-

Posts

13,275 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Tricky work, applying inside bulwark planking when all the outer detail is already installed!

-

That is a very nicely laid out planking job, Well done!

- 64 replies

-

- amati

- victory models

-

(and 1 more)

Tagged with:

-

Yup; we're interested, Steven! You always find such interesting and different subjects.

- 508 replies

-

Untangling and rerigging or start from scratch?

druxey replied to Rgpracer's topic in Masting, rigging and sails

There were many 'experimental' drawings made; the standard steering wheel didn't need a detailed explanation with the drawing. The example above was obviously a proposal that didn't eventually make the cut. -

Figureheads of English East Indiamen 1750

druxey replied to bruce d's topic in Nautical/Naval History

Although I cannot locate these drawings in his book, the style of illustration is very similar to those of L.G. Carr Laughton. (Old Ship's Figureheads & Sterns, 1925.) -

Alas, I'm of an age to know these things!

- 2,696 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Remember - the full-size builders didn't have elaborate building stations with jigs! Just plumb lines, squares and measuring tools. It helps to remember to check vertical in all three planes as you erect each frame: 1) vertical as seen from the side 2) at right angles across the keel 3) center of cross-spall centered above the keel No-one will notice, once you model is complete and mounted vertically, that your keel is very slightly canted to one side!

-

HH: you might consider 'progressive' vari-focal lens spectacles. Since I got mine, I've rarely needed an Optivisor - something that i wore extensively over the previous 10 years.

- 2,696 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Your leather looks very good. Nicely McGyvered!

- 51 replies

-

- Model Shipways

- norwegian sailing pram

-

(and 1 more)

Tagged with:

-

Yup, it's an 'advanced' all right! If a piece buckles as you describe, you can often selectively re-wet the buckled bit and 'massage' it into the shape you want. But it looks like you are coping well with that tricky countered stern.

- 146 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

It appears that the lowest strakes do not narrow sufficiently as they come into the bow and stem. Once you have lined out the planking runs, you must follow them accurately, or cumulative 'creep' will occur and you'll end up with the same problem again. Also, your garboard could end a little further aft as well to help things out.

-

Harold Hahn method

druxey replied to Essayons's topic in Building, Framing, Planking and plating a ships hull and deck

In fairness to Hahn, he used this for small-scale models, not large 1:48 scale ones. The wastage was significantly less. -

Harold Hahn method

druxey replied to Essayons's topic in Building, Framing, Planking and plating a ships hull and deck

