-

Posts

3,135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

If the masking tape sounds like too much work, you can use a tape measure flat on the hull and measure the distance at the waterline between stem and stern, then measure the distance from waterline to keel amidships, you would have a nice rectangular area that would include some extra room for waste factor.

-

Kieth may have more to say, but it depends on the rope in question. Lines like lifts, used to hoist the yards would have more slack when the yards were hoisted. Braces would have more or less slack deepening on the tack at the time & etc.. Rather than striving for modeling actual practice in this regard (who's checking ) just go for some nice looking coils that represents several feet of rope.. Here is one of my favorite examples.. From Glenn Barlow's Cheerful.. He provides some technique in his log.

-

Good to hear MS has brought that kit back; I didn't realize they did.. I'm tempted myself. Looking at the instruction, it appears to be a pretty good kit, that offers the opportunity for personal embellishment if you want improve on the fittings. Can't beat the ModelExpo guarantee for replacing parts for whatever reason.. I think it would be hard to find a better kit.

-

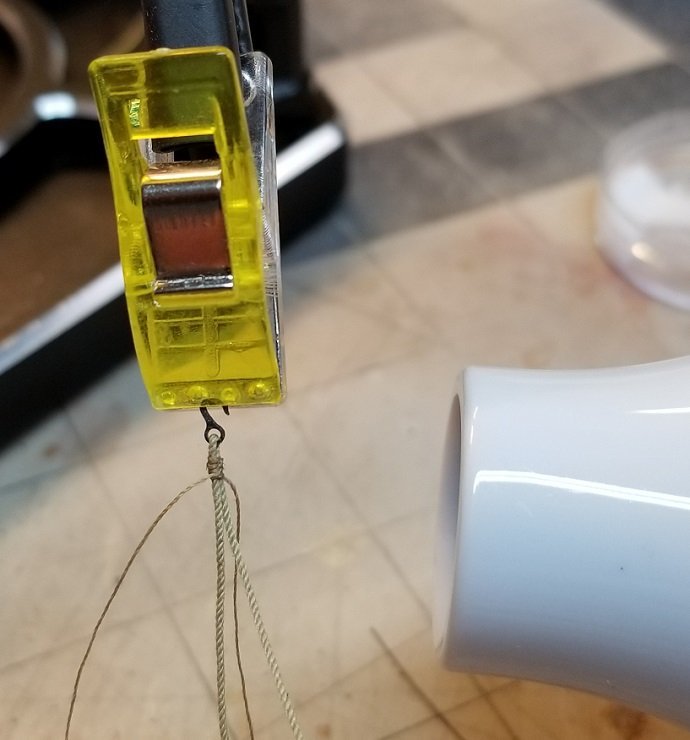

Anyone else use a mini heat gun? Mini Heat Gun - 300 Watt I got tired of waiting on the glue to dry on my rigging knots, siezings & etc. So I thought I would try this out.. Not too long, and not too close on the low setting, and my thinned white glue dries in seconds..

-

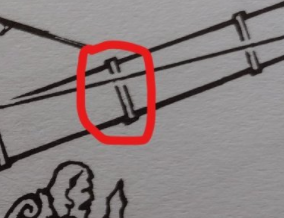

Are you referring to this in your drawing as bindings. Those are not typical for any bowsprit I have ever seen.. There are bindings on the masts, but you might save those for another topic. The bowsprit will have numerous other features, such as bobstays, shrouds and foot ropes. Here is a log with some bowsprit details. If your kit does not have the rigging details you would like to include in your build, you would do well to find a good reference on the rigging of a 74.. You may have to combine several sources. The basics would have been the same for any number of ships over many years.. The Petersson book is pretty good, but it is just the documentation of a model, and may be lacking in any number of areas. A good source, but somewhat pricey, might be The 74-Gun Ship Bellona (Anatomy of the Ship) ..

-

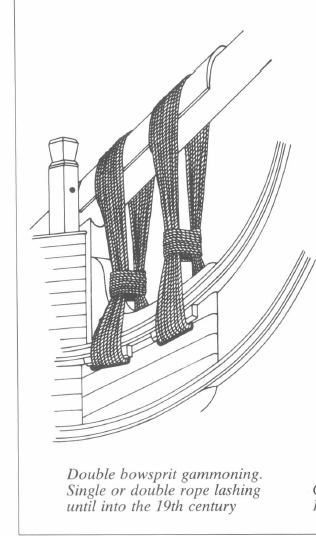

Here is the gammoning from Mondfeld: There is a lot of rigging on the bowsprit, so you may have to find some other references. I will try to dig up some more

