-

Posts

4,127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

CD? Those are still around? 😂🤣🤣 Stream it on Spotify. Seriously though, your rigging looks great. The details are excellent, nice work!

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

I used a by frame cutout of the plans for both the stern from the rear and the gallery framing from the side rather than trust gauge placements. At this point I’d go option 2 provided you can clear those slots. I think there is some room for margin of error in elements of the build, maybe take a moment and consider how others managed. I know I have a hard time recognizing I am not perfect much to my surprise. 😊

-

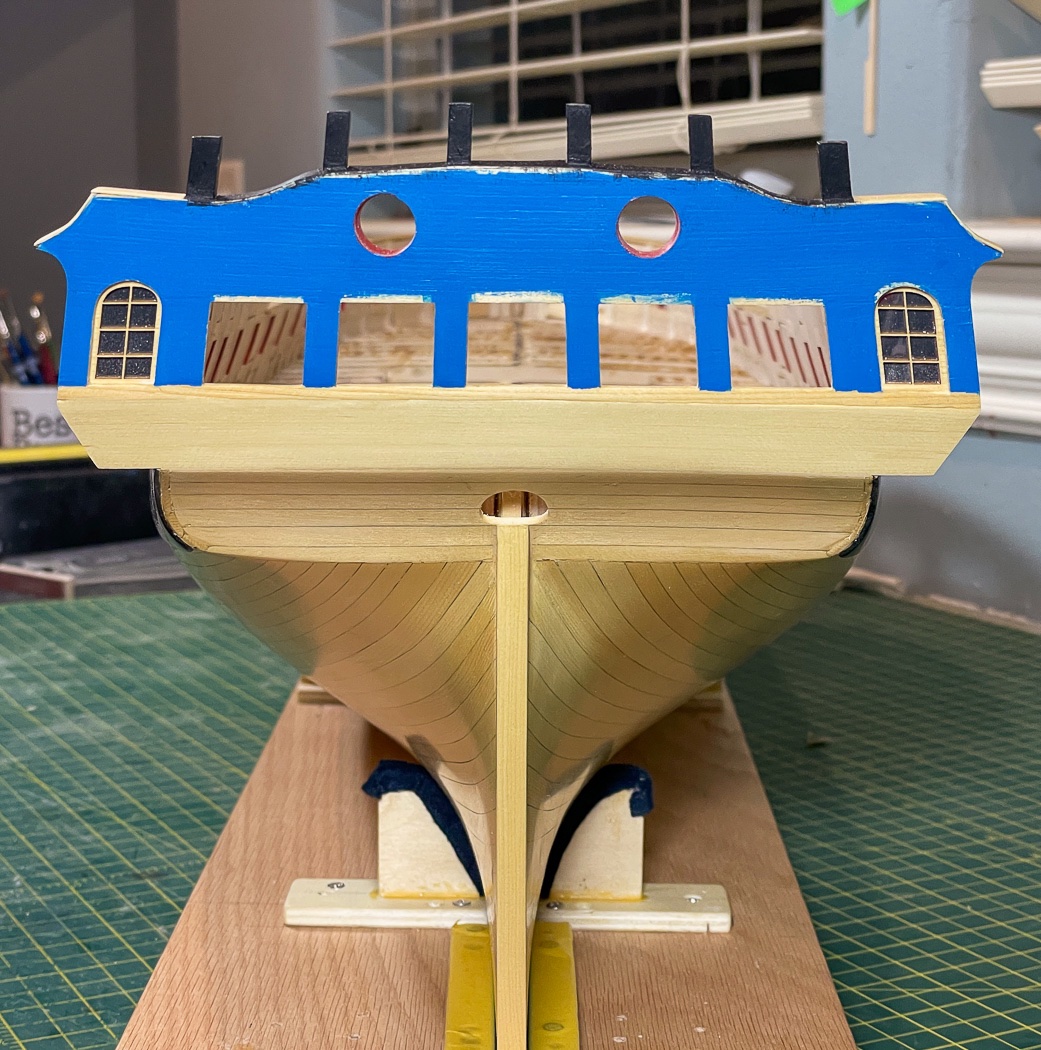

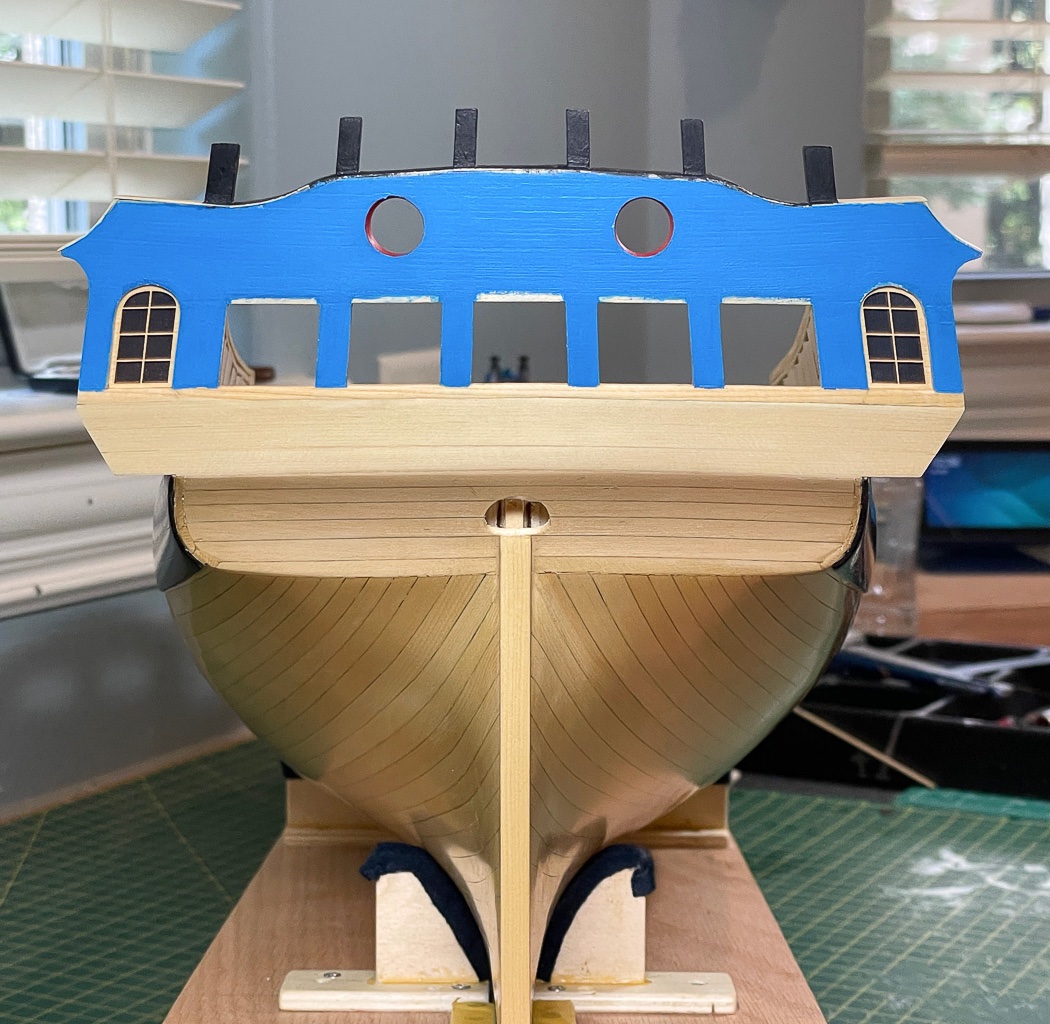

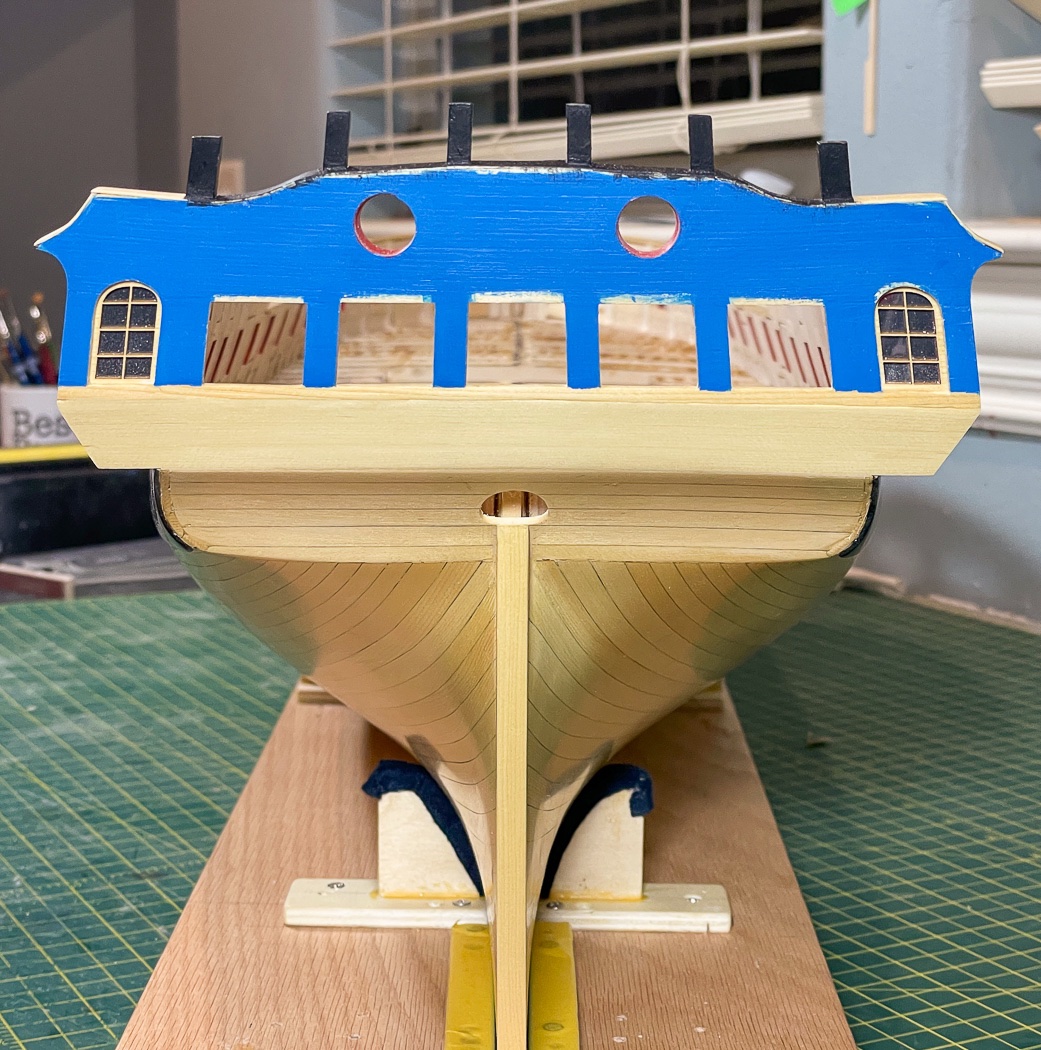

Following Chuck’s recommendation I re-painted the transom. I added a bit of Winsor & Newton Titanium White to the pure Cerulean Blue that was there before. The difference is subtle yet significant. It much more closely matches the shade of the friezes that will be added soon. So thanks Chuck, it is a definite improvement, on top of it matching it’s just a nicer color overall.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It does look pretty cool😊 Thank you Thanks Dave It’s all really fun, sometimes I get to do it over again for even more fun😂

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Chuck, I’ll do that. It’s Winsor Newton from the tube thinned with water. I’ll add a little white to the paint jar.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Using the "Chopper"

glbarlow replied to jdiven's topic in Building, Framing, Planking and plating a ships hull and deck

I cut every plank on Winchelsea with my Chopper I. I also have a Chopper II but don’t use it much. I cut them a little long then turn to my Byrnes sander and sand it square, or beveled, or at an angle, or both at once to the measured line as needed. Fast and easy. I also have the cross cut sled for my Byrnes saw which I use for more intricate work. -

