-

Posts

612 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Remcohe

-

ancre La Salamandre by tadheus - 1:24

Remcohe replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

I'd say it looks great! Remco -

Ed I admire how proficient you are with installing the knees. It takes me the better part of an evening to do maybe two, it looks like you did the whole deck in a fraction of that time. Admirable work as always. Remco

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Nice stash of wood, I bet you will really like working with Castello. Remco

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Thank you all for the kind words. For those interested in the soldering board, I purchased it here they also have the pins I use and some hold down clamps I didn't get but made them myself. Beware that the board quickly heats at the bottom so you should place extra heat protection underneath it (yes I found out the hard way and now I have a big burn mark on my bench ) Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

ancre La Salamandre by tadheus - 1:24

Remcohe replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

Clever to clamp the scribing tool Remco -

A sharp tool is a necessity, not only for draught marks Remco

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

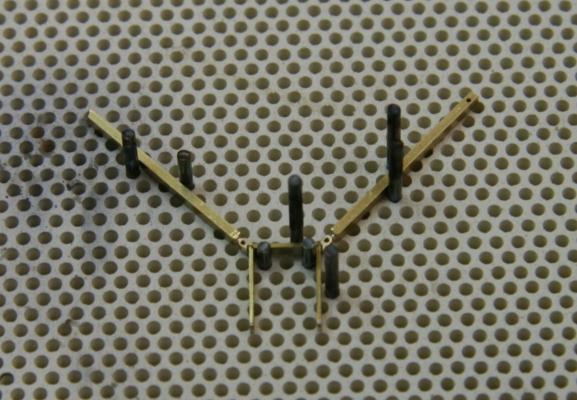

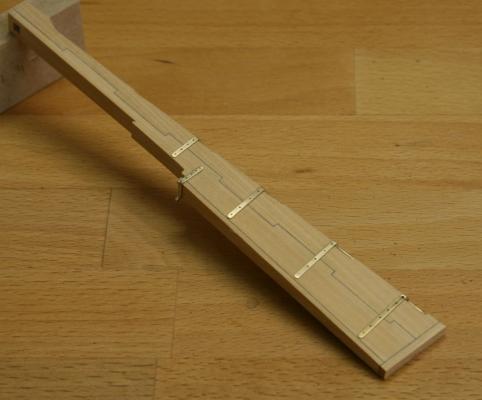

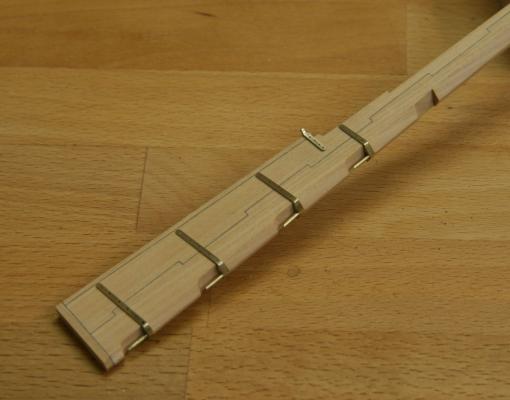

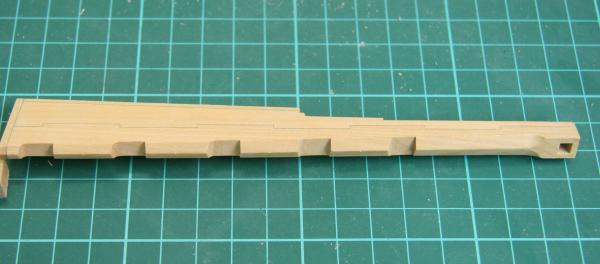

Thanks all. Mark, for delicate enhancing of the joints I use a pencil, but to simulate tarring like the joints on the rudder I use very thin paper (probably 0.1 mm thick). It comes in different colors but it's not water proof so I use the white one and tint it with a black Sharpy. All joints are lined on one side and after gluing the pieces together I used a plane to shape the rudder and trim the excess paper lining. Meanwhile the metalwork on the rudder is continued, the pintles and spectacle plate are made from separate pieces silver soldered together. Piet, when all metal work is ready I will try to brown them (instead of blackening) Here they are temporary fitted I noticed the hole for the tiller sits to close to the top of rudder, In need to make a little fix to lower it I'm not sure how that happened...... Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

