-

Posts

2,596 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

-

-

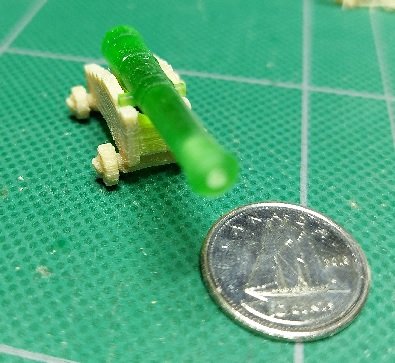

I must admit at first glance they do sort of look like the chewable candy! They were modelled and 3D printed for me by a member of our local club. I posted all about it earlier last year I believe.

The carriage could use a little more cleaning up if I was using it... but it was a test piece.

I added the quoin to the computer model and am 3D printing four at once at this moment. Should be done in about 2 hours at a material cost of 16 cents. That is $ Cdn 0.04 each

Going for my eye needle on Tuesday late morning so I will be working on 3D printing during the week.

-

-

Yes, it was quite the down pour. I had a little water in the basement in the furnace room due to a patio block sloping the wrong way and possibly a crack in the wall. I adjusted the patio block but could not find a crack. Guess we will find out tomorrow as they are calling for more rain.

Below is the carriage as removed from the printer. The supports have not been removed yet... it needs some clean up.

It measures 19.9 x 17.3 x .43 mm or .78 x .68 x .43 inches.

I will clean it up in a bit and set a 9 pound cannon barrel on it.

-

Did not get to the shop yesterday or today.

Had a crew over removing my eaves troughs and fascia. Expected them back today to install the new, deeper, with leaf guard system... of course they didn't show up.

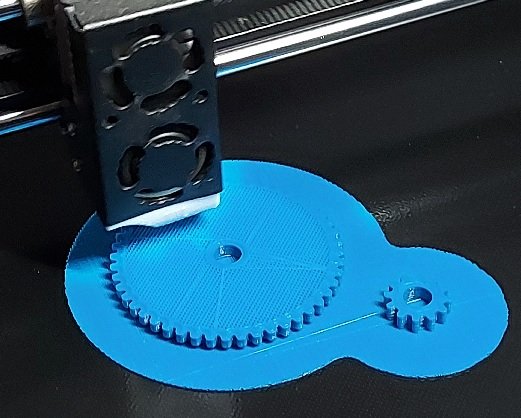

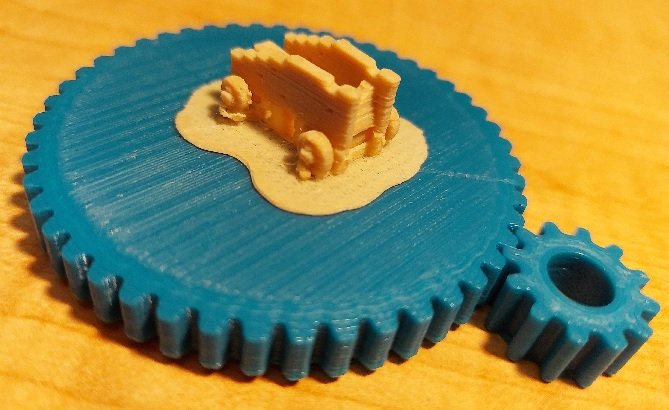

Worked on and printed a set of gears for my future rope walk.

They turned out quite good.

Then I worked on my 3D 9 pound gun carriage. It is presently printing in wood filament. It is quite small so I am not sure how it will turn out.

Could get the filament to feed through the 0.2mm nozzle so changed it to a 0.3mm nozzle and it seems to be working so far.

Nothing much yet to see on the printer so here is the slicer program image.

- GrandpaPhil, cog, Canute and 7 others

-

10

10

-

A good book for rigging French ships is The Seventy-Four Gun Ship, Volume 3, by Jean Boudriot.

Page 130 shows a single line wrapped about the mast with the two ends dangling to one side of the mast. A thimble is eye spliced into each end. The bight around the mast is seized tight up to the mast. The block has a strop and thimble, and it is lashed to the dangling thimble mentioned earlier.

Page 133 has the tye block strop eye lashed to an eye of a strop looped around the mast.

