-

Posts

1,557 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mike Y

-

Jaager, may I respectfully disagree about the need to mill your own wood? It's very nice to have your own bandsaw, and it's a good skill to have - but if you do not have the space or desire - it's not so expensive to just buy milled wood. I'm building 1:48 scale with Hahn method and the cost of swiss pear for framing blanks (where more than a half goes to waste) was 150 EUR, and I've ordered plenty of extra pieces just in case. And I was told this is not the cheapest supplier (though I am very loyal to them due to their quality). It's not peanuts, but definitely not too expensive. You don't _need_ to invest in all the machines to mill your own lumber, or find somebody with them. Ordering sheets and wide strips of pre-milled wood would be just fine. Especially since you can spread the purchase over many years while building. I am building POF in the apartment with no workshop, and just want to say it's definitely possible with a limited set of miniature tooling. Please never drop that idea just because you do not have a space for a large bandsaw Of course a 74 gun in 1:24 scale would be a whole different story..

-

Thanks Gaetan, nice to know! Sometimes I wonder how everybody else drills the treenail holes inside the hull? Most of the build logs omit that process, just showing a thousand neatly aligned holes I can't believe that it's all drilled by hand with a pin vice, especially since it is too long to reach some areas on the extremums of the hull.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

It’s mostly pear, castello boxwood and cherry, you will find plenty of older topics about pros and cons of all these woods. Cherry is the cheapest, pear in between, castello box is the most expensive of them all. There are a dozen of other woods, but they are even harder to get. there is also a dedicated topic with a list of wood suppliers, smth like ”where to buy wood”. One thing for sure - you would not want to go back to ”kit wood” after using that stuff

-

Hope now you will spend more hours in your cozy work area Glad that you are back to this build!

