russ

-

Posts

3,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by russ

-

-

-

Mike:

The rigging at the mast looks wonderful. If you had any trouble with the eye on that sling, it is well hidden. Very shipshape.

Russ

- Jack12477, mtaylor, Stuntflyer and 1 other

-

4

4

-

-

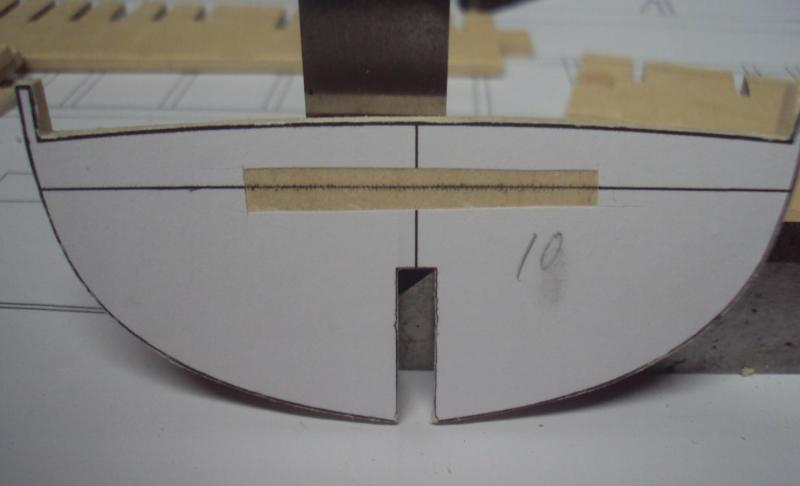

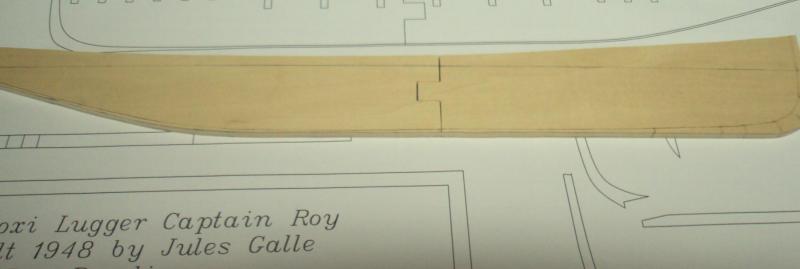

One other item. On my bulkhead drawings, I have placed a horizontal line to use as a reference. There is a corresponding line on the profile former. Once the line on the bulkhead meets the line of the profile former, I have the correct height for that bulkhead.

One problem I had early on was how to accurately transfer these lines from the drawings to the wood surface. Here is a how I did it. I used this on both the bulkheads and the profile former and it worked very well.

