-

Posts

1,521 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mike Y

-

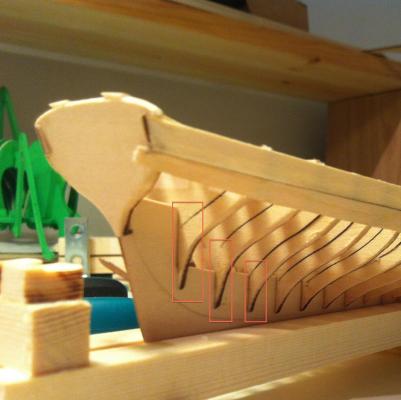

To illustrate the point about smoothing the transition from rear frames to false keel. Here is how it's done on Pinnace, frame bottoms are forming a smooth curve: And here is the Longboat. Hmmmm... How am I supposed to twist planks that way without leaving a gap between plank and frame? Probably the wisest thing would be to make a filler, which will transform frame shape into smooth shape as on Pinnace. But it's too late on that phase of the build.

-

HMS Druid by Krug - FINISHED - 1:48 - Hahn

Mike Y replied to kruginmi's topic in - Build logs for subjects built 1751 - 1800

Hm, maybe you can go further, add two servos and a stick, to tilt the model? Stick could be embedded into display case, it will control the servos and tilt / rotate the model, so viewer can look from various angles? All electronic for that is quite cheap (I bet on something close to $30-$40), but will require enough space inside the display case, so model could move there without problems. Of course, viewer can just move the head to get another angle, but it's boring and not fun! P.S.: sorry for a crazy idea, but since you are going that way, adjusting the display case so viewer will have a better overview of hull internals... -

Typical argument for planking wale first is to make the hull stronger and avoid wobbling of the frames. But I have a "false deck" for that. If you follow the reference marks - you will end up with a proper shape of wale plank even if planked from the keel. The benefit of planking from the keel is that you don't have a tricky "last plank" somewhere in the middle it requires lots of time to shape, and if not done carefully - there would be a gap around this plank. I planked Pinnace as suggested im the manual (starting from wales, meeting in the middle), and can't find any benefits of that, if frames are already fixed together with a false deck. However, usual disclaimer - all methods will work

-

Floyd, unfortunately I do not have lots of pictures, all of them are in that log, but there are some on page 4 and 5 of this log. I clamp rear ends of first planks together, with a strong plastic clamp (see page 4), that helps to keep the bend. When plank is drying, it keeps that bend perfectly. Also take a look on a grain direction, plank is twisted easier in one direction than another. At the bow, I fix the end of the plank with another clamp, that is attached to the stem and pressing plank to the false keel:

-

Amazing! Are going to add a hole in the hull, to imitate the boat that hit the rock, and hence require the service?

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Floyd, no worries! I am happy to help, if I can, so questions are welcome! Both bents are done at the same time - soaking plank, curving it with fingers a bit (to make it softer), and then clamping to the hull. So just one soaking, snd leaving it until the next day clamped, to dry and keep the shape. When unclamped, it bounces back just a bit, and you can glue it without any problems. First I glue the stem part lf the plank - where it is inserted into false keel / stem, and few top frames. Then I glue next part of the curve, 2-3 next frames. Remaining part is close to be straight, and the last gluing is near transom. So around 3-4 gluing stages, with 10-15 min between them. Since I also edge glue planks, it is hard to glue whole plank at once - need to make sure it is properly pressed to all frames and previous plank, to avoid gaps. Please let me know if you want some detailed pictures of some stage, I can make them without any problem. Pops, boxwood does twists easily, it is very elastic! Surprisingly Bending boxwood is as easy as bending basswood. The important thing is that it's still hard, so you can't just smash one plank into another and let it be glued - need to shape edge of the plank to tightly fit into edge of the previous plank. I failed to join edges of 2nd and 3rd plank without gaps, so decided to let 3rd plank run on a smooth line, and added a filler plank between them. Probably a proper solution would be adding a filler wood pieces to the bottom side of rear frames, to smoothen a joint between false keel and a frame.

-

Here is a shameful workaround for a tricky area, where false keel meets with rear frames: And also not sure why I have that stealer plank there... At some point I forgot about shaping planks to reference lines at the stern, and decided that it is a good idea to practice a proper stealer plank Current state of the hull, around half of planking is completed: Discovered that scraping the boxwood hull is much better then sanding it. The more I plank with boxwood, the more I like it!