-

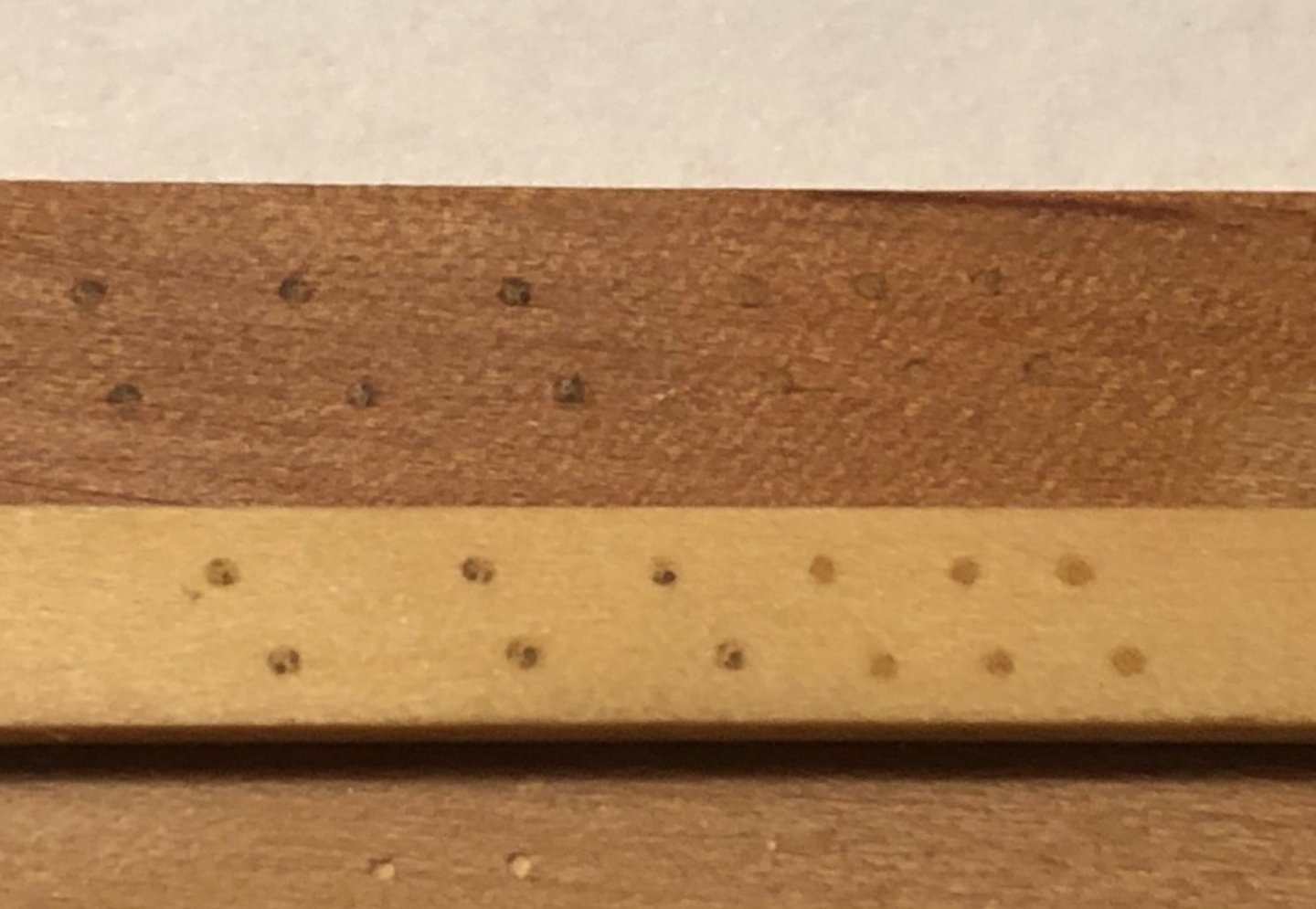

Richard, interesting idea for the next generation of the tool! I'm pretty sure this one would break before I finish the model Had a few late-night drilling sessions in .45mm size (#77, third smallest hole in Byrnes drawplate). This corresponds to 7/8in in real life. First problem: tiny drill bit is too tiny for any collet. I tried wrapping it with masking tape, aluminium foil, etc - all was fruitless, it was spinning once bit bites into the wood. I turned the internet upside down trying to find a proper chuck/collet or a set of bits with larger shank. That was fruitless, but I found a great advice on MSW from Von Stetina in 2013: https://modelshipworld.com/topic/4348-micro-drill-holders/?tab=comments#comment-125198 You basically wrap a wire around a bit, which provides enough grip. In my case just a wire was not enough, but if you add soft solder on top - then it works like a charm! Looks like a horrible feat of redneck engineering, but it works Due to a low rpm of my drill a minor wobble induced by this abomination is not an issue at all. So after all a set of tiny holes was drilled. I tested it with both bamboo and boxwood treenails. It is much easier to draw bamboo (I managed to do it all the way to second hole in the drawplate without breaking), with boxwood it becomes even more delicate. Results were quite different when oil is applied, bamboo has some dark blotchy spots, while boxwood is evenly colored. Here bamboo is on the left side, boxwood is on the right. Top plank is pear, boxwood is in the bottom. Will probably go with a compromise - using bamboo treenails for internal planking and boxwood ones for external planking and deck planking. If somebody asks - will blame the crew for the poor maintenance of their living quarters 😜

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Mark, I am also worried about overheating, the problem is you can't know how hot it is inside. If the outside gets hot too - then it's probably already too late So I'll just make sure to take tea breaks, no drilling marathons. Alan, I did not know you can attach 90deg attachment to a flexible shaft, interesting idea! But then control is still an issue, when your fingers are 90deg to a hole.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Thanks everybody, it's so nice to be back GuntherMT, the motor is geared down significantly, so it's pretty slow, but provides enough torque for the purpose (tiny holes that are not very deep). So you only need a moderate pressure. Though it's not fast, each hole takes around 5 seconds. Dremel would do that in a second, but the cost of mistake is higher. I chose a weak motor simply for the size, anything more powerful is also bigger. And the design goal was to have a tiny little thing. Unfortunately collet is as long as the motor itself, but I do not have good enough tools and skills to machine my own collet on this scale... Foot switch would be nice, but I did not have one, and making it would be a bit more complicated. Can be retrofitted pretty easily if needed. I usually do not have space for both hands when working on a model, at least not for internal planking. The power supply is a simple "adjustable power adapter" from any electrical / hobby shop, with a range from 3 to 12v. I run this motor on 5-7.5v usually, but trying to be careful and take breaks. I am worried about frying this little motor, wooden drill body would not dissipate the heat, and I would not feel the motor getting hot. Machining it from brass and attaching with some thermal paste would probably be smarter, but it's another can of worms (surrounding a bare motor with conductive material is probably not great).

