Nunnehi (Don)

NRG Member-

Posts

321 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nunnehi (Don)

-

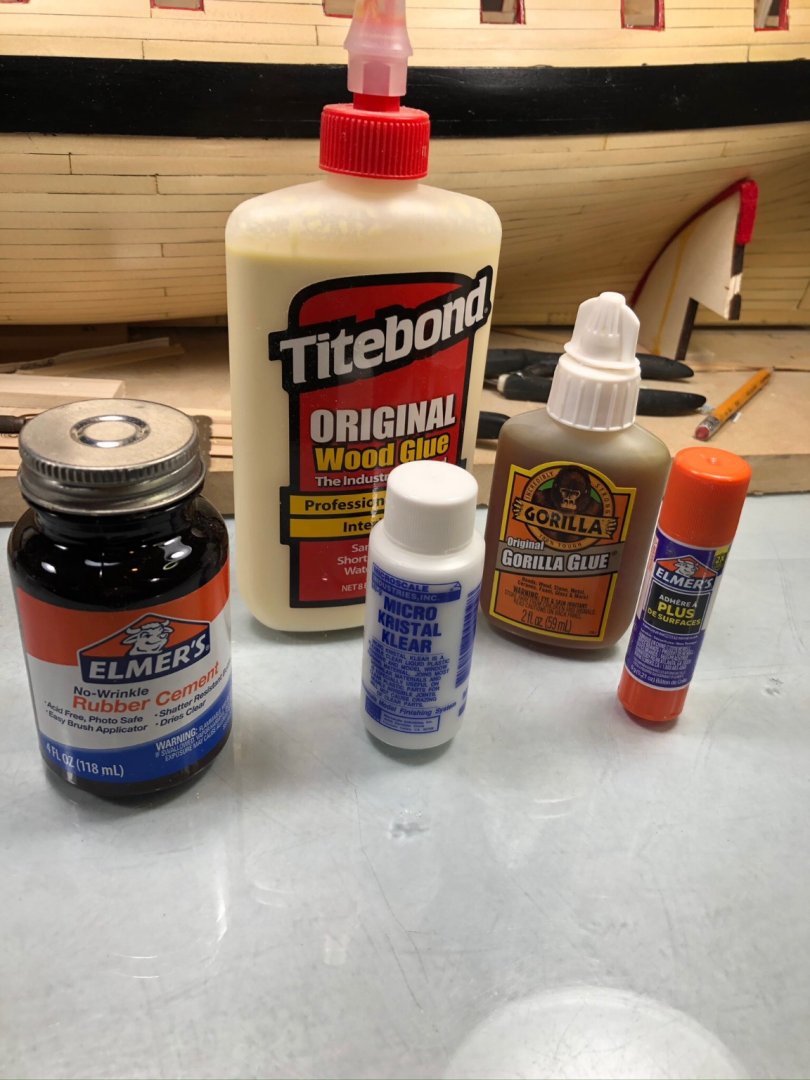

Don’t want to leave the impression that CA is the be-all and end-all, it’s not. While it’s great in the plastic world, particularly for photo-etch detail stuff, and filling seams and gaps, these also have their place and may be the better tool for the job. Micro crystal clear is great for attaching clear plastic parts and filling portholes. I’ve never used wefalck’s varnish technique and would like to give it a try. Don