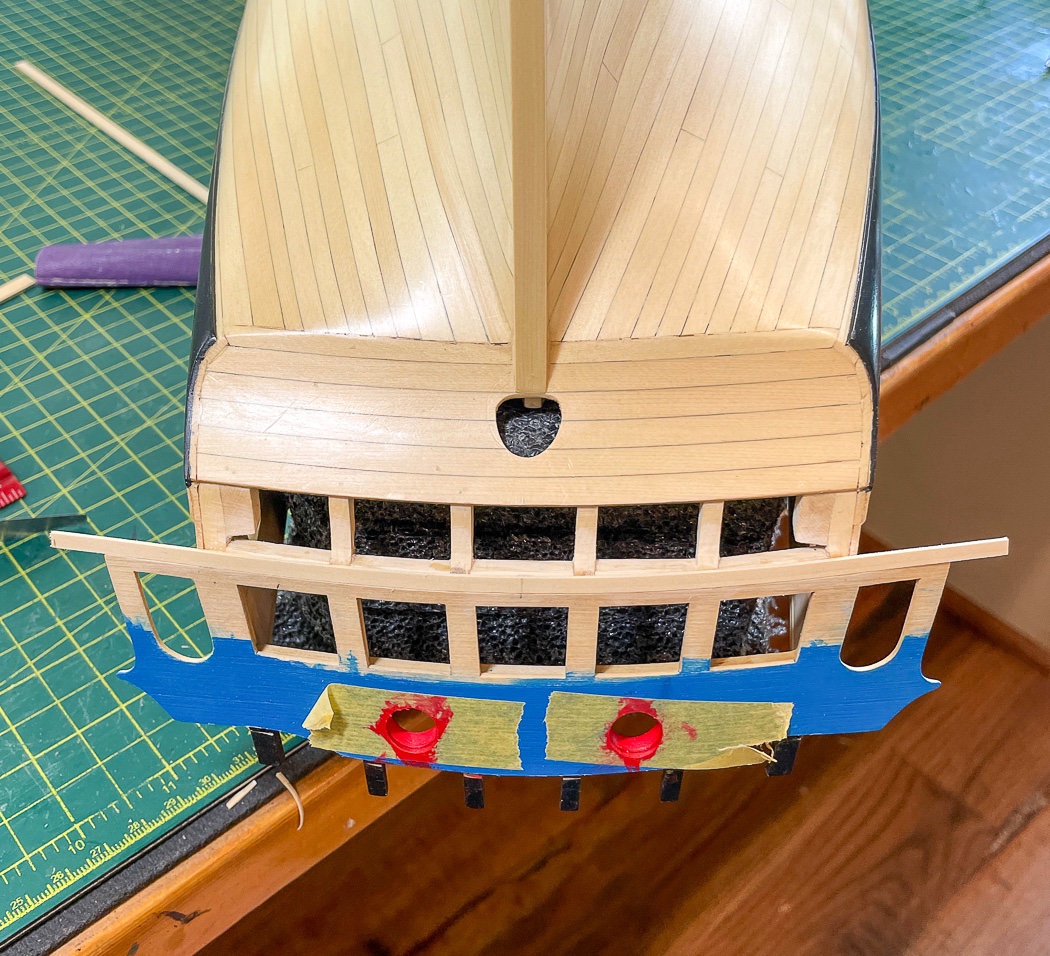

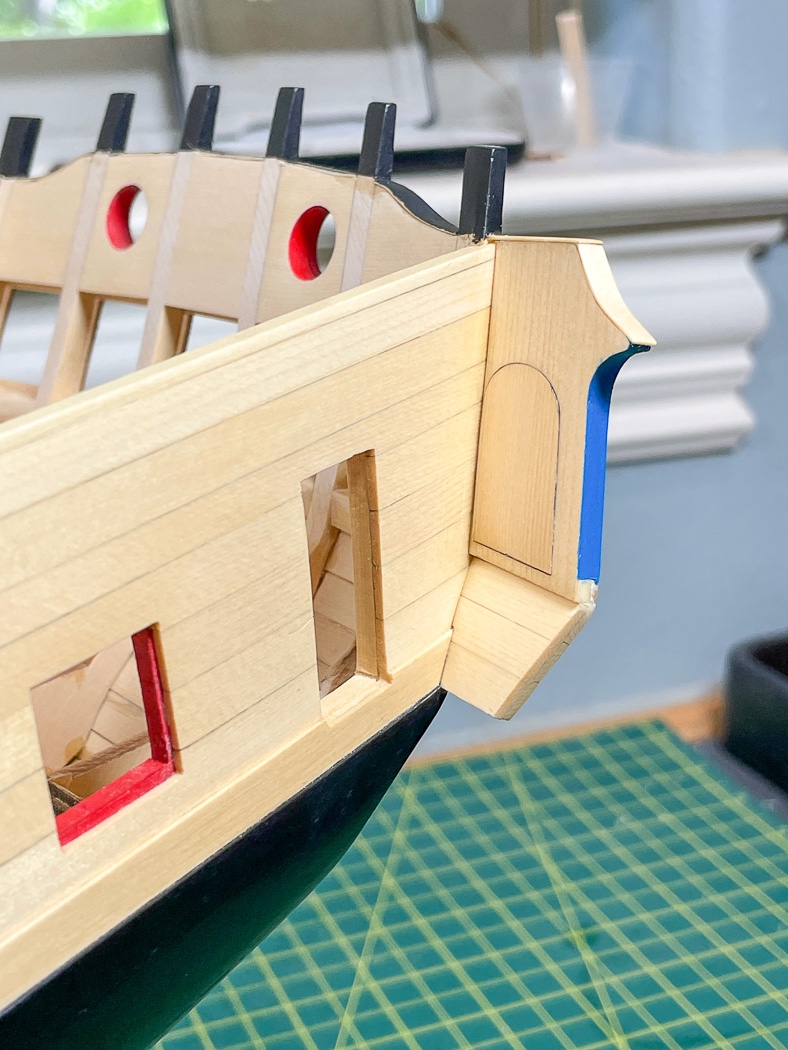

The Beginning of a Transom Normally I dread building out the transom on a model, it seems to me commercial manufactures just throw whatever on the back of the ship and move on. Not the case with Winchelsea just as it wasn’t with Cheerful. This is much more complex, much more fun, and will look great if I can pull it off. It much more complex, oh wait I said that already. The first step, adding the transom itself, was a bit anti-climatic, so much so I forgot to take any photos. I had this part when I was building out the stern frames, I also had the windows - I spent a long time back then making sure I had the right fit and alignment of the frames to properly fit the windows. I marked the transom accordingly and put it away until now. Of course I rechecked all those measurements before I glued it on. I pre-painted the transom Cerulean Blue (I later painted the area between the windows, just didn't have a photo) knowing I’d be touching it up a lot - I didn’t want paint on the inside of the window frames, it was easier for me to make that happen now. I also widened the two ports to match the fillers and painted it the same Crimson red the deck area will be and the cannon ports are now. I like this RED color. With that done I added the three 7/32 planks for the upper counter. I felt a little guilty not including pencil marks between planks, but this soon will be covered by the ships name frieze. Looking at it and the lower counter really demonstrates the difference a little #2 pencil can make. I did have to make adjustments to get the fit I wanted, once again proving I was far from perfect building out the frame no matter how careful I was at the time. Good news, it’s wood. The adjustments weren’t difficult to make, just took some time. I left room for additional sanding once I get to that point of adding the frieze and molding. I guess I should have faired more of the stern frames way back when, I had very little room to fit in the quarter gallery stern window piece. All I needed was enough to fit the frame properly, so with lots and lots of sand, test, sand, test I got the fit. I faired the frames at the time to match a cut-out from the plans, still the variance here is only about 1-2mm, so I guess I should have faired the upper frames a little more. In my defense my focus at the time was not under-sizing the lower counter to match the plan template, which it does so… This was fun. I elected to use my jeweler’s saw to cut the upper counter excess to fit. I had made the counter extra long knowing it would be easier to cut with this saw. I just stayed well outside the line and sanded it to the line