-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Good to hear that you're well enough to be back in the shipyard, Mobbise. I missed seeing your updates. Great looking work.

- 1,279 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Gil, Just an FYI... Hahn also used RIT to dye wood. He wanted a "worn" blue so dyed the wood and then lightly sanded it.

- 755 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

Very nicely done, Gil. The difference is eye-catching to say the least.

- 755 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

Steam plank bending tool

mtaylor replied to captainkangaroo's topic in Modeling tools and Workshop Equipment

Go buy her a brand new one.. and then take the old one.- 15 replies

-

- planking tool

- plank bender

-

(and 1 more)

Tagged with:

-

Looking for old article from MSW 1

mtaylor replied to acdblujns's topic in CAD and 3D Modelling/Drafting Plans with Software

Pat, Update it and contact Chuck (the admin) about putting it in the database. -

Piet, What Joe and Joe (Joe-Joe?) said goes for me too. I like what you've done. Will you be shooting some dull coat on her?

-

Looks good, Dan. Minor detail.. For the eyes used for breeching and the run out tackle, the French usually used through bolts with a square washer and a forelock on the outside of the hull.

- 241 replies

-

- queen annes revenge

- pirate

-

(and 2 more)

Tagged with:

-

Thanks for the kind words of support. I'm not so much off and running, but off and walking. I ran the first time and we all know where that went. Now that I think about it, I'm more like treading through a minefield at this point. Nenad, Thanks for the Pink Floyd. That used to be a theme song where I used to work... That and Sam Cooke's "Chain Gang".

-

Hi Udo, Just because Hahn didn't plank his ship doesn't mean it can't be done using his plans for framing. He does leave a lot of areas to builder. Have the planking tutorials been any help? Post a picture of the area you're having an issue with and let the collective mind of MSW have a look.

-

Looking for old article from MSW 1

mtaylor replied to acdblujns's topic in CAD and 3D Modelling/Drafting Plans with Software

That is an old article. Sadly, Cut-Throat Jake passed away. It's possible that someone may have the article though with all the iterations of Photoshop since then, it may work entirely different. -

Fair-a-frame

mtaylor replied to Don Quixote's topic in Building, Framing, Planking and plating a ships hull and deck

Brian, Have a look here: http://modelshipworldforum.com/ship-model-materials-and-tools.php -

Thinking of getting the AL Artesania Latina HMS Hermione

mtaylor replied to Lucius Molchany's topic in Wood ship model kits

I appears that there is only one build going on at this time: http://modelshipworld.com/index.php?/topic/2649-hermione-la-fayette-by-nickvn-artesania-latina-second-wooden-ship-built/?hl=hermione -

Please please please..... DO NOT PUT Personal Info in a post to a seller. Use the PM's. Posts are visible by entire Internet. You're giving spammers and miscreants information that is useful to them. Check out the sellers history of posts....are they well known? They must have a minimum of 25 posts to reply to a topic or post a topic in this forum. Look at their post history. If paying a seller...Use PayPal. They have great buyer protections. Always select "paying for goods and services" If you dont get the goods or services...you have a good chance of getting your money back. Scammers usually insist you send it as "sending money for friends and family" because its less likely you can get your money back. Personal information is things such as phone numbers, email addys, home addresses, etc.

-

Help with king plank

mtaylor replied to captainbob's topic in Building, Framing, Planking and plating a ships hull and deck

Gary, I tend to agree with you but that method seems to be for English ships... ???? Maybe not??? Some of the French ships have it the way Bob shows with the gratings flush to the king planks. Thus, it might have served a dual purpose, strength (marginally) and also as a coaming. The weird part is that some French ships had their coamings above the king plank level. The Licorne has them for most of the main deck, stopping short of the great cabin and on the quarter deck but not the forecastle. I think there had to be some pupose other than decorative. -

Raymond, The way you're building your frames now is much like the Hahn method. That method does leave a few things to be desired in that it wastes a lot of wood, and if every joint isn't perfect the frame won't be as strong, however, it is faster. Cutting out each futtock and joining them saves the wood, ensures each joint is precise and if chocks are added, it can be exactly as the real ones were made. The disadvantage is that it's slower. As Russ said, build it your way.

-

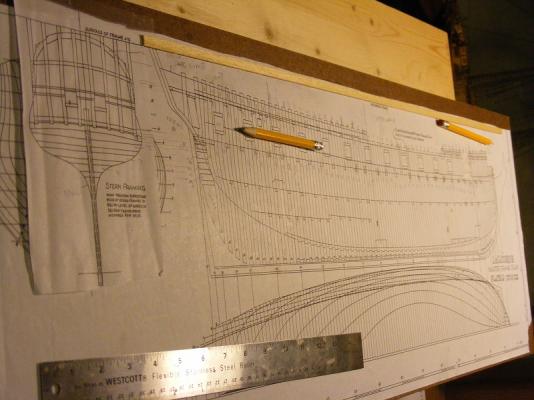

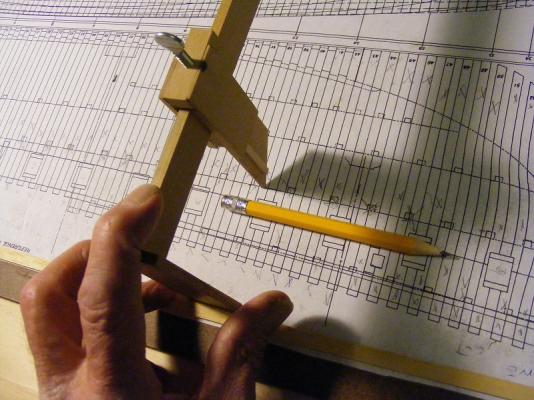

Update time... Things have not been quiet in the shipyard. I laminated the plans to some MDF and attached a strip of wood at the reference line. Also attached the stern framing to this so as not to mis-read any critical dimension. The strip allows me to use the Ed Tool without any induced errors from having it canted slightly. I've marked all the plans with appropriate reference marks and rescanned them all. Also broke up Version 1.0 in order salvage certain bits.. like everything along the centerline... bitts, grates, pin rails, pumps, capstan, etc., some or all of the deck beams but none of the deck planking. Also salvaged the mast steps and the stern framing. I'll use the stern framing for some references. I'm currently cutting out with as much precision as I can muster, a new build board. I noted that on the old one, there were some frame notches that we either too deep or not deep enough. Stupidity on my part. I'll be re-using the previous version of the frame squaring jig (on the right in the picture). Hopefully, in the next week or so, I can start cutting the keel, deadwood, and stem. Since the wood for framing won't be here until early May, I'm planning on building some sub-assemblies such as most of the deck furniture. I've located a local source of good birch plywood, and am considering Woodcraft or the local source for masting materials and some other items.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.