-

Posts

843 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by pirozzi

-

Hi Brian, I really don't like the way the windows look in the metal castings and would like to make them better since they will really show on the stern galleries. As I recall, you cut them out and filled them with a clear plastic filler. I was thinking of doing the same but placing a clear plastic sheet behind them like used in bubble wraps. How did you cut the openings out? I am not sure I have the proper tools to do it cleanly. When you cut them out, did you leave the window frames and just cut out the panes? That would seem to be quite a chore. Thanks, Vince

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

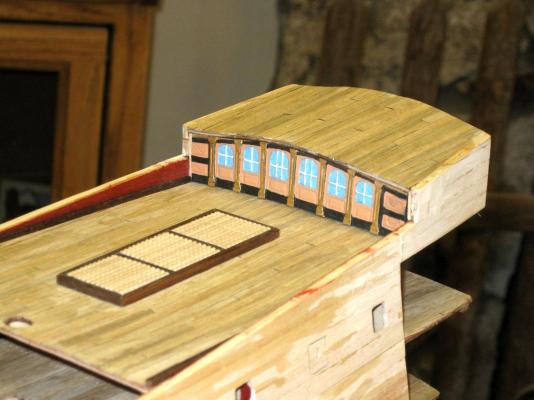

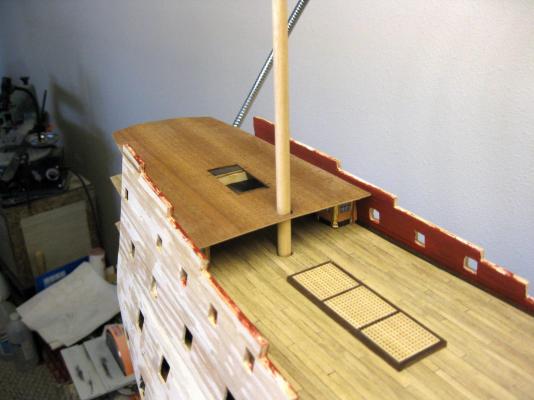

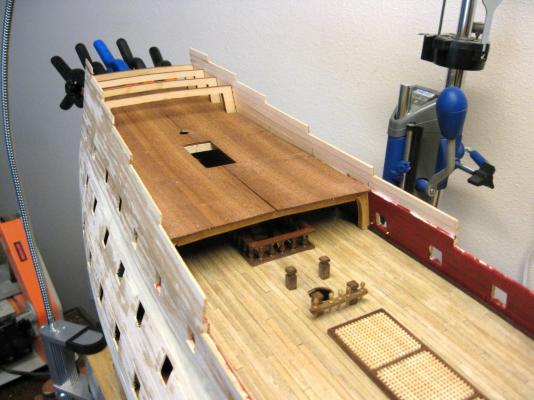

Working on and finishing the last deck, the poop deck. This was by far the most difficult part of the build so far. Unlike all of the other decks that are supported by the bulkhead frames, this deck has no real support. The kit comes with 2 small pieces of plywood made from the same wood as the false decks. These are to be glued in a vertical position on the upper quarterdeck to support the poop. That to me was not a satisfactory option, as it offered little support to the deck. I constructed a bulkhead for the aft end and side supports to link the forward metal bulkhead and aft bulkhead . When I planked the hull at the aft end at the level of the upper quarterdeck and above, I should have extended the planks past the last hull bulkhead by at about 100mm. I cut them off flush with the last bulkhead, which meant I had to extend them aft to support the poop that hangs over the aft edge of the upper quarterdeck for most of its length. Oh well, you live and learn. The exact horizontal location of the deck, its height from the upper quarterdeck below, the vertical slope, and the camber all required considerable measurements between plan sheets 2 and 17. These sheets do not exactly agree, so a compromise had to be made, and I hope I guessed correctly. The false deck and the metal forward bulkhead had to be modified considerably in length, height, and shape. Once the false deck was placed on the frame, it had to be bent considerably at both ends to provide the heavy camber and required some serious clamping. Also on another note: If you are planning on using the larger dimensions for the deck gratings as the plans show and not the smaller sizes as per the cutouts on the decks, you will not have enough grating pieces. There are enough to do the decks, but not to do the quarterdeck overhang and the heads at the bow. More will have to be aquired. Next up is to prepare the hull for the finish layer of second planking. Since the finish layer is only going up to the bottom edge of the metal hull decorations from bow to stern, all of the pieces have to be placed temporarily in their exact locations to mark the upper boundary for the planking layer. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Mates, I subscribe to "Seaways - Ships in Scale " magazine. It is a great magazine for model ship builders of all flavors. In the issues of Nov-Dec 2013, Jan-Feb-2014, Mar-Apr 2014, and May-Jun 2014 there is a 4 part tutorial by Robert E. Hunt on planking a hull. It is one of the best I have seen and really hits the spot on how to plank a hull perfectly from start to finish. I would really recommend getting a hold of these magazine articles if you want to learn how to plank. Vince P.

