-

Posts

2,954 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by thibaultron

-

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

thibaultron replied to Torbogdan's topic in Non-ship/categorised builds

I got the two Hagasawa engine kits. The detailing looks good, at least good enough for me. The Le Rhone 110HP The Clerget 130HP A close up of the cylinder and vale rocker arm parts. -

Vallejo and AK Weather wood paint and washes

thibaultron replied to KAT's topic in Modeling tools and Workshop Equipment

Is that the AK 259 REALISTIC WOOD EFFECTS , book? -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

thibaultron replied to Torbogdan's topic in Non-ship/categorised builds

One source I found, said that the Germans would reuse Le Rhones in the DR.1, if they captured any. Similar to your post. -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

thibaultron replied to Torbogdan's topic in Non-ship/categorised builds

I broke down and bought one the Hagasawa Le Rhones. Should be here next week. Haven't decided whether to keep or resell the Williams Brothers 80HP model. When the 110HP arrives, I'll post some pictures of the parts. I also bought one of there Camel engines, its coming from Canada. -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

thibaultron replied to Torbogdan's topic in Non-ship/categorised builds

Enjoy your vacation! -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

thibaultron replied to Torbogdan's topic in Non-ship/categorised builds

Received the 1/6th Le Rhone 80HP engine model kit. Unfortunatly the 80HP has the valve pushrods at the front of the crankcase, and the 110HP has them at the rear! Did not notice the difference until after the kit arrived. May have to find a Hagasawa 1/8 Le Rhone kit. -

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

thibaultron replied to Torbogdan's topic in Non-ship/categorised builds

Its a nogo on 3D printing the cylinders, for the Le Rhone/UR2 engines. There are 33 fins in a actual 22CM length, and the minimum thickness for the Shapeways detail plastic is ~.5CM for a supported wall/fin, and ~1CM for an unsupported wall, AKA a fin. This is for a cylinder scaled to 1/16th. A built up PE stack might do it. You would need some combination that comes out to .0163" or .0164" thick for each fin and spacer(s) combination. It comes out to .666 real CM from top of one fin to the bottom of the "gap". -

Its in the Micro-Mark catalog.

-

Thanks from me, also, for this great build! Fantastic workmanship, and the clear explanation of the reasons for each step, it adds much to the interest of the build.

-

Maybe you could do your own PE. Here in the US, you can buy complete kits for do it yourself PE. Should be able to get them in the EU.

-

Is the pin in the gun base plastic, or part of another PE? If plastic cut it off, and drill for a smaller pin.

- 151 replies

-

- duke of york

- tamiya

-

(and 2 more)

Tagged with:

-

Frank; I forget, what period in her life are you modeling her in? As built, present, etc. Did she have power dredge winches, or hand wound?

-

Did you use Chuck's method to create the volutes?

- 449 replies

-

- sultana

- model shipways

-

(and 2 more)

Tagged with:

-

I insulated mine. Well worth the cost in reduced power bills.

-

A look at the above picture also answers your shroud question. The shrouds run under the yard, not over it, as in some of your pictures of the model.

-

Fokker Dr.I by Torbogdan - FINISHED - Model Airways

thibaultron replied to Torbogdan's topic in Non-ship/categorised builds

A note: Amazon has the "Fokker Dr.I: The Aces’ Aircraft (Legends of Aviation 3D)", 2nd edition hardcover, listed as in stock for about $30 today! I just ordered one -

If you have a scanner, scan the instructions, and blow up the pictures. Great work, so far.

- 151 replies

-

- duke of york

- tamiya

-

(and 2 more)

Tagged with:

