-

Posts

9,703 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

The base is just as important as the model itself. A poor base and case can really degrade the overall look of a project. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You dont really have to. Its up to you. Some people like more filler at the bow and others dont. For fairing…just try many methods and approaches until you find one that works best for you. Its not a fun job so try and find the most comfortable approach for yourself. Chuck

- 274 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

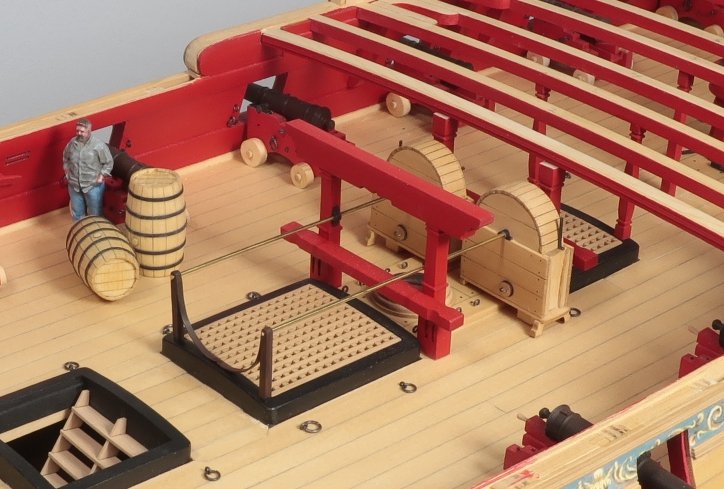

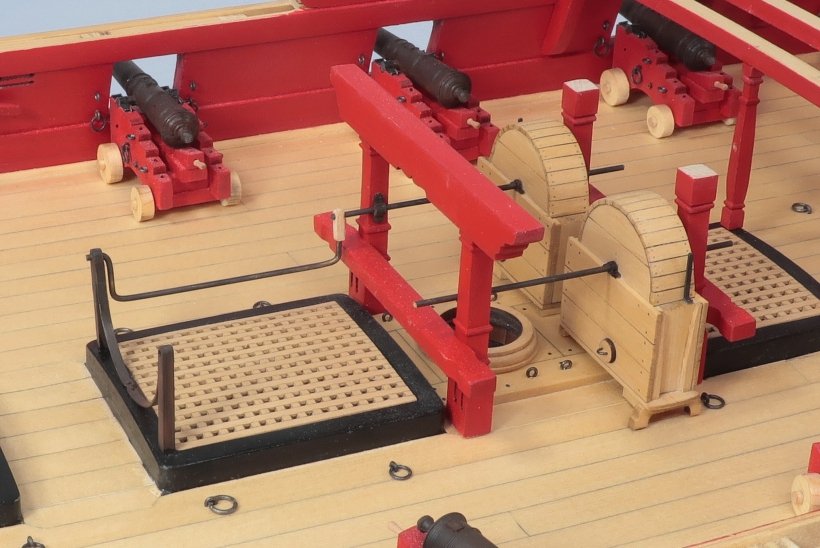

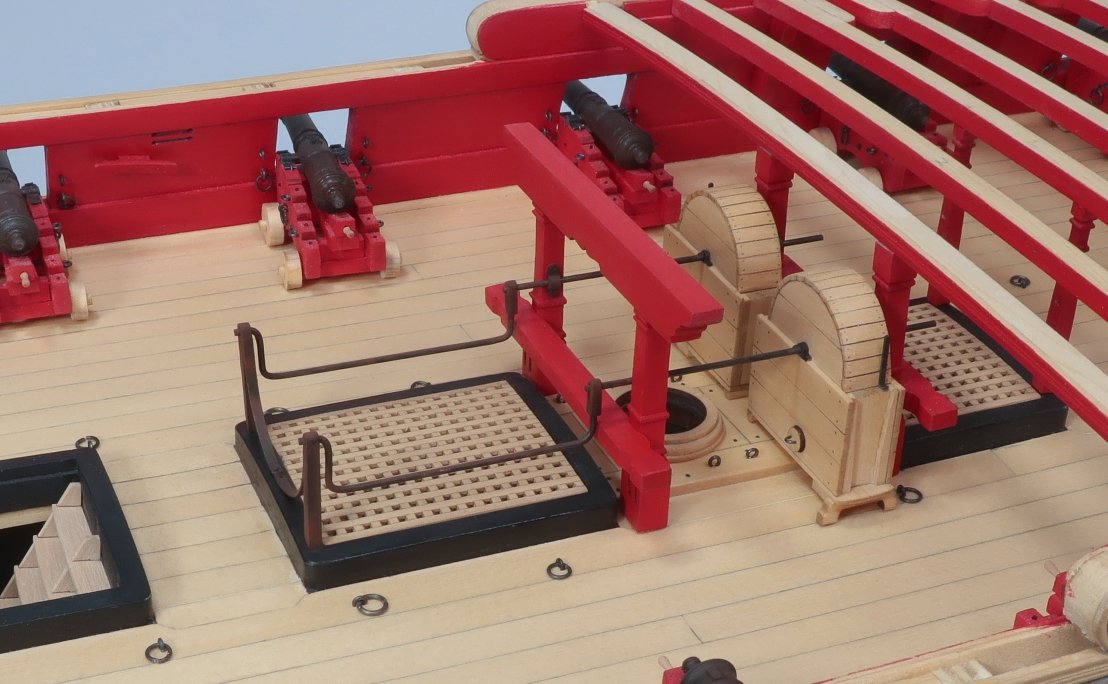

Finished the elm tree pumps which effectively finish chapter 7. I will get the printed chapters ready this week for both chapters 6 and 7. I will also be working on getting the parts for this chapter ready within a week or so. There are a whole bunch of laser cut parts for this chapter and more than usual so it will take a little while. There are probably more laser cut parts in this chapter than in many complete kits. Making the elm pumps is pretty straight forward. Same as those for Cheerful and other kits. 1.You can use a 7/10/7 ratio to transfer lines to each side of the 3/16" square pump tube. This will help you turn the 3/16 x 3/16 x 5/8" boxwood strip into a neat octagon. But its such a short piece that like me you may be able to eyeball it and sand it to the octagon shape with a nail file. Carefully file the tube to an Octagon using the lines or your eye as a guide. Drill and bore out the top of the tube to a depth of about 3/8". Carefully use a bit that will leave the pump tube walls not too heavy. 2. File and shape the bracket for the handle. The part that sits against the pump tube is tapered thinner so it fits on one facet of the octagon. Use a slotting needle file 1/32" thin or less to file the slot in the top to a forked shape. This will accept the handle. 3. Place a 1/16" x 1/16" strip in a dremel to round it off for the spout. Using an emery board this takes only a minute. This will become your pump spout. Drill a hole into the end before parting off a 5/64" long spout. Glue it to the pump tube. All pieces can be painted first. 