-

Posts

1,412 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Martin W

-

What do you use your mill for ?

Martin W replied to captainbob's topic in Modeling tools and Workshop Equipment

Hi Nigel -- That's really exciting. The ladder jig is enough to make me want to get my own mill set up right away. I'll definitely be checking in on your milling jig, since I want to learn how to use my mill and what for. Cheers, Martin -

Nice work, Jon. You're right to toss the kit's blocks. I tried making my own for a while, and the ones for the gun tackle don't look too terribly horrible, since they're pretty tiny, but the ones for the anchors are, to put it simply, unsightly. As for the hooks, I followed the very same procedure as you, and if I recall, I got it from someone's log on MSW 1 -- maybe it was even Chuck's log. The main point is that it works. As to why I didn't treenail the billboards (and it's great to have a name!), I think it was because I didn't notice them on other builds. I could be wrong there, though. But I also imagined that in a real ship these would probably be replaced frequently, and so would not be considered permanent. Probably the real -- and most honest -- reason was that I was too lazy, and too ready to start on the masts. Keep at it! Martin

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Hey, I like the treenails in those anchor planks -- they look so good that I'm starting to think of going back and adding them to my own.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

What do you use your mill for ?

Martin W replied to captainbob's topic in Modeling tools and Workshop Equipment

That's the one I bought alright. Thanks for the advice -- I'll try to step up the work on realizing my dream of having a good looking AND functional workbench (I've studied the pictures that Wacko and others have posted of their benches, along with countless plans). Until then, I'll just keep cutting out sister blocks & thimbles etc etc by hand. Oh, and I should mention that I did read your review of this milling machine, and it made me pause for a very long time. Still in the end, I went with it instead of the larger one. Cheers, Martin -

What do you use your mill for ?

Martin W replied to captainbob's topic in Modeling tools and Workshop Equipment

Hi Duffer -- glad you like your new milling machine. I bought the smaller version from Micro Mark this summer while it was on sale. I went back and forth trying to decide between it and the larger one that you bought. That R8 spindle was a major plus for the larger machine, since, as you say, lots more accessories fit it. But, when I thought long and hard about it all, I decided that at most I would be using the machine for modelling purposes almost exclusively, so went with the smaller -- and cheaper -- model. (A quick footnote: how many times have I gone with the less expensive tool saying that I wouldn't use it enough to justify the higher price, only to end up buying the more expensive version when I found out how useful the tool was?????) A question, though: how is your machine for vibration? What is your setup like? Did you have to bolt it down to a workbench? I ask because I am currently building the workbench I plan to set my milling machine on, so I haven't actually used it yet, but have thought many times, "here is something where that milling machine would be just the right thing." If it doesn't have to be bolted, then maybe I could set it on the floor for a quick job, like milling a sister block, eh? Cheers, Martin -

These look good and accurate. Sorry about your cat, but they do tend to get anxious hearing sailors speak like pirates, aar!

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Hi Ron -- First off, thanks for the link to your build log. And second, about those deadeyes -- WOW! I had wondered how they might be done, and I'd even tried cutting some out (UGLY), and hadn't thought of a jig like that. And third, this is a good looking build you're putting together. Lots of interesting detail. I'll be looking ahead to seeing you progress. Cheers, Martin

-

Help. Need 4 5mm deadeyes.

Martin W replied to Ulises Victoria's topic in Masting, rigging and sails

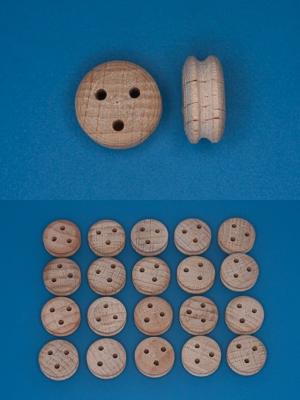

Hi Ulises -- I just thought you'd be interested in this. Keith Jewell of Modelling Timbers sent me a photo of the deadeyes he sells. Unfortunately for me, his smallest size is 6 mm, but I thought these might work for you. Cheers, Martin -

At $20 you got a pretty good deal! I bought a chunk of boxwood from some place a few years ago in hopes of doing some carving. But most of my free time is devoted to the ship or to building the workshop where I hope to build my future models. I think hobbymill also carries some good sized blocks. I'll look forward to seeing your anchors. Here's a shot of one of mine: It was the metal strips that gave me the most trouble. I ended up using blackened paper. Cheers, Martin