-

Heh, I have an great wife who also have a hobby (knitting), and mostly I do modelling during 1-2 hours when kid is already sleeping, and I'm not And I thought it's moving very slow! No picture of fairing from the stern, unfortunately. All pictures are in this log... Stern shape is smoother then in a bow, so just a light fairing required. Main problem I faced was around 2-3-4 planks from the keel, right on a stern. If I build a longboat again - will definitely add some fillers to smoothen the transition from false keel to rear frames. They are pretty smooth in Pinnace, but on Longboat you will either have a gap between frame and plank, or planks will meet on some extreme angle So before you plank it, try to dry fit a few planks there. Maybe you will want to add some fillers

-

It looks amazing! Thank you for a detailed photos of the process! Preparing for my Hahn's build, and trying to catch every detail

-

Very interesting build! That archiepelago ships have their charm Would you mind if I pull the chair? Oh, glad midsommar, btw!

- 113 replies

-

- bohuslän

- nordic class boats

-

(and 1 more)

Tagged with:

-

Have you stained the wood? Interesting color! Or it had that color out of the box?

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Looks good! Looking forward to see it sanded! Just be careful, use lamp to see where the hull is already too thin, and extra sanding will just make a hole in it.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

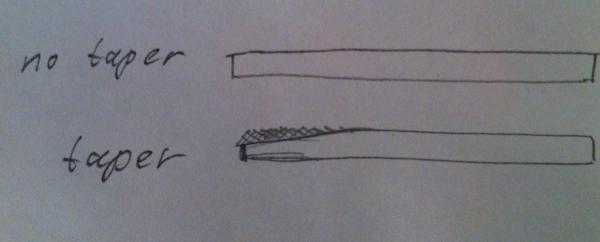

Yes, still look good! especially the tricky bend in the rear part of the hull. I failed there, will show my workaround later The front photo confirms that planks are not tapered. A bit of taper will make them really better! Chuck recommended it in my pinnace log, see the first pages. Like this: (Sorry for spoiling your log with my photos, but it's just for illustration - sometimes simpler to show them, instead of explaining the theory).

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

It looks pretty good actually! No, seriously. No gaps between planks, should look amazing when finished and sanded smooth! Just one thing to mention - there is a problem around second planking streak (from top of the hull, so on your photos - second from the bottom), the place where it is attached to first bulkhead. It should be tapered, to smoothly follow the curve of the hull. Then you will avoid that "warping" around first bulkheads. Tried to illustrate it.. Or maybe it's just a camera angle? Can you make a photo looking on a stem, instead of a side photo? Here is an example, looks not very good, but illustrates the point. Notice that plank is getting narrower around a stem:

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Both options are possible - I planked Pinnace with a perfectly straight gardboard plank, no bending. It just forces to taper planks heavily, because there is less room for planks at the stem Terminating gardboard plank earlier gives you more space, hence less taper.

- 132 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Ouch!! But looks fixable with a good wood glue? Joint between stem and keel will handle the load, and false keel is thick enough to be edge glued?

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

It is in my build log, here: http://modelshipworld.com/index.php?/topic/6801-18th-century-longboat-by-mike-y-model-shipways-148/page-2#entry201485 I just made a jig that makes sure that * keel is 90 degrees to the table * bulkhead is 90 degrees to keel in all projections That is enough to get a proper alignment. No need to mark bulkhead centers, they will automatically match if all angles are straight. But, again, any kind of 90deg jig will work! Or I misunderstood the question? What alingment is problematic? Do you have some photos illustrating it?

-

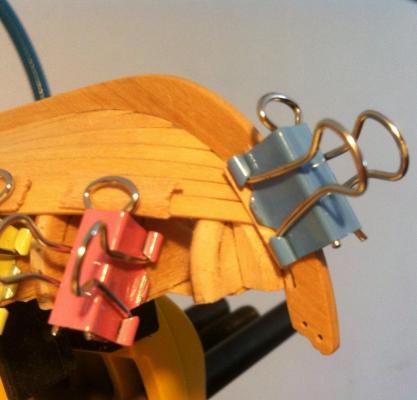

About edge bending. Conventional method (clamping under glass) do not work very well for me, because planks remain pretty wet even after a day of being clamped. Which is reasonable, moisture have no way to escape if it's under glass. And when you lift the glass, planks kicks back and loose half of the bend. Probably this is the point where hair dryer would be useful, but I don't have one. I only have a heat gun, which I use to start the grill. Used it once, it accidentally melted my clamps So instead I'm doing edge bending by simply clamping soaked plank to the previous plank and leaving it overnight: Works pretty well with boxwood. Jeff mills them with a good tolerance, as a result - planks are thicker then the kit ones. So it bends evenly, without warping up or down. That will not work really well with basswood (tried it), or with big bends probably.. But there is no kickback, next evening it's fully ready for final installation. And if you need to have a very severe bend - that something is not right anyway. I guess that next update will take a few weeks, so far it's just a iterative process, where I install one-two pair of planks per week... Happy summer!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.