-

Posts

355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jhearl

-

Best glue for paper templates?

jhearl replied to andante's topic in Modeling tools and Workshop Equipment

I second glue sticks. I used to use rubber cement, but it always dried out between boats and is messy to use anyway and it is expensive. Glue sticks are cheap, work very well and there's no wait time between applying the template and cutting the wood. I'd never go back to rubber cement. -

Another site with some pretty awesome stuff is from one of the sponsors here - Scale Hardware https://www.modelmotorcars.com/museum/scale-hardware-model-museum/ If you're into cars, there are several other pages of models that you can get to from the top level of their site - https://www.modelmotorcars.com/ Click on the Museum button at the top of the page.

-

Getting Back Into The Hobby After 45+ Years

jhearl replied to Tom in NC's topic in New member Introductions

Al, at Bluejacket, is working on a large-scale cross-section of Morgan. See this newsletter from them - http://campaign.r20.constantcontact.com/render?m=1105166336677&ca=ea8525a8-1642-40ab-b1c0-a0c1d55c3998 Cheers - John -

White caulking?

jhearl replied to Bare_Koala's topic in Building, Framing, Planking and plating a ships hull and deck

The Dumas Chris Craft kit included styrene strips for the caulking. See this video - -

If you decide on Latham, you might want to consider getting a copy of American Fishing Schooners by Howard Chapelle. It's a tremendous resource for these boats. https://www.amazon.com/American-Fishing-Schooners-1825-1935/dp/039303755X/ref=sr_1_1?ie=UTF8&qid=1537706149&sr=8-1&keywords=american+fishing+schooner It's an expensive book, but well worth it in my opinion. Another model to consider is Bluejacket's Smuggler. Similar boat and same scale as Latham but solid-hull construction instead of plank-on-bulkhead. http://www.bluejacketinc.com/kits/smuggler.htm Cheers - John

-

Cutting Planks

jhearl replied to sfotinos's topic in Building, Framing, Planking and plating a ships hull and deck

-

New to ship modelling? But what do you build first?

jhearl replied to MSW's topic in Wood ship model kits

I'm a little surprised you didn't mention any of Bluejacket's entry-level kits. The first kit I successfully completed many years ago was the Grand Banks dory. As well, I think some of the easier solid-hull kits, like Yankee Hero are a good choice for those with little or no experience. Cheers - John -

Recommendations For A Good Milling Machine

jhearl replied to Thistle17's topic in Modeling tools and Workshop Equipment

I would suggest getting the tilting angle table (3750) over the right angle attachment. It's much more versatile since you can set it to any angle between 0 and 90. Cheers - John -

I have this quaint habit of looking at real ships when I want to know how something is done. Here are a few examples: Cheers - John

-

My bad - I mis-remembered a newsletter last year where you were working on Notman and then there was a picture of Al holding plans for Wyoming. That's going to make one helluva model! Thanks - John

- 31 replies

-

This is off-topic, but I'm curious - whatever happened to your build of Wyoming? Cheers - John

