-

Posts

1,490 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Maury S

-

This is NOT a full review of the book, hence not in the Book Review Section...just some comments: The Evolution of the Wooden Ship by Basil Greenhill with illustrations by Sam Manning has been extremely helpful. Sam Manning's drawings are tremendous and answer so many detail questions that arise in the course of a model construction. Maury

-

Museums used to require linen lines. Has that changed over the years? Chuck is probably the biggest supplier of scale rope. What are his thoughts? Maury

-

Very interesting deck weathering. I LIKE IT. Chuck Doan's work is amazing and an inspiration to us all. Maury

-

Druxey, All the info I've garnered about off-center masts indicate they were plumb (head does NOT lean to the center). This countered the sailing impact of the centerboard being off center (on the other side of center-line). I've seen quite a few examples in my journey with this build. Re: glue, I learned of this at Modelshipworld link: https://modelshipworld.com/topic/943-gluing-techniques-and-associated-information/page/4/?tab=comments#comment-628081 post #93 (Thank you Vossiewulf). The dye really stands out under the black light so you can clean up smudges and spills before it sets. Maury

-

While waiting for glue to dry, I knocked out the blanks for the two mast steps. Notches around the several keelson timbers cut on the Byrnes saw using a sled. Mortises will be cut once the masts are ready to be set. The fore mast is on center-line and the main is off-center to right of the centerboard well. At this stage, the starboard side has one more strake than the port. BTW, I've started using Yellow Instrument Glue from Luthiers Merchantle Int'l. Seems to hold every bit as well as Titebond, and has a fluorescent dye that shows up under black light for better cleanup. About the same cost. Maury

-

Chuck, You are bringing Kit making to a new level!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

More ceiling strakes. Long-nosed clamps where they fit, Pressure from gantry above deeper into the hull. Butt pattern is the same as the outer planking, but not on the same frames. Maury

-

She's back on the building board and ready for planking the ceilings. Since the centerboard is off-center, the keelsons are not equal port and starboard. The first course of ceiling planks will line up for the subsequent strakes. The first pieces are just spiled, bent and laid in place. Some more tweaking to be done. By the way, since Chuck has been praising Alaskan Yellow Cedar, I thought I'd give it a try on the interior. It's certainly a lot softer than box. When I sand the edges, there is some fiber left hanging so I'll have to be careful about that. There is an obvious cedar aroma, so I won't be getting any moths (or shipworms). Maury

-

Druxey, That's what I'm thinking. It exposes the frames to wear but I expect the bulwark frames were abutted to the top futtocks and were replaceable. Dowmer, there is no other info. about the boat than the Chapelle drawing and commentary in the National Watercraft Collection. Maury

-

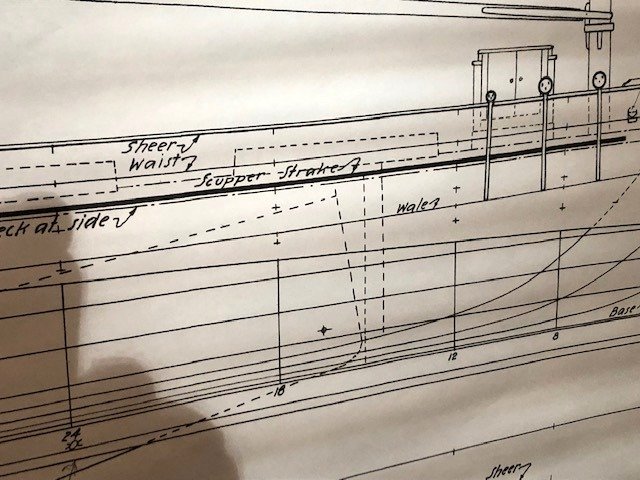

Back to the shipyard after a vacation. Attached is a photo of a portion of Chapelle's original drawing showing a "Scupper Strake" just above the wale. Does this mean that there is a continuous opening in the bulwarks or that scupper holes were placed as needed in that strake? All evidence I've gathered indicates these were "wet boats". Getting water off the deck would have been important. Appreciate any comments. Maury

-

What else can be said? Thanks for the journey. Maury

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

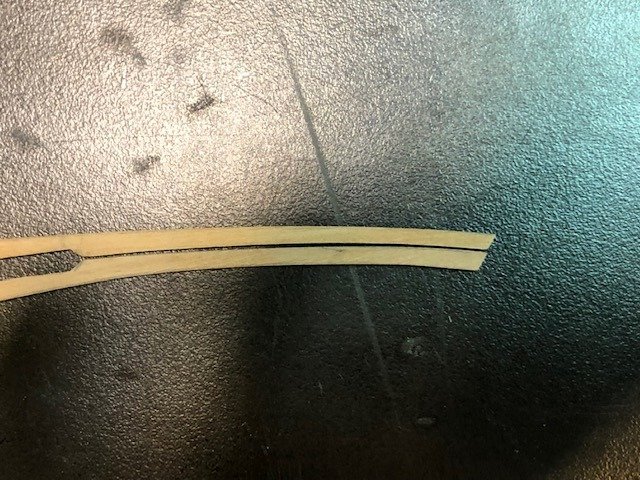

Whiskey strake is in. Counter is planked. I'll finish the transom before reattaching to the building board for the interior. Rubber band is to protect the stem. Maury

-

And such a clean shop. OK, OK, OK, I'll clean up mine this weekend. Maury

-

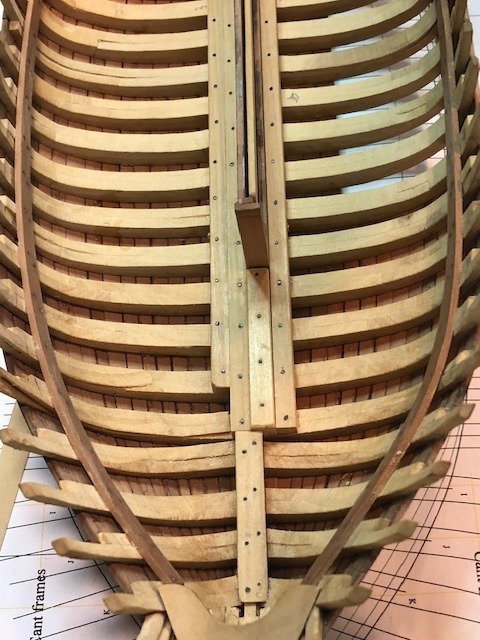

Starboard Planking is done. I'll finish the port side, leaving a portion unplanked. Three strakes to go, then some sanding and touchup. Maury

-

Ed, So where is it going to be displayed when finished? A new room added to the house? Maury

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Getting near the end of the outer planking...The remaining starboard drop plank(s) have been spiled but not yet bent. They were shaped and fit but not glued in place 'til everything lines up properly. Maury

-

Ed, It looks like you've got a good system laid out and that's what any captain would do with the running rigging. Maury

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Planking continues. Using the sacrificial bass wood for spiling patterns has really simplified the process. It's really nothing like using card for patterns. Being able to sand to a tight tolerance on the pattern makes a huge difference. You can see the un-planked window on the port side developing. Maury

-

Heads up! For all you Bench bashers...Current Harbor Freight catalog has the 60" work bench on sale for $119.99. (I think you need the coupon). (I have no connection to HF) Maury

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.