-

Posts

4,129 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

Excellent work, it’s a great looking model and a Speedy well done. Great work!

- 91 replies

-

- Speedy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I agree, it doesn’t make much sense, they’d climb either side for the stability. It would be a unique look, but I’d leave the center gap clear. So two opposing Glenn votes😏

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I space them 10 then 5 then 2. Not only for keeping them lined up but it also makes it easier to tie, and even better at least for me, somehow it makes me physiologically feel like am making more progress in less time.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

Looking great. I dread ratlines but once I get started I go into a trance😳

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

You should definitely do that, you’re not finished until you’re finished. I showed my method in my Cheerful long, along the way I discovered clear acrylic being a better option for me than diluted PVA. Definitely not CA for these.

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

I’m by own worst critic, there does come a point where I know I’m over-optimizing. I usually figure that out after I’m well past it.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I’ve built with both and that is the correct answer. Cedar is softer, easy to work with, and has the unmistakable golden glow, plus it ages well. Boxwood is beautiful, but it’s harder to come by (and harder wood) quality stuff and it’s very expensive when you do find it. Bottom line they are both great, along with cherry and pear the best modeling woods.

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

You discovered tweezers during rigging the ratlines 😊. You can get those clove hitches at the top, but it is tight. You did a very nice job with them.

- 362 replies

-

- Amati

- Lady Nelson

-

(and 2 more)

Tagged with:

-

Thank you all for the kind words. It’s all going to be worth it when I finally turn it right side up. Though I’ve seen about enough of those lovely ¼ cedar planks, don’t tell anybody but I kinda like planking. I’ll probably have withdrawal pains not working on her for a couple of weeks. I hope to finish the planking by the end of July.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

A milestone reached…..sorta. 1/3rd of one side of the hull complete….sorta. The first light coat of WOP and these macro photos reveal additional touch up and additional sanding needed. The top half has more WOP coats. I’ll sand it all down with 800 grit at the end of my planking marathon. Still nice to complete something. Lots of other June activities, she will have to be waiting for me for a while.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Your attention to detail, faith to historical accuracy, and ability to convert complexity and elegance into something us mortals can follow into building a beautiful model never ceases to amaze. I can’t wait to get past planking and on to building all these wonderful elements. Well done Chuck!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You’ve done an amazing job with the details and customizations you’ve done. A fine looking model.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Mine’s not all that neat at the moment, bits of planking everywhere. Plus I have the advantage of cabinets with doors, who knows what’s behind them all. Same thing with my office and all the camera gear I’ve accumulated. Meanwhile, I’m off to do more planking, and more planking….

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Great work area, you are a true dedicated hobbyist. I’m ver impressed, and jealous.

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Way too many cool tools, I’ll never catch up😜

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

About 1/10th of what it will take the rest of us

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Yep, that’s why I break them😜

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

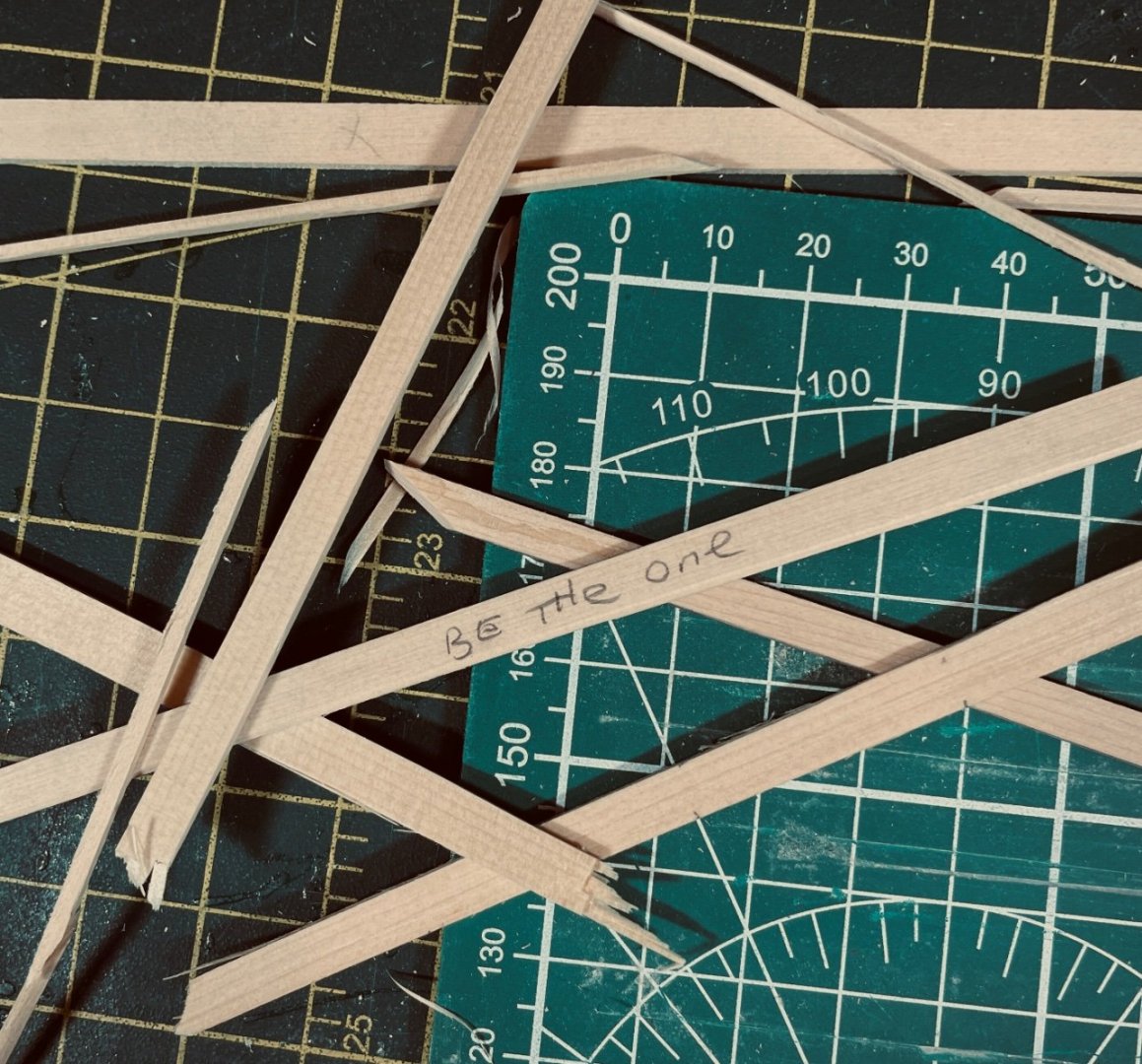

We know that every plank is a project. Often for me one plank is many projects. If they’re close but not right, I break them to avoid the temptation of “it’s good enough.” With summer, travel, and grandkids my rapid pace of 1-3 successful planks a day may slow. Hopefully by July my hull will be planked. sigh…..

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

So there is such a place, a world of completed planking…🤣😂

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.