barkeater

-

Posts

387 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by barkeater

-

-

4 hours ago, Ronald-V said:

I think it would be handy to line the hull off with some tape/string of to determine the run of the planks...at least that's what I have experience with. Not sure if you can do that without this and just calculate the total width.

I've used the method that Chuck Passaro outlined in his youtube videos.

But I'm curious if there are people who work without bands, and can shine their light on this

Ronald,

Think of the hull as one big batten instead of dividing it up into multiple smaller battens. I plank from the keel up. Now, I know at the top planking at the bulwarks, if I've cut out my bulkheads correctly, I will have a true or correct run of the planks. The needed taper of planks in between the keel and the top plank can therefore be calculated. Using the entire hull gives me the advantage that I can correct any tapers that need to be made gradually rather than having to make larger or greater corrections in a briefer run. This is especially useful along the stern where you can have an area where you need to increase your widths and have another area where you need to taper. I don't mean to disparage other methods, but this method works best for me.

Rich

- robert952, Ronald-V and John Murray

-

3

3

-

I measure the run of each bulkhead once the first planking is done and pencil them in on the hull at their appropriate bulkhead. I then do a run of 10 planks and remeasure allowing me to adjust plank widths ahead of time repeating every 10 planks. This prevents me from running into trouble and having to use a drop a plank or stealer. I do trenails and plank lengths in scale. To help facilitate this I may add false bulkheads where needed to allow me to stay below 20 feet to a plank in scale.

Rich

- robert952 and John Murray

-

2

2

-

Mark,

As Jim said, you can purchase milled lumber which is actually easier than milling your own for the planking or deck. The exception would be if you want to include exotic woods such as yellow heart or ebony where milled pieces can't be obtained. The one machine I would find tough to replace by other means is a scroll saw for cutting odd shapes. I have a table saw and a thickness planner. I find the thickness planner very useful for making sure the stock I personally milled is uniform. I also have a mini lathe. I don't have a drill press. Welcome to scratch building. It's a lot of fun and it opens up a lot more opportunities as to what you can build.

Rich

-

What scale? I've used the liquid glass product before, and it works well as long as your openings are not too big. I work in 1/48 scale. If your window is divided into multiple panes, it makes it easier. I've used thread to make panes in the frame. Also, the liquid glass is semi opaque. Lastly, I have bought mica chips which I'm going to try on my current build but have no experience with yet.

Rich

-

- GrandpaPhil, dvm27, Thukydides and 6 others

-

9

9

-

If you are talking about furniture (steering wheel, ships bell, catheads etc.), I pin these with one of the brass-colored nails they include in kits. For glue I use cyanoacrylate on the nail shank and a small bit of wood glue on the wood parts where applicable (areas free of varnish).

Rich

-

I use room temperature water, but I would think 20 minutes should do it for 2mm. Mahogany tends to be a bit brittle. Don't overly force it. With a tight bend you may need to partially bend it and repeat your water bath before bending more.