- 31 replies

-

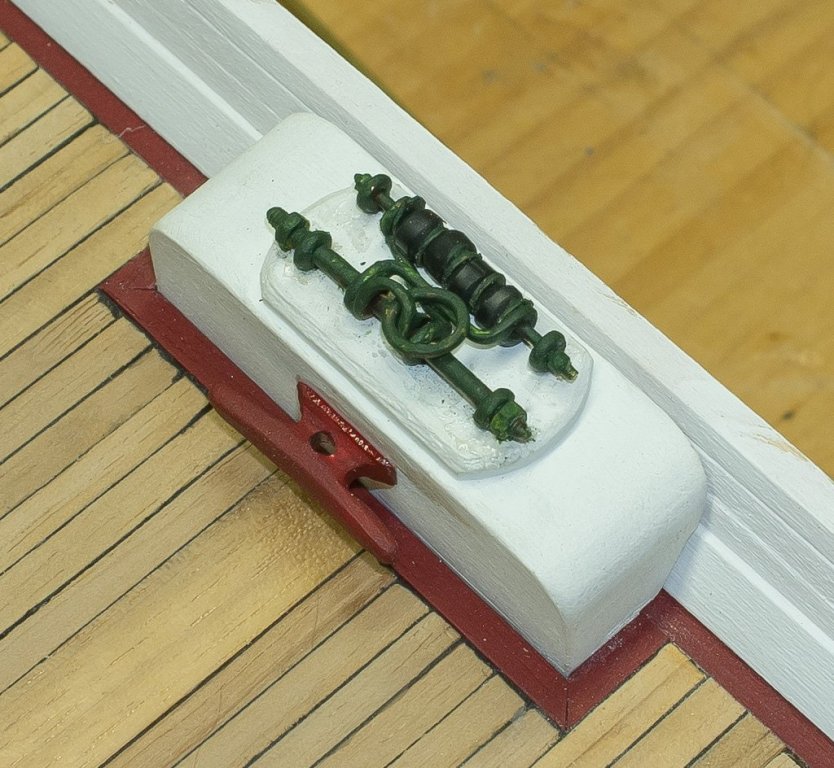

Here are two examples from real ships. The first is from the whaleship Morgan at Mystic Seaport. The second is fishing schooner. As you can see, they're just lashed in place. Cheers - John

-

I thought I'd make one other suggestion that, in retrospect, makes me feel dumb that I didn't think of it immediately. You don't always need that depth stop part. I mean the little hangy-down part on the right. I had gotten into the habit of removing it and laying the piece of metal and the screw down on the bench. Doubtless, everyone elses' workbenches are neat and tidy at all times, but mine quickly becomes a disaster zone while I'm working. So small parts like that can often get moved out of sight or separated from each other by the gremlins who live in my shop. The simple and obvious solution is to simply turn the part around and hang it down on the back side of the fence. Like I say, I feel dumb that it didn't occur to me to do that until yesterday, but maybe it's something that hasn't occurred to someone else yet either. (Not saying you're dumb! ) Cheers - John

-

I got my sliding table last week. The little plastic-topped screws for the depth stop really annoyed me - too hard to grab and start in the holes. So I went to the hardware store and got some brass 6-32 machine screws and knurled brass nuts. I glued the nuts to the screws with a bit of medium CA. I find these way easier to use. Cheers - John

-

I am no expert on glass or much of anything for that matter! During the time I was there, the house underwent a major restoration and a great deal of effort was put into determining what parts of the house were original. There is also a well-documented chain of ownership of that house. The majority of the window sashes were determined to be original to the house. There was at least one replaced after the American Civil War because a cannonball penetrated the house, largely destroying at least one window. In any case, the experts were able to determine which panes were original and which were replaced in the 1880s. Exactly how, I can't say. Perhaps through examination of the paint and glazing around them or perhaps some sort of examination of the glass itself. As best I can recall, they didn't remove any of the panes during the restoration but the restoration started about 2 years before I went to work there. Window glass in the 1700s was made in a different way than glass made in the 1800s so it had a different appearance. A web search on "dating window glass" will turn up a good bit of interesting material.

-

I spent 12 years working in a Colonial American house museum. http://kenmore.org/ The house was built in the 1770s. Most of the glass in the 16 large windows in that house still have the original glass. Some of the panes were replaced in the 1880s. It was easy to tell which glass was original because it looked much better than the 1880s glass. It was as clear and transparent as any glass you would see today. The 1880s glass had a number of blemishes and bubbles. It was still clear however. Cheers - John

-

For the rubber bushing, if you can get to a hardware store, you can find a large-diameter rubber o-ring of the appropriate thickness and cut a small slice out of it. A large diameter is desirable because the smaller the diameter, the tighter the curve. A small slice from a large o-ring will appear to be straight. You can drill a hole through the center of that slice so it will slip over the tiller shaft. Below is an example where I used an o-ring to make the rubber bumpers on a main-sheet horse. This was at a scale of 1:32. Cheers - John

-

Very interesting article here about the windmill at Colonial Williamsburg in Virginia: http://www.history.org/foundation/journal/autumn02/windmill.cfm Some great videos of the same mill here with an article about its restoration: http://www.dailypress.com/features/history/dp-nws-cw-windmill-update-20160215-story.html Cheers - John

-

Sherline mill and lathe questions

jhearl replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

I kind of wound up with the opposite situation - inch lathe and metric mill. I use metric a lot in modeling, so I thought it would be good to have a metric mill, purchased a year or two after the lathe. However I didn't think about the fact that the end mills that come with the tool are in inch sizes as are most edge finders and much of the stock I work with. So I have to keep a chart next to the mill that shows the size of the cutters in mm. Sure - I could replace them all with metric end mills, but the ones that came with it are perfectly fine, so I haven't done that. And if you want to move to the center of, say, a 1-inch part, you have to convert that to mm as well. So a minor annoyance but if I had it to do over again, I'd just get an inch mill. Since my name was mentioned above with regards to the 17" lathe, I'll say I still wish I'd gotten the longer bed. It would only have been $100 more up front but the cost to change out all the parts is around $300. While I don't often need the length for parts I make, getting that tail stock out of the way would really be helpful when I have something like the 3-jaw chuck and a drill bit in it. Although I would probably use the DRO on the lathe if I had it, I really can't say I've missed it. And because I don't have room to leave my lathe out all the time, it would just be an extra effort to move the DRO box and plug in cables. The two machines don't sit anywhere near each other. Just wouldn't be worth the cost to upgrade the lathe to DRO to me. Your mileage may vary. Cheers - John -

