-

Posts

967 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by alde

-

-

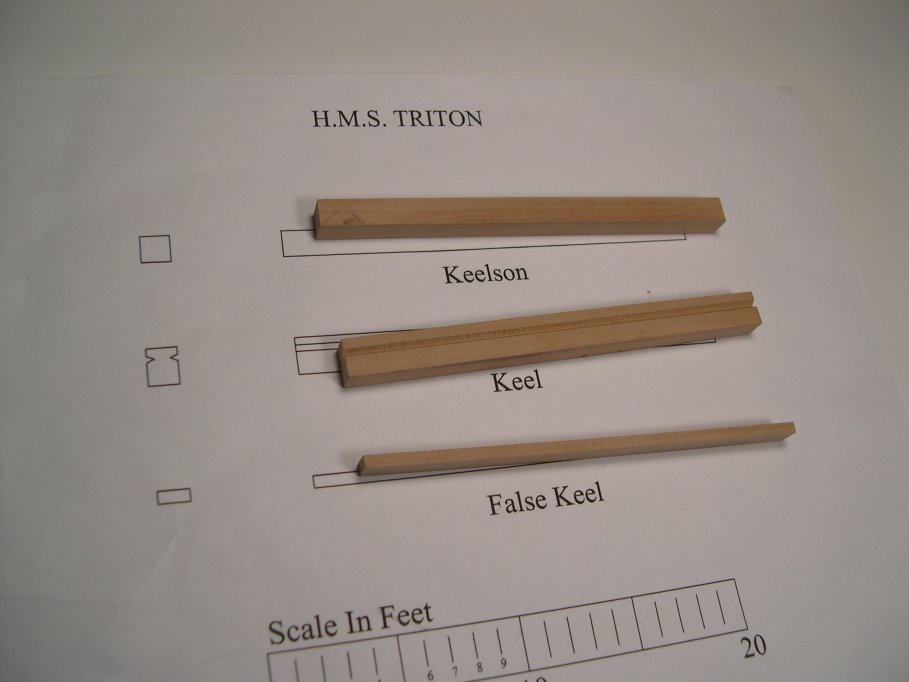

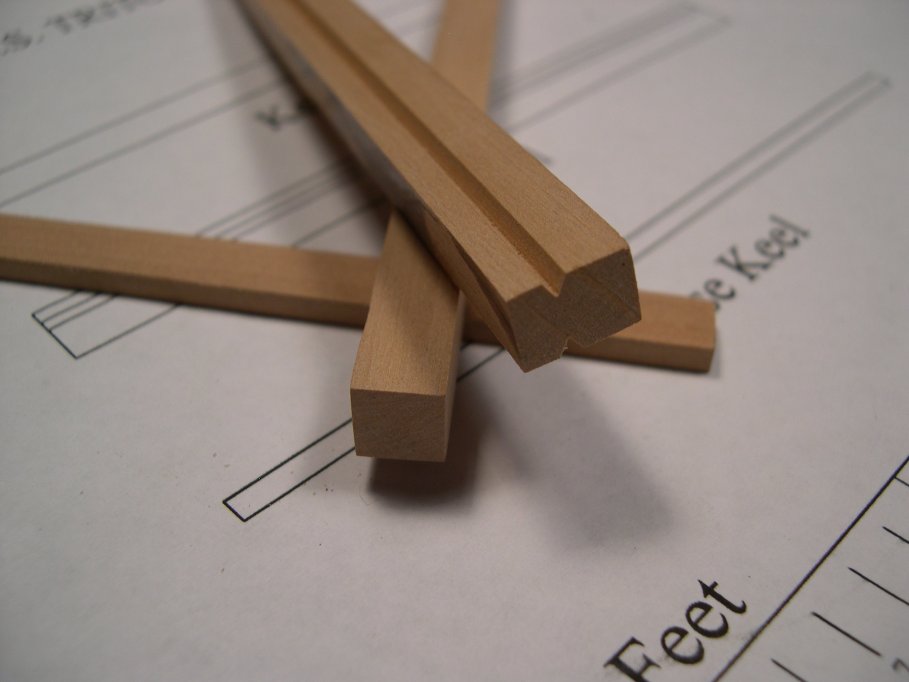

Richard, I didn't take any pictures but I just used the Sherline vise with a strip of wood under the keel section to get the keel edge above the top of the vise and level. Then it was just a matter of getting the point of the bit lined up with the center of the rabbit and cranked down to the correct depth. Then I just ran the mill as fast as it would go and ran it down the length of the keel section. I then just flipped it over using the same settings and ran the length on the other side. It came out perfect on the first try. I used a 2 flute pointed mill bit. I don't know the angle of the flutes but I had it and it looked right. This is the first time I used the mill to make a real part so I am far from an expert.

