-

Posts

13,377 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

gun carrige colour

druxey replied to Ray's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I suspect this may be a 'captain's choice' decision. I'm not certain that there is a definitive answer to this question. Anyone else? -

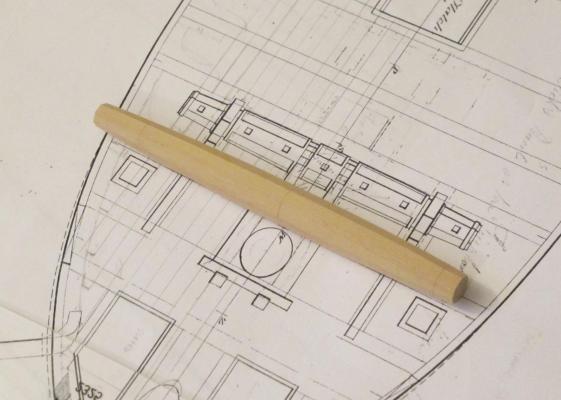

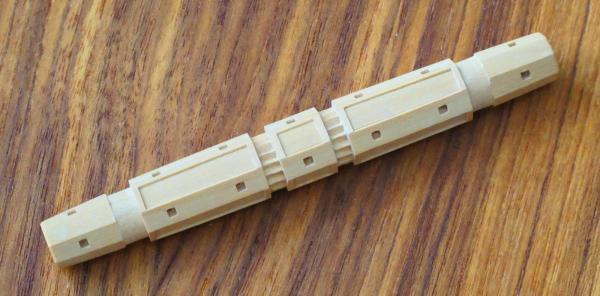

The low areas are the basic windlass. Juan Carlos. The high areas are all thin wood added on afterwards. It's how the original was built: these wear areas can be replaced.

-

HMS Euryalus by egen -

druxey replied to egen's topic in - Build logs for subjects built 1801 - 1850

Your deck framing and cants for the cabin bulkheads look very good. Well done! -

Good going, Ben. You are going to switch back to your other model just when things are getting interesting??

- 147 replies

-

Very, very nice, Gary! And the riding bitt crosspieces took a lot of abuse. They had a wear strip on the aft side as well that were easily changed, as well as the main crosspiece, as you mention.

-

You are absolutely correct: the thickness of pencil lines matters! If you draw your own plans, these should be as thin as possible. In the case of plans such as you show, it can be a problem. One test might be to know the thickness of the bulkhead material and see which side of the lines of the slots match this. If that is not possible, then I'd cut to the outside of the lines. It's easier to sand a bit more off than glue it on again!

-

ancre Le Fleuron 1729 by rekon54 - 1:24

druxey replied to rekon54's topic in - Build logs for subjects built 1501 - 1750

Thanks for answering my question, Rekon! -

Castello boxwood, Janos.

-

It's the real thing, Janos.

-

Whew! It's amazing what can happen in a split second of inattention or distraction. That, I'm glad to read, was NOT a disaster this time.

-

An example of an octagon cut using the method I've described is shown here. The overall length of this windlass at 1:48 scale is about 4".

-

ancre Le Fleuron 1729 by rekon54 - 1:24

druxey replied to rekon54's topic in - Build logs for subjects built 1501 - 1750

Oh, my! Now that is ornamental 'ironwork'. Seems almost a pity to blacken it.... Beautifully done. As a matter of interest, what kind of soldering mat are you using there? -

Definitely you are correct, Robin: this 1853 mention was a successor Alfred, the third of the name.

-

A promising beginning! Looking forward to reading more as you research her.

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

-

Well, a schooner shouldn't take as long to build as a frigate, Allan! All the best on this new model and also for your annual getaway.

- 86 replies

-

- schooner

- effie m morrisey

-

(and 1 more)

Tagged with:

-

Nice progress. Now you can imagine what it's like for Greg as he frames a complete hull!

- 147 replies

-

And I innocently thought this thread was about ship modelling.... Isn't it?

- 1,148 replies

-

Echo by oneslim - cross-section

druxey replied to oneslim's topic in - Build logs for subjects built 1751 - 1800

Well, Bob, I for one am delighted that you are here to report. I'm sorry for your health issues and wish you a speedy and uneventful recovery. Get young guys to move heavy stuff in future, please! Take care, now. -

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

druxey replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

You continue to surprise and amaze us! Not only do the details look terrific, but the the overall effect has visual unity; a very tricky balance to achieve.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Is there no stopping you in any material??? Real leathering is a pretty good trick, Michael.

- 2,215 replies

-

Plank Beveling and stealers

druxey replied to bigpav's topic in Building, Framing, Planking and plating a ships hull and deck

Whoops: you are quite right, Russ! I apologize. It was rather late last night when I wrote that. Drop planks, i.e. reducing two strakes to one, or three to two will be required on a bluff-bowed hull form.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.