Ronald-V

Members-

Posts

1,934 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ronald-V

-

Been a little busy with other things in life. Also side tracked a bit with exploring other modelling things. Made a "facade" in 1/24 scale. Was fun to do and liberating not to care about measurments etc. . Will definitely make something like this in the future again. Now trying to get back in the Sphinx

-

Great result! And she looks beautiful in her display case, very well done! I need to try and get back on track with mine

- 422 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

Love it! Very nice done, congratulations on finishing

- 170 replies

-

Lovely planking, but also a nice red color, very well done!

- 88 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Congratulations on the sale! I can imagine that at some point you have to sell models because there is simply no more room for them, especially this one! But it will indeed hurt a little bit, because you have put so much time and energy into it. Especially if it is gone so soon!

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Congratulations on finishing this masterpiece Glenn! Superb

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Planking fan

Ronald-V replied to Ironhead's topic in Planking Techniques's Planking Downloads and Tutorials and Videos

The video's in which Chuck Passaro explains how he planks his Winchelsea model are here: Planking tutorial Winchelsea -

Welcome! And l echo the others...start a build log, it really helps to track your progress and get help from forum member who are building also the Dory. Even the designer of the Dory kit is a member here

-

I would try different materials and see what you like best. Everyone has their own preferences. I have experience with wooden battens and tape. Wooden battens follow the natural curves more easily without "sharp corners". And with tape you have to be more careful not to get "sharp" corners. For example, with my current Sphinx build I used wooden battens for the first layer because I didn't quite understand how the lines would be, and for the second layer I used tape because I already felt a bit more confident to set out the lines with tape. (Tape is easier to attach than wooden battens). In terms of dimensions I wouldn't go wider than 4mm (and not to thick say 1mm), whether it's tape or wood...and anything below that is fine. Again, experiment to see what you like

-

to paint or glue first?

Ronald-V replied to Mark Pearse's topic in Painting, finishing and weathering products and techniques

Not related to your question, but lovely planking! -

Very nice and clean build! Congratulations on finishing it

- 65 replies

-

- Maine Peapod

- Midwest Products

-

(and 1 more)

Tagged with:

-

That is some serious bending there! But you managed that well, looks good

- 35 replies

-

- vanguard models

- Adder

-

(and 2 more)

Tagged with:

