-

Posts

2,869 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

I make a scrapper and scrape the rabbet groove in.

I was told to use an old metal saw blade. Heat it cherry red with a torch to soften (anneal) it (quench in cold water), and then file the desired shape into it.

- mtaylor, Canute and thibaultron

-

1

1

-

2

2

-

temporary spacers!?!?

of course not.

Once I had all the aft and dead flat frames in I was going to check the fairness and make adjustments, then put in permanent chocks near the head of the top timbers, above and below the chocks where I can, and above and below each gun port location to lock everything before sanding inboard and outboard.

That should only take me forever and two days since I operate at the speed of dark. 😁

.... temporary spacers .... 🤔 hmmmmm.

there is a simple answer for everything.

-

-

cablejim

I cannot see the image, only the path to your android device.

could you please re-post it

Thanks

- mtaylor, Canute and thibaultron

-

3

3

-

This will be one gorgeous finished model some day soon!

-

-

Join the meeting on Sunday at 1:15 and you can ask him directly.

I have silkspan here and my sail I made at the seminar that I can show you. I can drive over and you can look at it at a safe distance from me in your driveway. Just give me a date and time.

The material reminds me of what they use for teabags and is more appropriate for the reduced scale.

-

Paint job looks great.

I have no idea about linen sails.

I was taught to use silkspan and acrylic paint by David Antscherl at a workshop he did a number of years ago.

-

-

The wood filler and paint will look like a million dollar job!

Can't you just rotate the steering box 180°.

-

Derek,

I just tell myself what that masters do is all smoke and mirrors... then I try. Sometimes after a day or two I convince myself I can do better and try again. Usually I am right. Possibly because I learnt something valuable the first time and after pondering on it for that day or two I envisioned what I might try the second time.

I believe that drive to try again is what made those masters.

Never give up and don't sell yourself short.

We all have it in us if we just try.

-

Nice to see you getting back to your Bluenose Derek! Hope to see some photos in the coming weeks.

See you at the club Zoom meeting on the 12th.

-

-

-

Excellent video as always!

However you gave me a fright having your fingers that close to the cutting blade!

Might I suggest you consider a small piece of wood with a lip on it to hold the item down and will allow you to push the item to to fence at the same time. I put a dowel handle extension (goes 90° to the fence) on my tool.

I almost lost a finger when the wood I was cutting flipped over and pulled my hand into the blade. Now my hands never get near the blade.

-

I just used similar rotary cutters for my figurehead.

My rotary driver was my 25 year old Dremel tool and flex cable.

The cable needs to be disassembled occasionally and greased.

You need to keep control of the tool as it sometimes wants to climb away! So take small controlled bites off the work.

I found the cutters with spaces between flutes removed material best.

Smaller regular dremel style cutters worked great for tiny bites.

I recommend them, but keep your scalpel, carving knives and micro chisels at the ready.

It was my first successful time using them...as I just got the proper (spaced flute) cutter set.

Prior to that it was a mess... for me.

Others seem to have no problem.

- thibaultron, Canute, allanyed and 1 other

-

4

4

-

Thank you Druxey.

I was told to do the heads first and that was indeed the most difficult part. I kept going away and coming back to it. Taking off a little here and a little there. Even when I thought I was done I kept going back to them. They are not in anyway masterpieces but from 1 foot away they are okay.

This was not my first attempt. I've been at this on and off for almost 3 years.

I suppose "on and off" should be my motto.

There is one local fellow I could have commissioned and it would be a masterpiece but then it wouldn't be mine.

