, but I make my own carriages, so it's no big deal to make a new one if I break one.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Harold Hahn method

Gregory replied to Essayons's topic in Building, Framing, Planking and plating a ships hull and deck

There is some comprehensive information about Hahn and his models here: Harold Hahn - The man and his models -

Has your wood darkened, or is that just the lighting.. It really looks good..

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Impressive! The look like they are carved..

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Do you think these would lend themselves to some lamination like you did with the hair brackets?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I can't wait to see how Chuck tackles the head rails. I'm sure it will be something to carry forward with any future build.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I've used sanding sticks to round off square axles but I came up with something that works better for me. I use a brass collet in a rotary tool. Smooth and perfectly round.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

While I don't foresee tackling the Winnie, I hope you keep coming with the 10s.. They are a great resource to enhance any kit or scratch build.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

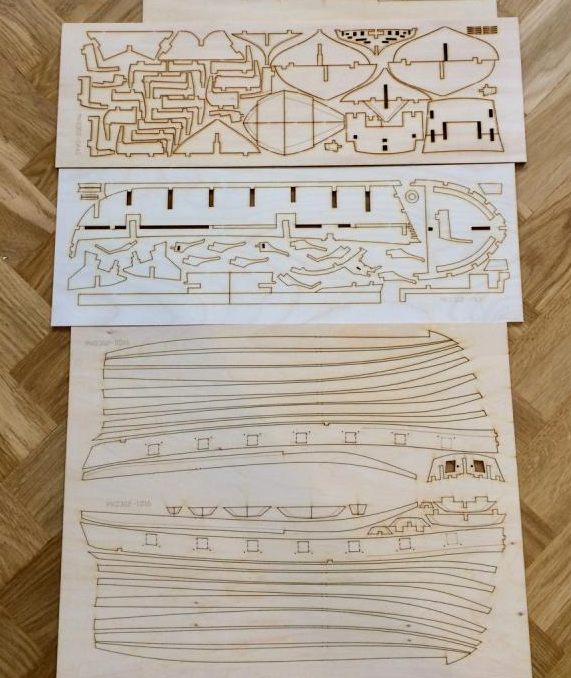

With some time to spare, you might hold out for the New kit from Amati..

-

Don't forget the Medway Longboat There are several Master Korabel kits with pre-cut planks.. Another nice one is the Schooner Polotsk seen in this log:

-

Planking Question

Gregory replied to Malazan's topic in Building, Framing, Planking and plating a ships hull and deck

This works, but can be a challenge to look nice and clean.. Not that this shouldn't always be your goal. Having a rabbet at least at the stem, gives you a little wiggle room for shaping the ends of the planks and having a nice clean look and fit. -

Planking Question

Gregory replied to Malazan's topic in Building, Framing, Planking and plating a ships hull and deck

The Rabbet ( rebate ) is a groove that the planks fit into at the Stem and along the keel. Here is Glbarlow's Cheerful.. The ends of the planks butt into the rabbet at the stem. The garboard plank sits in the rabbet along the keel. In modeling it can be simulated in a couple of different ways .. It isn't always necessary to cut it.. In this topic, I showed an example of how a thin strip down the center of the keel and stem simulates the rabbet when separate keel and stem pieces are added to the backbone in a plank-on-bulkhead model.. There are probably hundreds if not thousands of examples in the build logs.. Just search for " rabbet " ..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.