Roger Pellett

-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Roger Pellett

-

-

It’s good to hear that the Drs are not wasting time patching you up. Get well soon.

Roger

-

-

Ships boats can be categorized in two ways; by design and by function.

A cutter is a boat of specific design; lines finer than a Launch but not as fine as a pinnace, designed to both row and sail well, and usually equipped with a wash strake for additional freeboard.

A jolly boat is a small cutter.

A gig is a boat intended to serve a particular function; transporting the ship’s captain. It’s design could vary. It could be a cutter or any other easily rowed boat like a pinnace. Its finish is usually fancier than other ships boats.

Likewise, the term “Barge” refers to function, not design. Barges are the designated boats for Flag Officers.

Roger

-

There is a classic movie taken by Irving Johnson rounding Cape Horn aboard one of the large four masted steel barques. The movie starts out with him practicing for the voyage by standing and balancing on top of a telephone pole.

Roger

-

I recently plated a Great Lakes Steamship Model with Paper. In this case the paper simulated steel shell plating, not copper sheathing. The principles would be the same for either. The actual shell plating of the vessel that I am modeling would have been 1/2 in thick; at a scale of 1:96 this equates to about .005 in.

Observations, lessons, etc:

I used an archival quality paper. Actual thickness was closer to .010in; twice scale. I didn’t want later coats of paint to hide plating laps. The eye is not particularly good at judging the difference in thickness.

I first saturated a full sheet of paper with shellac. I then cut individuals plates with a guillotine paper cutter. BTW: I find this to be a handy workshop tool that I use all the time. I found that paper without shellac was easily damaged.

I glued each plate in place with regular PVA woodworking glue. I spread the glue with a palette knife and held each plate in place until the glue grabbed. In cases where the edges curled up, rubbing the paper edges with my fingernail was sufficient. Clamps, pins, etc were not necessary.

Almost all plates were a “developed shape”; they easily fit the curvature of the hull in two dimensions. The few that had a 3-D shape were formed by draping a wet piece of untreated paper over the area in question, allowing it to dry, and then cutting it to its finished shape; an advantage of wet paper, it can be shaped in three dimensions.

The plated hull could be lightly sanded to clean it up.

Paper Copper Plating could be painted in two stages. A full sheet could be painted with a base coat; copper paint, metallic dust, etc. After the plates have been attached to the hull, it could be shaded, highlighted, etc.

Roger

-

For a future project, I have been thinking simulating copper sheathing with painted, very thin paper. I believe that this offers several advantages, namely:

It would avoid the need to use either pressure sensitive tape or contact cement. I am concerned that pressure sensitive tape will “let go” later in the model’s life and contact cement can be incompatible with modeling material. The old fashioned contact stuff that actually works gives off explosive fumes.

Paper can be glued on with ordinary PVA glue.

Applying paper does not leave a trail of fingerprints and surplus glue that are difficult to remove. Surplus PVA can be easily cleaned up with alcohol.

Very sophisticated color patterns, shading, etc. not possible with real copper can be applied with paint.