4. Using some black tape or even painted painted black paper, cut it into thin strips about 3/64" wide. This will simulate the iron band at the top of the pump tube. 5. Glue the bracket into position. You could paint it black like I did or leave it natural. 6. Insert a length of 24 gauge black wire into the hole on the end of the handle. Like an eyebolt. Insert the end of this long wire into a pre-drilled hole in the bore of the pump tube. Adjust the length of the wire until the other pivot-hole in the handle sits in the bracket nicely. The handle should be in the downward position to be correct. 7. Finally insert a small length of 28 gauge black wire into the bracket hole and through the handle to lock it in position. Snip it off on both sides so it stand proud of the bracket's surface just a little bit. Finishing all of the deck fittings and beams does really change the overall look of the model. Its starting to fill in with all of those wonderful details. This makes you want to add more of them which I will do shortly. Chapter 8 will be doing this same work but under the forecastle beams. Finally get to make the stove and other bitts. Just look at how the model is filling out nicely with detail. Just try not to snag those elm tree pump handles as you work on other stuff on the model!!! Boy that forecastle area looks so empty!!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chapter 6 is just adding the guns. Its not written yet as a pdf chapter but is described in robust detail in my log. It is also described in the instructions for building gun carriages in my store. Its the same carriage. Kent...when are you gonna start a build log?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very nice. She looks perfect and to scale. Well done!!

- 185 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful start. Enjoy the project!!! 😊 I will follow along....

- 274 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks fantastic Glenn You are almost all done. The ratlines came out really good. It will be a nice relaxing coast to the finish line now.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes indeed.....chapter 7. Chapter 8 will be the fittings and beams for the forecastle....

