-

Posts

1,649 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SJSoane

-

Thanks, everyone, this is beginning to converge on what seems to make the most sense. I will assume the Bellona scantlings were at the thinner end of these ranges, since everything seemed to grow larger towards the end of the eighteenth century. The scantlings for 80 gun ships in the 1719 and 1750 Establishments most closely match many other sizes for the Bellona 74 that I have been able to verify from other sources, so I will assume the 6 ½" for the thickness of the black strake as set forth in the Establishments and further stated by the Ship's Repository a few decades later. Looking at the fully planked Bellona model, this was of a constant thickness, although it does seem to have a rounded upper surface as seen at the gunport. And the later sources and the Bellona model appear to call for a 1'-0" width (plus ½" in some sources), close enough for me at 3/16" scale. In most of the primary sources that call for a second plank above this, they specify a plank 1" thinner than the wale, or 5 ½" in this case, wearing off to the 4" planks above. But this does not appear to be the case in the Bellona model itself. The difference in thickness between the black strake shown in the model, and the planking directly above it, looks to be more like 2" --since the planking above is 4", this exact difference would be 2 ½". And so there appears to be no special second plank above the single black strake with its rounded top, just the normal 4" planking. Given this, I am inclined to follow druxey's lead here, and use a single strake, not painted, 6 ½" X 1'-0", with a rounded top. So why would the Bellona model use only one black strake, as called for in the Establishments that finished in 1750, and not two strakes, as called for in all of the sources and all of the contracts for individual ships a few decades later? I will assume that the experimental Bellona design in 1758, the first 74 in the British navy, drew upon the last Establishment revision of 1750 for most or all of its scantlings. As best I can tell, the old 80 gun ship in the Establishment was about the same overall size of the new 74; so why not use the well-tested scantlings for a ship of that size? The creative energy would have gone into changes in deck and gun layouts to convert from an 80 to a 74 of the same size, not changing the fundamental fabric of the structure. And of course the later 74s following in the footsteps of the Bellona grew increasingly larger; and so a few decades later, their scantlings would have likewise grown. Interesting that an additional transitional strake above the black strake creeps in over the next few decades. I have no idea for explaining this evolution! Druxey, did you round the top of your black strake, like in the Bellona model? Mark

-

As I wait for planks to dry after steaming, I started looking at the black strake again. Since the Bellona was a transitional ship designed in 1758, between the earlier Establishments (finishing in 1750) and the later consolidations reflected in Steel (1805) and the Repository (1788), the scantlings are not easily confirmed. Here are the data points on either side of the Bellona's time: Only establishment shown in Allan Yedlinsky's book is for 1719 for an 80 gun ship--because the Bellona was the first 74-- (blank for 1745 and 1750 because presumably the same): "One strake above [the wales] 6 ½" thick." (and no width specified). Steel: 2 strakes, one 7" X 1'-1 ½", the other 6" X 1'-0". Repository: 2 strakes, one 6 ½" X 1'-0", the other 5 ¼" X 1'-0". Brian Lavery's book on the Bellona calls for 2 strakes, 6 ¾" reduced to 5 ½", but this has no reference to a primary source. My own photo of the Bellona first model does not seem to show a black strake (at the stern, the wale is showing 5 strakes rather than the specified 4, so the partial upper one must be the black strake but it is the same thickness of the rest of the wale; not helpful). Very compelling is the photo of the second Bellona model, shown on Lavery's Ships of the Line cover (see photo below). It appears to show only one strake thinner than the wale but thicker than the planking above, and compared to the width of the wale (4'-3"), this black strake appears to be about 1'-0", the width of individual strakes called out in Steel and the Repository. And then there is the very good discussion on Gary Shipwright's build log with Gary and druxey (page 14 in the link below), which suggests that there is an additional strake above this one, that tapers from the black strake to the planking above. Assuming the lower strake is 6 ½" thick and not tapered, and the planking above is 4" plank, then the second black strake would be 5 ½" tapering to 4". At 3/16" scale this will be very subtle! Mark

-

Mark Who would ever guess that those cannon would take so many parts? It looks so simple when it is all done; only the builder knows for sure! Looks good. Mark

-

I further recommend the Tamiya tape. Used that a lot building plastic models with my son years ago, and it has transferred nicely to wood projects. Mark