-

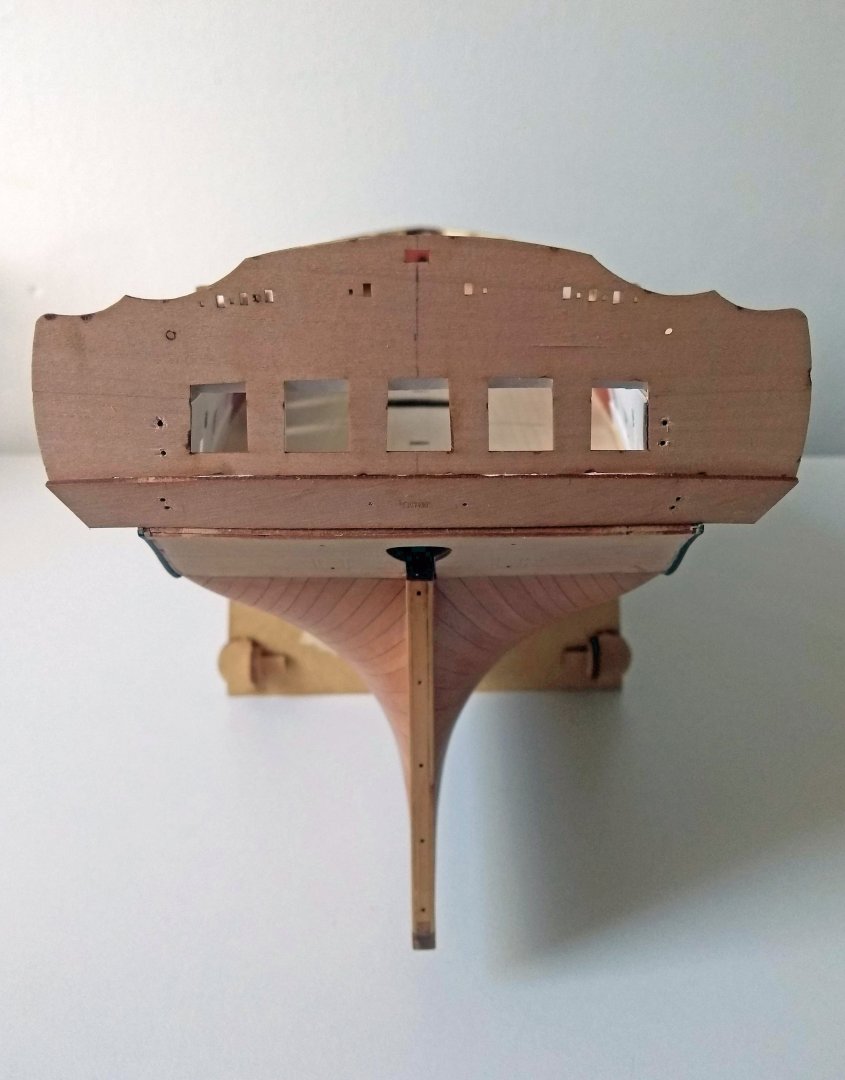

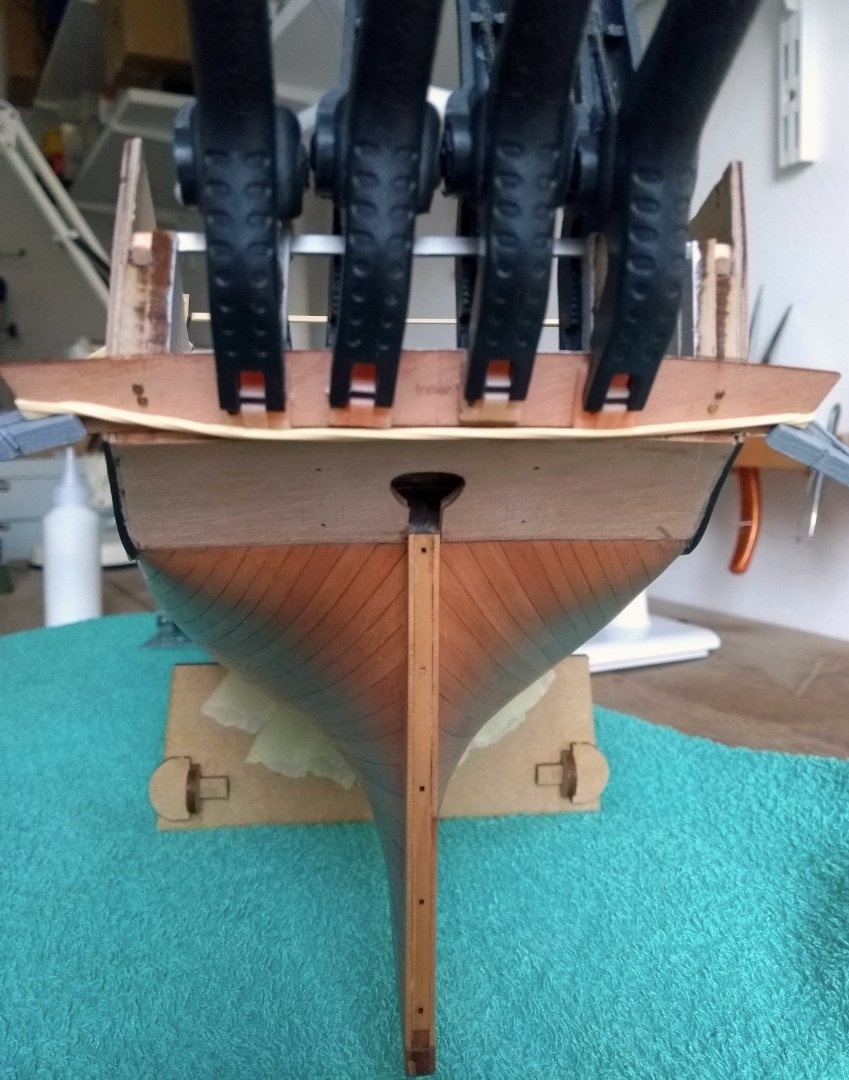

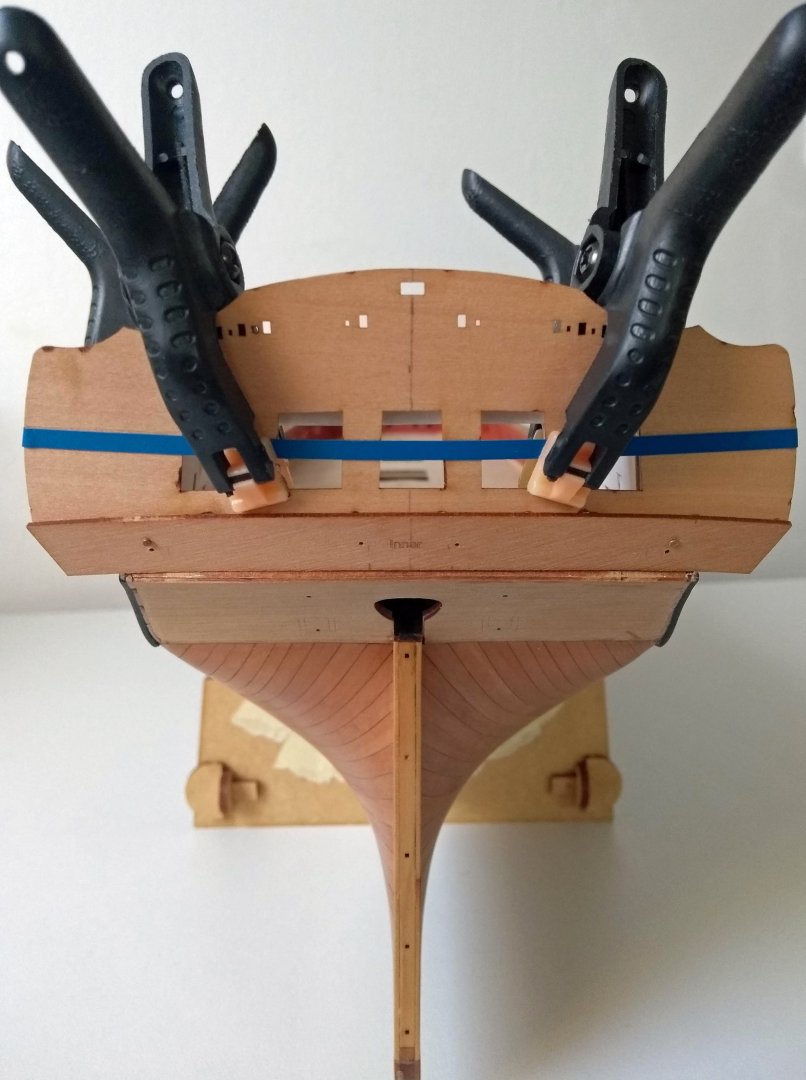

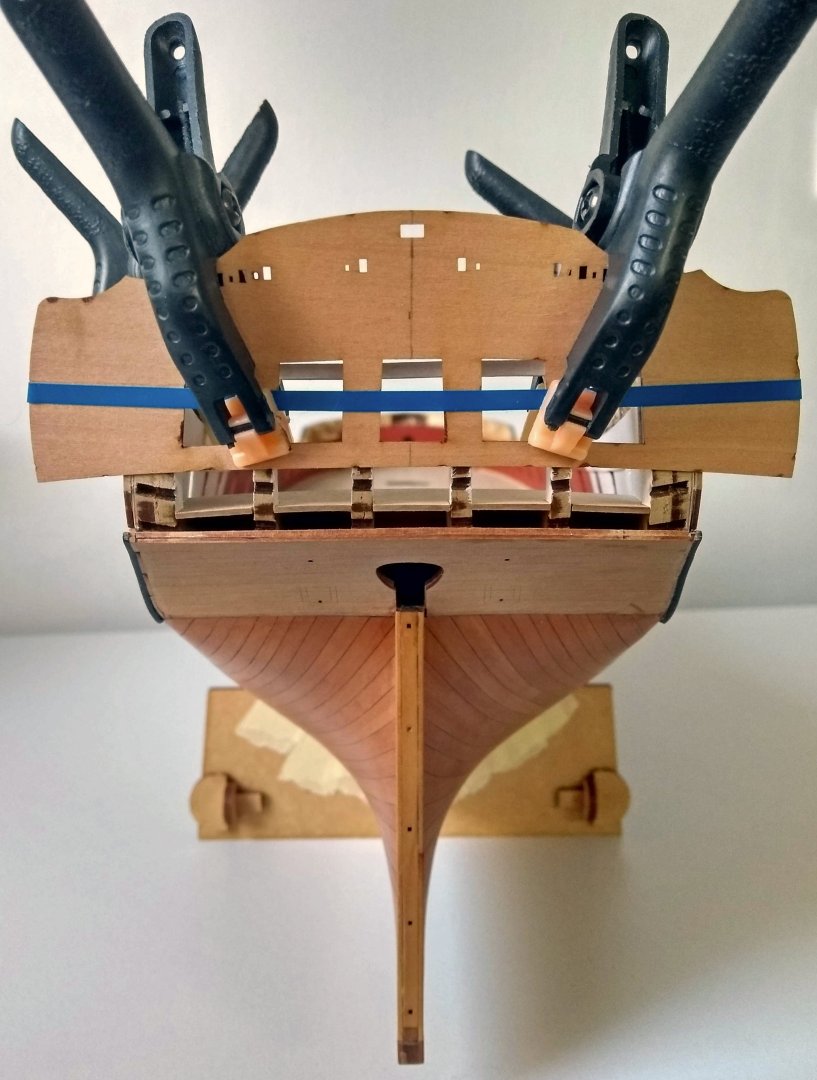

Update: Installing the stern gallery...this part went pretty smoothly! I think the pre-fitting when I was attaching the lower stern counter (post #92) definitely helped everything fit nicely...below is a photo report of how I glued the parts. First pre-fitting the (inner) stern fascia. This is the base that has to look good. Everything measured and worked from there. It turned out that the (inner) upper counter fit perfectly in between, which was a relief and confirmation that everything was exactly where it should be. Already tried the nails so that I can later push it into place with gluing. Gluing was easy and clamping was not difficult. Then it was just a matter of gluing the Stern fascia in place (it could rest nicely on top of the upper counter) And the result looks nice and straight and good (I think so ) Now comes the trickier part...the side galleries that probably need some modification since I have open doors. Let's take a step by step look at how I'm going to tackle it.

-

I wish you all the best with this one! A brave choice to go for an (old) Corel kit but I think it will be good in your skilled hands I do think it's a nice handsome little ship when it's finished.

- 97 replies

-

- Corel

- Große Jacht

-

(and 2 more)

Tagged with:

-

It would be nice if manufacturers would upgrade their products as newer techniques become available...but of course there is a price tag attached to that. I do wonder why some manufacturers continue to stick to white metal castings (like Artesania Latina with the new Victory) and don't switch to new techniques in the newer models

- 37 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.