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

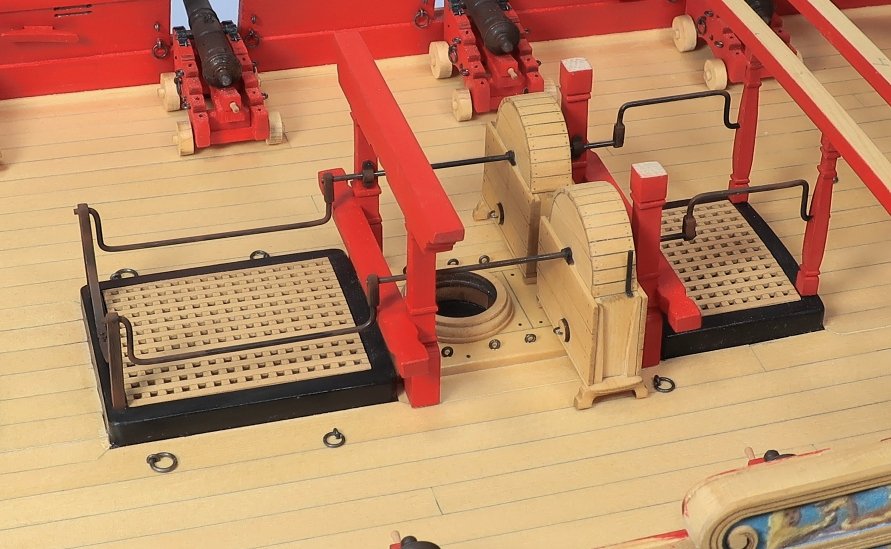

The chain were completed. I finished the crank handles on the aft side of the pumps. They were done exactly the same way as the forward crank handles. Then those two remaining qdeck beams were permanently glued in position along with the lodging knees. It feels good to get those done. All that remains in this chapter is to make and add the two elm tree pumps. I may start on those tomorrow.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

