-

Posts

1,557 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mike Y

-

Some finish would be nice - will show that bookmatched cherry grain and protect from fingerprints. It is a tool that supposed to be touched Was thinking about cork, but all the cork sheets I saw were out of scale for those tiny clamps. It really feels like making a scale model of a real thing.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

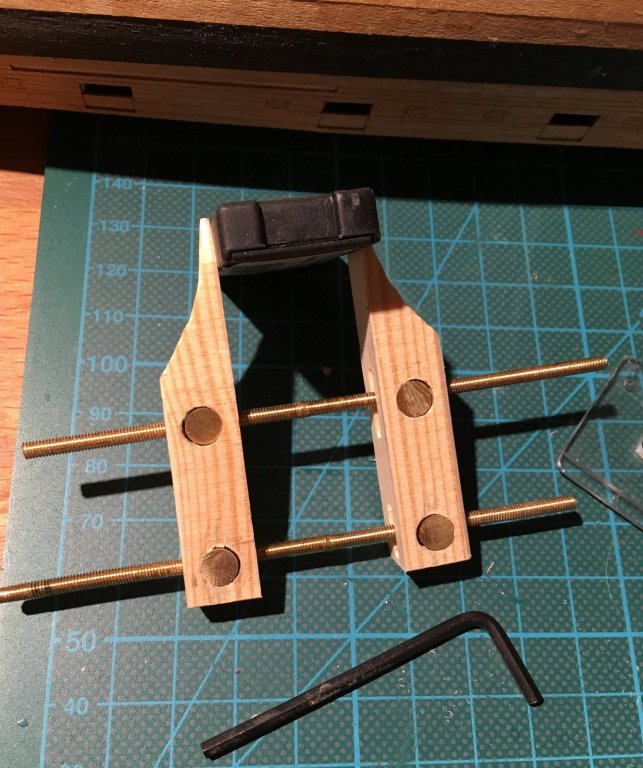

Thanks for the compliments! Clamps got their butts rounded and slots cut: So now it's juts a matter of sanding, assembly, breaking the edges, more sanding and applying some finish. Some oil would be great, but I do not want it on a basswood contact surface (they will act like a sponge and, when pressured, release oil into the model parts). So it would be probably some kind of less penetrating finish. I have three bottles of various sanding sealers to play with!