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

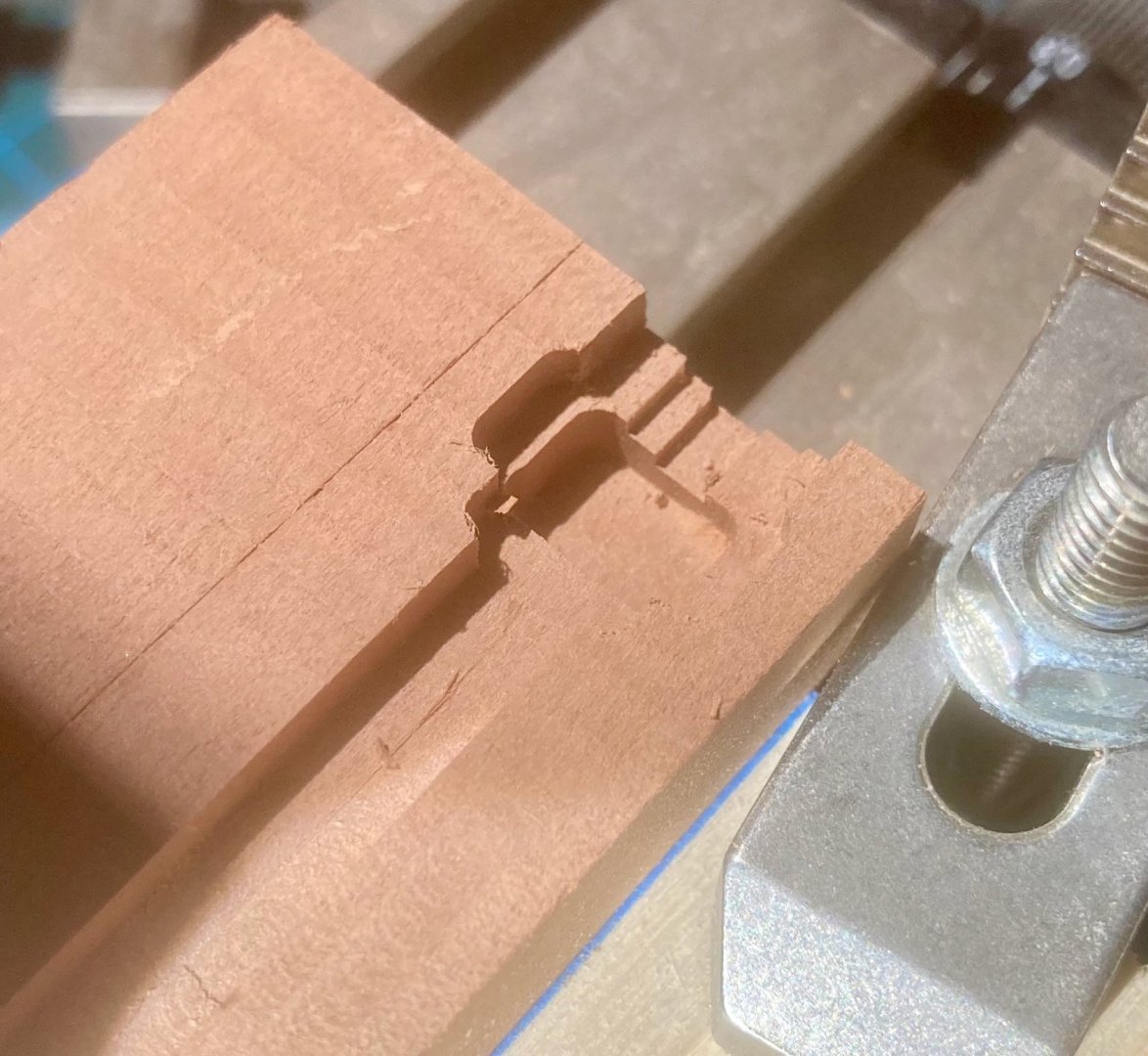

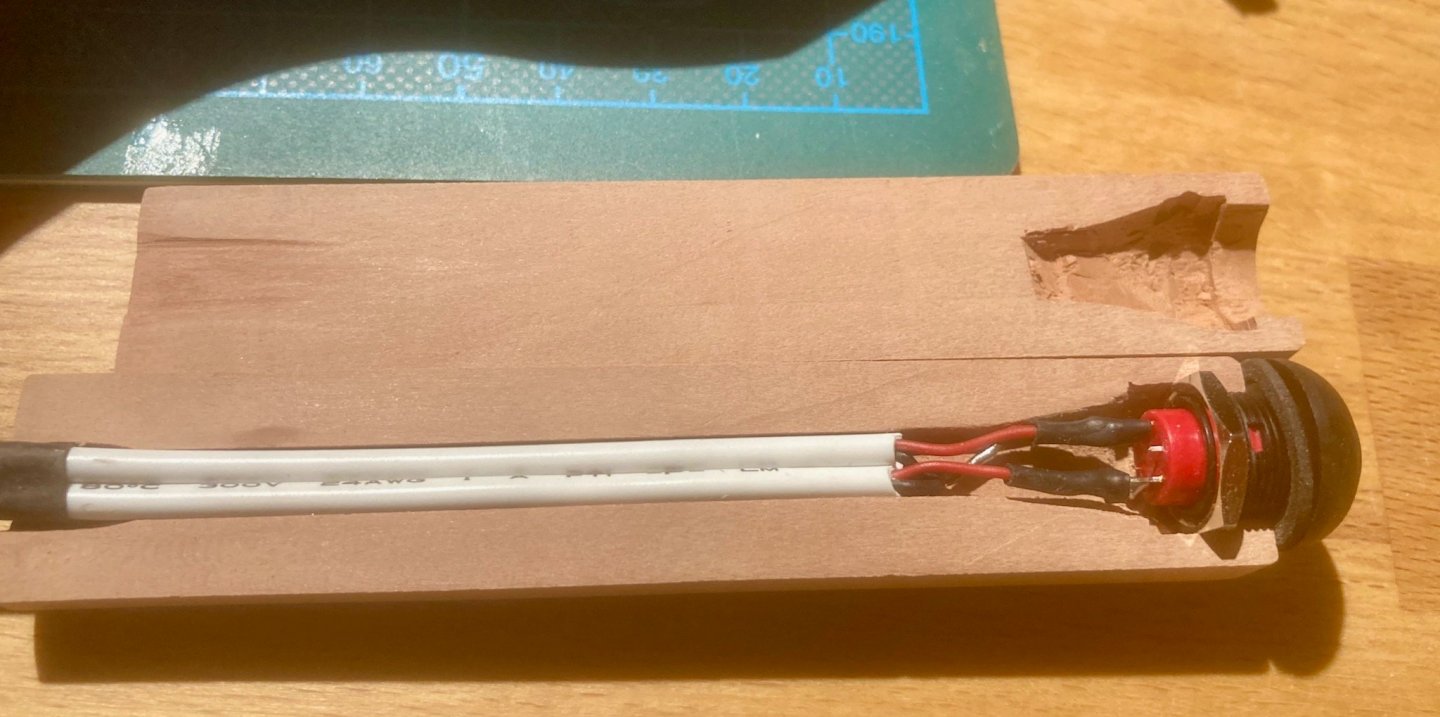

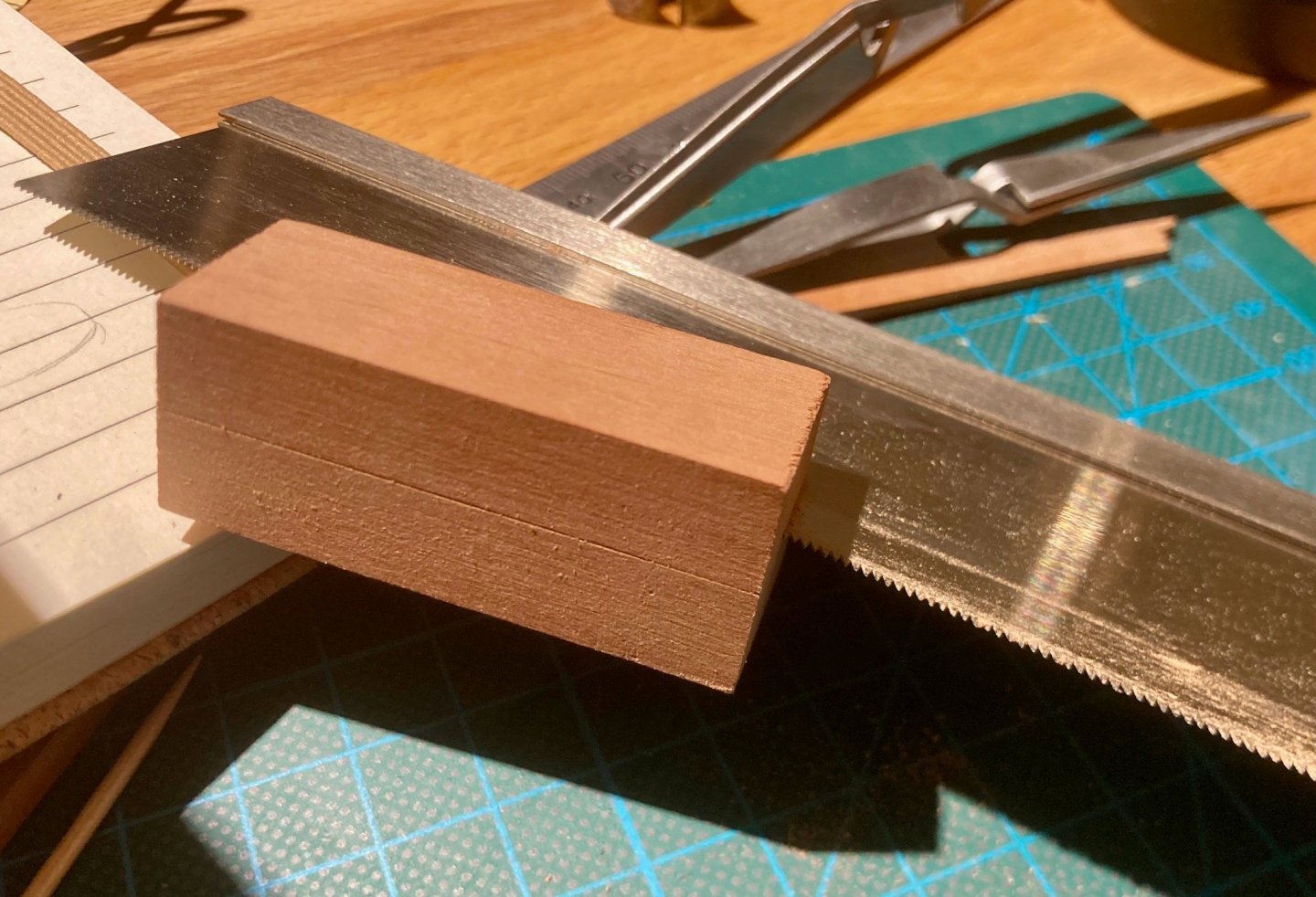

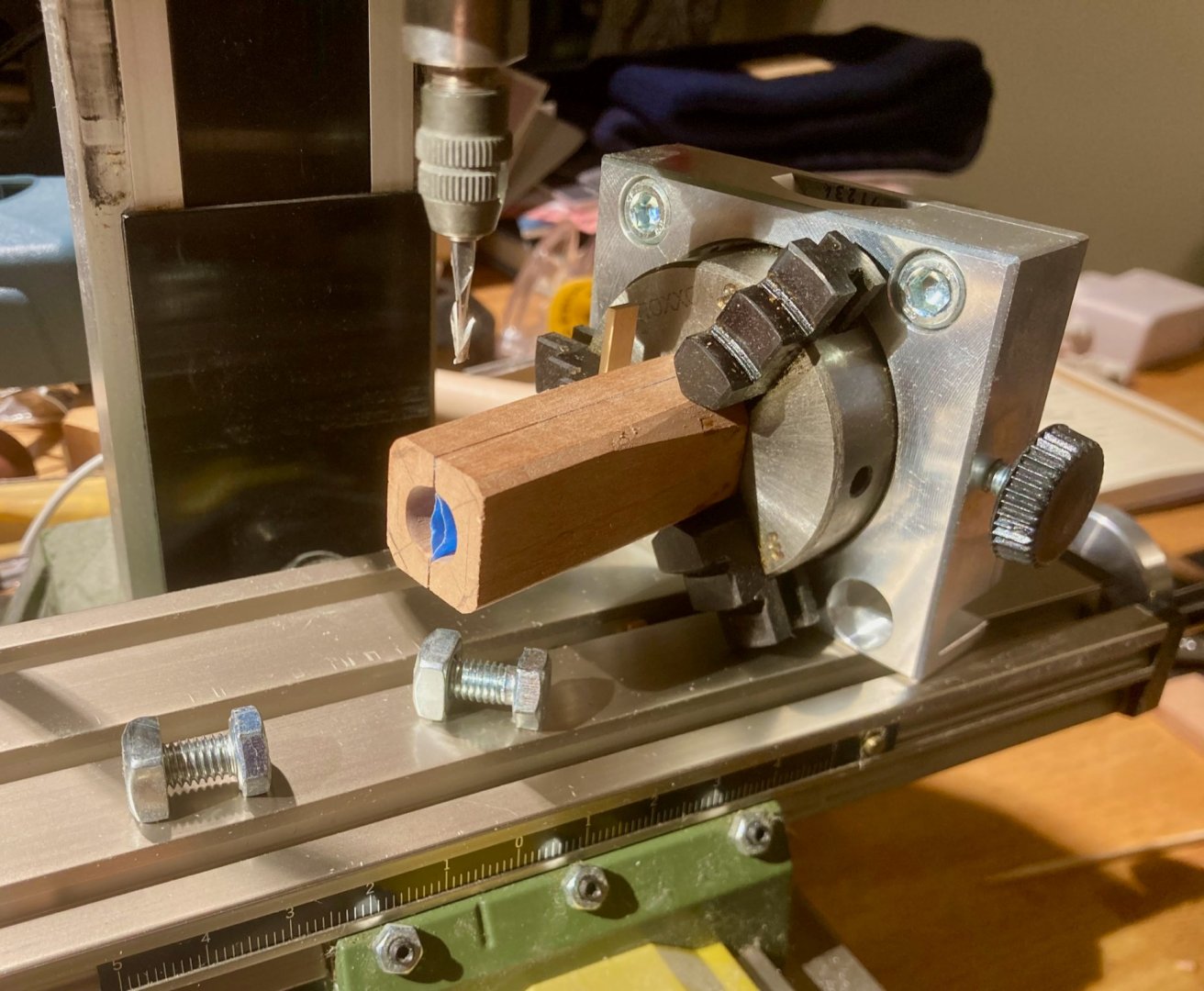

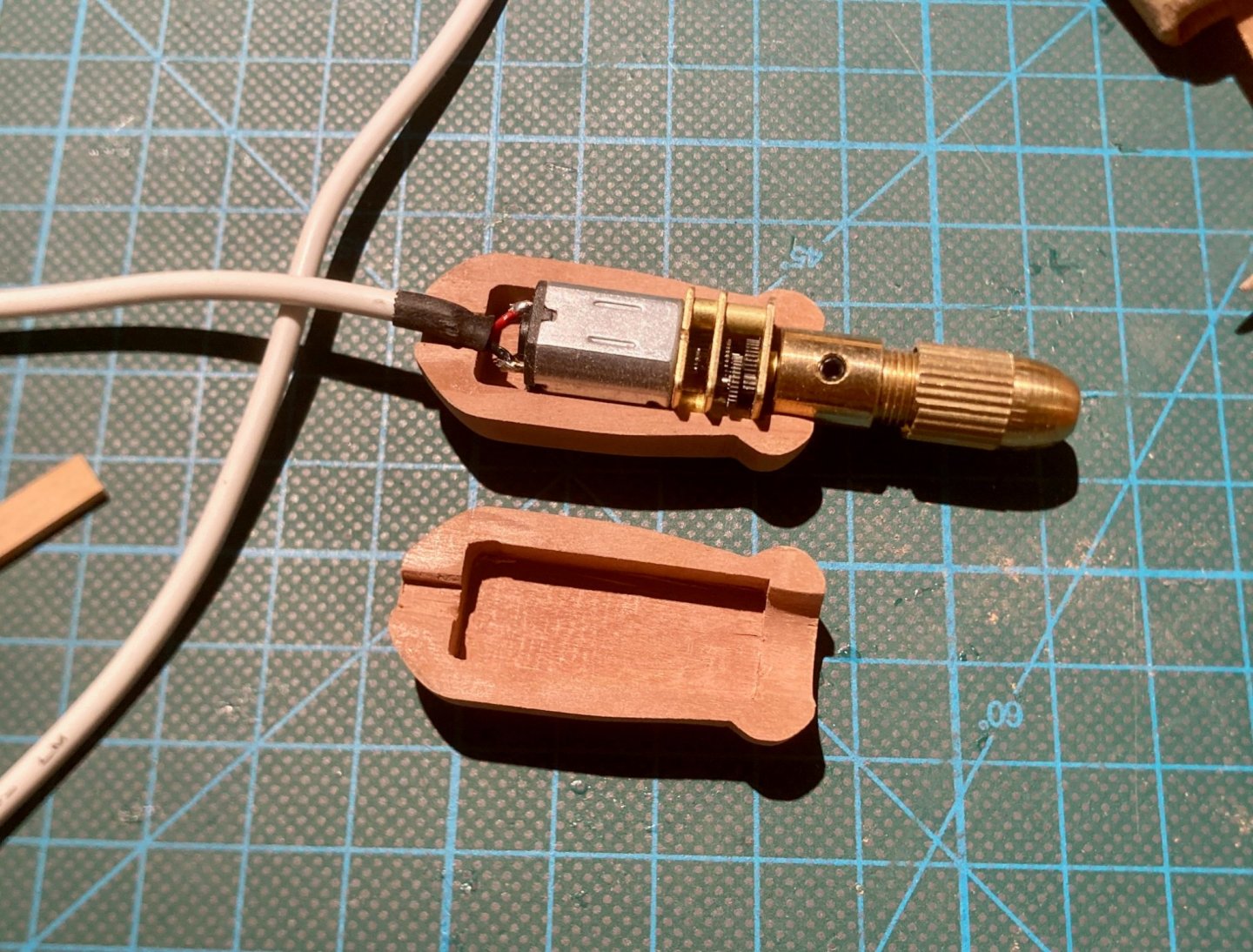

Once I've lined up the treenail holes - I realised that I do not have a way to drill them. Dremel is too long, manual drill is too long as well, so I need to make a tiny micro drill that is as short as possible. But then the spring came, I got into mountain biking hobby, youngest daughter started to grow up and need attention, then we had a fantastic boat trip in the archipelago, one thing lead to another - and I found myself in the middle of Christmas holidays, realising I haven't touched the model for a year, such a shame! When you have a break