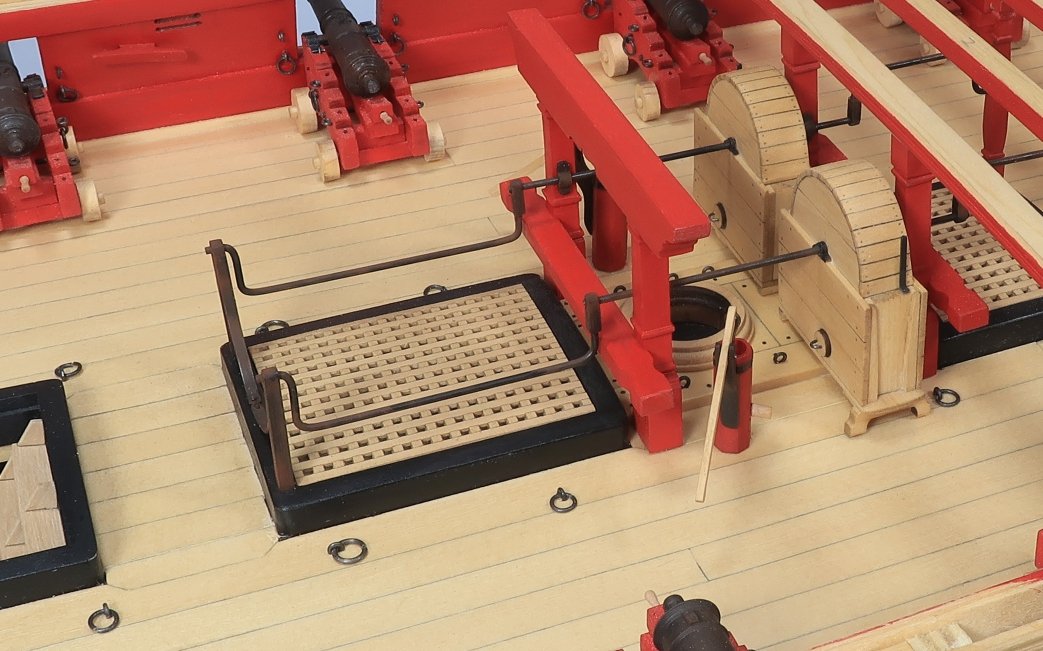

Today was a good day to work on the model....cold and rainy. Continuing the chain pumps.... The crank handles are next but I needed to make the forward stanchions for them. I posted some contemporary examples of those earlier. You can make these all out of brass if you like. Like so many other parts, they can be made using boxwood if your careful and neatly built them. It becomes all about how you finish them or paint them. The stanchions will hopefully look similar to these. I used a 5/64 x 1/16" boxwood strip and shaped it as follows. Attached to this was an actual brass strip that was bent to the curved shape needed and blackened. I drilled a hole for the crank in the top of the boxwood strip and rounded off the top. I determined the height of the stanchion by using the 1mm brass rod as before. Once the height was good I glued the bent brass strip....1/64" x 1/16" brass strip to the wood stanchion. Its the same width so it will all look like the same piece if carefully sanded and painted and weathered. Here is what it looks like on the model. This is also how I determined their height. Then it was time to make the crank handles. I cut the center brass rod to length and blackened it. It was cut so the crank handles would clear the horizontal cross timber on the gallows. so the brass rod overhangs the horizontal timber of the gallows and jeer bits on the other end. See below. The crank handle was bent to shape from the same size 1mm brass rod. But the square portion was once again made from boxwood. I left it unpainted in the photo below. I used the same 5/64 x 1/16 strip. I drilled one hole for the main shaft and another for the bent crank handle into the end of the piece. I glued it onto the end of the bent crank handle. Its a very simple concept. Once painted black and brushed with some weathering powder it will all look very convincing....I hope. To position it, slide the wooden end onto the main shaft first. But the crank handle needs to be in the "up" position. just rotate it so the bent crank is on the top. This will allow you to clear the cross beam of the gallows. Slide it on and then insert the forward end in the "iron" stanchion on the edge of the grating. Below both crank handles are completed and painted....with some weathering powder. Next I will repeat this for the bent crank handles on the aft side of the chain pumps. I think it turned out pretty good for a low tech assembly.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Simply beautiful!!! No other words for it. Well done. I am glad you enjoyed the project. That is a superb model.

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

They sell pre cut small square sheets of copper like gold leaf. Its thicker than gold leaf and is quite durable. It sticks on any surface just like goldleaf would with the same techniques. Easy to cut and perfect scale. You take several sheets at a time and cut them to plate size with a scissors. Then apply. Its easier to cut when you hold several sheets together. Its super cheap and you get a million sheets in a package. This is the stuff the apply to picture frames and architectural items. so its sturdier and thicker. https://www.google.com/search?q=copper+foil+sheets&tbm=isch&ved=2ahUKEwjGtM31iO_wAhUMeDABHcLpC20Q2-cCegQIABAA&oq=copper++Foil&gs_lcp=CgNpbWcQARgFMgQIIxAnMgIIADICCAAyAggAMgIIADICCAAyAggAMgIIADICCAAyAggAOgYIABAHEB46CAgAEAgQBxAeUJSSGVjKpBlg8boZaAFwAHgAgAGjAYgB9wSSAQM3LjGYAQCgAQGqAQtnd3Mtd2l6LWltZ8ABAQ&sclient=img&ei=YUuyYIaACozwwbkPwtOv6AY&bih=594&biw=1293&rlz=1C1CHBD_enUS907US907#imgrc=r9I6_xHdNEextM