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

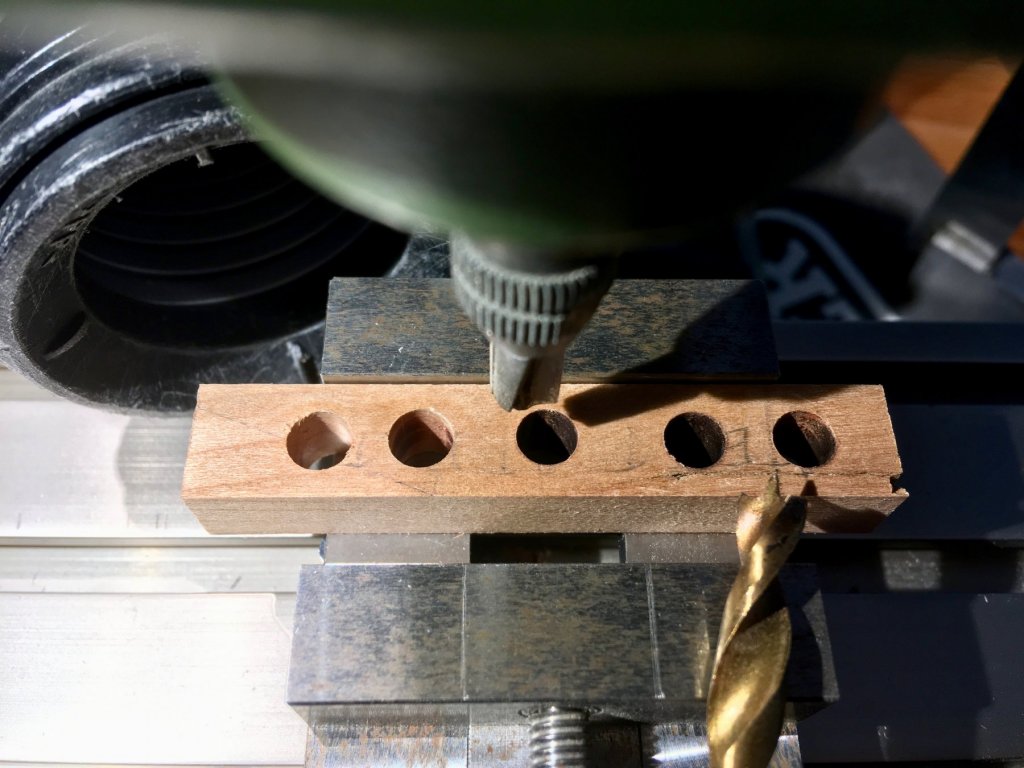

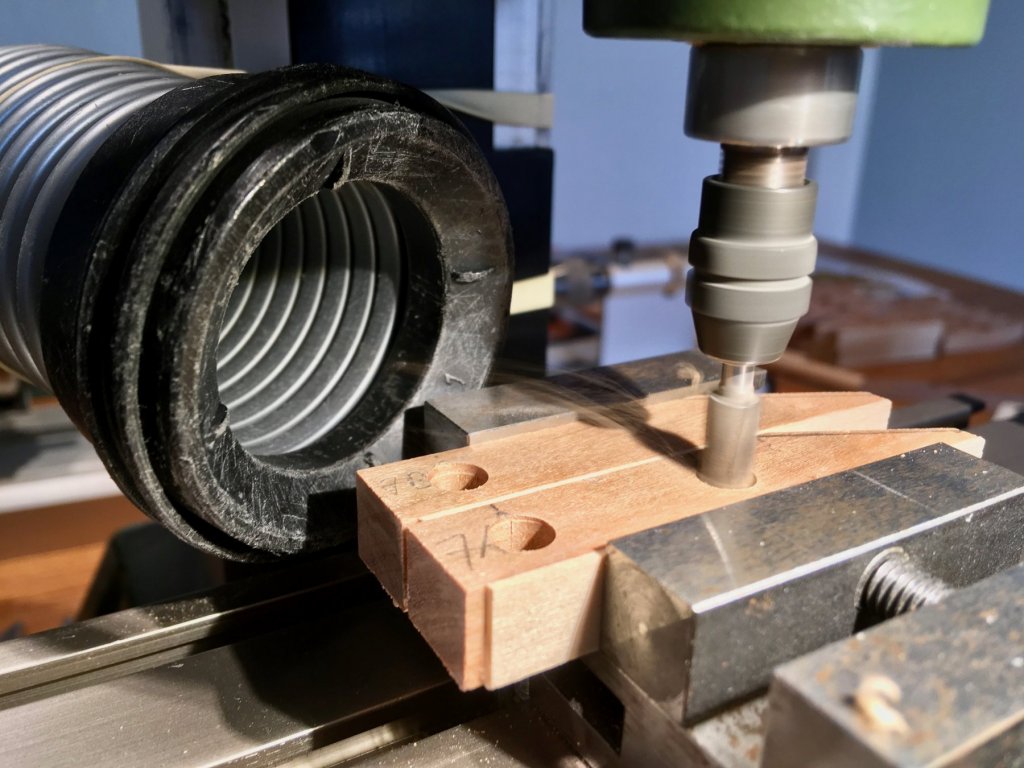

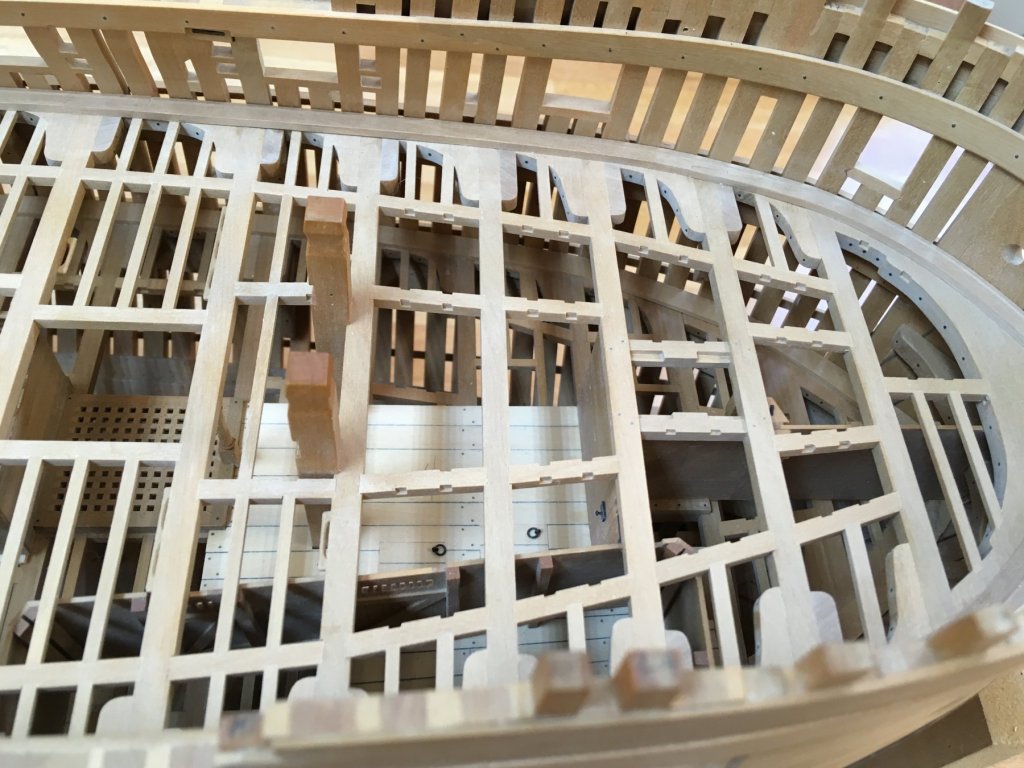

... And this is the moment when I would really love to have a CNC mill - for repetitive and precise tasks... Ok, even a regular mill is better than trying to do it by hand Surprisingly, drilling with a mill bit works better than with a wood drill bit. No idea why, maybe the speed is too high for a drill bit. It causes burning and some chip-out on the back side of the hole, while a milling bit just pushes fibers outside without causing them to chip out. The fuzzy fibers are easily cleaned up later with a knife. Mill is pretty amazing for the precise work, I really love the control and having everything square in all directions! Current state of things. The wisdom says that you can never have too many clamps, challenge accepted!