Russ

- src, mtaylor, captainbob and 9 others

-

12

12

-

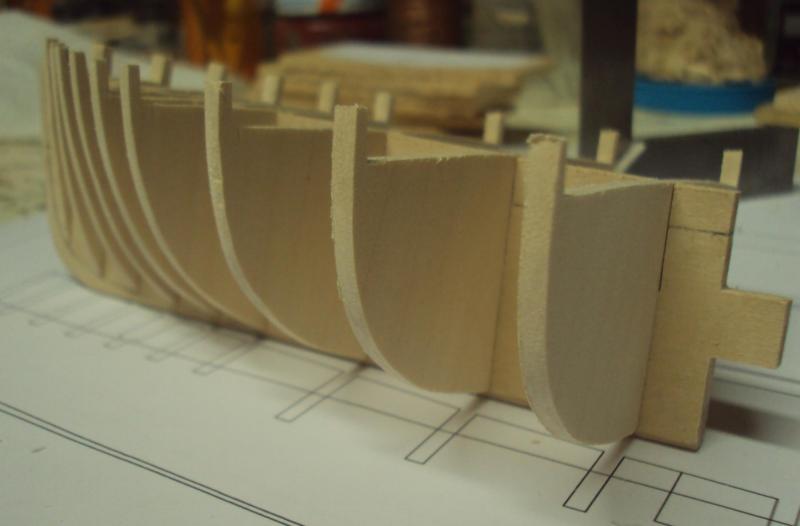

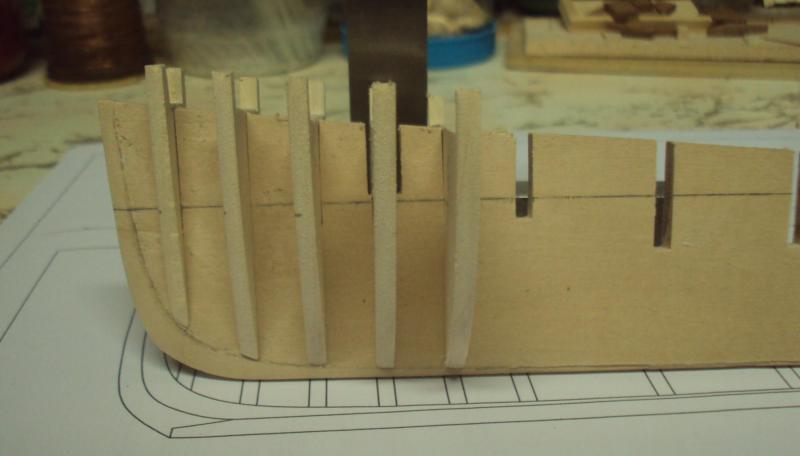

Some more progress. Nothing earthshattering, but I have shaped and dry fitted bulkhead frames back to about the midsection. So far, good plans and careful cutting and sanding have yielded very good results. A sample plank was laid over the outside of the bulkheads and everything looks good so far.

Needless to say, I am feeling pretty good at the moment.