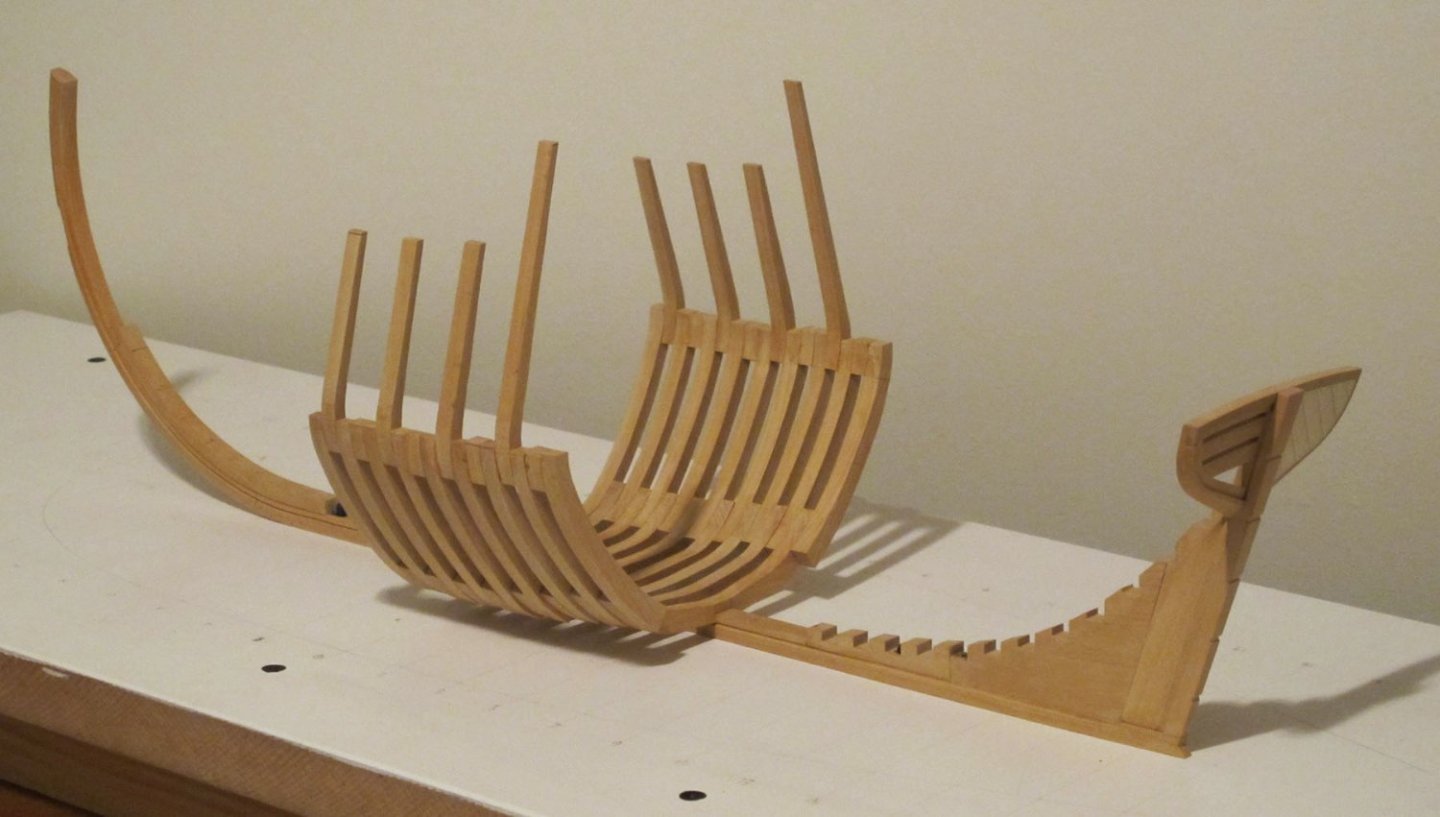

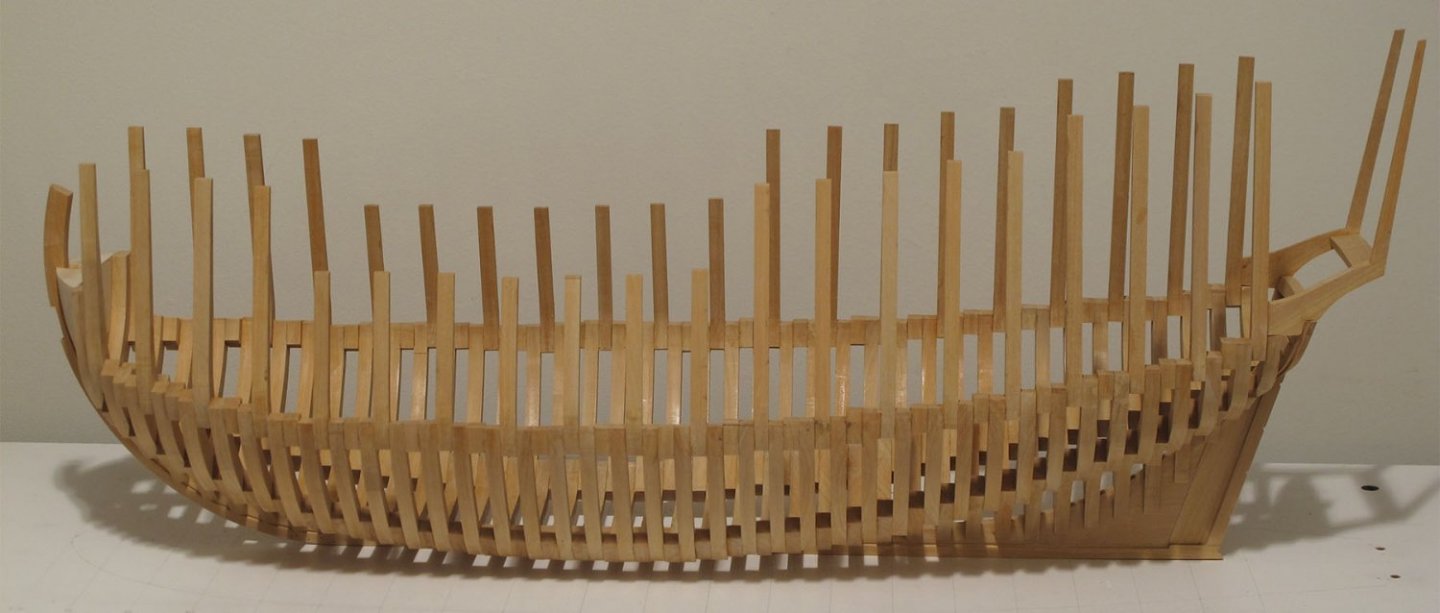

Here is an example of the open 'Navy Board' style of framing. Note that the model was built right side up, with no wasted extended toptimbers. -

Well done! Your final result looks great.

- 12 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.