-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by allanyed

-

-

Hi Snedley

4mm equates to 14 inches which seems to be much too large to be realistic on every deck. While not Spanish, but based on scantlings from the Shipbuilder's Repository 1788 a first rate of 110 guns had pillars in the hold for the gun deck that were 9.5 inches X 9.5inches, less than 3mm at your scale and they get smaller as you go up. For the pillars under the middle deck they were 7.75 inches across at the top and 8.75 inches at the bottom. For those under the upper deck, they were 7" at the top and 8" at the bottom so about 2.5mm. If yours are typical the largest pillars will be square or close to square for about 10 inches at the top and 12-14 inches at the bottom then round in between. They may be a bit fancier on some decks which means using a lathe. If the simpler design was used, get square stock of the appropriate sizes and you can easily carve the cylindrical portion with a simple carving knife or chisel and sand paper. The center portion was often more of an octagonal shape rather than round so very easy to make your own with a carving knife or file. Note that the pillars were a bit larger by 1800 but only the beams in the hold were close to 14 inches (4mm). The others were much smaller in cross section.

Allan

- druxey, scrubbyj427 and mtaylor

-

3

3

-

15 hours ago, scrubbyj427 said:

I do have the Bristol Drawings but I’m curious to what hi res Portland drawings you have? I have Portland framing plan ZAZ1719 and Portland inboard profile ZAZ1720, these the ones you are referring to?

Those are the ones I have in high res from the Wiki Commons site.

Allan

- bruce d, scrubbyj427 and mtaylor

-

3

3

-

Hi Tim,

My gun has about a one inch opening with 6 settings for the temperature and to date I have had no problems. The highest setting will scorch the wood so I stay just below that point. I prefer to pre-form the pieces off the hull by spiling or hot edge bending when possible but have had times at the stern where I find it easier to form it on the hull and heat/dry it while it is temporarily clamped in place and have not had any issues. Even then, once it is apparently dry I remove it for some hours or more to be sure it is completely dry before gluing it as it will contract if it is at all wet and leave unsightly gaps. This may only be me, but I have never found speed to be a consideration as I assume a fully framed hull will approach 1000 hours and POB several hundred hours to get things right. If speed was a criterion for me I would not consider ship modeling as a good choice of hobbies, but that is just me. Everyone has their own priorities, so go with what makes you happy which is one of reasons we have hobbies. 😀

Allan

-

3 hours ago, AON said:

I don't think the canvas back in the day was painted.

Good point Alan. I was taught that it was painted/coated but do not recall where I got that information. I checked in Goodwin's Construction and Fitting of English Ships of War and he states that the canvas was coated with tar, not paint, to make it waterproof. Unfortunately he does not give a reference and I cannot find any other reference regarding this cover so even though he is a single source, it may be valid. I do notice that on contemporary models the cover is very dark compared to canvas.

Allan

-

-

I have a few high res plans for Bristol and Portland, if anyone is interested, PM me.

Bristol 1778 Body plan and inboard profile with frieze and stern painting, and Orlop and Gundeck. The frieze work is a rarity.

Portland 1770 Framing plan and Inboard profile. If anyone has the body plan in high res I would love to see it as I would like to compare it to Bristol.