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

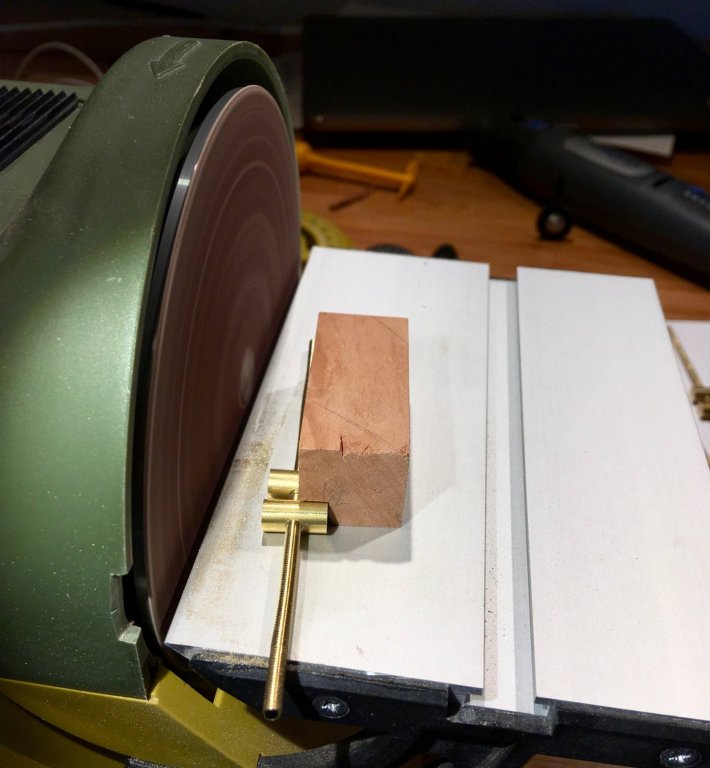

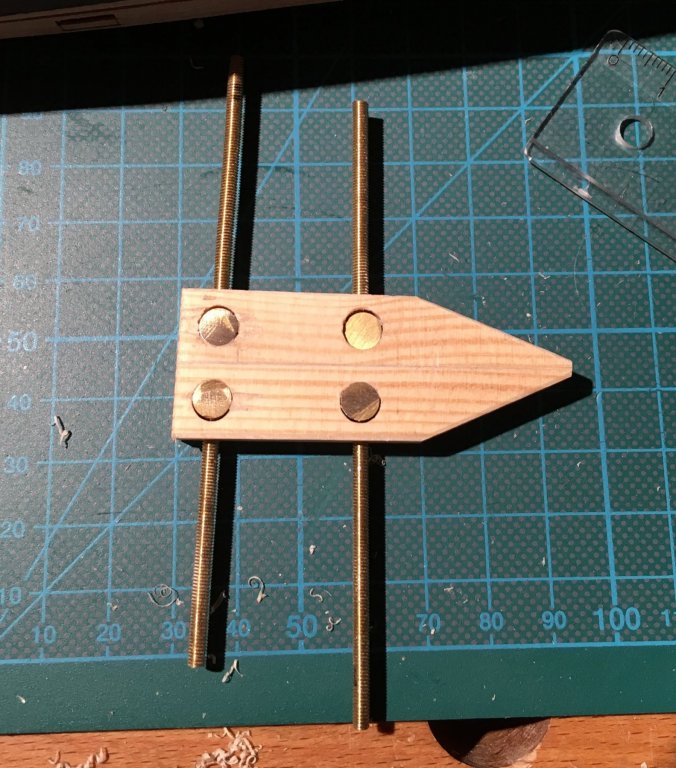

Who could have known that making clamps will take so much time But I hope it worth it! Sanding that metal pieces to ensure uniform length. A simple jig prevents them from tipping over when in contact with the sandpaper. Cutting clamps, this is mostly cherry: Also made three pairs of long clamps, specialised for things like wales. To make it easier to clamp around hull shape, they will have a gap in the center: Gluing soft basswood strips that would help to prevent damage of a pieces being clamped: Mill as a drum sander, works fine: Big Clamp help to make a tiny version of itself Experimented with various shapes of handles, the most elegant and simplest to manufacture is just a smoothened slightly conical cylinder:

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Very accurate and methodical process, thanks for all that "in progress" pics. A bit of a pity that part of the result is painted on top. Love the ribbon and letter carvings!

- 487 replies

-

- ship of the line

- 80 guns

-

(and 1 more)

Tagged with:

-

Regarding treenail installation - isn't it easier to drill and install them while the hull is still attached to the base upside-down, before it is sanded and before the frames are cut off from the build base? Or I miss some problem with it? Otherwise it would be easy to scratch that nice and delicate hull while drilling treenail holes... Just a thought.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Gaetan and Toni, will go with a slimmed / curved shape. Strength should not really be a problem, if you need a lot of clamping force on a model - I think it is a sign of a bigger problem. Applying too much force will just cause more troubles... So it is more about heaving a light, soft and miniature clamps. The metal ones are too heavy (I have them as well) and will leave marks in the wood with their jaws. The wooden ones would be lined with a super soft basswood to prevent any damage. I finally finished all the thread cutting and tapping (phew!), so hope to start cutting some wood tomorrow!