after cutting. I’ll have to admit to being a bit skeptical about the bending properties of a 1/64th strip of wood - sure Chuck can do it, but could I. It turned out deceptively easy to bend, though it took me more than the required nine pieces (I’m not saying how many) to get a fit I liked. Once complete it looks exceptionally nice, a perfect design to finish off the top of the transom. Per the monograph I painted the top of the rail and stern frames black where it eventually will meet up with the side railings and left outside of that bright. I added the frames, windows and back fillers, sanded it flush and added a coat of WOP. I elected to fill the seam on the outside edge and paint it blue. Though it is covered by a carving and won’t show much I didn’t like the seam and I thought the blue would highlight the carving. Time will tell. I could have mixed a little white into my flat black paint for the stern view of the galley windows, but where is the fun in that, instead I brushed on a little white weathering powder from my Doc O’Brien set. The frames are centered, just a trick of shadows and lighting making it appear a bit off. I also checked with the other windows in place to make sure it had a consistent look. I did not sand the window frames, at all, way to fragile for me. I did though lightly brush on a coat of WOP. Frankly I think the light laser char gives them more depth and character. The transom looks a little beat-up at this point, there is a lot of molding and carving to add in addition to the upper and lower counter friezes. It’s prepped for when that time comes. Until then I turn my attention to the fascinating challenge of building the two galleries, did I mention its all very complex. Thanks as always for your likes and comments and for stopping by to take a look.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Much ado about nothing. MSW is an extremely well run site, fast, both in response time and uploading large files, and is an amazing community of people. Facebook is a widely accepted social media platform and all that’s needed for any offline messages. Those that don’t want to follow MSW on Facebook, like those that do, need only patience to wait for the site to return during extremely rare times the site is down. I also received notice from NRG, another good reason to become a member there. I’m sure there won’t be another 2013, and even if there is I, like others, create my build logs offline and post them, ensuring they won’t be lost like my long detailed Pegasus log. I can count on one hand the number of times the site has been down. The impressive availability of the site doesn’t require or benefit from any changes to the IT structure, nor the expense that would go with it. MSW is not free to run. I’d encourage everyone to click on the donations tab on the upper right of the home page a periodically make a contribution to keep the site we all love up and running with the latest technology. Thank you admins!