Rich

-

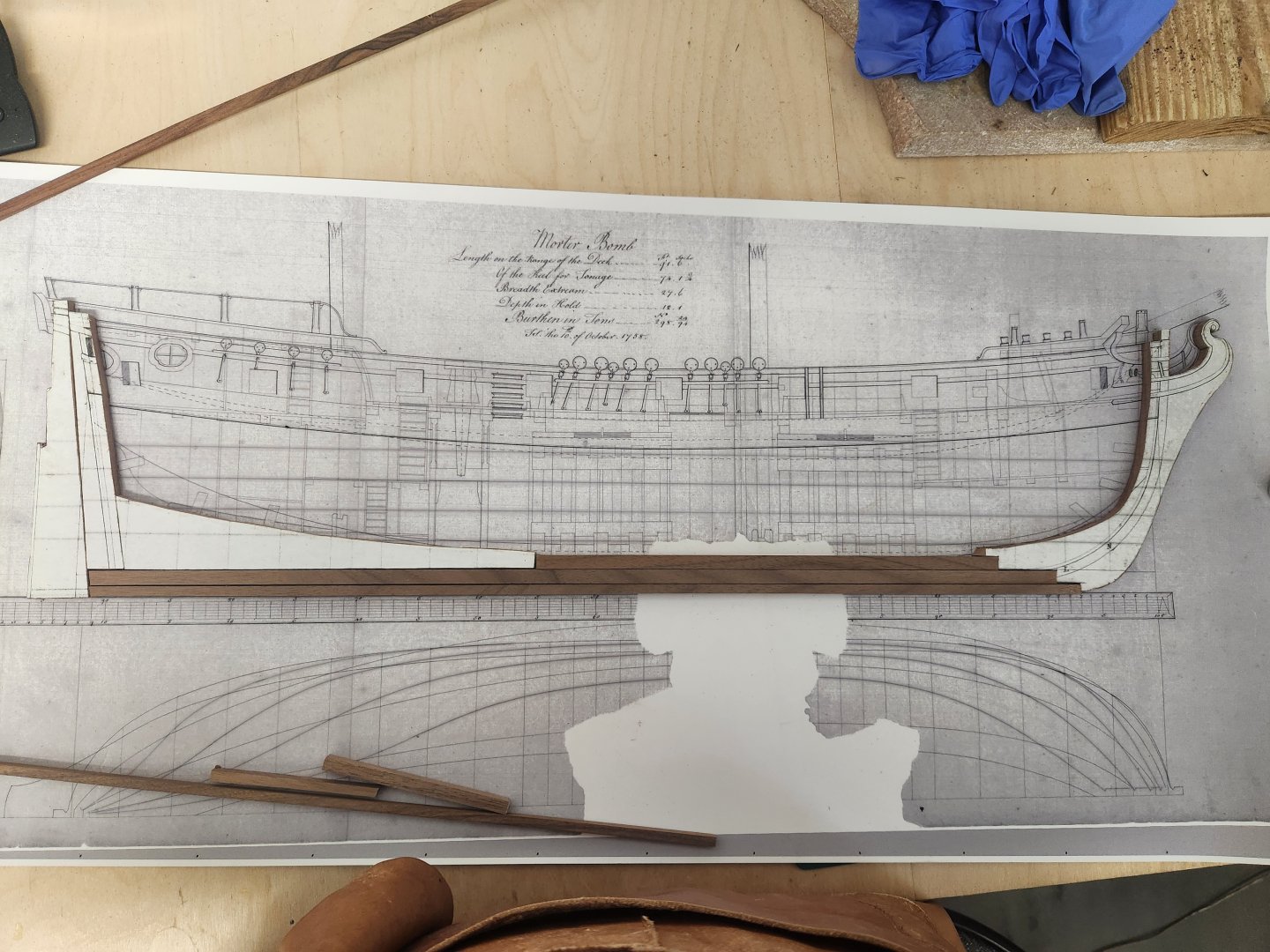

The Carcass bomb vessel saw action in the Seven Years War as well as the American Revolution. Horatio Nelson served on her as a midshipman during the arctic exploration of 1773. The build will be double plank on bulkhead. Plans are from the National Maritime Museum. It will be as originally commissioned with mortars which were removed for the arctic exploration.

- Javelin, GrandpaPhil, druxey and 4 others

-

7

7

-

-

Gregg,

I noticed in your drawing that there isn't a yard arm cleat. I don't know where you are on your build, but these help your lines from slipping when under tension. They are a lot easier to do before the yard is hung. They are easy to fabricate, I first drill the cleat for the trenail. Then I glue it in place and drill into the yard itself then insert a glue coated trenail. They varied over time and country of origin. The ones I did would be from 1660 to 1815 according to James Lees "The Masting and Rigging of English Ships of War

Rich

-

Easier would be to do each block on their own line going round the yard twice then lashing the afferent and efferent portions tight to grip the yard. If you do the two-block idea one line with the third used to tie it all together it becomes more complicated. Especially tying in that third line while keeping the other two tight to the yard. For looks you want all blocks to have the same length, and this is a lot easier to do doing one at a time. Added to this, you want your port to match your starboard. Easier to get it exact if you match up port and starboard blocks one at a time. If you really want to put 2 on 1 use a clove hitch and do the third separate.

Rich

-

-

-

I install all sections of the masts and platforms prior to adding the shrouds. Even if you tied in the shroud just distally, you still have to have the platforms in place as your lines need to go outside of the crosstrees and bolsters. Plus, you attach the shrouds in a specific order. The order could get messed up if hanging free for any length of time. You have to leave enough room to fit in the heel of the topmast or topgallant and this is tight. Easier to fit the lines one at a time rather than all at once and still keeping them looking neat and in correct order. Also, the topmast and topgallant have to a fit tightly together and adjustment with shrouds in place may make it more difficult. You want to get your masts all aligned midline and with the correct angle. I feel for me this is easier to set this up all at once and glue it rather than doing it in stages.