Russ

- dj.bobo, Jack12477, captainbob and 9 others

-

12

12

-

-

-

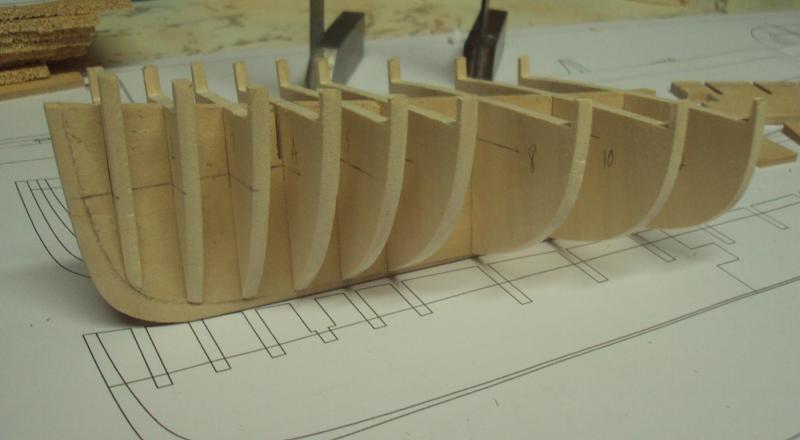

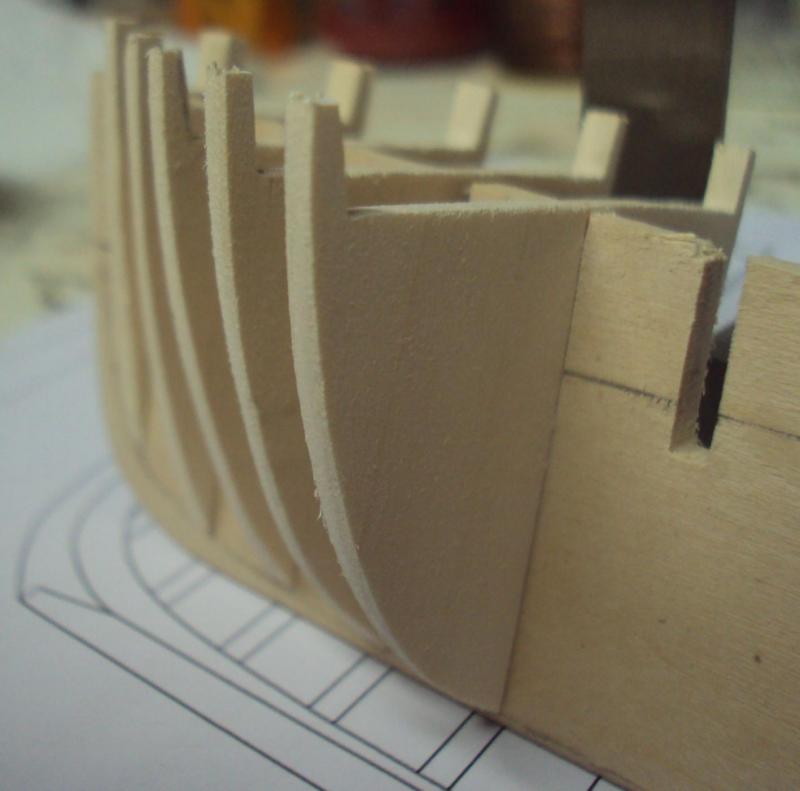

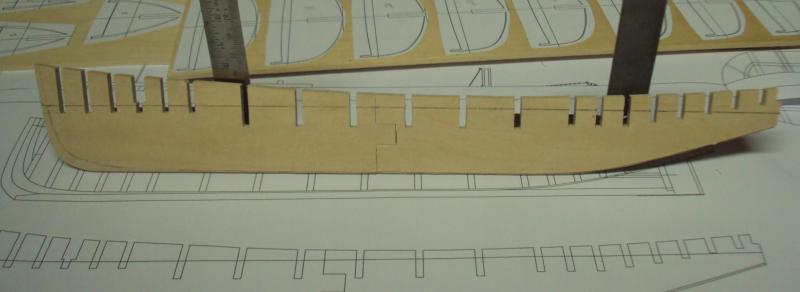

At the risk of boring anyone, here is the latest (and not much of it) progress in the framing. Bulkhead frames 1-5 have been cut and fitted into their slots in the profile former. Still some tweaking to do along the bearding line. I am going to fit all the bulkheads to make sure they slide in with just a little friction, but not glued in until the profile former pieces are glued together.

Bulkhead 5 will likely be replaced because during the fitting process, it broke right alongside the former and along the bulkhead's wood grain. I have another pattern glued up and I will probably recut that bulkhead tomorrow. I glued the bulkhead back together and the joint is solid enough, but I will have nightmares about it breaking during the final sanding before planking. If that happens, there will be the devil to pay. Better to recut it and not worry about that glue joint.

Russ

-

-

-

Ken:

Thanks. The components do resemble what you see in a kit, albeit with a few more bulkheads. If you cut and trim everything carefully, there is nothing here that is beyond the experiences of one who has built a kit or two.

There may be some plan sharing in the future.

Russ

- Elia, popeye the sailor and cog

-

3

3

-

-

Michael:

Thanks for looking in.

This was a fairly typical local fishing vessel from the 30s on through the 70s, although the later boats carried the heavier double rig instead of the single rig.

So far, I am trying to make sure that the framework is as close to the plans as possible. That will make planking (and everything to follow) much easier.

Russ

-

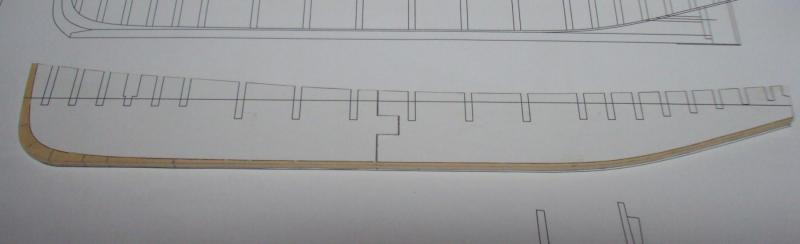

The rabbet has been trimmed, although it will require some fine tuning. Here is a photograph of the two pieces of the profile former roughly fitted, but not glued together. The daylight in the center joint is deceiving. When it goes together properly, the joint is much tighter. The paper pattern has been removed and the bulkhead slots have been cut and the trimmed to size. The bottoms of the slots will be fine tuned as each bulkhead is fitted.

Next is cutting the bulkheads and fitting them to their slots in the profile former.

Russ

- KennyH78, michael mott, mtaylor and 8 others

-

11

11

-

John:

Looks great. I agree about the ratlines.

I also was able to use regular chain for my anchors. I was a bit surprised when I looked at old photos and saw no stud links. Made my life a bit easier, for sure.

Russ

-

-

-

Ken:

Thanks. I have made the history of these boats my work and I hope to publish about it eventually. I am working from original customs house documents and photographs, as well contemporary newspaper articles, half models, etc.

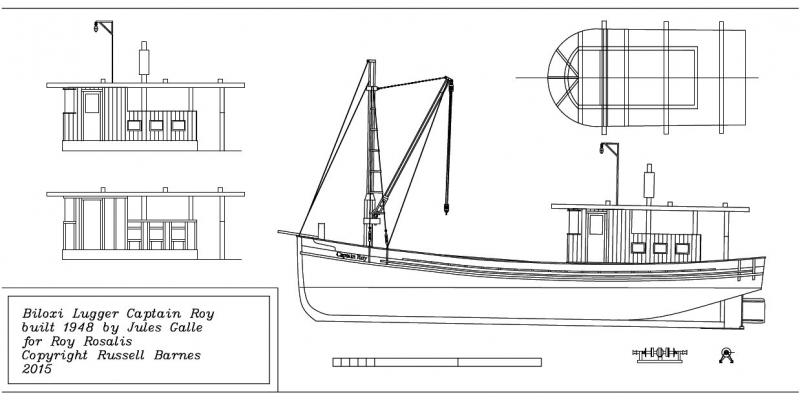

The plans are mine. They are developed from tonnage admeasurements and photographs. Nothing traced from any other plans.