-

Rigging Tension-how do you do it?

pirozzi replied to capnharv2's topic in Masting, rigging and sails

The knot to use is a sheep shank with a half hitch. You can adjust it up and down to make it as tight or loose as you want and it will not slip. This knot is used to tighten and hold tent stake lines. Vince P. -

Hi Andy, Excellent job on your SOS. You started and stuck with a very difficult build and did a fabulous job. You also look very distinguished next to your ship. You should be very proud of your accomplishment. Vince P.

-

The upper false quarterdeck is secured in place. Before planking it, the bulwarks that run partially on this deck need to be cut back substantially because the forward end actually falls slightly below the deck surface itself. This is where you really have to pay attention to the plan drawings. Sheet #17 shows the run of the decks and the hull detail in scale. Making careful measurements off the drawing is needed to mark the bulwarks for cutting. The first photo shows the bulwark before and the second after cutting back. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Hi Leo, While I am not familiar with that kit, it does not surprise me about the scale being off. It is common for kits of many makers to be off considerably from the published scale on their kits. Not sure if the problem is with original data on ships or poor measurements, but it is seen frequently with kits and plans. Vince P.

-

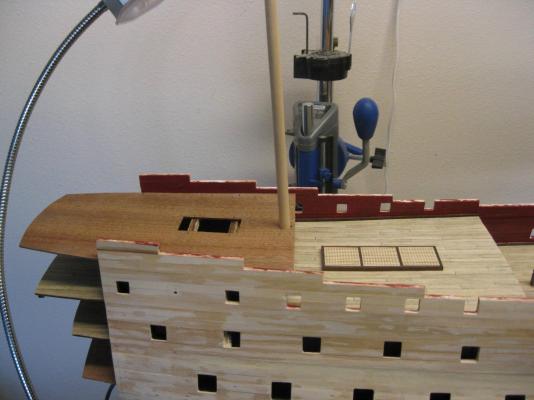

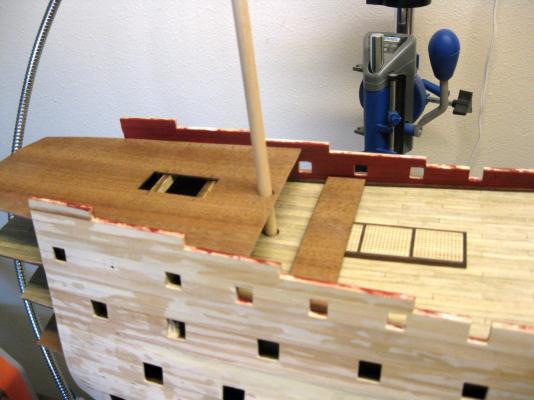

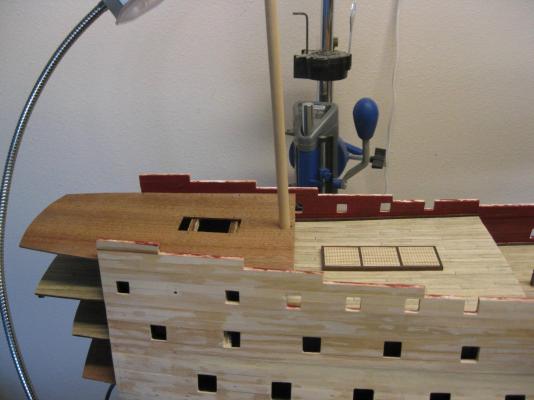

Ok, here is what I mean by differences between the plan drawings and the provided parts. The first photo shows the false upper quarterdeck laying in place with the piece cut off of it to match the plans. I trimmed the side edges so it makes a clean fit along the bulwarks and placed the mizzen mast to make sure it is positioned through the hole properly with the correct cant. The deck is just laying on the frames at this point. According to the plans, the bottom of the forward edge needs to be 23.5mm from the top of the quarterdeck below. A breast beam needs to be fabricated and placed just aft of the edge to support the deck and secure the correct height. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

The quarterdeck is complete with gratings, waterways, and gunport cutouts. The bulkhead to support the upper quarterdeck is also painted and installed. Next up is the upper quarterdeck. In this area and further in is where things get a little foggy with this build. There are many discrepancies between the plan drawings and the parts supplied. It is going to take some research to figure it all out. Then comes the dreaded "Round Staircase". There are so many versions out there and all very difficult to construct. I am working on a plan as we speak. Oh, I got a promotion! I am now a Lieutenant Commander. Not sure what I did, but I must deserve it. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Proper light for a modelling table

pirozzi replied to Mike Y's topic in Modeling tools and Workshop Equipment

Hi Mike, I find the need for several different light sources when building ships. Because of the close in work on very small parts in tight places, it is necessary to have different auxillary lighting. First I use a good quality fluorescent hanging lamp for the overall lighting. There is no flickering and the light is bright but soft. I then have an LED hi-intensity lamp with a bendable shaft that can be tilted in any direction or height for closeup lighting. This can be clamped anywhere on the bench where it would be needed. I also have LED handlights that can be used to look into tight places, and lastly an LED head lamp that frees up the hands. I use all of these at different times depending on what I am doing. All of these can be had for under $100 total. Vince P. -