Roger

-

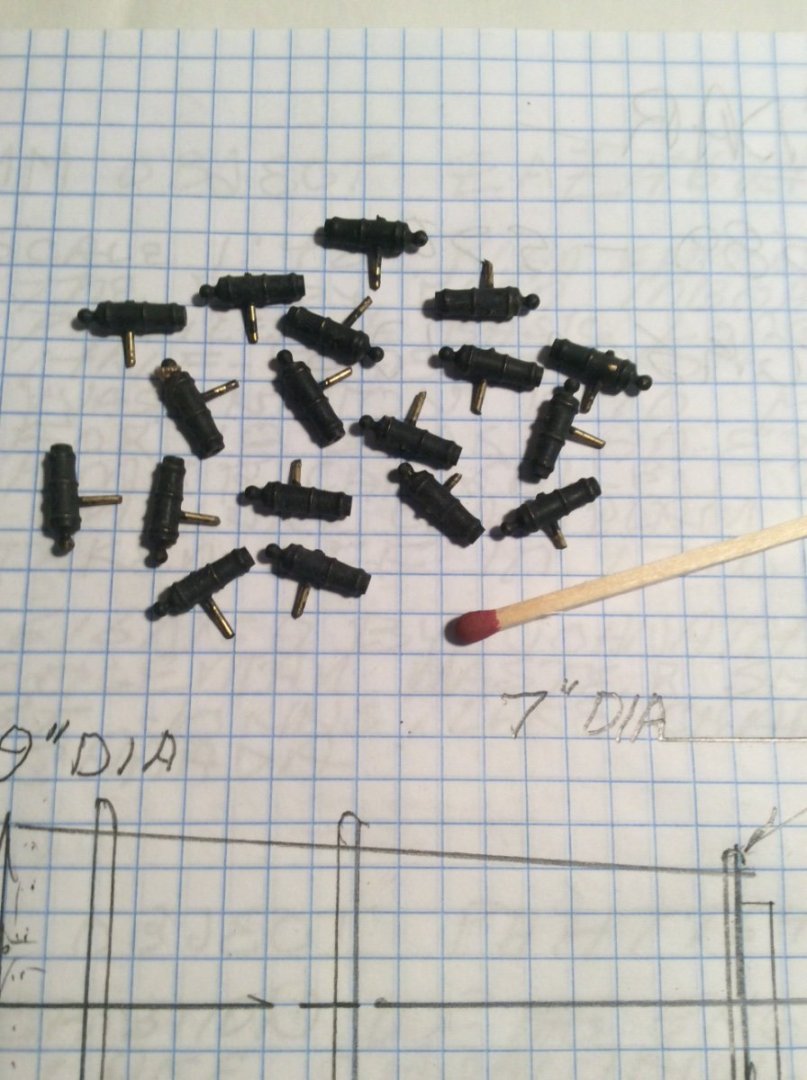

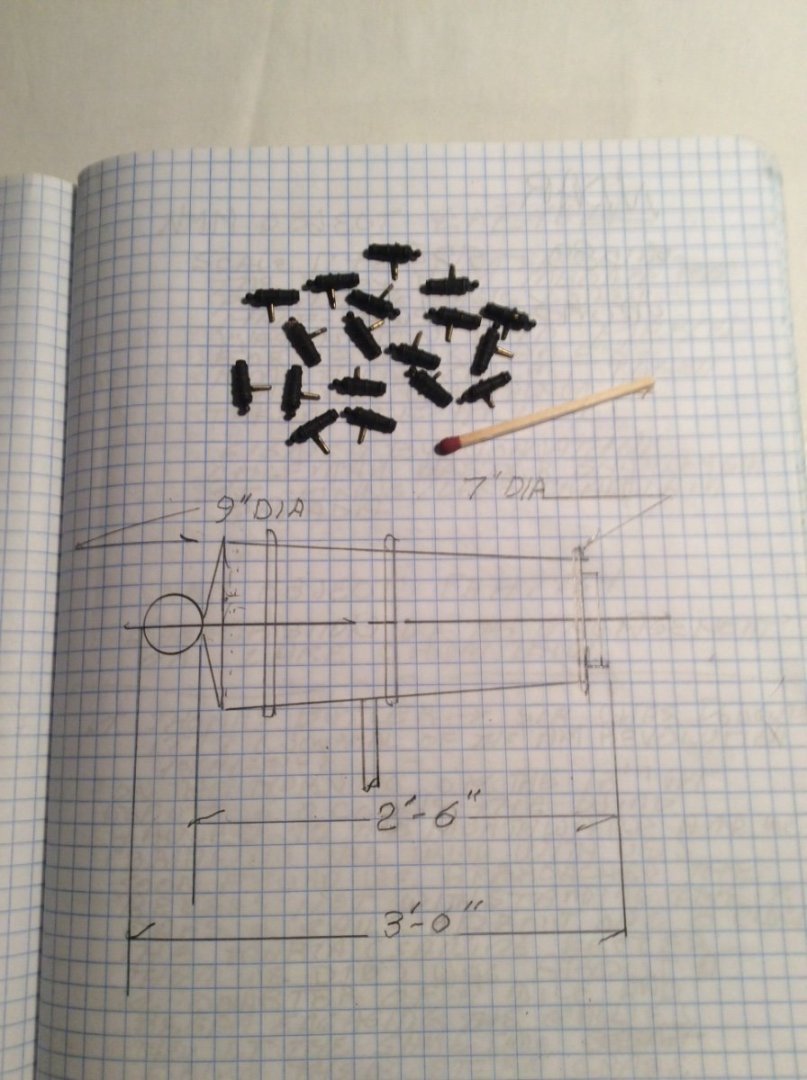

Dennis, see PM associated with this post. These 18 carronades were turned from BRASS by A.J. Fisher way back in the 1960’s. Yes, they are 60 years old. Their bores are even drilled concentrically. Dimensions to 1:64 scale are posted in the 2nd photo are posted below. The black finish is an “oxidized” finish applied by A.J. Fisher. They are actually all the same size despite the photo.

Roger

- GrandpaPhil, mtaylor, thibaultron and 2 others

-

5

5

-

The Classic wooden ship model seldom included sails. Why? As Jaager explains, they are next to impossible to make to scale; they collect dust, especially with an uncased model; and old time model makers were often more interested in hull shape and deck arrangements than rigging. Even today sails are seldom seen on models offered for sale by known professional builders. If you want to build a model from a kit, don’t bother paying extra for the sails.

Roger

- Keith Black and mtaylor

-

2

2

-

At least this didn’t happen on your personal ski hill where medical help was not available. Get well soon!

- mtaylor, Dave_E, Old Collingwood and 4 others

-

7

7

-

Based on your previous efforts including the “Credible Hulk,” this should be a show stopper!

Roger

-

-

-

I am acquainted with Jim Delgado. He has attended a couple of our Gales of November maritime history conferences here in Duluth. One year I was his duty driver and spent the afternoon with him touring the whaleback Steamship SS Meteor. He also reviewed my book about whaleback steamships and his favorable “blurb” is quoted on the back cover. He’s a nice guy.

My impression is that he has a good understanding of maritime history and of course specialized knowledge of projects that he has been involved with. He is not a Naval Architect or Marine or Mechanical Engineer. The last that I heard, he had left Government Employment (NOAA) and had joined SEARCH, a private maritime Archeology firm. I would think that your group and Brian Pierce are now the Civil War Gunboat experts.

Roger

- Cathead, Keith Black, mtaylor and 2 others

-

5

5

-

-

