-

Posts

1,696 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

HMS Granado 1742 Kit - CAF Model - 1:48 Scale

scrubbyj427 replied to cafmodel's topic in Wood ship model kits

Excellent work Tom! -

That looks great Ben! This stage is a nice reward after all that planking. JJ

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck, Where is the show this weekend?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks awesome Chuck! out of curiosity, even though the forward gunports are typically closed, would there have been guns up there or did the ports serve another use? Same with the aft most ones?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

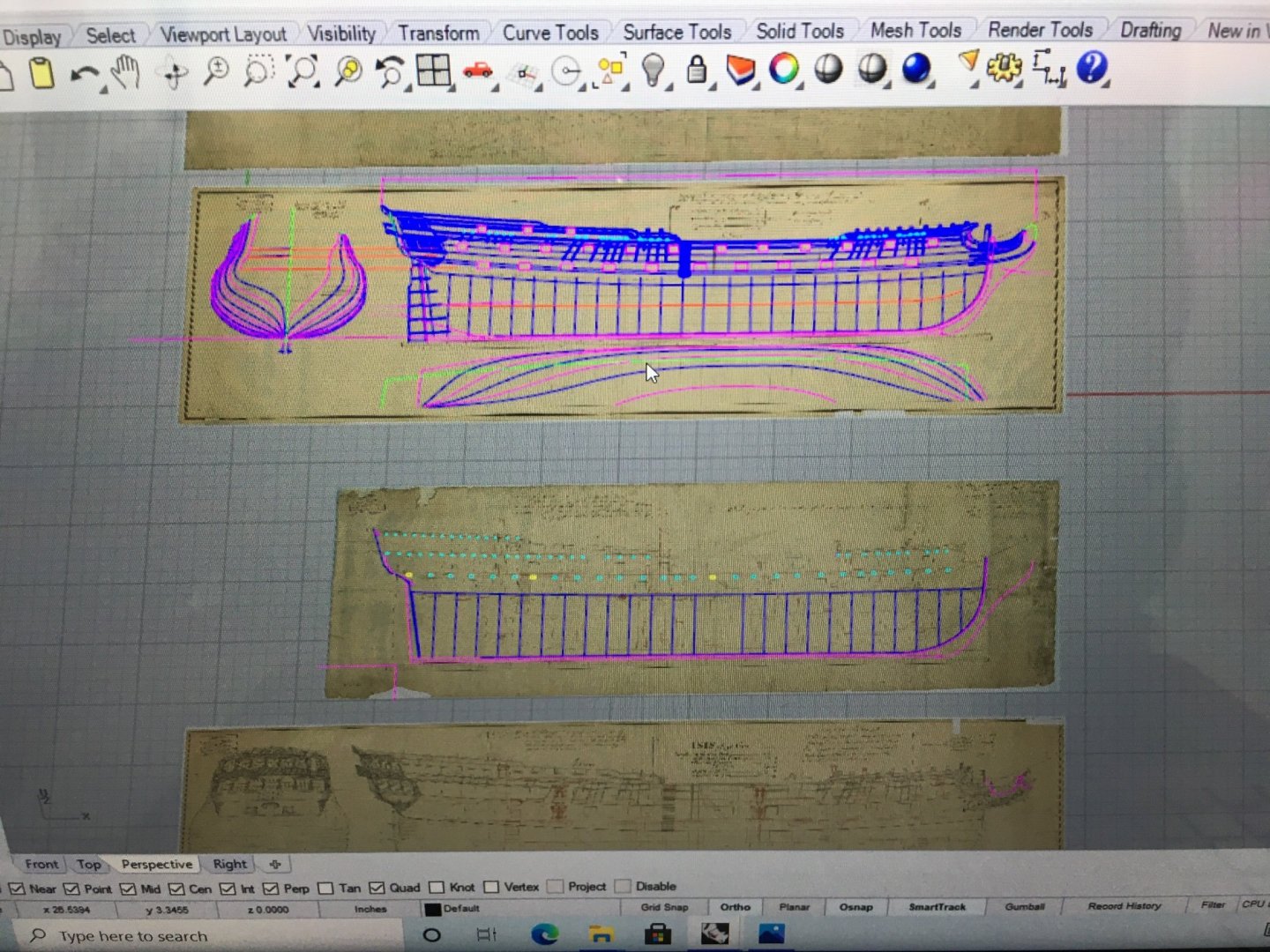

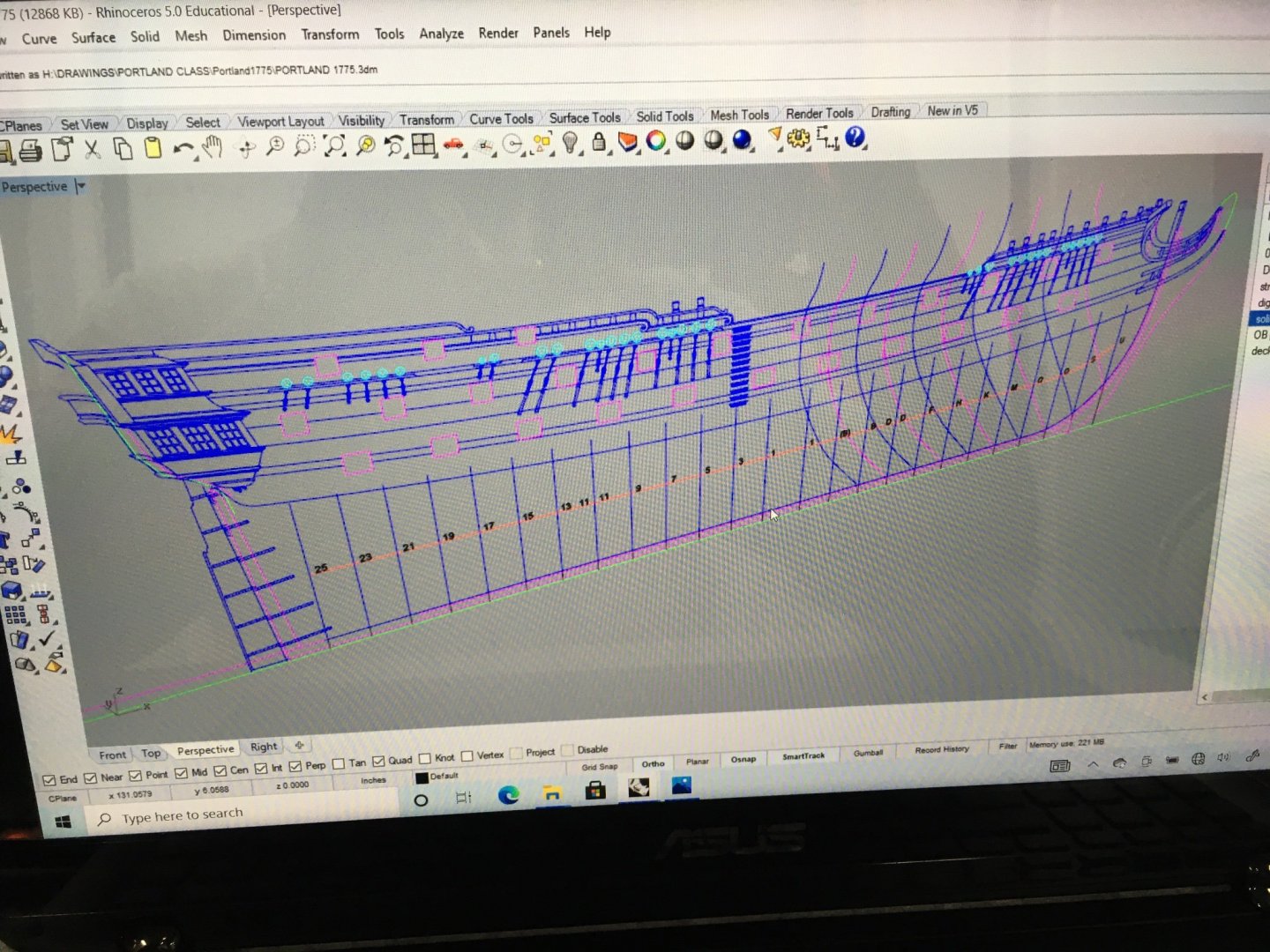

Thanks Rusty and Glenn. looking forward to some more updates on your Winnie, Rusty. Glenn, your cheerful is a delight on the eyes, can’t wait to see your Winnie get going. I finished up chapter 5 last week, took care of the rest of the gun ports and the small stuff which is a convenient stopping point as my mobile shipyard has sold to new owners so my tools and supplies are packed and my Winnie is crated up in a wonderful smelling custom pine box. Hopefully I’ll get back to her soon, but In the meantime I’m working on developing another project for the future, HMS Portland 1770, a 50 gun 4th rate at 1:48. I’m aiming for the Joseph marshal painting, similar to how the Winnie is built. I’m hoping to get the hull surfaced soon and the basic structure and framing built. JJ