-

-

-

-

-

Pete, When are we going to see more? I have been rubber cementing frame patterns to wood and hope to start cutting them out tomorrow. I will update my log soon. I am really excited about this project and hope I don't neglect my schooner too much.

A question though. How much meat should I leave on the frame parts for fairing? I am working at 1/48th scale. I don't want to leave too much to sand but want enough to fair them well.

-

-

Mike, I'm with the others on this one. I would get the separate tool if space is the main concern. The mill attachment will take up almost as much space as the mill. I have both and they are fantastic tools. As far as cost goes the attachment is almost $400. How much more is the whole mill? They would both be ready to go when you need them without converting them and worried about alignment and set-up every time.

- Landlubber Mike, Canute and mtaylor

-

3

3

-

-

Good luck with your Triton build. I just started mine today too. It's going to be a fun project.

- Canute, mtaylor and CaptainSteve

-

3

3

-

-

I feel like I am jumping in the deep end with this one but since I got the new Byrnes saw I wanted a special project to learn how to use it and my Sherline mill. I used the mill to cut the rabbit and it came out pretty good if I must say so myself.

It will be slow going for a while because I am still working the schooner and don't want to set it aside completely.

I will have plenty of questions and welcome any help offered.

-

Mick,

One thing that I love about this forum is the support offered and the fact that nobody is judgmental and when mistakes are pointed out it is done in a very constructive way. My experience is that it is like that to a person, from the new modelers to the most experienced artists. I have never been given so may words of encouragement and assistance as I have on this forum. People take time away from the little time they have to pursue the hobby to help others. That really is a special thing that this forum offers. It's very much appreciated.

-

Mick, you are far and above me in skill and work quality. I am getting closer to being able to take on a project like yours but small steps for me. I am taking your suggestion and starting the Triton Cross Section. It will be very slow going though because I still have the schooner to finish.hi albert

thanks for looking in.....I hope one day to be able to emulate your standards sir!

cheers ......mick

-

Al

The 24 tooth carbide is for roughing down thick stock. Use one of the slitting blades on the thin boxwood

Jim

Jim,

Thank you for taking the time to answer my question personally. I only have the one slitting blade I ordered with the saw and will be ordering a couple more. Can you make any recommendations? Again, the saw is fantastic. If anybody is on the fence about getting one of these tools just know you are getting super quality and great customer service.

Al

-

-

-

I got my new saw this morning and it's a thing of beauty. Now I have to learn to use it. I tried to cut the keel sections for the Triton Cross Section project out of boxwood but I'm having problems. The cuts are uneven and pretty rough. I can't seem to get a nice straight cut. I did a little better with cherry. When I cut boxwood with my little Microlux saw the cuts are as smooth as glass and even. What am I doing wrong?

-

Tom,

Thanks for the inspiration. I really feel like my skills are improving and getting more confident. The Glad Tidings has taught me quite a bit so far but the most important thing is patience. It seems like it's taken so long to get to the point I'm at. In the past it would have bothered me but now I'm fine with it. It's become fun to solve problems and re-do things until they are right. I don't know if Constitution will be my next build but I will build her.

Al

- CaptainSteve and Aussie048

-

2

2

-

Tom,

I have really been enjoying your build and learning a lot. I am considering this kit once I finish my Glad Tidings. I am still pretty new to the hobby and not sure I can handle it and want to do the ship justice. How are the instructions? Would I be taking on too big a project for a beginner? I do see other people taking it on early in their building and see mixed results. Some look great and others just fall off the grid and probably never get finished.

Thanks, Al

- CaptainSteve and Aussie048

-

2

2

-

-

I just ordered one of Jim's saws a couple of weeks ago and it will be at my house on Monday. I can't wait to be able to mill my own stock. I ordered everything but the tilting table. Also got some spare blades, an extra belt and a zero clearance insert. Did I need it? No, but for a lifetime hobby it's a good investment for me. I hope to order the thickness sander in a few weeks.

- Landlubber Mike, mtaylor and Canute

-

3

3

-

Nice going Matt, she looks great.

- Elijah, CaptainSteve and MEPering

-

3

3

-

Thanks Hamilton.

I was going to try to sand out the imperfections and not use filler but I'm afraid the planks might get too thin in places. I hope to get to the point of painting by the end of the week. I at least want to get some primer on it so the problems will show through better.

I was thinking of going with Yellow Ochre for the hull color but might go with something a bit brighter. I don't want it too bright though.

Triton Cross Section by RedDawg - 1:48

in Cross Section Build Logs for HMS TRITON

Posted

Your scroll saw cuts look perfect. I cut my first pieces too close to the line. I need more meat for fairing.