Hi Denis, Very nice job. You are so close to finishing her. That is quite an accomplishment. Vince

- 555 replies

-

- sovereign of the seas

- mantua

-

(and 1 more)

Tagged with:

-

Thanks for posting that link Keith. I think I will look into this kit for my next build after the RW. I do want to build the Prince since she is related to the RW. It would be a nice touch to see them side by side. Nice job Spirerpig. Vince P.

- 73 replies

-

- prince

- constructo

-

(and 1 more)

Tagged with:

-

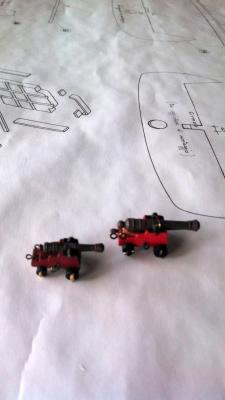

Hi Brian, You can't see it in the photos, but I tapered the carriages along the length and at the front like the real thing. Vince

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Before making the gunport cutouts on the quarterdeck and forecastle, it is necessary to make up at least one deck gun in order to get the correct height of the ports off the deck. You can not just use the plans, although they were right on at 11.5mm from the deck to the center of the ports. These guns are smaller than the main deck guns and somewhat of a challenge to construct. If you are going for detail such as the cotter pins in the trucks, drilling such small holes without splitting the wood was a fun project. I used the pieces of brass pin cut off the eye bolts, as they were a perfect size (0.5mm) diameter. The drill size was a #76. Next up is to make the gunport cutouts. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

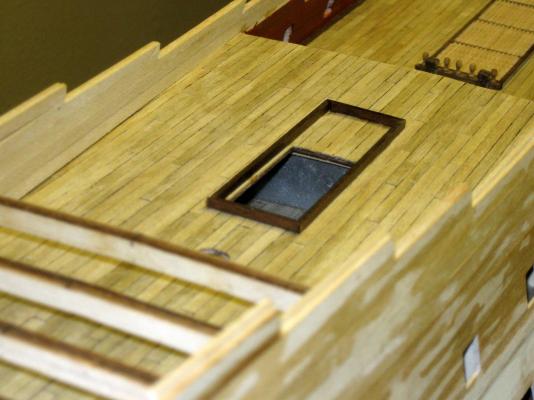

There is a huge difference in the dimensions of the grating opening on the quarterdeck, between the plans and the cutout provided in the false deck. As you can see by the photos, the cutout is much shorter than the frame I installed. The frame matches the size in the plans, which I chose to follow. The grating will be seperated into 3 equal sections. I also noted that the grating on the upper quaterdeck has the same issue. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

The quarterdeck has been planked. Next up is to add the double first layer of planking to the quarterdeck bulwarks. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

Denis, Model Expo does sell a case that will fit the SOS. That is what I put mine in. Vince

- 555 replies

-

- sovereign of the seas

- mantua

-

(and 1 more)

Tagged with:

-

what is the ideal modelling table?

pirozzi replied to AON's topic in Modeling tools and Workshop Equipment

The ideal work table is whatever fits in your shop and allows the best access both in height and around the ship. Vince P. -

Hi Denis, Thanks for the compliments, but you donx't give yourself enough credit. You got this far on your own abilities. You are a first class builder and I learned from you as well. Vince As I am getting to the end of the build of my SOS although it will be some weeks away yet. I wish to take this opportunity to say a big thank you to my MENTOR Vince P without him I would never have got as far as I have. So thank you Vince you are a good friend and well respected in the modelling world . Denis.

- 555 replies

-

- sovereign of the seas

- mantua

-

(and 1 more)

Tagged with:

-

Strip storage

pirozzi replied to capt-j's topic in Building, Framing, Planking and plating a ships hull and deck

Hi J, I have a huge storage of strip stock. I keep the long plastic bags that the stock comes in and label the size and then place all that size in the bag. Every size and wood type has its own bag. The size and type is marked on the top of the bag. All of the bags are stored upright in a tall bucket. It is easy to find what I need this way. If you have different types of wood, you can also have different buckets. I have several buckets. Vince P. -

The false quarterdeck has been placed. As you can see, that lovely staircase and fancy painted bulkhead are all but covered up now. If you wanted to take shortcuts, you could eliminate the staircase and fancy bulkhead. The kit allows you to add or skip as much detail as you would like. If you do add the details as outlined in the plans though, you have to supply your own materials. I plan to add as much detail as possible. Next up is to plank the quarterdeck. Vince P.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.