-

Posts

528 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by harvey1847

-

It´s Amazing that in one or two months ago from the "crash" we´re all remaking our logs!! Yours has help me a lot. Thanks for posting again!!! Regards. Daniel.

-

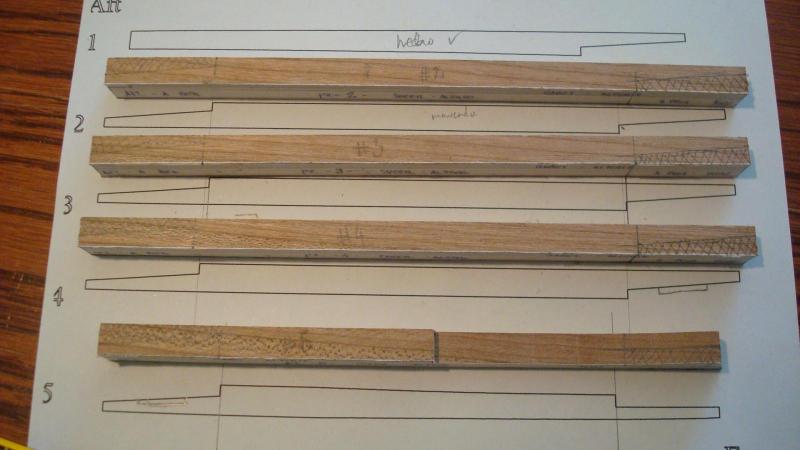

Hello all! Here´s where I am on right now. In order to lay all the frames I have so far, I need to do the keel. Here are the pieces marked with pencil. It has reminded me someway the work I did back in 2011 with the pillars and the joist in my house. It´s amazing how things changed working from 1:1 to 1:48. Good Weekend! Daniel.

-

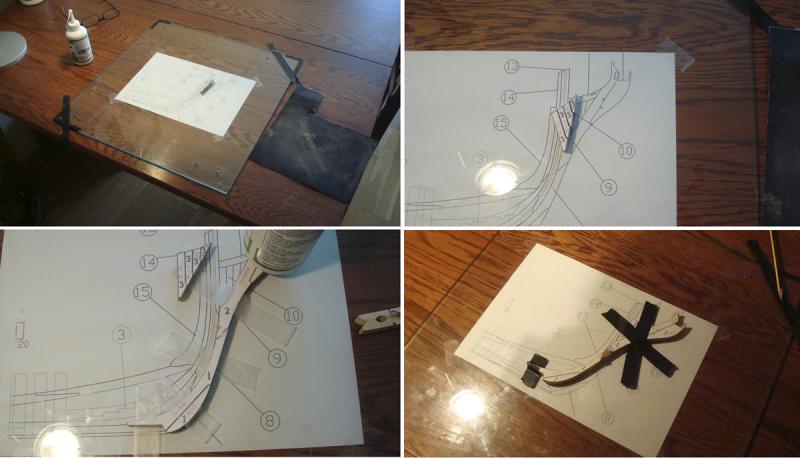

And the thing is completed!! HU HA! (Chimo Bayo) Using a piece of glass has been very useful to ensure the whole piece is flat. I took it from a trash bin on the street. It´s amazing what we trash. I guess is this market economy we all live in. I did my way. (Frank Sinatra) I have glued first all the #3 chocks, then I glued the #2 mainpiece to the #5 bobstay, then #1 + #1 gripes and then the whole thing. I have to repeat the #4 piece. Do not Know why but it does not fit. More scrap pieces!! Good Night! Daniel.

-

Amazing... What a hands god gave to you!! Daniel.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Thank you all for answering! Three replies in day is World record in my log... Thanks rocker for the advice. I did just to try and it will not happen again. I hold the piece using my finger nails, actually I look like a guitar player. They are quite helpful. Pete I am not going to simulate the caulking. I´ll do it with the deck planking only. I don´t like the caulking stuff. I hope that with the finish with wax or tung oil (not decide yet) all the lines will come out. The joints are there! Grant, The stern jig was a copy of the John´s and Bublehead logs from MSW 1.0. I separated the top of the upper jig 17.9cm. Jonh separated 16.5cm. If I have had to do it again I would use the three of them not just the upper one. Back to the workshop! (my living room) Thanks! Daniel. info about treenailing (copied from the Matrim´s notes) 1/48 scale Frames, no 61 bit (.039", 1mm), hull planking, no 76 bit (.020" .5mm), deck beams, knees, bitts, etc, no 68 bit (.031" .8mm), and for securing the frames and the keelson, a no 52 bit (.0625" 1.5mm) will do fine.