-

Really well done! All your extra touches, especially the friezes, headworks, and your deft touch on the scroll work really make this version of Sphinx stand out above all others. Consistent with your usual outstanding work your result and the well defined and detailed log you've provided will be the preeminent guide all others can follow. Very impressive!

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That’s one great looking transom! Nice work on the cannon carriages, you must have hours in on removing char so well, do you have a secret method😊?

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I first learned, then quickly purchased, about Quad hands from @Delf. Another nice thing for those interested is there are several models and sizes, all are available on Amazon. It is indeed a great tool. Another option for weathering powders is Doc O’Briens Weathering Powders, I got mine from MicroMart. I Have a dedicated brush set for application. I agree with Ron, both are excellent additions, whichever option, to the workshop. Appreciate his sharing their versatility with his excellent build.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Great looking model Rusty. Very crisp and tight!

- 201 replies

-

- Duchess of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I found Chucks recommended approach of measuring and cutting the sills based on the measurement between bulkheads up next to the former, not at the outside where they go, critical to keeping the ship square. I agree with Chuck, you can find and make adjustments to recover from a 3mm variance. It’s a really big model, there are and will be more such opportunities. I also cut out the side profile of the quarter port framing and frequently held it as a guide to positioning and length. It seems some of yours may not be beveled to fit the angle. Hang in there, you can make the need adjustments and keep moving forward.

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I could think of a few others, but thank you very much.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Frank, I appreciate your saying so.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ha. We’re going on an Alaskan cruise starting from Vancouver in September, let me know how it goes. I hope you both have a great trip! Don’t forget the hard shell golf bag carrier to fill with the Alaskan Yellow Cedar 😂

- 345 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.