Russ

-

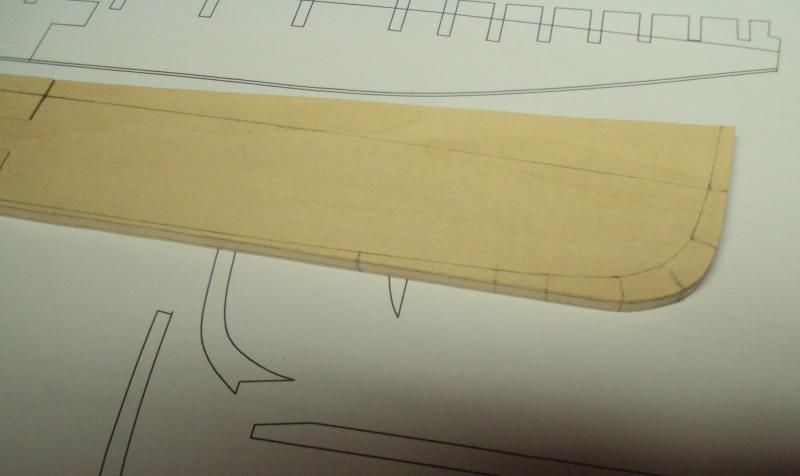

The next step is to cut out the pieces for the profile former. Although I could try and get the former out of a single piece, it is always possible/probable/likely that there will be a warp or twist that would ruin it. So, I decided to cut it out of two pieces with a jigsaw type joint between two bulkheads.

It is also important to trim that joint carefully to get a decent fit and alignment. On the pattern there is a reference line that must line up from one end to the other. This will help me fitting the bulkheads later on. Also, there is the bearding line that is marked on the pattern. This needs to flow from end to the other. This is all about sand, check, sand, check until each area is right down to the line on the pattern and it all fits.

Once the profile former pieces have been trimmed to their outer shape, the center joint fits and all has been checked for fit with the plans, I used a scalpel blade to trim along the bearding line on both pieces. The paper in the rabbet was removed and the bearding line transferred to the other side of the former.

I also measured and marked the edge of the former pieces for the depth of the rabbet. Next is actually trimming the rabbet.

Russ

- BANYAN, michael mott, rafine and 10 others

-

13

13

-

Great work. The skylight looks much better now with the black underneath.