These river gunboats were hybrids: warships built by civilian contractors using western rivers steamboat technology. To further complicate matters, they originally came under the jurisdiction of the Army. And, these guys were in a hurry! It therefore makes sense that few of the usual Navy or even Government design practices applied and at least some engineering happened on the job.

Doctors for pumping feedwater might have been available or at least there were mechanics locally who knew how to quickly build them. Such might not have been the case for a combination Doctor/Auxiliary Engine.

There are also some unknowns involved in building ship models and the more details the more unknowns. Both you and Brian Pierce have done an excellent job of untangling snarled information to build excellent models

Roger

- mbp521, mtaylor, Keith Black and 2 others

-

5

5

-

-

The couple formed by the opposing weight and buoyancy forces always tries to rotate the hull so that these forces are perpendicular to the vessel’s actual waterline. If the vessel is in a heavy sea traveling parallel to the crest of the wave then these forces will try to rotate the hull until they are perpendicular to the slope of the wave. The stiffer the hull from a stability standpoint, the more violent this action becomes. The mathematical measurement of this stiffness is called the Metacentric Height. I tried to explain this in a non technical manner in post #34 above. While a large metacentric height makes the vessel stable in still water, it is not necessarily desirable in rough water. Passenger vessels and battleships were intentionally designed with smaller metacentric heights to reduce motions in rough weather.

Wether the rolling hull actually capsizes depends on the vessel’s Range of Stability, the point where the couple trying to right the vessel disappears. This is actually heavily influenced by the shape of the upper part of the hull.

The tenderness that I described in post #34 caused by a very small or nonexistent metacentric height will not necessarily capsize a vessel. Often the hull will list until the two forces align and will not tip further. The danger is that the list will allow flooding through hull openings that are normally above water. The “free surface” from this unrestrained water further destabilizes the vessel.