that is soo long - it feels pathetic. You don't remember when some tools and parts are, there is a thick layer of dust built up on some tools, and so on. So back to making tools The idea is simple - use a tiny geared down motor as a drill, control it with a button that is held with another hand (to reduce the chance of whoopsies when drill bit wanders off when it touches the pilot hole). Milled the recess for the button, using a blue tape + CA trick as a workholding method. That would be a perfect job for a CNC mill, if only I had one... Shaped it with my new toys - miniature rasps. They are fantastic for that, cutting pear pretty easy: That's how the assembly looks before the glue-up. Next was the drill part. Due to noise limitations imposed by a younger kid - I am trying to avoid using power tools if possible. While table saw is gathering dust - tried ripping a block of pear with a handsaw, following the scribed lines. The result was surprisingly ok, nearly straight, and took just a few minutes. Interesting shot - here is the blank after drilling the hole for the chuck After milling the internal recesses or the motor I tried to mill the outside shape using a vertically mounted rotary table, but faced a very stupid problem: jaws of the chuck hit the milling table. Adding a spacer underneath the rotary table would have solved that problem - but requires a longer mounting bolt, which I did not have No mill then, back to shaping by hand with a rasp. That was pretty satisfactory, though the result is clearly hand sculpted and not as precise. Everything is ready for the glue-up, and I managed not to cut off too much wood to expose the inner recess. Got pretty close though. The glue-up was delicate, I forgot to seal the gear block, so used very little glue in that area to avoid it getting into the gears. And the final result - the mighty Turbo Buzzr 3000 🤣 It works and make a buzz, the drill bit rotates, you can actually drill with it! Now I have a few hundred holes to make Feels very strange to hold a wooden drill, so used to the feeling of rubbery plastic when drilling, wood feels entirely unnatural in that situation. Glad to be back! A lot of build logs to catch up on MSW... Which is a good problem to have. Stay safe and Merry Christmas to all! 🎄🎄🎄

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Monumental work on a clinker hull where you can't just smoothen everything with a gentle swipe of a sandpaper.. Amazing!