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

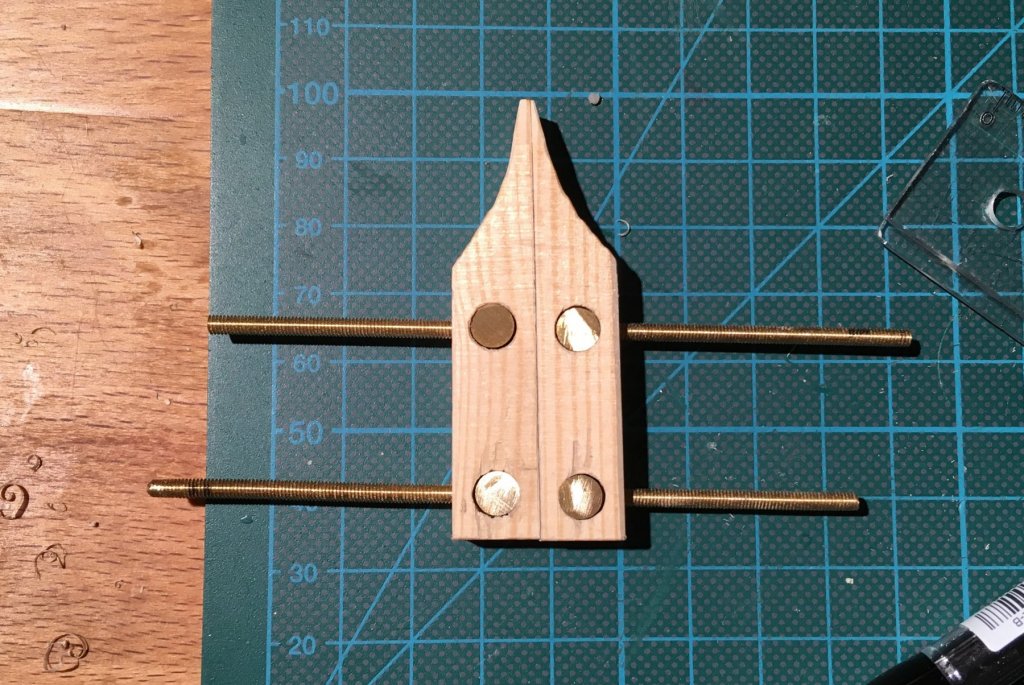

Experimenting with clamp shapes (on scap pieces, real clamps would be made out of pear). The shorter version looks better (needs a bit more meat on the back side though): But it should more practical if I taper the jaws: That would allow to grip in narrow places (between frames, carlings/ledges, etc). I was worried about them flexing too much, but it is not an issue even on a soft pine that I use for this prototype. The clamping force on the very end is more than enough for all modelling applications. I could not clamp it hard enough to get any flex. The only downside - it looks kind of ugly. On the upside, I can make a lot of dad jokes about a clamp that looks like a duck, walks like a duck and quacks like a duck Any opinions? What clamp shape is more practical based on your experience?

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Congratulations! It is incredible, and it is very handy that you can actually see both sides with a mirror! It was a pleasure to follow the journey, looking forward to the next one. There is still some place left in your display wall