It’s a surprisingly complex subject and not particularly intuitive.

Roger

-

-

The initial stability of a floating object is not a function of sea state. A boat with a low metacentric height can be tippy in a flat calm due to the moving weight of the people on board. The worst loss of life on the Great Lakes of the USA occurred when the excursion steamer Eastland capsized at her dock in the Chicago Harbor.

Roger

-

That’s a really interesting paper that deserves careful study when I have time. Thanks for posting it.

Meanwhile, a hopefully simple explanation of a subject that has confused more than one Naval Architecture student. We can limit our discussion to Initial Stability or the tendency of the boat to list slightly from an even keel. This is what makes the boat feel “tender.”

There are two forces involved. These are “vectors” as they each act in a specific direction. Acting down from the boat’s center of gravity and perpendicular to the surface of the water floating the boat is the weight of the vessel. Acting upwards from the boat’s center of buoyancy and parallel to the weight vector is the buoyancy force. According to Archimedes these must be equal.

With the boat floating on an even keel, the two opposite vectors lay atop each other. If the boat is heeled slightly, the boat’s center of gravity remains unchanged but its center of buoyancy and associated upward vector shifts in the direction of the heel to reflect the new shape of the submerged portion of the hull. Since the two vectors are separated, the resulting couple formed by the downward weight and upward buoyancy acts to return the boat to its upright position. The tendency for the boat to return to its upright position therefore depends on how far the center of buoyancy moves when the boat is heeled.

We are used to equating stability with objects where the object’s center of gravity is below the center of the upward force, but except for heavily ballasted sailing yachts this is often not true for floating vessels. Hull shape that determines the center of buoyancy therefore becomes an important factor. The center of buoyancy for a boat with a rectangular hull cross section shifts considerably when the vessel is slightly heeled so the hull feels very stable. On the other hand, a when a cylinder rotates, its geometric shape never changes so the upward buoyancy force does not move. Unless the center of gravity can be made much lower than the center of buoyancy the boat becomes “tippy or tender.”

The hull cross section that Steven posted above will produce a more stable vessel than a cylindrical one. One with “harder” bilges will be even better. On the other hand, with so much of the vessel’s weight concentrated in the rowers well above the waterline it was probably difficult to design adequate initial stability into these hulls.

Roger

-

-

The google book scanning project began with two major US. universities, Harvard and the University of Michigan agreeing to digitize their library collections for public use. Other large libraries have probably joined since. Michigan’s collection is particularly important since their College of Engineering includes an important Department of Naval Architecture and Marine Engineering.

This project was probably staffed by students paid with financial aid money, not faculty with a deep love of the subject matter. Much scanning would, therefore, been done more or less on “autopilot” without stopping to unfold drawings or to adjust scanning equipment. I have several reprinted books published by the University of Michigan Press and although they are much better done than the many of the reprints, they are still missing all or part of some fold out pages.

Roger

-

The things that you are looking for are not specialized. For these, I would look on Amazon. For example, they or their affiliated suppliers carry Vallejo products. For a wood filler, I keep a can of Durham’s Rock Hard Water Putty on my shelf. This is easily colored with a dab of poster paint powder; the stuff used for grade school art projects. I bought the last can of water putty from Amazon but our local Ace Hardware Store also carries it.

For specialized items; blocks, rope, fittings, etc. I defer to others.

Roger

-

Eric, Can you use the resin casting as a former to be removed once the Pilot house has been assembled?

- Keith Black, Cathead, mtaylor and 2 others

-

5

5

Small Boats: 18 foot Cutter, Jolly Boat, Captain's Gig

in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

Posted · Edited by Roger Pellett

Allan, That certainly looks like a small cutter. This sort of documentation is really useful as it often shows details not shown on Admiralty draughts. The forward mast step is interesting.

Another poorly defined boat that could also be called a Jolly boat is the yawl.

I also suspect that back in the day seamen could identify these boat types using their seaman’s eye to identify hull subtle shapes not apparent to us today, eg. the difference between a yawl and a cutter.

Roger