-

Remco, thanks for sharing your situation, and truly hope it would be back on track soon! The journey of the Kingfisher would continue one day, I believe! Someday when it's done I hope to see it again, regardless of the location (it's worth a roadtrip!) Merry Christmas, and let's hope that this curveball is a beginning of something new, something great! 💪

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Basic but Good kit recommendations for granddaughter and I

Mike Y replied to glbarlow's topic in Wood ship model kits

It's so nice to realise that we inspired some to start building with their kids Hopefully there would be more! Will try to share all my observations, maybe it would be useful. Of course, everything is different, and I only have one child to compare. The modelling sessions were around 20-30 min at the age of 6. There was no expectation of a quick result, but more of "I want to do the same thing my dad is doing", plus a natural interest in doing something crafty. Each finished phase was treated as a semi-finished thing you can play with. I remember same when I was a kid - finished model was as exciting as an unfinished one, so do not stress too much about it. It is unlikely to be finished unless you can do it many times per week. Expect some deviations from the plan, this is normal and increases the interest. For example, my daughter likes to build things from small scrap pieces left over from my build, by gluing them together and to a piece of paper. The starting skills are non-existing, every technique needs to be explained with some practice and help. How to hold a file? Sanding? Gluing? Cutting? Every single operation is new, account for that when planning a build. Prepare every session, so you have parts at hand, tools ready, etc. Each method and skill is introduced the following way: show it first, explain how it works. Let the kid practice on some scrap, first holding hand, then letting go and allow to make some mistakes. Do not start with safety precautions, introduce them gently where necessary. Dremel is quite kid friendly, by the way (if you do not use cutoff wheels and such). One of the hardest skills is keeping a consistent angle / plane when using a tool, as well as consistent pressure. Steady hand when using a file, for example. Still struggle with that a little bit, so do not have a very high demands on filing quality. Sanding is tedious, plus a pressure level is different. Split the time evenly, so kid feels that the contributions is fair. But just because of skill and pressure, your sanding would do 70% of the job. The other person holds a vacuum hose, which also counts as help. Let the child help, find some "busywork" in a delicate situations. For example, some of the planks in our kit are a very thin and delicate veneer, which breaks easily. I was doing any edge shaping, but she was helping to fit, hold the light, etc etc. Safety-wise - perfect time to introduce dust protection and safety glasses, no problem with that if you both use it. Dust protection is mostly decorative, all the masks and respirators are way too big for a child face, but it's still a good habit. I used a vacuum to really catch small particles when sanding. Plastic or wood? Plastic models involve CA glue or cement, both are harder and more risky to use by a child. Also parts are smaller. Wood - larger parts, safer tools (file, sandpaper, PVA glue). Some machine tools are also fine - with some help and introduction, she learned how to use Dremel (nylon brush to clean the glue squeeze-out, sanding drump, drill), disk sander (low power, so it would stop even if you stick finger into it) and even a bandsaw (of course, all supervised). At the same time, I would not dare introducing table saw or a mill, that one is too risky. Planking is actually doable by a kid if planks are pre-shaped (laser cut). Assembling the hull (bulkheads and so on) - doable as well. The rest is up to you, probably a lot of details needs to be skipped. But even if you will end up with just a planked hull - it is already something that is nearly finished. Add a mast and few sails - imagination runs wild! Do not forget that it's all for the process - positive reinforcement, highfives and a good mood is the most important technique in the whole exercise. It helps to be a big goofy, make stupid mistakes and let a child correct you and help you - it makes them very very proud Hope you will have many enjoyable sessions with your granddaughter, that she will remember for a long time afterwards. Does not matter if she will end up with a finished model. -

ancre La Belle 1684 by Nenseth - 1:36 scale

Mike Y replied to Nenseth's topic in - Build logs for subjects built 1501 - 1750

You need quite some rigidity when sanding, to achieve it and prevent misalignment when humidity changes - you need temporary spacers between frames anyway. Hard to imagine how that can be done with a non-temporary joints. Replacing a frame or two is doable by just dissolving PVA as described above, but getting them all in and out? -

YTL-45 Taiwanese Navy tugboat by Erik W - FINISHED - 1/350 scale

Mike Y replied to Erik W's topic in Plastic model kits

Wow, that is quite an impressive weathering (not overdone) and quality of details on this scale! -

Yay, another Hahn build! Like your surface sanding jig, very neat!