- 1,449 replies

-

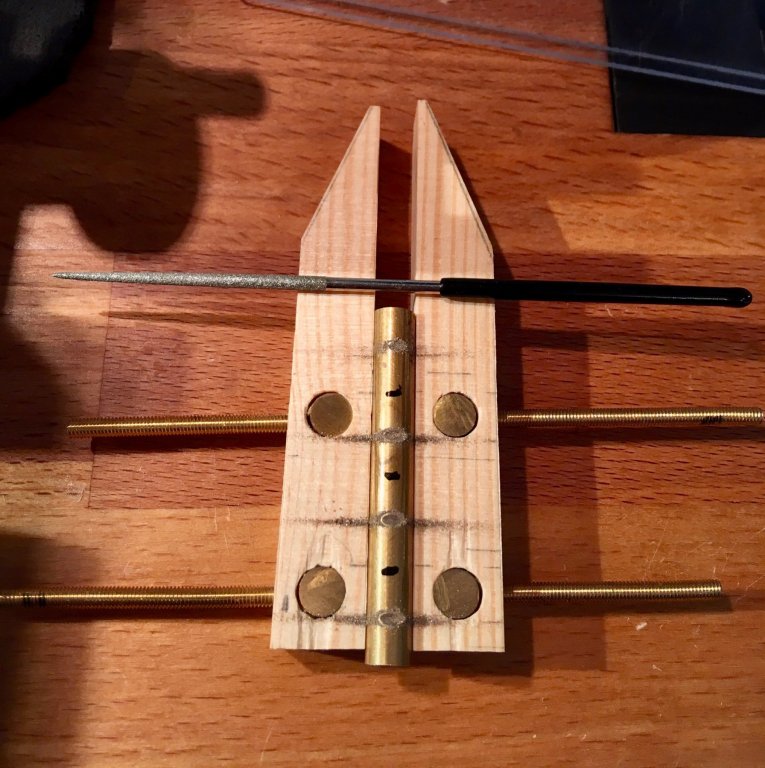

This summer I had a perfect plan - send off the family to their parent/grandparents in July, and enjoy the hobby in the evenings. "Ha ha oh come on" said my work life, and I ended up with a series of business trips instead Some of them were good though, can't complain. I am still making the "Tosti-style" clamps. Drilling the holes on a mill: To prevent the drill bit from slipping to the side of the rod - I flatten it with a file first: That method is simple and works well enough. Thread is tapped manually, no problems with that approach: Then slicing this rod with a Knupfer slitting blade. It is really great, cuts brass like butter, I am impressed! Cutting the thread in a thin (3mm) rod is trickier though. Frequently the thread is being cut off-center, resulting in a wobble closer to the center of the rod. Googled a bit, most common reasons are incorrect angle, uneven feed, etc. I found a method that works well in the end. Die is placed on top of the benchdog hole, vaccuum is placed below it, and everything is held in place purely with a vaccuum. In action: Being on a flat surface, it is easy to control the angle and is easy to apply a steady pressure. As a bonus, air flow immediately cools both die and rod, and all chips are sucked into the vac. The end result is a clean and straight rod (on top), versus wobbly alternative (the same die was used for both rods): I am nearly done with metalwork, but now my left-handed die died (no pun intended), it cuts a larger radius and gets a lot of resistance - I broke two rods when trying to cut that thread Ordered a new die, will cut the clamp jaws in a meanwhile. P.S.: machining is, actually, quite hard! You can't sand away the excess or cover gaps with sawdust and glue mixture. There is only one chance to do things right.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