-

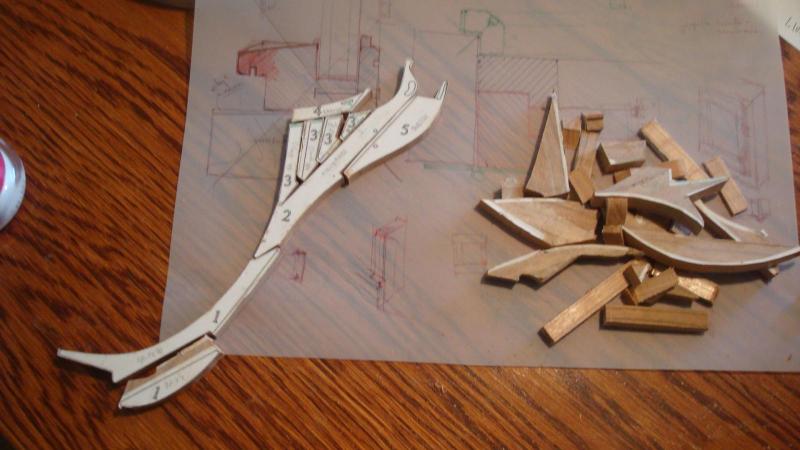

Hello all and thanks ! (We are just four or five... ) I have stolen a little time just to cut the parts of the stem. My intention is to glue all the four pieces #3 together and then sand and fair them. That´s why I´ve left some extrawood above where they joint with piece #4. Here are the rough cut pieces and the lefties. Then in order to sand them I always ensure the perpendicular of the table sand machine. Here is the tyniest piece I´ve ever sand with the disc sand. And here is the result of sanding. I have to fair them much more. I hope to have some time tomorow and glue the whole thing together. We´ll see. Best wishes! Daniel.

-

HMS Euryalus by egen -

harvey1847 replied to egen's topic in - Build logs for subjects built 1801 - 1850

Really nice work Egen! Good pics and very good explanation about them. I will folow you for sure! Regards. Daniel. -

At last a Spanish ship! Here I am being from Madrid close to the MNM and I am building one from Her Majesty Service ship... Shame on me! Here´s a link with some photos of the San Felipe completed http://www.modelismonaval.com/galeria/category/75-san-felipe-de-san-martin and here is the homepage of the museum. You can sail on it in english and you can ask for plans. Send me a PM if you´re interested on and I´ll explain you how to get them. Link to the museum: http://www.armada.mde.es/ArmadaPortal/page/Portal/ArmadaEspannola/ciencia_museo/prefLang_en/ And here´s a link with a video (youtube) with a very good music from Master & Comander: Good Good Luck with this endevour! Daniel.

-

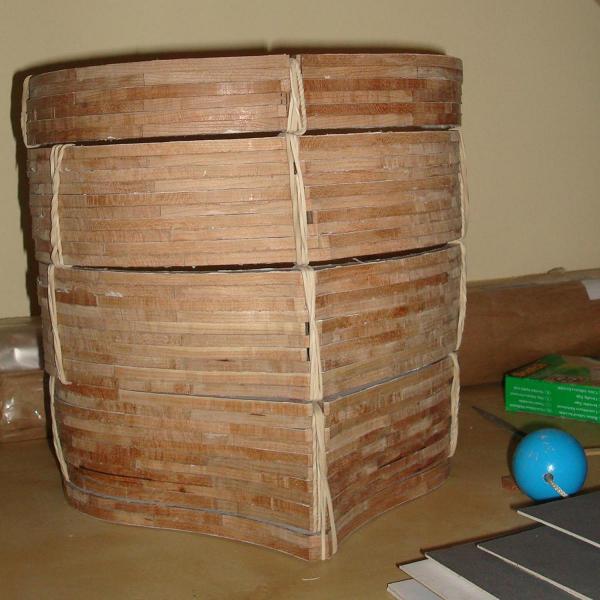

Good morning people! I have completed all the aft frames from #19 till #0 The dead flat one. Number 3 is not in the picture. I´ve allready printed out the copies for the fore frames so the next days I will be busy again writing and cutting more patterns. Back to the post #4!! Enjoy your day. Daniel.

-

Set, ready and Go!! Here´s a ruler at 1:24, hope it will help you...When print the ruler in the scale box just put NONE. 2 feet at 1:24 = 1 inch 4 feet at 1:48 = 1 inch. the plan at 1:48 fill completed an A4 (297x210mm) (I do not Know the ANSI size you have there in USA) and at 1:24 which is exactlly the double will fill an A2 (594x420mm) and an A2 is FOUR A4´s... We´re all waiting you to make some dust so we can start to blame you!! Best wishes! Daniel. 24 to 1 ruler A4.pdf

-

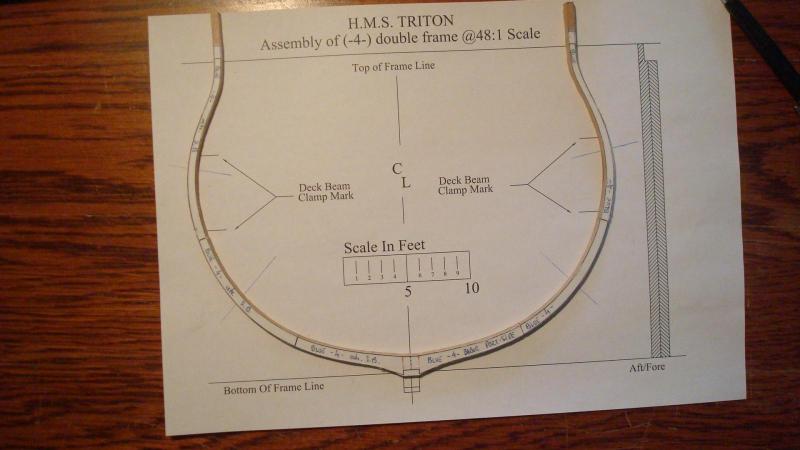

Hello Olphart! I like this jig better than the other one. I have never use a jig to assemble the frames. I glue the "blue pieces" to the assembly patern with "Pritt" or similar. What I do and I have found it very important is to extend the line where the futtoks of the red ones come together (you can see a pencil pointing the intersection line) Then with a brush and water I remove the paper and glue the "red pieces" with white glue using clamps. As you can see I leave some extrawood at the end of the frames. There will be time enough to cut it later when all the frames were in place. Good work so far and excellent workshop you´ve got there. Good luck! Daniel.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.