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

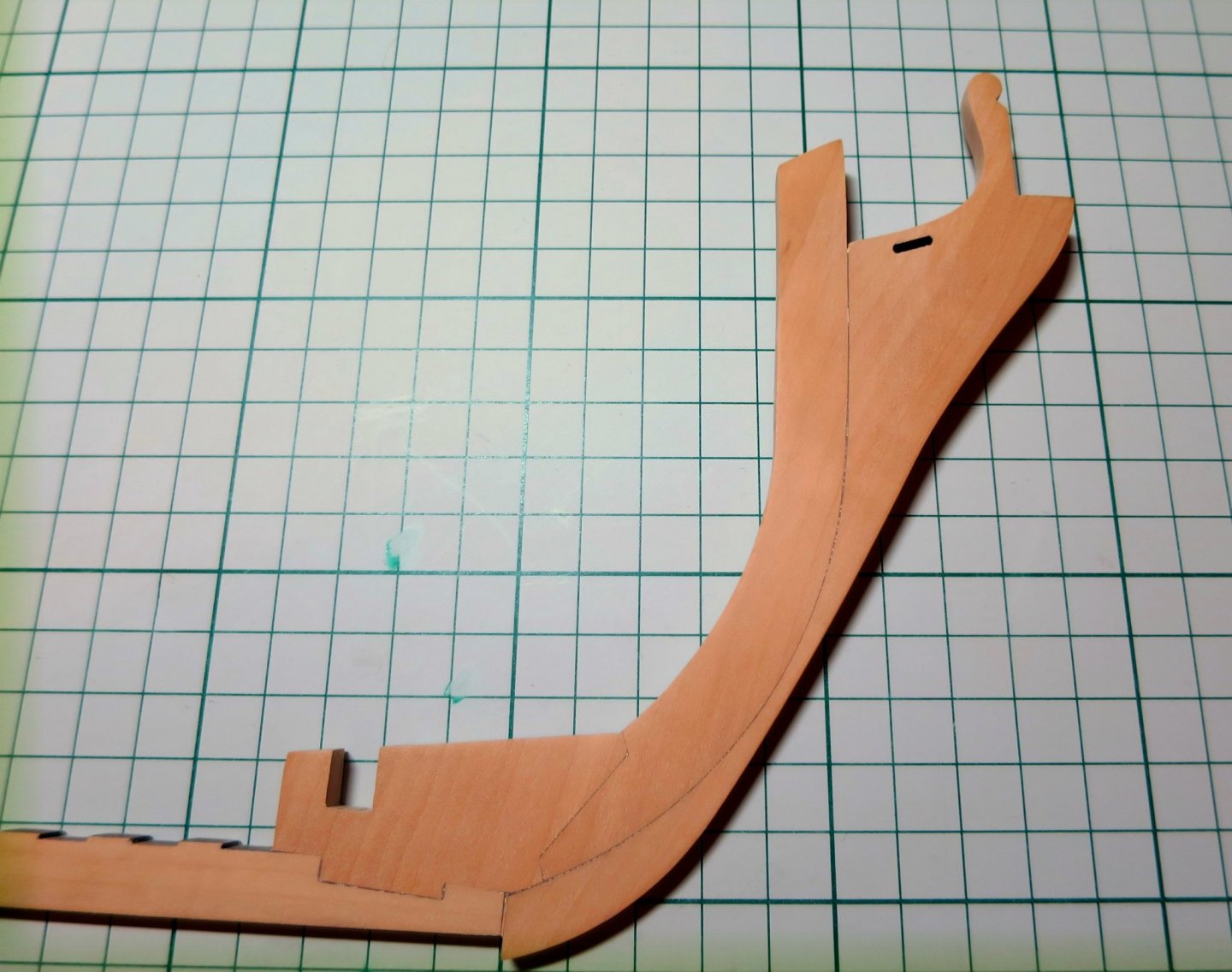

Great start! Hahn simplifies a lot of details in his drawings, you will find plenty of "giant pieces" that were built out of multiple pieces in reality. Just use more detailed sources if you want to build it in a more realistic way. For example, the stem is likely made out of more pieces, etc etc. They are quite visible on a model, and actually look way nicer in a detailed form, to my taste... On my model, Hahn version looks like this: Looks too crude, so I scrapped it and re-made in a bit more detailed way, based on other drawings and books. Note that this is not a full level of details, for example that triangle in the middle should have been broken down as well, etc etc. But still looks a bit better.

-

This is something else, but there is more than one "correct one". Try it, shake it, make sure it is not too flimsy, check the max height if you are tall

-

Hof van St Janskerke by niels wilhelm

Mike Y replied to niels wilhelm's topic in - Build logs for subjects built 1501 - 1750

You have one of the most unusual workshops! Nice build! -

Välkommen!

-

Hi Andre, They are fairly common in modern offices, and allow to work while standing. Height is adjusted smoothly and continuously with two buttons under the table, no tools required and it takes a few seconds. It is not a fixed set of positions, you can move it like you move your car window. I move it up and down all the time, depending on the work being done. They used to be expensive, but then IKEA released a very decent version for half the price (model name BEKANT). You can buy the ready-made office table, or just a frame separately. Screw any tabletop on it and you have your custom made electrical table. It is nice to have a solid wood instead of an office fiber board, so you can add a vice and clamp things without damaging the top. They exist in different sizes, colors and even corner versions are available: https://www.ikea.com/us/en/search/products/?q=bekant frame stand The only downside - it is a table for light work, not a replacement for workbench, since legs have motors and screw rods embedded into them. So I would not recommend chiseling a tenon an mortise joints for your furniture projects on such table... Otherwise it is great There are a few topics on this forum where this was discussed in details, with photos, etc.

-

Thanks, Michael! Your words mean a lot to me Getting second thoughts about some distant plans on making a 1:96 model, too fiddly indeed. At least planking at my scale is easier than with 1:24, I guess!

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.