You should get this book, translated to English version unless you are fluent en Français.

-

Jason

It seems some were lashed as discussed above where as others were a single splice strop making an oversized loop of rope (line).

The deadeye (or thimble which is the example I am looking at in The Anatomy of Nelsons Ships, page 235) is fitted with the "item" inside the strop, rope in the groove and wrapped around it, then seized tightly to it.

Possibly this is what was done in your case.

-

Reading The Anatomy of Nelsons Ships (C.Nepean Longridge) page 233 and looking at the image in Rigging Period Ship Models - Square Rigged (Lennarth Petersson) page 11:

"The first pair is doubled in the usual manner, the third shroud goes over the mast head with an eye splice."

"Each shroud reeves through a hole in the outer end of the top mast cross trees, where it is served. Inclined inwards, the shrouds pass between the topmast shrouds, and inside the topmast futtock stave."

"The top gallant shrouds are lashed to the first, third and fifth futtock plates on the fore and main masts, to the first and third on the mizzen."

-

-

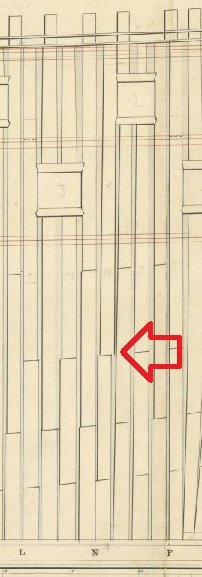

Seems the foot or bottom of the column is pocketed into the deck (hidden or dashed lines below the top surface of the deck in the image).

The head or top also is recessed into the beam from one side allowing it to slide out once the beam is lifted.

-

Thank you Siggi,

I have been wondering how they would swing a column up if it were hinged without the foot of the column being rounded to allow it to pivot, or even pull a column out. Hinged or not... of course they jacked the overhead beam up a smidgen to create the necessary clearance!

DUH.

-

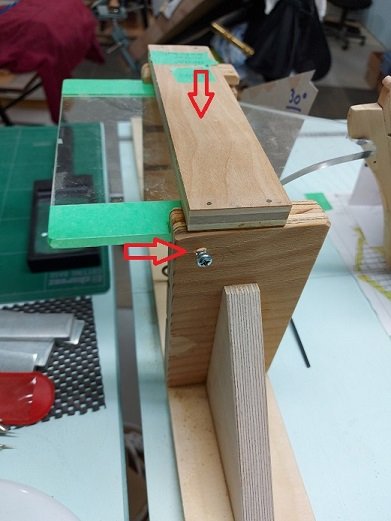

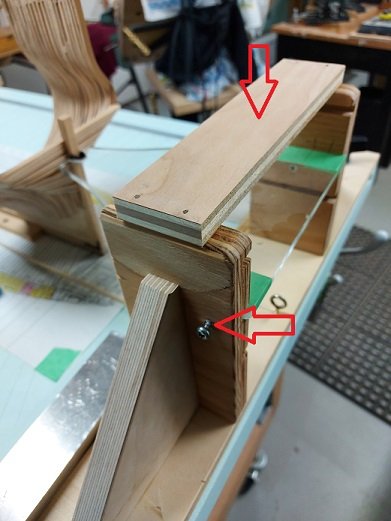

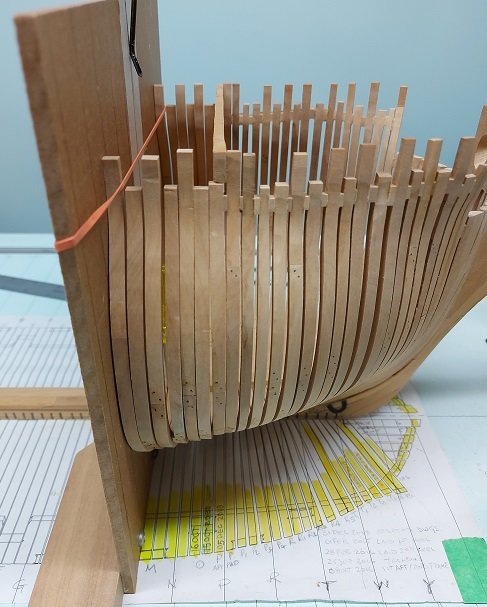

I had six square frames installed... had to remove five of them and then alter my bow and stern supports as they were wandering again.