-

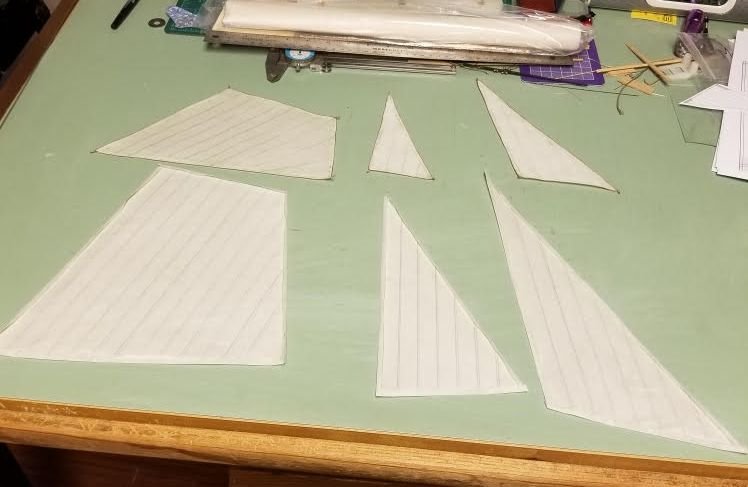

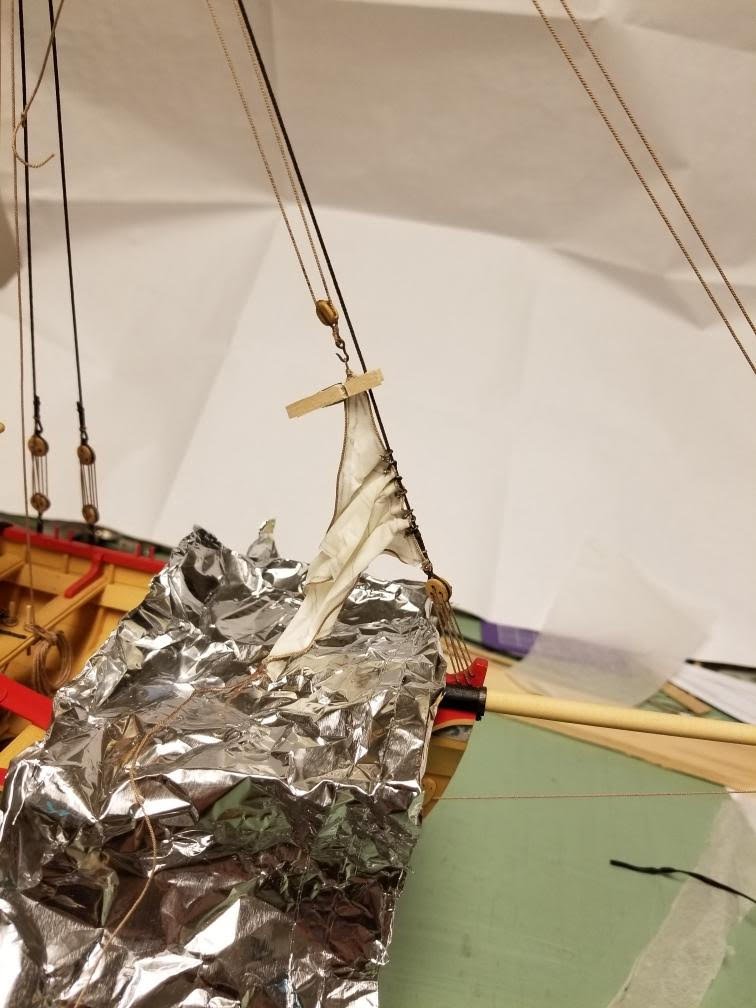

This model is 1/2" scale so I believe he went with 3 layers of silkspan. I cant remember. This is what it looks like completed. Note how the jib sail is furled and brought in close to the fore staysail. Just a small portion of the sail on the bowsprit with the traveller ring brought in a bit more. I will have better photos soon enough and hopefully Tom will post his step by step....all three sails are on the model and look very natural and to scale. These furled or semi-furled versions are smaller in size than if you set them full sail.... Below you can see the two sizes of sails. The full sized sails as if you were setting them raised. The three smaller versions are on the top row with bolt ropes ready to be used as the furled versions. If you tried to furl the full sized sails it would look to heavy and thick and out of scale. So Tom reduced their size accordingly....before setting them on the model as naturally laying furled/semi furled sails.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I love the look of furled or partially furled sails on a small boat like this one. A good friend of mine and fellow club member "TomShipModel" was kind enough to take my Medway Longboat model and do just that for. I am horrible at this and would have certainly made a mess of it. Tom is certainly an expert at it and I have seen the work he does with sails on his models. So I was so happy he agreed to do this. It has been a learning experience just watching him do this. He used the sail plan that is available for download here. Here are a couple of in progress photos. Tom said he has a bunch of pics and post a how -to of sorts when its all done. I will certainly post more pictures. The sails are made of silkspan. And one of the fore staysail underway....just beautiful work. Hanging very naturally.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks lovely. I am close to getting a shipment of milled cherry so I will soon have more of these kits available. You are doing an excellent job on it. Very elegant indeed.