Rich

-

You could try fly tying thread. It comes in many colors and thicknesses.

Rich

-

I use fly tying scissors to cut the thread I use to splice or seize the lines which is 6/0 or 136 denier. For cutting the lines themselves which are heavier I use Bonsai scissors.

Rich

- thibaultron, Justin P., paul ron and 2 others

-

5

5

-

I've used Mahogany on builds. You are correct in that it has a tendency to crack or split when bending. I soak in water or steam in the microwave in a wet paper towel then use an electric bender. If using the microwave be sure not to put your face in the steam as I found out I was allergic to Bolivian Rosewood this way with a rash that looked like poison ivy. My advice is to bend it in stages if it is cracking on you. Put a little bend then resoak or steam and bend it a little more until you get the bend you need. I also use Ebony which wants to split a lot and I get it to work with the same technique.

Rich

-

Actually, your planking for a first build is not bad other than you needed to taper more. You can either taper or drop a plank. Tapering won't look good but since this is the first planking of a double plank, it won't show. Dropping a plank at the bow and perhaps the stern would also work and again since this is the first planking, it won't show. Either way just try to get it smooth without using too much filler. For your second planking I would suggest the following. You should have 17 planks if the final plank width is the same as the first planking. You can divide up into battens but with only 17 plank runs what I would do is measure in mm the length you have at each bulkhead. This gives you the taper you need overall for the hull. . Pencil the numbers on the first planking right at the bulkheads where you won't be affixing the next planks. Do a run of say 4 or 5 planks and then remeasure and adjust your taper. Another 4 or 5 and remeasure. This allows you to taper gradually and not plank yourself into trouble with the taper. I used this on my Badger and L'Unite and prefer it over dividing up into battens.

Rich

- catopower, Desertanimal, mtaylor and 1 other

-

4

4

-

Another vessel from the revolutionary era that was probably colonial built was the armed brig, Badger. This may not fit you needs as it was Admiral Nelson's first command seeing service during the war in the West Indies.

- thibaultron, Canute and mtaylor

-

3

3

-

The lines you indicate are not actually part of the shrouds but rather separate single or double blocked lines whose blocks are hooked or spliced to eye bolts in the channel. This arrangement would be used for yard lifts, braces, tyes, clue lines et al. The use of blocks allows for tension adjustments to rigging or raising and lowering of the yards. Your rigging plans should show further elucidate their relationship to the masts or yards Typically, they would be tied off to a belaying pin, cleat or stanchion. The one in the middle in this case has the line originating from the single block at the channel then spliced to the line going from the other block through a third block and the probably belayed to a pin rail.

Rich

-

-

I third Chuck's recommendation. If you want to see what beech decking looks like, look in thread "snapshot of members current builds". I've put a few pictures of L'Unite in there as I've been doing the build and it has beech planking.

Rich

i also secom

- mtaylor and Chuck Seiler

-

2

2

-

The right side is the bow, and the left is the stern in the first image top left. The figure directly below is a puzzle to me as it is different. Maybe somebody else knows. Also, the lines are not the ribs but rather depict the contour of the ship. Ribs are more numerous however if you are going to do a plank on bulkhead and not a plank on frame, you can use the lines for your bulkheads.

Richard

This was already answered as I was formulating an answer. Did not intend to repeat.

- JacquesCousteau, KLarsen, mtaylor and 1 other

-

4

4

-

The brass blackening agents work as a powder coating on the surface and therefore could be and was pulled off when you stuck tape on. You can help keep the powder coating on by using a sealant. I always give any blackened part an overcoat of Testor's Dulcote (non-shiny) which locks it in. The more you handle blackened parts the greater the risk of removing the coating and I would never use tape on them.