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Wow that sounds like a real find! Could you perhaps post some photos of the wood prior to its encounter with the saw and after? I'd love to see how big the pieces were and how you passed them through the saw -- I know that saw is powerful, but it's still kind of small. And congratulations on getting your signed book. I'm hoping someday to be able to attend that conference too. There are also some workshops offered by Greg Herbert and David Antscherl -- unfortunately, the latest one just passed, but you can track them here: http://www.admiraltymodels.com/Workshops.html As for the rudder & post -- yours came out just about where mine did; I jiggled with it for quite a while, filing it and cutting the inner edge down so that I could get it away from the transom. I don't seem to have any photos of that part, but maybe I'll take some this evening and send them to you. And you're right to follow Blue E for the anchors -- mine gave me loads and loads of problems. Bob's instructions are too complicated there, with too many unnecessary steps. Cheers, Martin

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

You might just set a dowel in the hole for the mizzen mast, and remember that you'll also need space for the binnacle behind the mizzen mast. That way you'll know with some certainty how things will line up. I got the email describing the conference, and it sounds like it was great. And of course you also got to see some of the big names in modelling in the flesh! Cheers, Martin

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

That is an appealing workspace. But don't the holes (for the dogs) in the butcher-block table lead to lost parts? Cheers, Martin

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

That's a well-built rudder & tiller, Jon. Good job. Have you tried fitting it in place yet? I only ask because that's where I had to make lots of adjustments, and found that Bob's instructions/measurements were actually off. I can't recall exactly, but it seems that the rudder passed through the Captain's Cabin more forward that Bob says it does (each build is different, of course). I also figured out -- after the fact -- that my tiller was too long, so that I had to pull it out and trim it. And how was the conference? Keep at it -- Martin

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Hi there, JPett -- I can feel your pain over having to look at a piece that just isn't right. Glad to see that the 2nd effort is all it took to make everything better. Your window is especially impressive -- it's nice and even, with the mullions in good proportion, and all the joints tight. And the sheave does add a very nice touch as well. Bravo! Martin

-

Hi Peter -- That is a very impressive Granado. And I've enjoyed reading you log on the Pegasus as well -- you're a genuine craftsman. Cheers, Martin

- 431 replies

-

- pegasus

- victory models

-

(and 1 more)

Tagged with:

-

The "other" company is The Royal Shipyard of Plymouth, and here's the link: http://www.royalshipyard.com/Home.aspx They bought the equipment from Bob Hunt when he decided to throw in the towel. But as you'll see if you go to the website, they don't seem to be ready to do any business yet. You're right, though, it is a great kit -- especially in the skilled hands of someone like Remco. Bob Hunt used to put these up for sale at deep discounts, and back then I thought they were still too expensive. Now I kick myself. -- And Remco, let me say that I do, do, do admire your skills. I have read you log several times just to admire it. Cheers, Martin

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Hi Kenneth -- I've just now found your log and enjoyed catching up with your great build. I like the paint job, and didn't even mind the grey that much, though the red does fit with history. It's always good to have another Rattler around! I also have to admire your work bench -- is that butcher block your own production? I'm envious. Cheers, Martin

- 152 replies

-

- rattlesnake

- Model Shipways

-

(and 1 more)

Tagged with:

-

Hi Eric -- I actually don't think you need to worry a whole heck of a lot about lining up the wale with the transom, since the stern carving will cover over the edges there. The carving extends from about 1/4 inch inside to about 5/16 inch beyond the hull, so any slight error will be hidden. Your planking looks good. Cheers, Martin

-

Hi JPett -- Your careful work seems to be paying off on a great build. As for the boxwood, I'd say that it's about my favorite wood to work with, since it's might forgiving, doesn't splinter too badly like other common hardwoods, and can always be sanded to cover up those unforeseen mistakes (the ones that were such a good idea at some time). My gunports were also all individually sized, though I didn't use the plywood base for the bulwarks, I just planked from bulkhead (or frame) to bulkhead, stopping each plank just inside the boxwood port, and then I could file the plank flush. It was a long, slow process, and I have a vague hunch that I also sought refuge in beer. (I just looked back at the section of the practicum that I've followed for much of the build and saw that it insists "all gunports are the same diminesion, approximately 3/8" wide and 5/16" tall" -- but I know from the emotional scars I carry with me still that they didn't work out that way.) Thoughts on treenailing the gunwales -- have you seen photos of actual 18th-century ships with treenails there? My personal view is that they provide a striking visual line showing off the sweep of the hull, and that treenails would interrupt that line. My own Ratt has so many treenails in her that she could even be called The Leopard. And the deck is one place I think they really look good. Just my thoughts. Cheers, Martin

-

Well, hey, they worked! They make a nice, realistic touch to the build. Cheers, Martin

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Thanks for checking in, JPett. And I appreciate your kind words on the crowsfeet -- they're something I felt intimidated by, but wanted to try. I always have to remind myself that this build is not the build, but a learning experience. Cheers, Martin

- 104 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Hey lucky you -- I've dreamed of going to that conference for years, but it always takes place right when I happen to be very, very busy with work. I can't quite imagine convincing my boss that I need to attend a conference on modelling. Soak up every little detail. Cheers, Martin

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.