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Hi everyone, Thank you, everyone, for the helpful suggestions. It turns out that it was spiled accurately but it had the opposite of spring-back from the steaming and bending; it was bent a trifle too much, so the middle was sitting about a 1/16" away from the hull in the longitudinal direction while the ends were touching the hull. Finger pressure was enough to get it in place. So after trying a number of failed clamping ideas, I went with Greg's suggestion to use spots of cyano in between the carpenter's glue. After experimenting with a few spare pieces, I just went for it. It took rather longer than 90 seconds to grab, and I was able to get some vertical clamps in. And all held well. Nice to have that behind me, and I learned a new good trick. I also took off the batten, because my clamps are too short to span the entire wale plus the batten. Without the batten, you can begin to see the true lines, as in the second photo. Mark

-

After more careful fitting of the lowest, foremost plank, it bows in the center, keeping the two ends tight against the hull if I can just pull the center tight to the hull by about 1/16". I am contemplating a Spanish windlass, using a cord I managed to thread under the gundeck to a point on the port side opposite the line of force needed. If I smoked, I would smoke a pipe now while contemplating whether this would distort my hull or put creases in the hull where the cord is pulling tight. Since I don't smoke, I will try gently tightening to see whether things start creaking or not. Mark

-

Hi Russ, I just had a chance to catch up on your project. It is looking very nice! Mark

- 420 replies

-

- captain roy

- lugger

-

(and 2 more)

Tagged with:

-

Thanks, everyone, these are very helpful suggestions. In hindsight, I now know it would have been better to build the wales before building the gun deck. I was just very curious about what the gun deck would look like all those many years ago! Greg, did you alternate cyanoacrylate with carpenter's glue, within each inch of your gluing process? Is there any problem if they interact or mix together? Best wishes, Mark

-

Hi Paul, Do you have a source for those, or a brand name? They look handy. A challenge I have with the lowest, foremost plank is that the gun deck is higher inside than the wale; so the inner side of the clamp cannot be aligned opposite the outer side of the clamp on the wale. It has to be made asymmetrical. But maybe there is a way to extend one of the arms. Best wishes, Mark

-

Greg, I think I now know the answer to your earlier question. The piece I just fitted is the longest plank in the wale, and it wraps so far around the bow that pulling it up tight towards its aft end tended to pull everything into place. The next lower piece, which I am showing in the first photo before beginning to fair it, is much shorter. And the vertical clamps pull it away from the hull, just as you asked about. I will need to clamp it in the fore and aft direction. And because my frames run only athwartships, I have no easy way to clamp fore and aft, or perpendicular to the wale on the diagonal to the hull. My first thought is to construct a device, shown in the second drawing, that would slip a piece of plywood between the frames, and then use this to bolt a former that would tighten up against the wale. But it will need cut-outs, so I can still get the vertical clamps in place. Looks like a long uphill project at this point in the day. Might look better tomorrow. Mark

-

Hi Greg, Interesting you ask that. The upper planks definitely needed some clamping pressure onto the hull, not just up to the batten. But this one fit really well, and the clamping to the upper strakes seemed enough to hold it against the hull. I had to put the horizontal clamp at that particular place because it was bowing out just a bit. When I first offered the plank up to the hull, it looked like the spiling had given it too much fore and aft bend, and I had to push the two ends up when I started fine tuning the joint. But after a while it just began to fit into place without much clamping pressure anywhere. I had left this plank in the former after steaming for a couple of days, because I had gone out of town and just left it for when I got back. It had less spring-back than usual, which is perhaps why it fit a little better. I dread the thought that I have to leave pieces in the former for a few days. I will leave the equivalent port plank in the former for just a day, and see if this was an issue or not. It just goes to show that no matter how much I try to perfect a process, it always throws a new twist, both good and bad! Mark

-

Thank you, Greg, druxey and montañes. Not boring comments to me, greatly appreciated! I forgot to point out the challenge of clamping at the round of the bow. I had to cut angled blocks as seen in the previous photos, to match the angle of the wale at the clamping point. But the angle means it tries to slide off when tightened. I tried tying it back with string, as seen in the photo (gave me practice tying a bowline knot), but this was insufficient. In the end, a strong C-clamp right next to it was enough to keep it in place. Mark

-

Hi Siggi, Your planking is beginning to show the lovely lines of the Tiger. And very nice mouldings! Mark