If it's in your budget, I'd suggest you buy a copy of American Fishing Schooners by Howard I. Chapelle. It will answer many questions about these type boats as you move through the build. It's available at Amazon and can be had used as well. https://www.amazon.com/American-Fishing-Schooners-1825-1935/dp/039303755X/ref=sr_1_1?ie=UTF8&qid=1522363869&sr=8-1&keywords=fishing+schooners Also, if you want to see the ultimate build of this model, check out Bob Steinbrunn's version - just incredible and certainly something to aspire to! https://photos.google.com/share/AF1QipM7nihATa1ff35NtyzKqnAPcI71Y76r93ddvZq_FtDY69uiBkvytrBfRp5oePTLZA?key=ZU9KTXUwbDF3RzJWM3d1RHdjXzliUnU0RnBMWXdB Cheers - John

-

OK - got it - thanks!

-

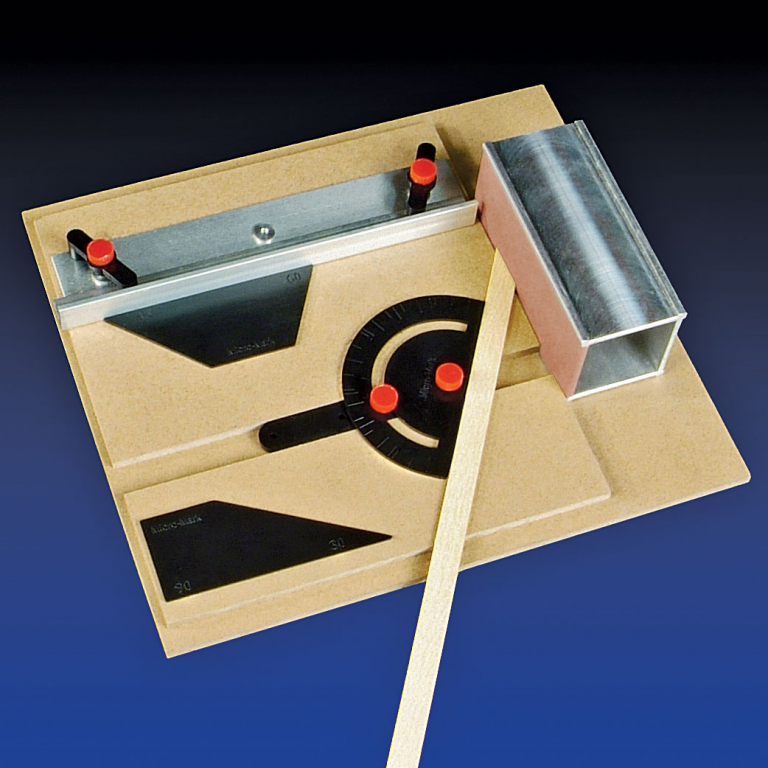

Would someone who has this already be kind enough to tell me the thickness of the base plate? I have the 17" version of the saw so the sliding table would fit without having to remove the fence. But the question is whether any long stock laid on the table would clear the fence, which is about 9/64" high (without the extended fence). Thanks - John

-

This is stretching my memory a bit, but I'll do the best I can. You want to wind up with the thickness of the false keel and planks being no wider than the width of the exterior keel. That exterior (visible) keel is added on top of the false keel so it and the outsides of the planks should blend together. The false keel and exterior keel are both 6mm thick, so that means you have to taper the false keel some to allow for the thickness of the planking. It's not easy to see in the attached pic, but it's the best one I have. It looks like you need to add more shim material to bulkhead 2 in the pics above. One tip about shim material - instead of cutting the material so the grain runs in the direction of the bulkhead, cut it so the grain runs across the bulkhead (fore and aft). That will make it much easier to bend around the curve. However much fairing you do of the bulkheads, the outer edge of the bulkheads at the false deck should match the outer edge of the false deck. So, for example, in the pics above, it's clear you're going to have to narrow the false keel as discussed above, so the false deck will have to be narrowed right at the end as well. Hope that makes some sense - John

- 22 replies

-

- bluenose ii

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.