- 185 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I doubt anyone would want to pay for that. The biggest issue is laser cutting the thicker boxwood. Its not easy using a 75 watt laser. The laser kerf is too thick and lots of burning. The Cheerful is easier because most of all the parts are laser cut from thinner boxwood sheets easier to laser cut. It would end up costing someone well over $2000 - $2500 to build it in boxwood because its so big. so probably not.

-

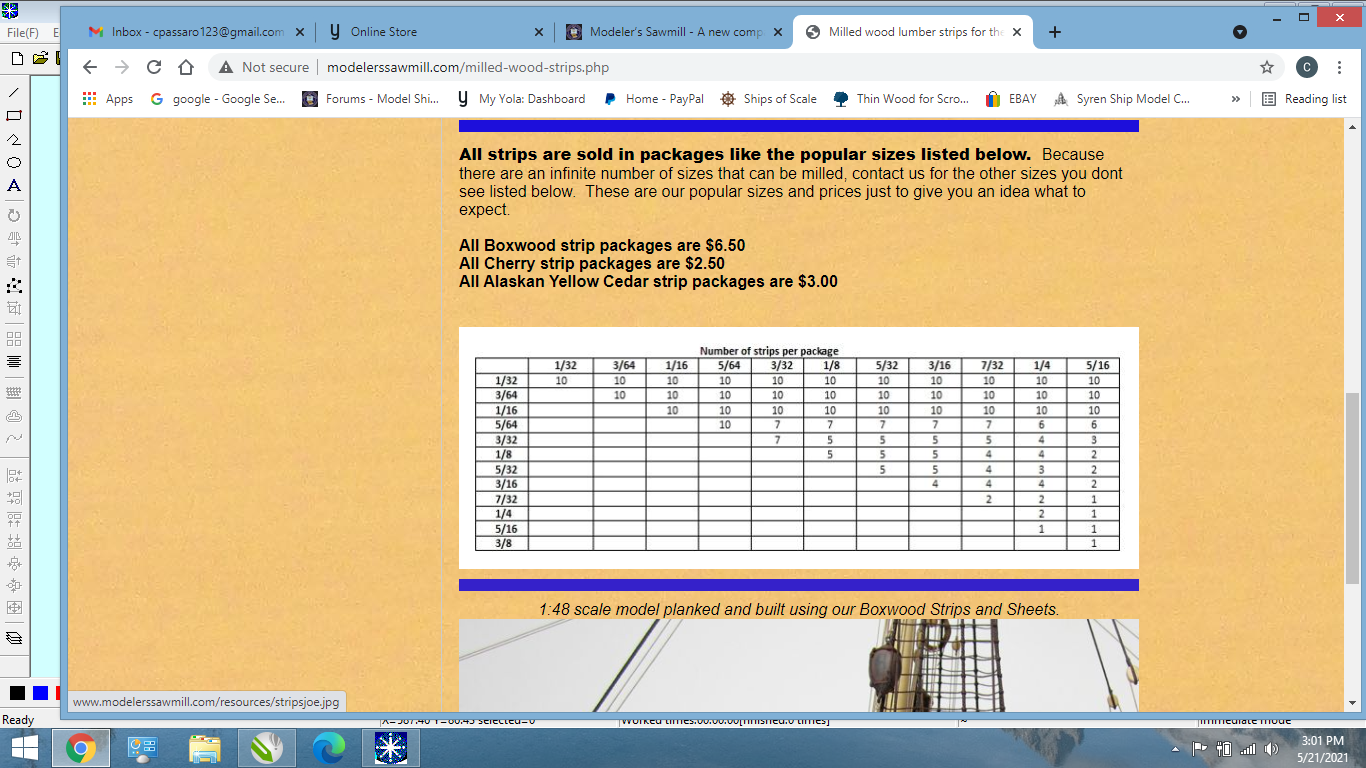

Thats great. Thank You. He has the list of wood required for the Cheerful wood packages. So if you want the pre-milled strips for the model in the Option B wood package....you can order it from him. Because he can do that now, I am even go to go back to offering an all Boxwood Cheerful starter package. You will be able to buy the parts all in Boxwood once again and get both the wood packages in Boxwood from Joe. That will be in stock next week sometime. He will start keeping lists of what is needed for all of my Syren projects for the strips needed and even other kit MFG's. Chuck