-

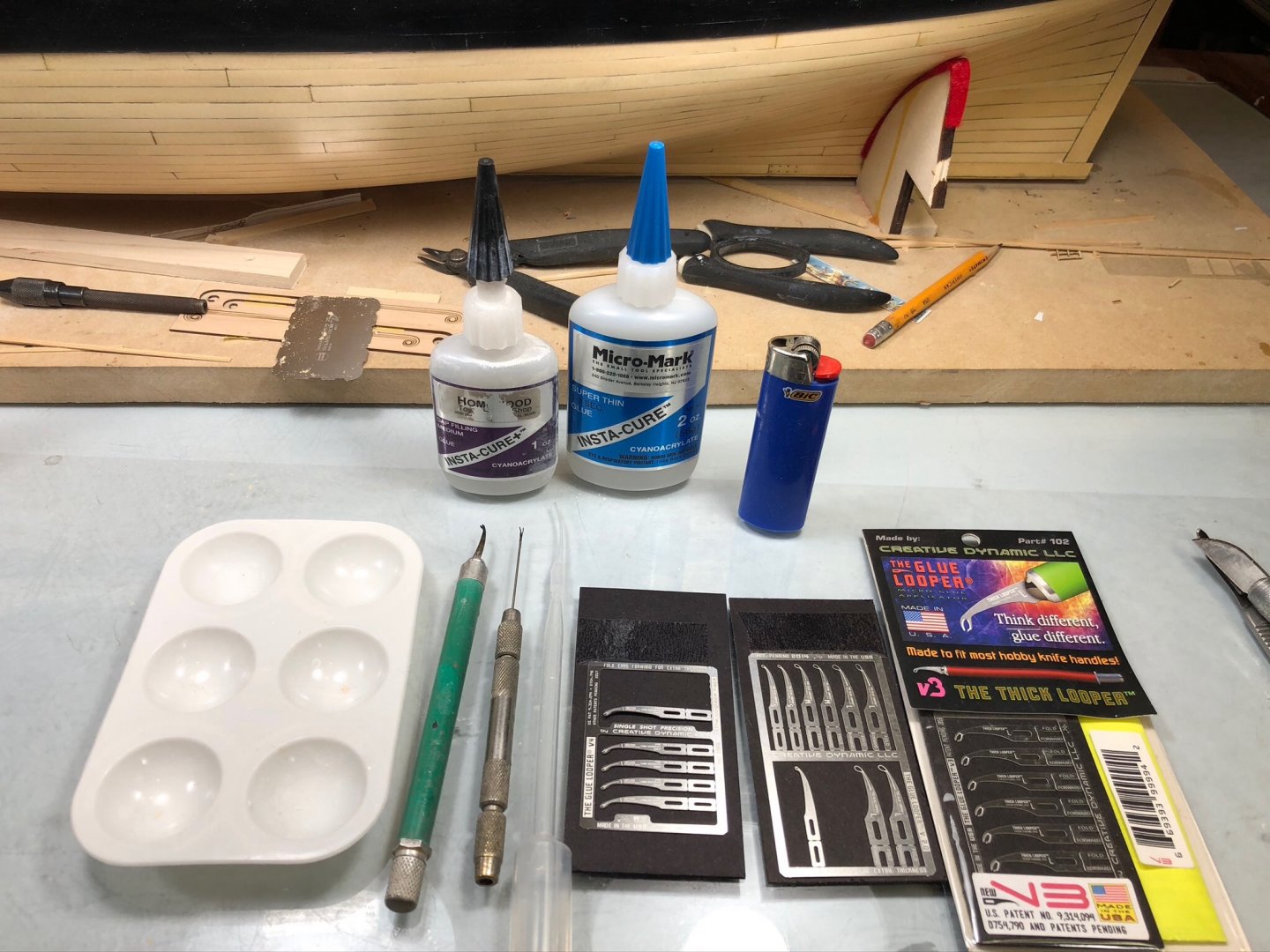

I like CA and use quite a bit on both wood and plastic and agree with the above comments with respect to using large sewing needles chucked in a pin vice to apply it, particularly the super thin version. I’ve also used an applicator called a glue-looper a bit and have been happy with it. CA will remain liquid for a couple of hours outside the bottle and I like the small, cheap paint mixing trays to hold it for dipping. A plastic pipette with a fine tip is also useful for both applying and for transferring from the bottle to the tray. You can get fine tip extensions for the bottles but I still like using the tray. How much to use is a matter of practice but it’s real easy to use more than necessary and make a mess. There’s been some discussion about its longevity but I’ve got models over 20 years old that are holding together just fine. Don

-

Derek, your log is a master class in how to do stuff, I really appreciate it! Don

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Bob, I really feel for you guys. My Son lives in Portland and it’s been really bad there too. Hopefully as you get into the winter rainy season it will clear up. All we have to deal with here are hurricanes. This year we’ve had more than we normally get but we’re about 250 miles inland so by the time they get here, it’s mostly rain with some occasional strong gusts. Now, Katrina was a whole ‘nother thing - we had many hours of constant 70+mph wind and many tornados, it was scary. Look forward to updates on your build when when you can get to it. I’m really interested in your solution to your rigging challenge, it’s going to be a really beautiful model! Don

-

Very, very nice - beautiful work! Don

- 54 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Brian, Those lanterns are incredible! Very impressive! I am very much looking forward to seeing them lit on the finished model! Don

-

Thanks, Bob. I’m very lucky to have a finished basement and a Wife doesn’t like stairs so She never goes down there😉. My oldest Son also did a stint as an apprentice cabinetmaker and built a desk that fits me like I wanted. It’s simple but has some good storage space and cutouts for power, etc. Thanks again, Don

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for the likes, guys, I really appreciate it! Don

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Fuji, you’re off to a great start - will be following with interest! Don

- 70 replies

-

- calypso

- billing boats

-

(and 1 more)

Tagged with:

-

I use a lot of CA and have had no problems with the exception that I have had a partially used bottle that seemed to lose its ability to work properly after sitting for an extended time. You can probably write a book on applicators and methods but experience and following the various logs here is a good start. I’ve used it successfully on wood, plastic, ABS, resin, photo etch brass, and combinations of all the above. Yes, I occasionally glue my fingers together or to whatever I’m working, and this can cause some heartburn, but if you’re careful this will not cause too much damage other than a temporary loss of finger prints. I’ve also got a couple of models I built over 20 years ago that are not showing any deterioration. Don