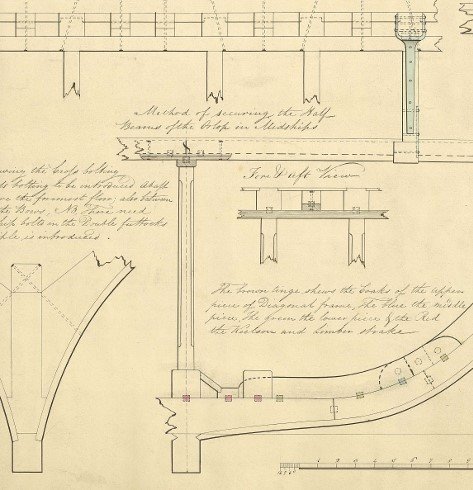

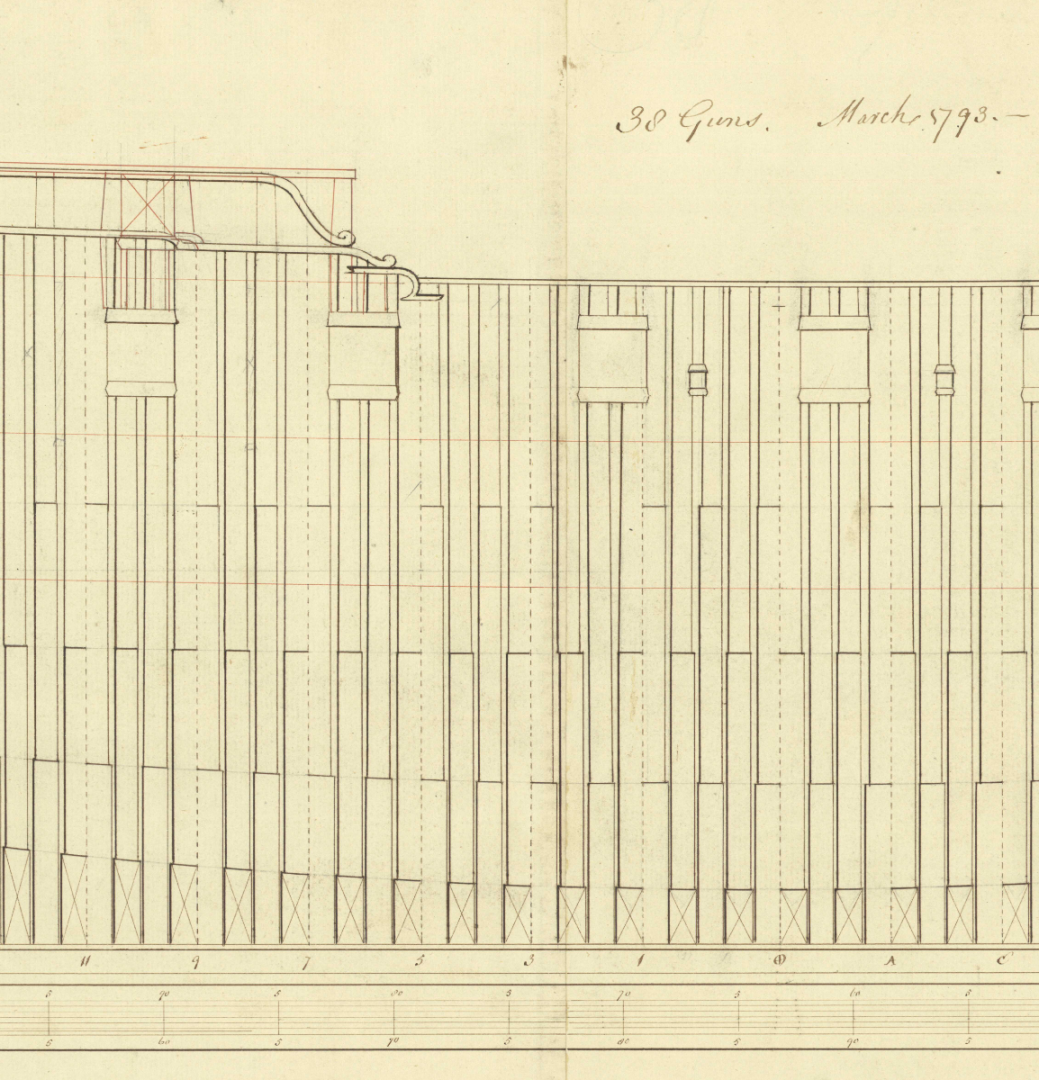

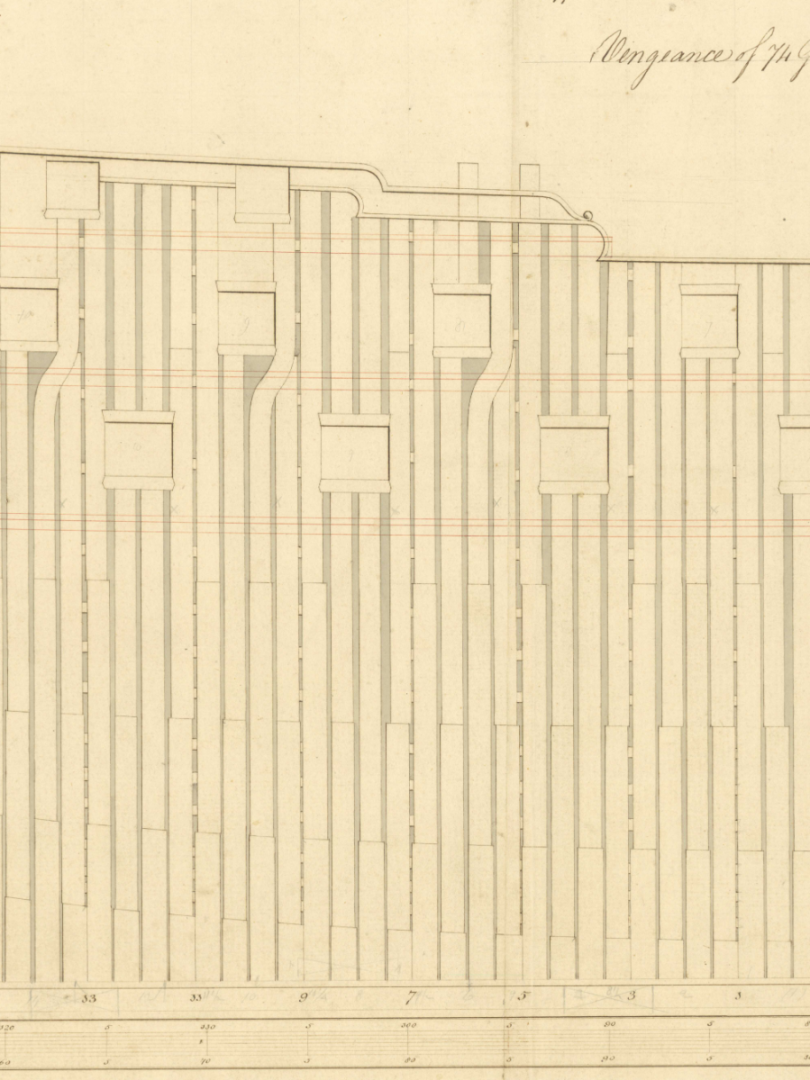

8 hours ago, AnobiumPunctatum said:In my opinion the framing design changed in 1775 - 1776.

Hi Christian,

You may very well be correct and this got me curious so I went hunting. I found only a few framing distribution drawings on RMG Collections prior to 1775, and these were close to that year, the earliest 1769. Included are the Royal Oak (74) 1769, Orpheus (32) and Diamond (32) 1774, and Intrepid (64) 1770. They are low res so hard to see, but it appears to be the same as those of later years, albeit with canting at the upper deck gun ports in some cases.

For years after 1775 one of the things I found that I thought curious is that every other set of floors/first futtocks touch on the plans for Ardent (64) 1782 but on the plans for the Director (64) 1784, no floors/first futtocks pair touch. Draftsmen, designer, actual practice?

Possibly of further interest, this is from a contract for a 74 in 1781, possibly of the Arrogant class. ....... and that the first futtocks be bolted to the respective floors of every bend with three bolts of 1 ¾ diameter It does not state one way or the other if there were spacers for air between them though.

Allan

- AnobiumPunctatum and mtaylor

-

2

2

-

2 minutes ago, Thukydides said:

he doesn't often explicitly address cutters