-

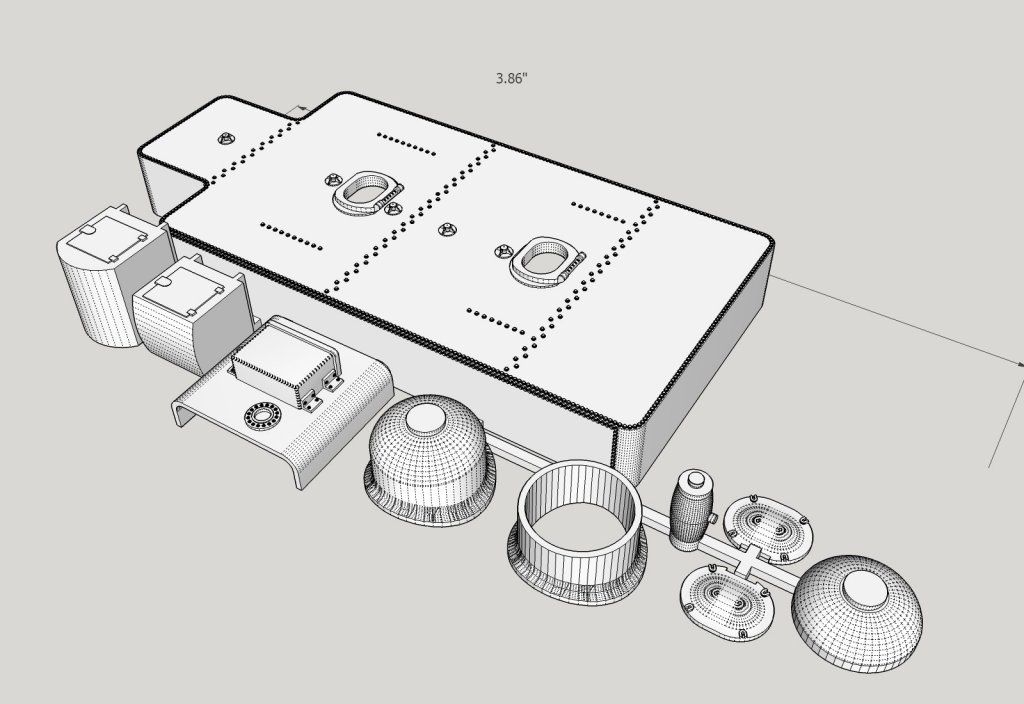

For my "stuff", I model it full size, then rescale it when I send it to the printer. I'll have to look into Blender. My tutorial is intended more to teach how to use SketchUp, rather than as a drafting lesson. I wanted to show a few tricks I'd learned along the way, also. Here's a shot of a piece of equipment I'm designing for one of my model railroad locos. It is a conversion set to modify a Bachmann 2-8-0 to a Santa Fe prototype. I could have built it long ago, but enjoy the challenge of CAding/3D printing it. If it works out I plan on making it available to others. It's an oil bunker for the tender, with a new dome for the locomotive. The second dome is for me to trial fit first, so I don't ruin the "good" one. One thing that will come out of it is a set of accurate oil fill hatches for Santa Fe locos. Most production models have incorrect ones, even the Brass locos. I have several tenders that I need to upgrade. Also the 2 tool boxes are missing on most SF loco models. I will have to stretch/shrink some of the dimensions to fit each loco, but I have the basic models to start with. It may be too complex, with all those rivets on the side, but I'm interested in seeing if it works.

-

Lazyjacks on a modern vessel, run on both sides of the sail, so the rgging would be mirrored on the other side. They are used to shorten the sail, and keep it contained while you do.

-

More tools - Luthier, jeweler, fly-tying

thibaultron replied to vossiewulf's topic in Modeling tools and Workshop Equipment

Ebay has the Horico dental sanding strips -

In one of the other threads, someone mounted his hull on an angled base, and drilled with a drill press. That is the method I'll use in the future.

-

3D-printing for modellers?

thibaultron replied to Jean-Pierre's topic in Modeling tools and Workshop Equipment

Just shapeways, for now. A 3D printer is on the list, but I need to finish my shop renovation first. -

3D-printing for modellers?

thibaultron replied to Jean-Pierre's topic in Modeling tools and Workshop Equipment

I use SketchUp as my main 3D software, with DesignCAD as my drafting software. I have a thread on going from 2D to 3D that I did last year, in the forum, see my signiture below. What you can print, depends on the size of the parts. I was able to 3D print hand powered oyster dredge winches, about 3 X 2 foot, in 1/64th scale, but not the pipe dredge frames. For Shapeways the minimum floor/wall thickness, in their Frosted Detail plastic is .3mm, with wire minimum about 3X that thick. Long thin parts have a tendency to warp. I've also printed HO scale steam locomotive tender frames, in one of their cheaper plastics, and oil hatches for the tender tank top.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.