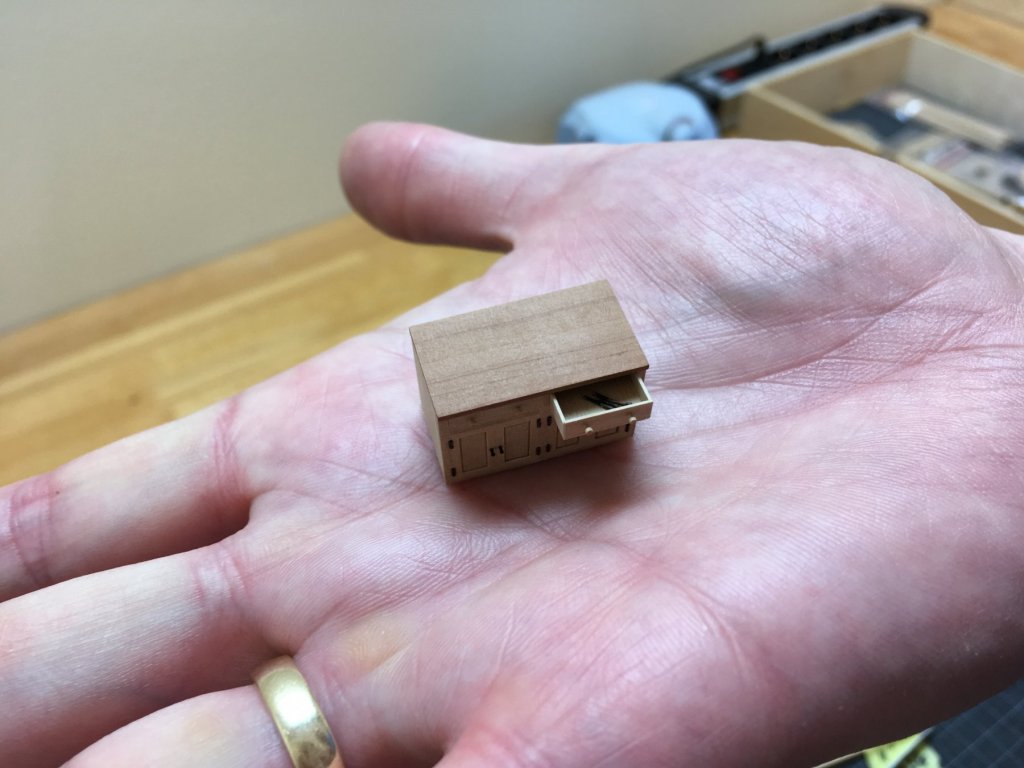

Dutchman, can't find your Polotsk build log, time to start one? Daria is back from grandparents, back to the build. The hull is sloooowly closing up, teaching a lesson or two about persistence, patience and planning. Here is final one, garboard plank. It is tricker, because it needs to be fine fitted carefully to the "keel". All the other planks do not require any fine fitting, except the front tip that meets the stem. Fine fitting was a nice exercise, with a dozen of dry-fits for each plank on a way there. But Daria managed to do it in one session, without getting tired. That made me really proud! Fine fitting with a plane (two-man job so far): In parallel, she was assembling a furniture for her cardboard-and-fantasy-made fairy house I am completely not involved, totally her design and implementation, she just casually walk to me to get some tool or glue. Getting quite comfortable with a scalpel, btw (used it to cut some windows). It is still in progress, she is making some furniture (gluing a book shelf out of cardboard strips in multiple iterations, which warms my heart). She already starts talking about making a fairy house out of wood, and hints that I have just the right tools for that and plenty of spare plywood 😎 Back to the model - a milestone is achieved, the last plank is in place! Now she will remove all glue spots with a Dremel nylon bristle brush, trim plank ends and sand it smooth. Daria is super happy about the milestone and asks me to post it to the log asap

-

HMS ANSON 1781 by albert - 1/48 - 64 guns

Mike Y replied to albert's topic in - Build logs for subjects built 1751 - 1800

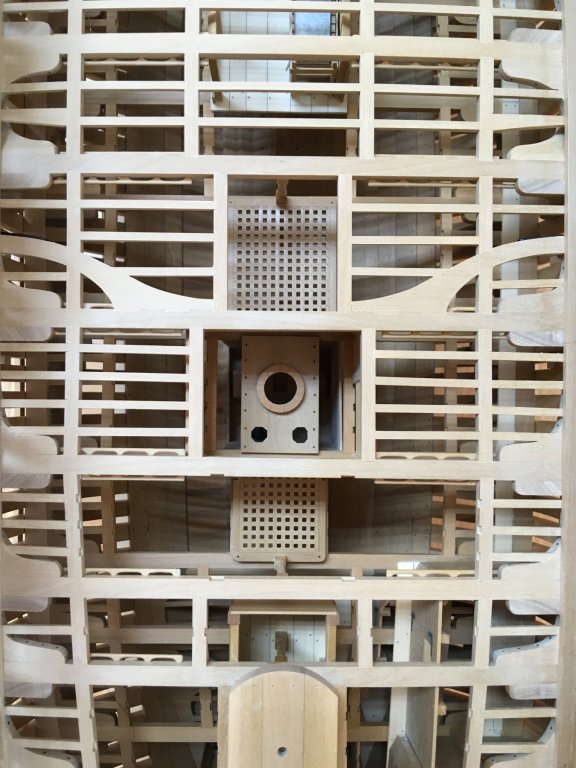

Nice frame factory! what are those squares in the middle of each frame assembly? -

She actually looks nice looking a little bit lower - making sure the ship would not hit any underwater rocks. Captain would be pleased with her help!