Very true, and frustrating 😀 Your priority list is well founded. Contemporary based rigging information is sorely lacking compared to timber which makes the rigging that much more difficult to research and execute, but harder for anyone to say what we have done is wrong unless grossly misrepresented.

Allan

- dunnock, Glen McGuire and Thukydides

-

3

3

-

1 hour ago, Thukydides said:

steele table for the rope

Steel is a good source and another of course is James Lees Masting and Rigging which is more detailed and covers from 1625-1860 as there were many changes over the years. Many consider it the most complete single book on masting and rigging for English ships.

Allan

- AON, Glen McGuire, Thukydides and 1 other

-

4

4

-

5 hours ago, oakheart said:

Onto planking the Port side now

Did you find any twisting issues by planking only one side first? I have always planked a strake or two on one side then the same on the opposite for fear of twisting the hull by planking on side completely before planking the other side.

Thanks

Allan

-

Thukydides

I realize this is being really picky for some and no reflection on your work, which is awesome, but why do the plans show cable laid rope for the stays on the drawing in post #365, but then shroud laid in the drawing in post #367? Cable laid was the more common for the stays while shroud laid rope was the more common, but not always the case, for the shrouds. Again, nothing to do with the quality of your build which is exceptional.

Allan

- Thukydides and Glen McGuire

-

2

2

-

14 hours ago, Admiral Beez said:

Question, should my canvas reach up the mast, like on HMS Victory below?