-

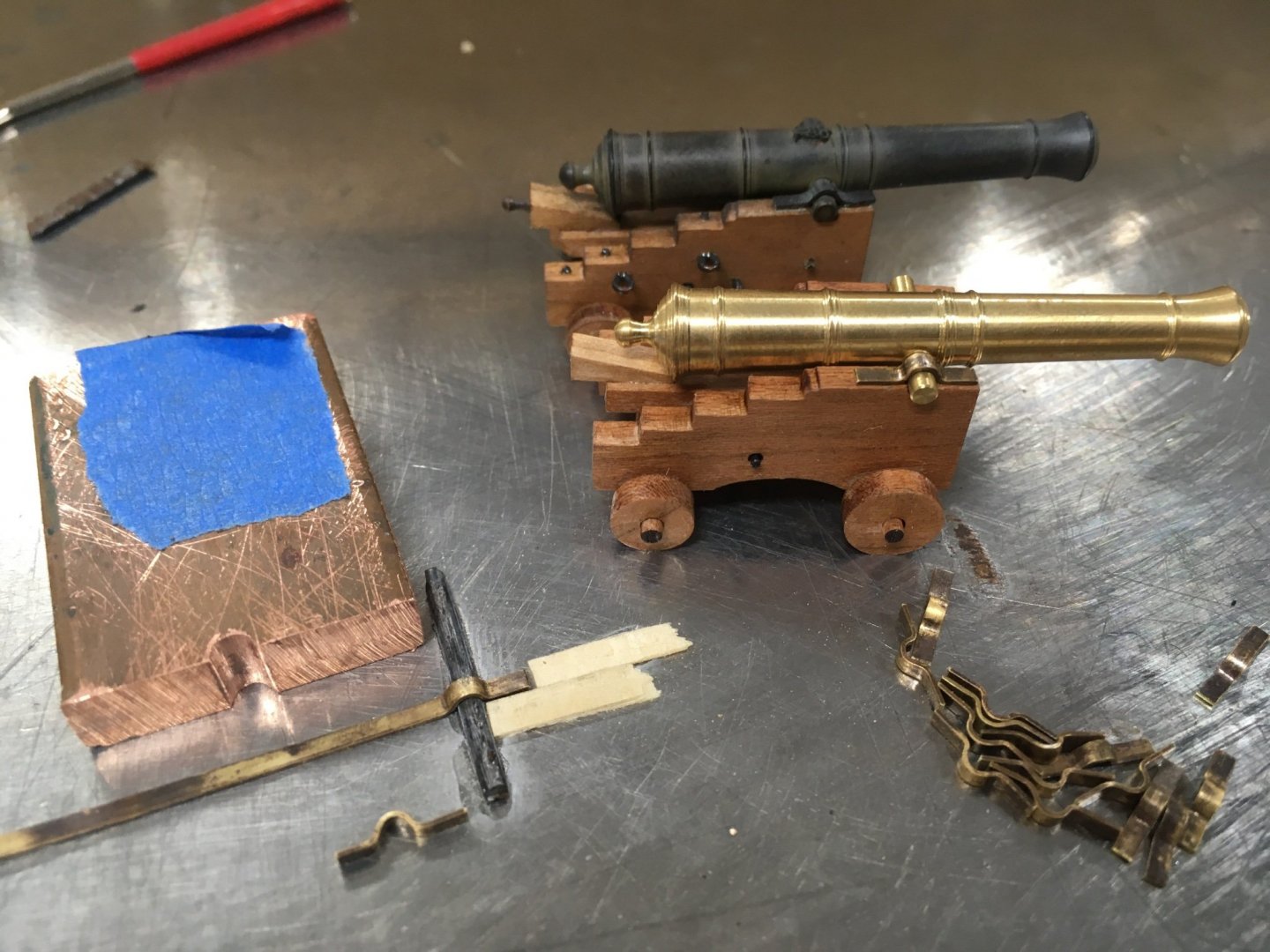

Been plugging away at guns, hinges and metal work. Still a long way to go but it’s starting to shape up. Need to add more details to the carriages as well as tackle. I Also got the capstan sitting temporarily, may take a crack at the cherry one and see how it looks but I like the way the AYC one looks so far. JJ

-

Papegojan 1627 by mati - FINISHED - 1/48

scrubbyj427 replied to mati's topic in - Build logs for subjects built 1501 - 1750

Beautiful work! -

Excellent design work Chuck! That really finishes it off. Looks spectacular!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Papegojan 1627 by mati - FINISHED - 1/48

scrubbyj427 replied to mati's topic in - Build logs for subjects built 1501 - 1750

Good lord this thing is a stunning piece of work! I want to build it but I don’t think I could come remotely close to these results! -

Thank you Don! I’m enjoying this group project very much. Everyone is doing a great job.

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Fred and Chuck and the likes. the cheeks and hair brackets certainly are not easy but they are indeed worth the effort. If I were to do it again I think I would change a few things as the learning curve was pretty big on that one. Fred, I knew you would spot those bolts!... don’t worry, I’m on it. I’ve got days of little messes to clean up before I move onto chapter 7. JJ

-

Looking really good Don. You’re moving right along, paving the way for the rest of us. JJ

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.