-

Posts

13,370 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Looking good so far! Your previous experience in planking is paying off nicely now.

- 146 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

I've made two-part pins as you suggest (but at a larger scale). The handle section simply has a short stub to insert in the rail. I did not have issues with collet 'pinch'. In your case, the lower part could simply be of wire - no turning required.

-

My rule of thumb for laying up is that the strands end up roughly 45 degrees to the axis of the rope. If you look at Chuck's line, you'll see this clearly.

-

OK, Clare, why wasn't it tiled like the rest of the roof? So, you are going ahead with the modifications. Good for you. I find rubbing alcohol (95%) does a good job of dissolving PVA and yellow glues. The advantage is that the very low water content won't warp the wood. It also evaporates very quickly so that you can continue work using the same pieces in just minutes. Looking good!

-

Thanks, Eberhard. So you do in fact have a black hole, albeit a small one, in your workshop! One excellent book on faux finishes is Professional Painted Finishes by Ina Brousseau Marx, Allen and Robert Marx, Watson Guptill, 1991.

-

Silly question, Eberhard; you say the completed belaying pin usually shears off cleanly. How did you manage to retrieve it? I find small turned parts fly off forever more often then not - and they are bigger then your belaying pins!

-

Amazing what a little practice does! This is quite a challenging hull shape to plank, by the way. The moisture/hair dryer method is a good one for refining the shape and fit.

- 90 replies

-

- Model Shipways

- muscongus bay lobster smack

-

(and 1 more)

Tagged with:

-

The official name for those stoppers are pawls. Nice detail of the rings attached for a rope. Setting them manually would be dangerous! I thought that they were kicked by foot, but this shows that wasn't the way it was done. Thank you for pointing this out, Siggi. It looks as if the end that engages the whelp of the capstan is a solid block.

-

Always nice to see unusual subjects modeled! This barge is interesting; do you know why the rudder is so long?

- 17 replies

-

- Vistula barge

- card

-

(and 1 more)

Tagged with:

-

I guess you passed the test, Kevin! Well done. Now, how about the other side...?

- 1,132 replies

-

Hounds and Cheeks for Endeavour finished in 1761

druxey replied to DaveBaxt's topic in Masting, rigging and sails

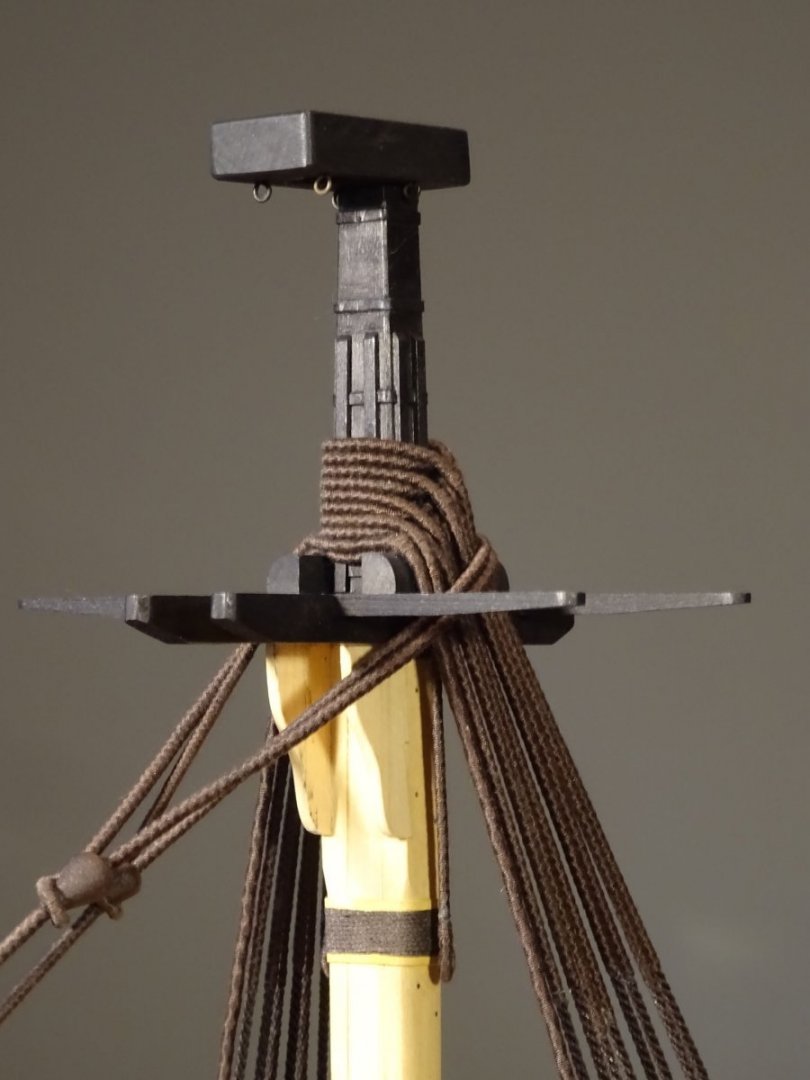

The cheeks extend up to the hounds (where the mast head begins) and the bibbs are scored with a zig-zag in to the front of them. The trestle trees sit on top of both of these. -

As well as elastic bands, try to get the planks tighter together using clips on the bulkheads. It will save a lot of filling and sanding!

- 90 replies

-

- Model Shipways

- muscongus bay lobster smack

-

(and 1 more)

Tagged with:

-

Congratulations, Gregg, on finishing your model. Every model is a learning process and on each one your skills improve. Proof of that is in the shaping of your mast and spars. What was tough the first time comes much more easily each time. Painting parts off-model before assembly is always preferable if possible, instead of masking off. Your sails and rigging look very good. Enjoy the next challenge!

- 29 replies

-

- Model Shipways

- muscongus bay lobster smack

-

(and 1 more)

Tagged with:

-

Those aft wale planks are very tricky. It's nothing to do with age, Kevin! You still have the last plank to shape, so that will test you even more! Looking very good so far.

- 1,132 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.