-

Joe is all set up and ready to go. Here is his website. He should have Swiss Pear in a couple of weeks. But for now....Boxwood, Yellow Cedar and Cherry. Contact him for stripwood needs. http://www.modelerssawmill.com/ Joe will be coming onboard as a sponsor real soon....so look for his banner. He has signed up as a member as well. If you need to send him a PM. His username is "Joe V" Chuck

-

I am helping him look for it but other than Domex its hard to find folks selling raw billets thicker than 1”. This is problematic. And when you do it is selling for $65 to $75 a board ft. With no guarantee it will be white like we expect. So the search continues. so for Holly it will be the last thing he probably sources and mills. Prices are crazy.

-

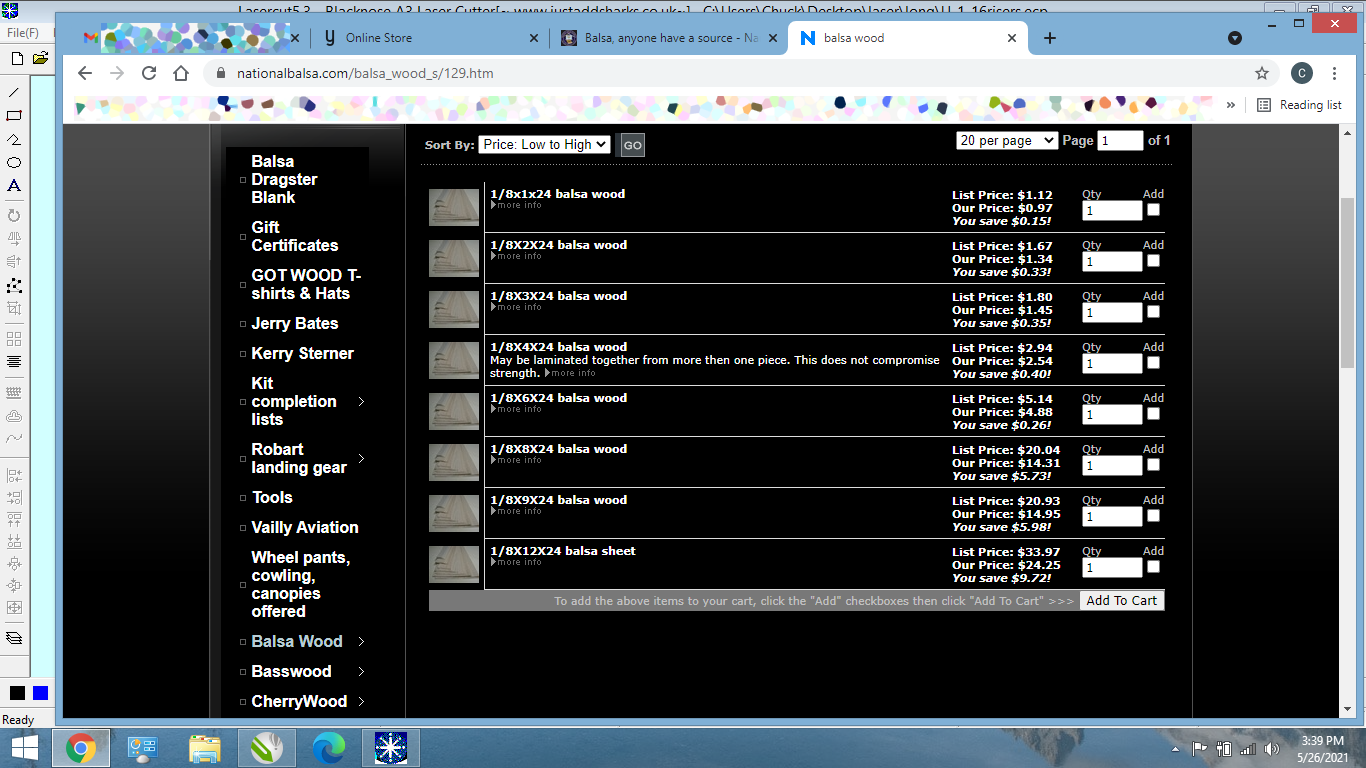

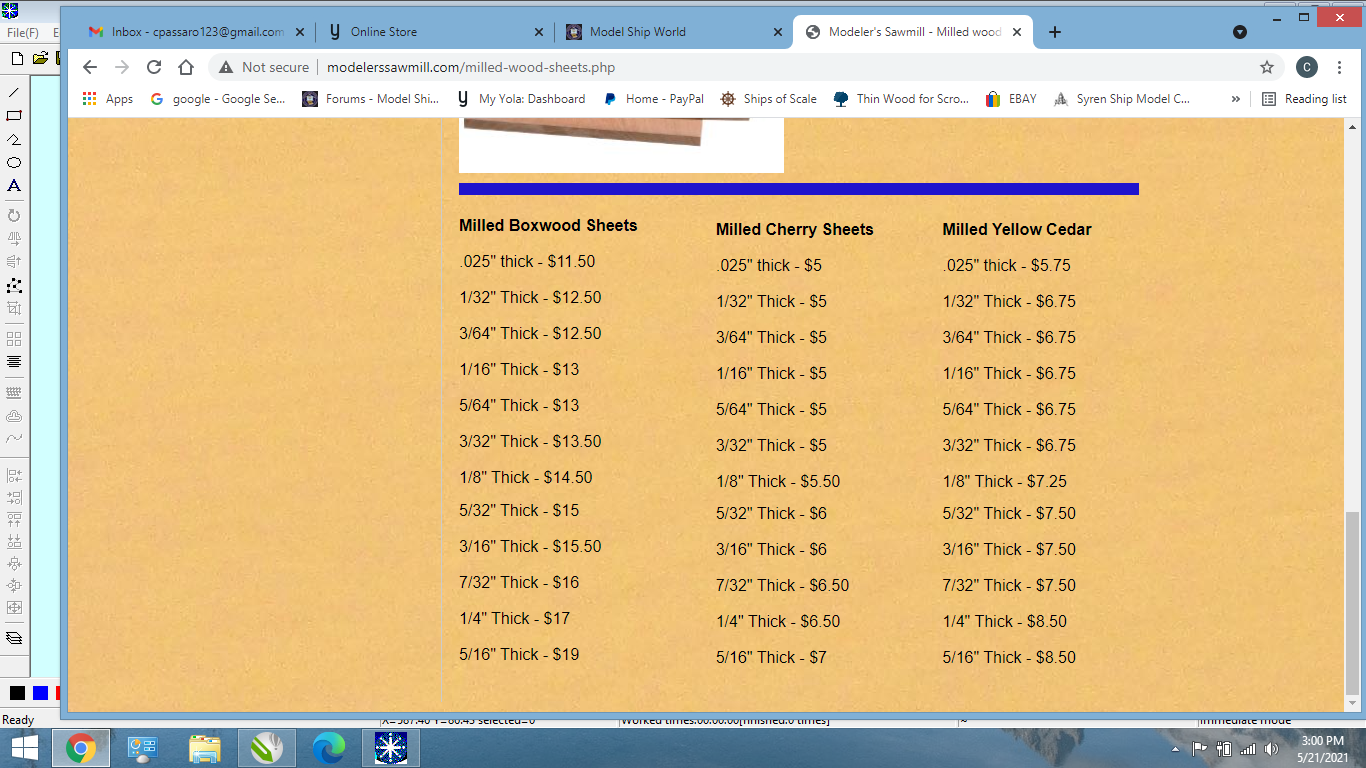

A bunch of people were PMing me about what he will offer.....I have this from his website under development.....wood sheets. He is starting with just these three species as he is awaiting delivery of others like Swiss Pear and Walnut etc. As he gets organized and gets the other stuff I will let you know. I asked him to sign up here and he will be a sponsor of MSW too.....just takes time to get it all off the ground. and strips will be for sale.... So all those folks who were reluctant to sign up for the Winnie project because you couldnt mill your own strips. This should solve that issue. Its gonna be a week or so before he opens up for orders. Chuck

-

Looking great. Nice and tidy. The ratlines will go just fine. Just keep them straight and evenly spaced. The worst thing that could happen is pulling in your shrouds to get that dreaded hourglass shape. No pressure.

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.