Richard

- SiriusVoyager, hollowneck, grsjax and 5 others

-

8

8

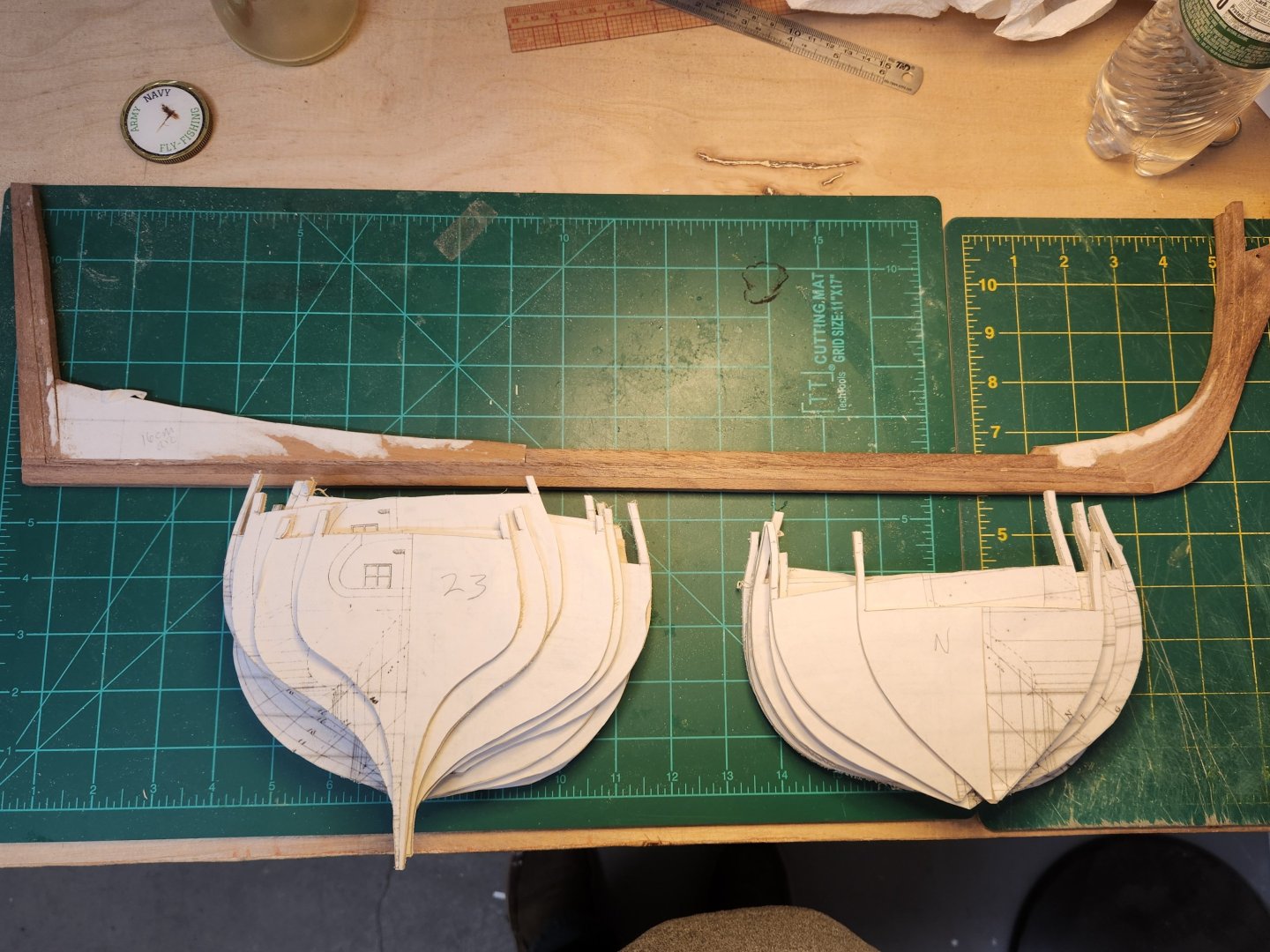

Carcass 1758 by barkeater - scale 1:48

in - Build logs for subjects built 1751 - 1800

Posted

The bulkheads have been installed as well as the sub decks for both the main deck and quarterdecks. There is a foredeck, but this is open to the main deck along its aft portion. I will not do a subdeck but rather a single plank on beams. I found two slightly different sets of plans from the NMR. One has two masts while the other has three and the quarterdecks are different lengths. I went with the 3 masts as this is how she is depicted by John Cleverly the Younger on her Nordic expedition with the Racehorse. Next job is fairing.