- 1,449 replies

-

Proxxon Bench Circular Saw KS115

Mike Y replied to RussR's topic in Modeling tools and Workshop Equipment

Same as Dave, the best way to fix KS115 problems is to buy Proxxon FET and advise everybody to do the same. It is a classical example of spending money on a cheaper tool, ending up spending more money on a proper tool. KS115 is, honestly, a junk (I had it, upgraded to FET and never looked back). It is hard to use the table saw if you can't event adjust the blade height, and the precision is super bad (fence alignment, miter gage, etc). You also can't make any sleds for this saw, since there is only one miter channel instead of two. Its real price should be around $30, there are "saws" in this range on AliExpress and Harbour Freight. But they are asking $130 for it 😳 -

There is a small class of scaled down power tools - starting from Proxxon (typically the most affordable), ending with Sherline and Byrnes in a higher price range. They are small enough to be hidden under a table when not used, do not produce a lot of dust (any home-grade vac would easily handle it, if needed), and are generally not very loud. I can't really imagine being without a table saw or a disk sander. Here are Proxxon tools in a living room. They are typically less visible because the table is usually lower (it is lifted a bit on this photo). Though if you build kits and do not plan a lot of improvements to the kit - then a rotary tool and a set of good hand tools (chisel, knife, etc) should be good enough!

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Mike Y replied to albert's topic in - Build logs for subjects built 1751 - 1800

It is an exceptional model! Do you have more photos of the display base under construction? -

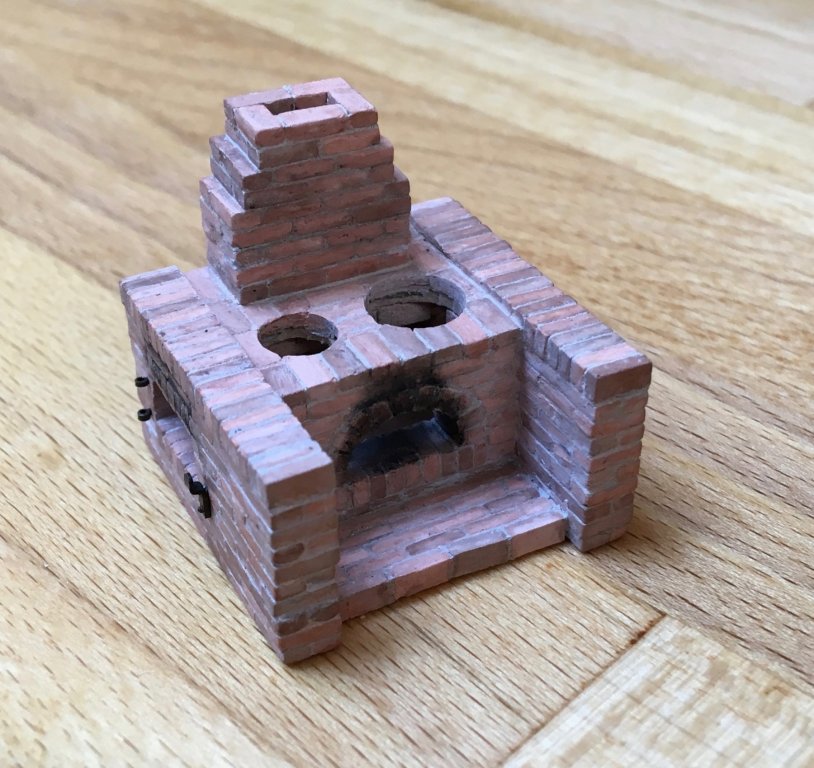

I could not miss the opportunity to visit Remco, since we are now basically neighbours Can confirm, the Kingfisher is feeling good in a new clean and super structured workshop. Hope it will survive the period of abnormal dry weather that we currently have... ' I was amazed how crisp and clean all joints are! It is not a photoshop, it is better than I imagined based on the build log photos The boats are neat: And, of course, various parts are still there, each could be a model of its own:

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Hi Lawrence, I do not remember to be honest - some books and a photos from some other build logs, plus experiments to see what angle and depth looks better. Once I found the scarf that looks the best from my point of view - I just made a template to keep that angle and use the same depth every time.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Pandora by marsalv - FINISHED - 1:52

Mike Y replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Marsalv, any plans to show the Pandora in Rochefort in October? There would be a big event with hundreds of participants, see the details on the french forum.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.