-

Bob, that’s very, very nice, the sails add so much! Beautiful work! Don

- 87 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I, too have the Artesania Latina scraper and used it on my Medway build - it worked great! Unfortunately, AL is out of business and a brief check with Ages of Sail and a couple of other sources didn’t show any in stock. Hopefully someone else will pick up on this. Don

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, Bob! Your Pen Duick is gorgeous - I’m deeply impressed with how you’ve painted it and finished the deck! First rate! Don

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, Chuck, I really appreciate it! Your design and instructions, as well as the excellent build logs and other information here, have made this doable here in the wilderness of north Alabama😸. Don

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks, Bob! I’m really enjoying your build and getting a lot from it - you’re making great progress! Thanks also for the likes, I appreciate it! Don

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

A bit of an update.......... l’ve started the planking process and have completed the portion from the wales up. While it’s not anywhere near the level of some of the other builds here, it’s starting to look like a ship - lots of cleanup in the future! Don

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

B.E., Thanks much for the kind words, I really appreciate it. Your work sets the standard that I that I try to emulate! Don

- 36 replies

-

- calypso

- billing boats

-

(and 1 more)

Tagged with:

-

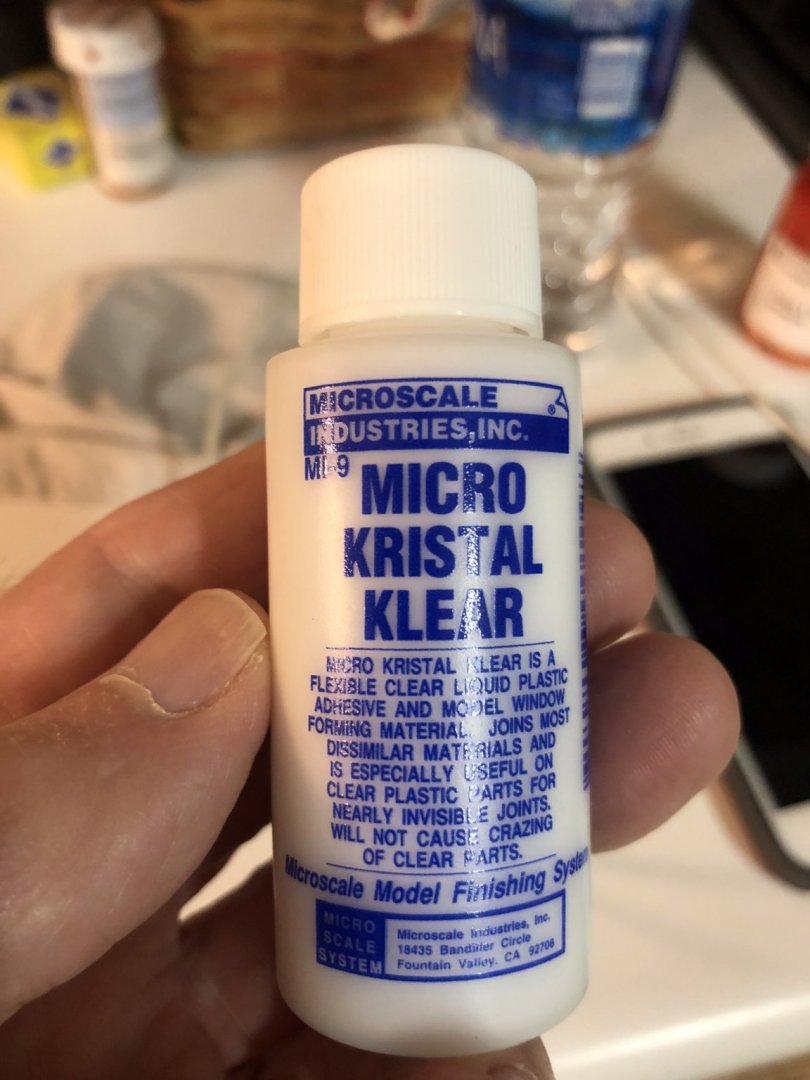

Fuji, Thanks much for the kind words, I really appreciate it! Good luck with your build and start a log, I would very much like to see some pics as you move forward with it! I used Micro Kristal Klear from Microscale on all the portholes and windows, applied with a toothpick. On the larger cabin windows, I first glued the acetate that was supplied with the kit using the Kristal Klear, then backfilled the opening once the acetate was firmly in place. It takes several hours for the Kristal Klear to set up and actually turn clear (it is opaque white at first) and it is not as transparent as the acetate, so if you’re going to detail the internal spaces, this may not be the way to go. Thanks again, Don

- 36 replies

-

- calypso

- billing boats

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.