I am not sure it really matters as it could have been done that way. In general I would not use the modern Victory for examples without looking at contemporary evidence to confirm. Below is what is more common on contemporary models. This pic happens to be of a model at Preble Hall.

Allan

- mtaylor, bruce d and Admiral Beez

-

2

2

-

1

1

-

Welcome to MSW from another Floridian

Allan

- Keith Black, mtaylor and SiriusVoyager

-

3

3

-

Welcome to MSW Brent. It would be polite if you would post an introduction with a little about you in the new member forum.

Regarding Steel, I am aware of The Elements and Practice of Naval Architecture which has a list of scantlings for all the timbers of ship sizes circa 1805, and his Elements and Practice of Rigging but am curious about this Timbers for a 100 Gun Ship as I have not heard about this one.

Allan

- mtaylor and hollowneck

-

2

2

-

There were wooden wedges between the mast and the partners. These were then often covered with canvas so you can just add a painted ring before you set the masts. Below is a sketch of a wedge ring that is actually just the ring and without the wedges going down and through the partners. They can be glued on top of the partners (or planking) as is. In reality the planking ends at the partners but this does not look possible on your model. The second picture is from Goodwin's The Construction and Fitting of English Ships of War.

Allan

-

McMaster Carr for lots of stuff from high quality drill bits to copper and brass sheets and rods. https://www.mcmaster.com/

Allan

- EdT, mtaylor and Michel Bénard

-

2

2

-

1

1

-

Two valid points IMHO, but as the admins have what is sometimes a thankless job, like herding cats, adding to their load may not be such a good idea. When it is my time I will post my library if I can. If not, is there any rule that says my admiral or sons cannot post here if they log in on my member ID with what is going on and what is up for sale? I looked but cannot find any rule to the contrary.

Allan

- thibaultron, JGR, scrubbyj427 and 3 others

-

6

6

-

The lines of every piece are so precise it almost looks like a cad drawing. The care and attention to detail are clearly evident.

Allan

- mtaylor, Stuntflyer, FrankWouts and 1 other

-

4

4

-

-

16 hours ago, Chuck Seiler said:

along with internal stringers.

Hi Chuck,

There were fore and aft longitudinals, or stringers, at the floor heads or at the first futtock heads below the water line outboard well below the wales. But internally I do not recall seeing these. Sorry if I am being obtuse or perhaps it is just nomenclature but I am only familiar with the spirketting, quickwork, sealing and clamps. The below is the Euryalus, 36 and might be helpful if it is terminology thing.

Regarding the knees both the hanging knees and lodging knees fay to the deck beams and internal planking. Other than appropriate bolts that go through the hull planking, the you're correct that the knees themselves are not associated with the wales.

The channel knees help support the channel chains and the main wale is to prevent hogging. -

-

Sizzolo,

The sail looks like a white ensign. Was a flag woven or painted on sails on the actual British ships? Guess they could not fly a false flag to fool the enemy with the sail giving them away. 😁 Either way it is a first for me

-

11 hours ago, newbee said:

Everything I tried resulted in at least one or more frames being behind where I thought the gunports should sit.

On the actual ships there were usually one and more often two frames that were in line with a gun port so there is nothing wrong with a frame crossing a port. The frames were cut and ledges put in place then the linings/stops on the bottom ledge and sides of the frames forming the fore and aft sides of the port.

Allan

- robdurant and Bill Morrison

-

2

2

-

6 hours ago, Keith_W said:

It provides additional protection to the side of the ship

Hi Keith,

This is an interesting point, but as there were main wales down low, middle wales on large rates and channel wales above, from what were they offering protection?

Allan

-

4 hours ago, Gregory said:

The sheer of the ship appears to be defined defined differently than what might be considered the sheer of any particular deck.

I agree but I wonder how the sheer of the ship was actually determined. I imagine one reason the deck sheer was to be flat enough to avoid cannon tipping over if the sheer was too great and sea conditions were at their worst. I just starting looking at Steel in how the sheer line was actually determined. LOTS to read, and will hopefully not fall asleep in the middle of it.

Allan

HM Cutter Speedy 1828 by oakheart - from plans drawn by Bill Shoulders in 1972

in - Build logs for subjects built 1801 - 1850

Posted

Tim,

Self discipline is about all I can think of. If things are not going right for me, it's usually because I am rushing and in the end it takes less time to do it right one time than to do it more than once because it was a mess up the first go around.

Allan