The Plexiglas inserts that slide into the notches was out of square. I had secured it once before but apparently it didn't hold.

This time I added a brace across the top, and then drilled and screwed the sides.

It will never move again.

The frames are back up and aligned properly.

The next four frames are underway.

-

-

-

-

-

- cog, Canute and GrandpaPhil

-

3

3

-

Unfortunately I do not have a mill, nor do I have the room in my shop to add one. Might consider moving a wall. It would be the third time.

I cut my 4x13 blanks from 4x6x60 inch castello boxwood stock, plane them to thickness (within reason), cut those pieces in half and rubber cement them into matching pairs. I trace my timbers onto the top of one blank set and scroll saw the pieces out keeping well outside the line. This gives me the port and starboard halves with one cut. Then the curves are sanded to the line on a oscillating drum sander. The flats are sanded to the line on my disc sander. I wish there was a market for sawdust.

The pieces are dry fitted on top of the pattern (my drawing) and once satisfied I then separate the halves and yellow wood glue the frames, floor and chocks together. This is done on the paper pattern, with the pattern under a thin plastic sheet, to assure everything is correct. The assembly is allowed to dry and cure for just less than 24 hours (probably 20 hours) then attached (glued) to the build and allowed to set another 20+ hours before the next frame is glued next to it.

I have three frames at various stages going at once so I have less waiting time.

I was taught how to properly use rubber cement, and to cut two pieces at once by a member of our local club.

Most everything else I learnt from this forum from people like you!

All the mistakes I've made I learnt on my own.

-

Druxey,

It should be easy to do. I opened the file and tried to adjust things and it was a nightmare, so I started it over as a new file ... and it will need some trial and error adjustments as yet.

Everyone,

I got going on my first stepped frame. N-Forward steps forward about 2-1/2 inches ( 0.04" at the build scale) to reach the upper gun port and receive the notches for the upper and lower cills as can be seen in the snip from the framing plans.

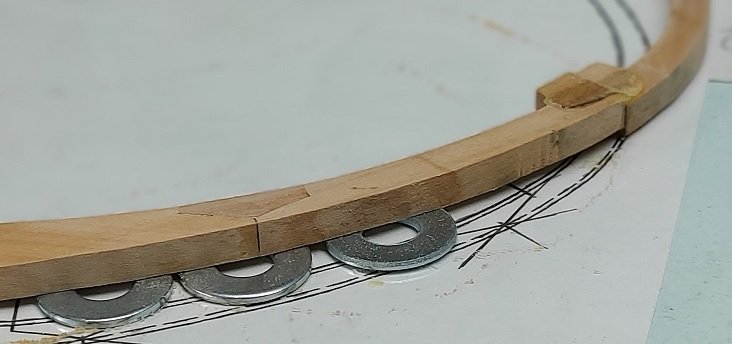

I found some flat washers I could use as supports while the glue set. One side has been roughly filed down and needs to be finish sanded the last little bit.

Full disclosure, I originally forgot to step it even though I have it marked in BOLD RED on my plan. Had to take it apart and redo the chock thicker to accommodate the step.

- GrandpaPhil, druxey, PeteB and 4 others

-

7

7

-

-

Yesterday I completed modelling and creating drawings for all the blocks. This includes the parrals which I had made a great error with.

I had not realized the different sizes of parrals had different diameter trucks to suit the different size ribs. It is only logical but I was fixated on the one drawing I had found with dimensions. It makes perfect sense why some trucks look like balls whereas others are elongated.

So for anyone interested the package is below as a PDF.

Today I go down to the shop.

-

-

Red Baron by pwog - FINISHED - BlueJacket Shipcrafters - 3/8" - Lobster Boat

in - Kit build logs for subjects built from 1901 - Present Day

Posted

IMHO

If you are not happy now, think of how it will eat at you for the next 20 years.

If it is truly a learning lesson what is to be lost by taking it off and trying again.

Only lesson learnt is by doing it over until you're satisfied. If something gets damaged, do that over too. You will be glad you did... eventually.

I was so reluctant to remove items... now I don't think twice about it...but it did hurt the first few times.