-

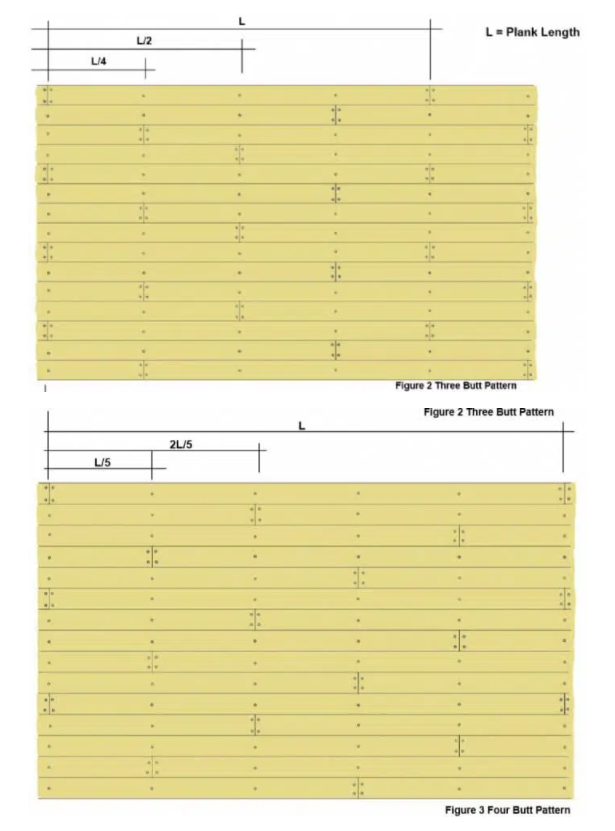

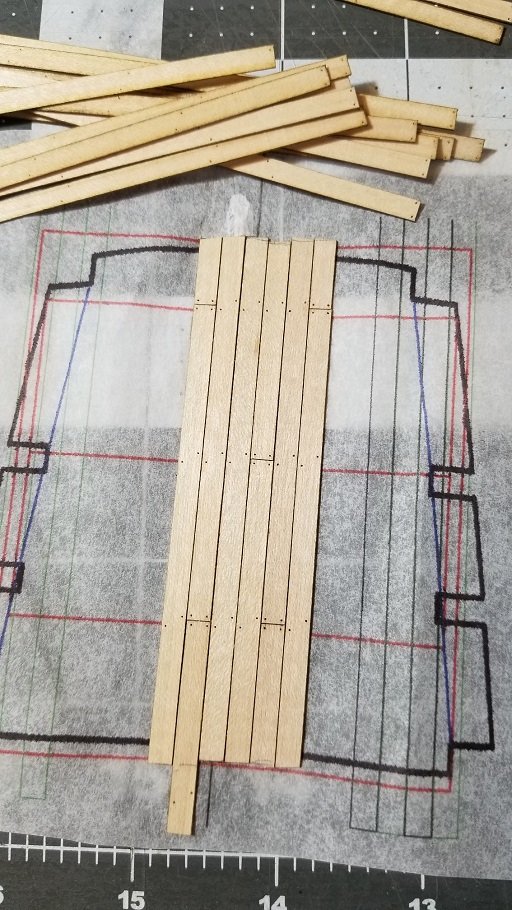

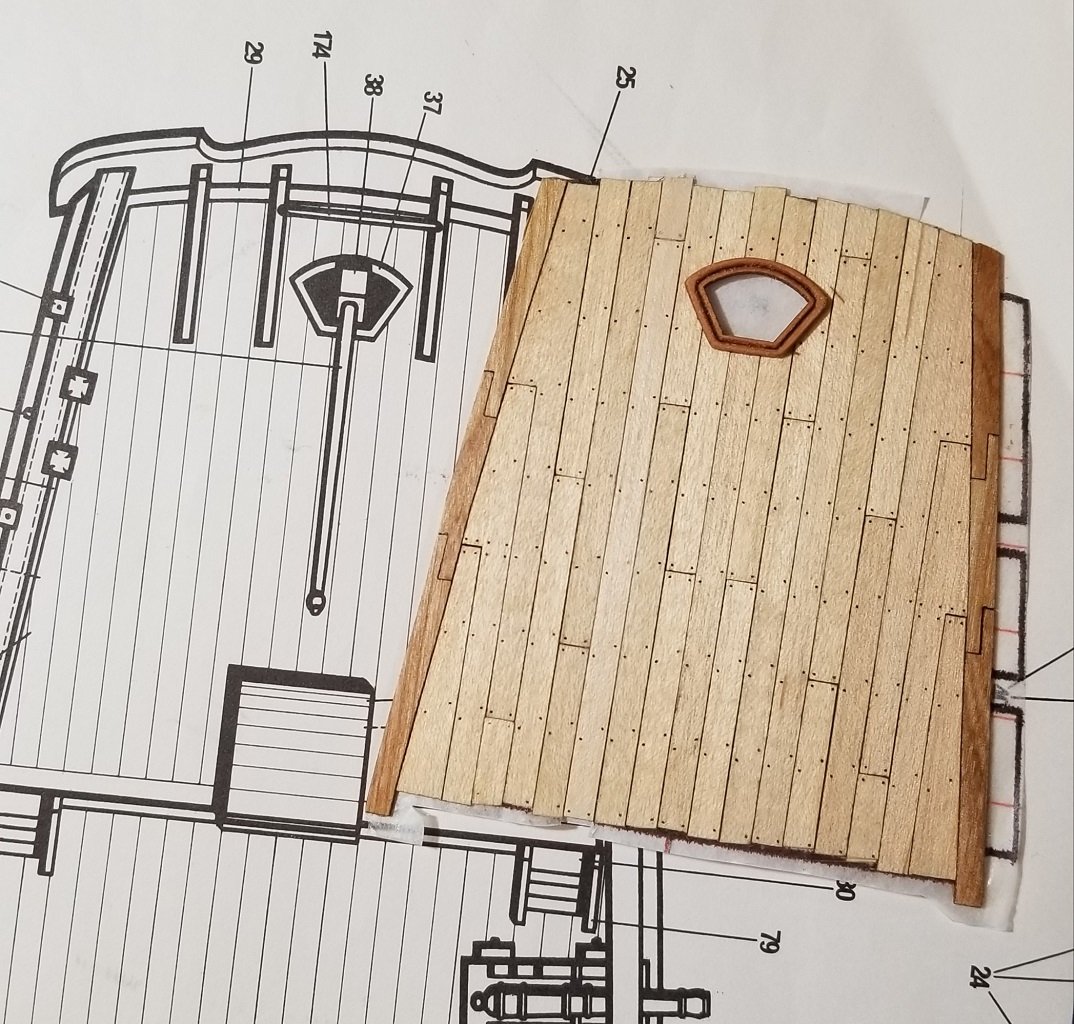

Here are a couple of patterns from How To Do Deck Planking On Wooden Model Ships A pretty good guide. There are other options for a tree nail pattern. Keep in mind that visible tree nails at this scale are a modeling convention rather than something that would be visible at scale. Use a look that you find acceptable based on other models you have looked at..

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

That looks really close.. Margin planks and waterway should provide zero clearance in the end..

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Paper is just a very thin layer of wood..😁

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Something you might consider in the future, and it might not be too late now, I do my deck planking on thin paper off the ship.. If the margin planks don't fit perfectly along the bulwarks, small gaps ca be covered with the waterway..

- 100 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

Harold Hahn method

Gregory replied to Essayons's topic in Building, Framing, Planking and plating a ships hull and deck

Here is a search for models with key words " Navy Board " Most of them are pre 1700. Centurion 1732 shows up.. -

This might have some useful information: Spanish Galleon 1530–1690 Reasonably priced.. It is doubtful step by step instructions exist. These plans of Golden Hind might be useful.. Golden Hind Plans Here are some plans at a Czech site .. Rigging for Golden Hind

-

Harold Hahn method

Gregory replied to Essayons's topic in Building, Framing, Planking and plating a ships hull and deck

Just to add another twist to " Admiralty " ( Navy Board ) style. I recall seeing a number of these at the NMM: The text in part: I don't recall ever seeing a build here, where the spaces between frames were painted onto a solid hull. -

Thanks for taking the time to show your work on laying out the belts... Very informative and instructional.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The quantity shown here is really overkill, but I was referring to the little Dremel sanding drums.. Sanding Kit As for holding the square stock, I rounded off the axles after the carriages were assembled, but there would be more than one way to approach it. You might hold it firmly in some padded pliers or clamp. I just carefully pushed the tool onto the axle. There is the possibility of twisting the axle off, which I did a couple of times, so practicing is in order to get a feel for how it works.

-

I've shared this method when it has come up before.. I use a brass collet with the desired opening in a small rotary tool. It's great for getting small round stock from square. Let me know if you want more detail. For the half circle, you might try making a template, tracing with a pencil and using small sanding drum with a rotary tool.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.