-

Away for a few days, to the annual Charlie Russell art auction in Great Falls, Montana. Some of the best Western traditional art in the US. I can't afford to buy any, just look and admire... I am continuing with the wales. I fitted the foremost, lower two strakes before bending, using artist's transfer paper squeezed between the two pieces. This notes high points which are then lightly filed down, and the two are tested again. With patience, one can sneak up on a very tight joint. The second photo shows dry clamping for fit after the bending, and a closeup in the third photo. Interestingly, the plank was carefully spiled, but it still needed a fair amount of adjustment using the artist's transfer paper. I think it has to do with the constantly changing angle of the upper surface, since most of the high points were on the inner edge. Glue tomorrow! Mark

-

Thanks, Ed, I knew there would have been some extensive testing involved in this decision. This makes perfect sense.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Dear Siggi, I have wondered about planking before the upper decks are installed. Would it help to install some temporary ties along the deck levels, like the ones you already installed at the stern? Mark

-

Ed, I forgot to ask about a previous post. You are using wipe on poly for the spars and masts, not your usual turps and wax as on the hull. Is there a construction reason for this? Mark

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

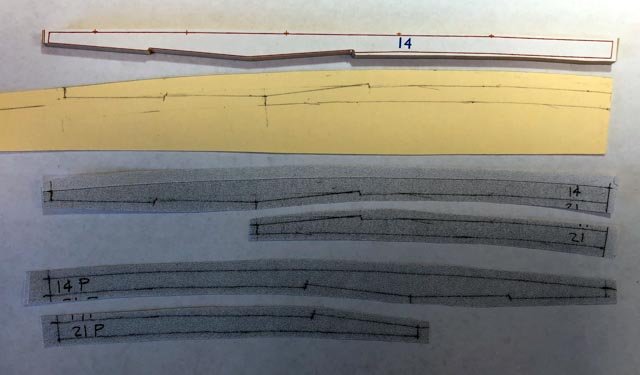

Thanks, everyone, for your support. I was taken away from the shop for a few days, to rig up a hoist for kayaks--real rigging. I am starting on the lower two strakes of the wales. I originally cut the foremost planks at the round of the bow according to my CAD drawing. But when I spiled to the strakes already installed, I discovered that the upper curve was much more dramatic than my original piece. The photo below shows the original piece at the top, and the card with the spiled edge below, showing the difference in curvature. In hindsight, I realize that I assumed the wales would be dead straight vertical, since they are so at midships; not so at the bow or stern! I made xerox copies of the spiled card for port and starboard. A couple of more pieces for the mistake box. I had spent a great of time on the first two strakes sanding and filing the edges of the planks. I did this freehand with shaped sanding blocks. The challenge was to keep the edge square, or tapered slightly where needed to tighten up the joint. It was a little hit and miss. So I am trying a little jig shown below, which clamps into my jeweler's vise block. The two hold downs secure the plank, and then I can run the sanding block against the edge, keeping it exactly perpendicular. When I need to angle the edge, I will slip a thin spacer under one edge of the plank to change its angle to the table. Mark

-

Very nice joinery on the stem, Mike.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

A couple of further thoughts on chisels, I do use small chisels, for example, in the hundreds of mortises in the gun deck framing below. The dockyard chisel shown works very well. Also, I use a strop with green compound, and strop my chisels large and small every few cuts. It helps maintain the sharpened edge, and I can really feel the difference when the chisel is freshly stropped. Sharp makes all the difference in the world when cutting miniature joinery! Mark

-

I concur with druxey's recommendation on Veritas. Equivalent quality at Lie-Nielsen, which is what I now use. The virtue of a good chisel is that it can be sharpened well, and then keep its edge. My experience with too many cheap chisels that I have bought over the years is that they don't sharpen well or hold their edges for very long. I wish I had bought good chisels the first time; the number of cheap chisels I ended up throwing away could have paid for the good ones to last the rest of my life. Also, when I started on my ship model at 3/16" scale, I thought that I would mainly need small chisels, like the Dockyard sets. I use these, and they are good. But I have found that the vast majority of my chisel work uses standard sizes, mostly ¾" and ½". This is because the larger chisel has a wide face that you can more easily align to a cutting line. Too narrow a chisel, and you can't see if it is parallel to your intended cut. Also, a good polish on a wide chisel allows you to use it as mirror to ensure that the chisel is being held absolutely vertical to a cut. The great books by David Antscherl on the Fully Framed Model, and Ed Tosti's books on his projects, give very good advice on how to cut miniature joinery with large chisels. I have tried no end of sharpening techniques, and have personally settled on waterstones with a Veritas Mark II guide. I never could make an oilstone work, but each to his or her own preferences. Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.