Russ

-

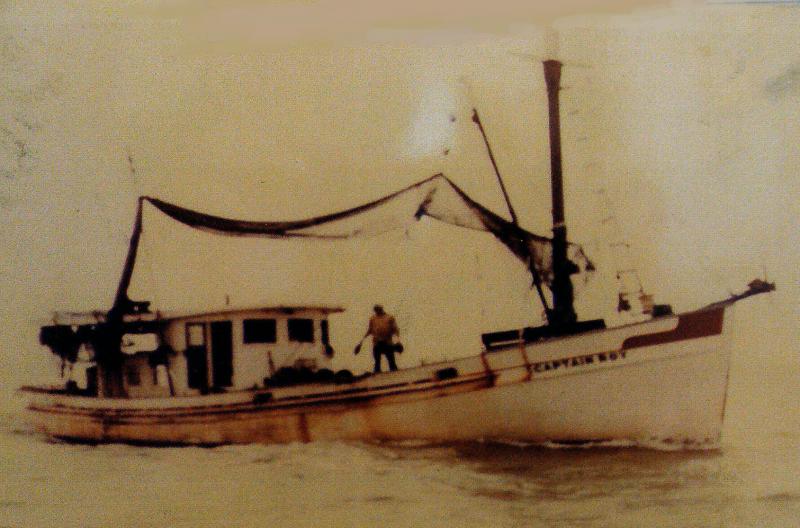

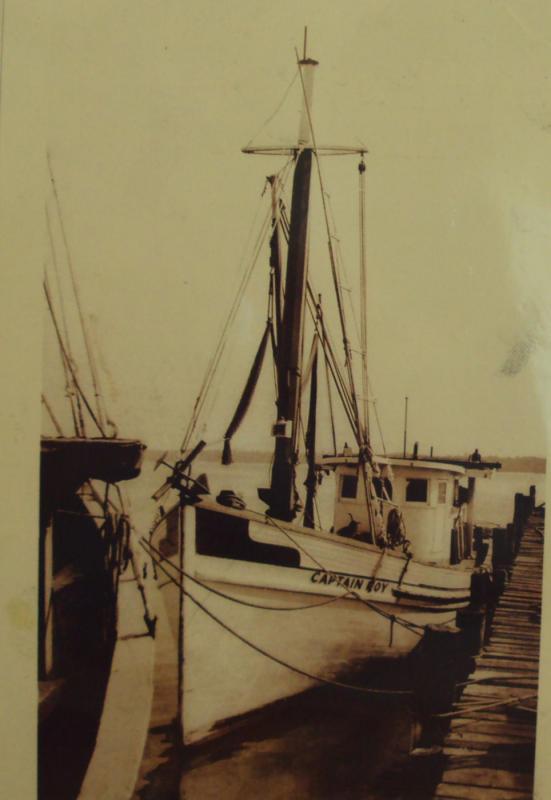

Most agree that it was taken from the sailing luggers that were used in this area in the late 19th century. They carried a dipping lug sail used in European waters, especially in the Mediterranean. They were built here by immigrant builders and sailors for local use. Many of those luggers were later fitted with engines and then later, newer boats that were built along the same lines were built with engines and were called luggers.

The Captain Roy is a later variety that is characterized by a larger hull that is a bit longer for its breadth and a bit deeper for its length than previous luggers. The earlier luggers from the 1920s-30s were rather small and tended to be a bit tubbier and more shallow.

I should mention that the term lugger in this instance refers to a Biloxi built motor powered fishing vessel with the pilot house aft. If the pilot house were up forward, as they were in many later built boats, they would not call it a lugger. The local term would be a "Florida rig", referring to the similarity with shrimp boats built along the Florida Gulf Coast.

Russ

- FriedClams, Elia, KenW and 3 others

-

6

6

-

-

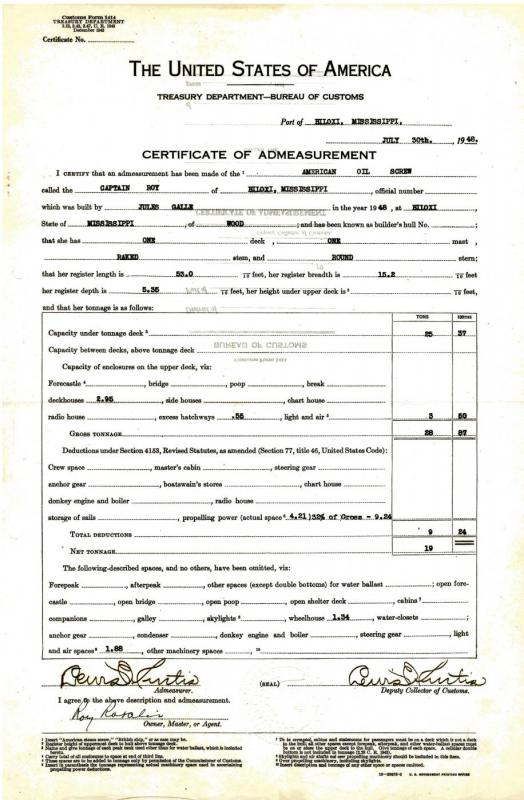

Hello everyone. I am starting a new project. This is a 1/48 scale scratch built model of a Biloxi lugger named Captain Roy, built in 1948 by local builder Jules Galle'. This was one of two identical luggers he built that year for Roy Rosalis, owner of Biloxi Canning Co. The other boat was named Boston Bill. I have used tonnage admeasurement data and photographs to reconstruct the lines and details for this model.

Here are two photographs; one is a rather poor copy, and a bow view. I also include the outboard view from my plans so you can see the finished model's appearance, and her original certificate of admeasurement showing her dimensions etc.

Russ

- FriedClams, Elia, KennyH78 and 12 others

-

15

15

-

Nice work on those vertical battens. That can be tricky work cutting and fitting, but they came out nicely.

Russ

Captain Roy 1948 by russ - FINISHED - 1/48 scale - POB - Biloxi Lugger

in - Build logs for subjects built 1901 - Present Day

Posted

Pat:

Thanks. Glad you found the build.

This one is a motor powered boat so very little rigging and no sails. There will be a trawl net and some machinery on deck, but compared with the schooner, there is a lot less fiddly work to be done above deck.

Russ