-

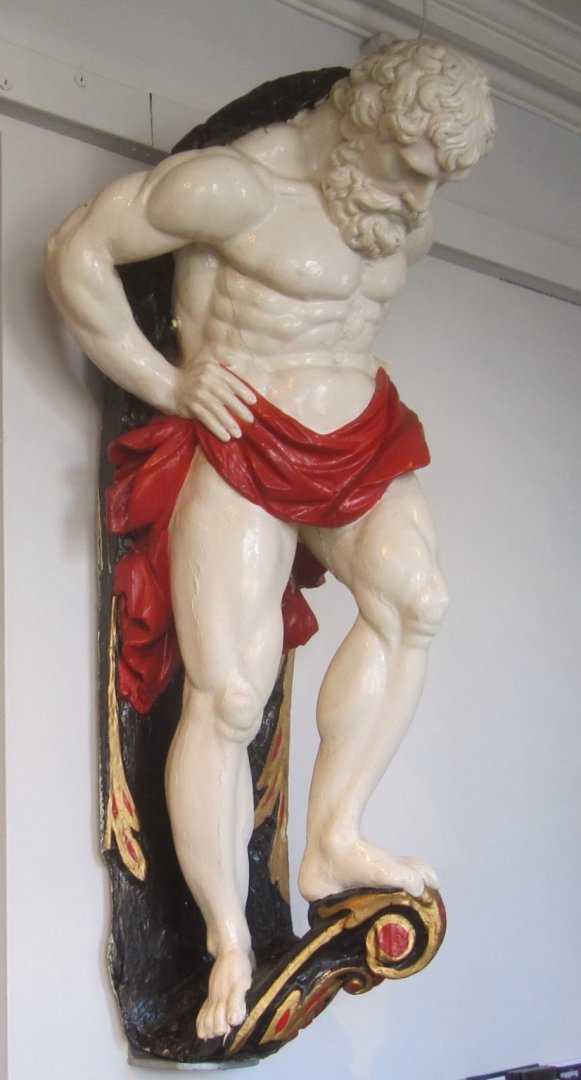

This is the result of my efforts in recreating my interpretation of the description of the first figurehead that was destroyed in 1793 when she collided with HMS Majestic in a gale force storm.

I am quite happy with it and do not believe there is another model of this ship in existence with this version of this famous ship's figurehead.

I hope I've done it justice.

WOOD: Block of Linden bass wood

TOOLS: Rotary cutters, Dremel rotary tool with flex cable, carving knives, miniature chisels, scalpel, and various sand paper (80 Grit to Super Fine).FINISH

PRIMER: Javelin - Black permanent marker

Remainder - Waterbase Folkart GESSO Surface Prep

WHITE: Bodies - Craft Smart White Acrylic Paint

RED: Cloak - Craftsmart Cherry Cobbler Acrylic Paint

GOLD: Helmet - Kingart Metallic Acrylic Gold

BLACK: Javelin - Craft Smart Black Acrylic Paint

SEALER: Everything - KRYLON Low Odour Clear Matte Spray Finish

-

-

- SJSoane, GrandpaPhil, BANYAN and 7 others

-

10

10

-

Made the javelin and the cloak.

The javelin head is glued to the shaft. I notched the head (a 1/8" diameter dowel) and stepped the shaft into it with glue. When dried I shaped the head with a file and sand paper, having filled the notch with glue so the dust might fill the small notch.

The cloak was shaped and fitted a dozen times and is now glued and clamped.

I also glued the tip of the wing back on.

From a distance it all look darn good to me... though I'm not particularly thrilled with Bellerophon's or the Pegusus' head up close.

Regarding painting most of the figurehead features white... it wasn't until 1814 that the Navy Board approved the use of gilding and colours for figureheads. (source: http://figureheads.ukmcs.org.uk/?p=1715)

- GrandpaPhil, PRS, druxey and 3 others

-

6

6

-

She has been cut free and is presently being fitted.

Almost there!

Once I have that done I will do a bit more sanding, add the cloak (because I'll have a better feel of the space left), re-attach the tip of the right wing that broke off, make the javelin (hole already in the hand for it) and paint it.

Then it goes into storage for safe keeping.

RE: Painting. Golden helmet with white plumes, and a red cloak. I understand everything else was simply painted white. Somewhat like the Atlas carving saved from the Captain's stern gallery as seen below.

- mtaylor, Canute, GrandpaPhil and 3 others

-

6

6

-

-

Bluenose by Worldway - Model Shipways - Scale 1:64

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Sorry to read your tragic story. I am assuming you didn't get hurt... or the shock of the damage to your saw has hidden any aches or pains you'll be feeling in the morning. Check for bruises.