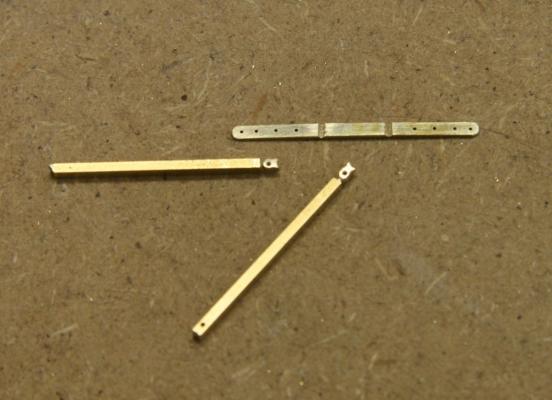

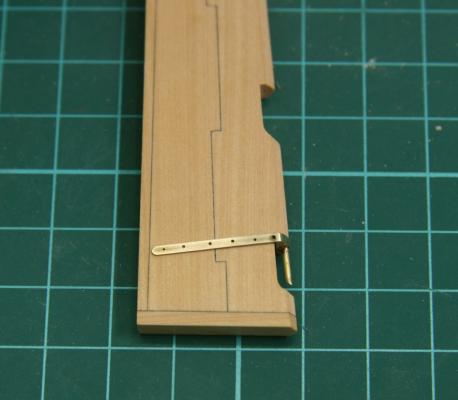

Thanks. I went to the hobby shop and got a better strip of brass that closer matches the size I need. Less material to remove, easier to work with. Two holes are smaller to receive a bolt the rest will get simulated screws..... Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Looking really good Danny. Can you explain how you serve your lines, they look really good. Homemade device? Remco

-

David B, I use a Veritas MKII honing guide and several (400, 1000, 3000 & 6000 grid) Japanese waterstones. It's a big investment but the results are great every time. Meanwhile I'm struggling with the pintles, the brass bars I have are to thick and need to be thinned down a lot, it's not working this way. I need to visit the hobby store to get bars that better match the size of the pintle straps. I not sure if I understand the TFFM correctly, are the straps let down into the keel? And is this over their full-length or partially? Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

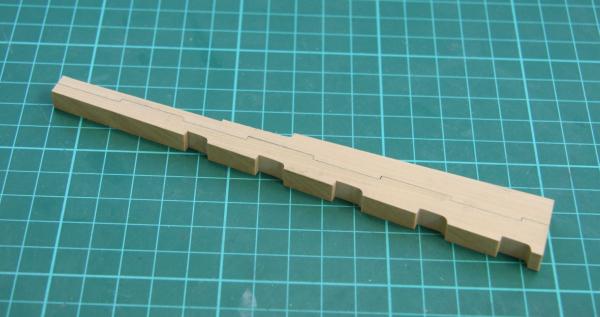

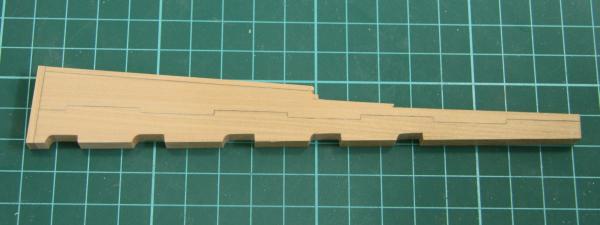

Thanks all, good quality chisels and keeping then very very sharp helps a lot... Robin I used the watering marking on my body plan to establish the position of the marks Next up the rudder, my first attempt to cut 'simple' tabs that go all the way from side to side failed. I had to much tear out from the mill, even with a backing piece of wood. So back to the chisels and I made the proper altering tabling. Cut to size with the table saw and scroll saw, tarring simulated with thin black paper Tapered with a big bench plane The square hole at the top tapers from fore to aft. Next up the pintles. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Ok, I added the marks on the sternpost by narrowing them down they fitted. I omitted one mark as the gudgeon will cover it. I'm not happy with how they turned out compared to the stempost marks. It was hard to maneuver being right handed, the hull got in the way Making a new sternpost is out of the question I'm affright ,.... Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Thanks all. Cog, I used a tripod and the timer to take that picture. Dave, the carving was done with small chisels of different sizes. Druxey, I was planning to tonight but ran into a problem. While marking their position I saw the stern post has the same with as the largest XIV and XIII marking. So adding them here will look odd. In the picture they are roughly penciled in but the final markings will take the full with of the stern post. I'd better leave them off Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Thanks Joe, Vivian & Mark. Indeed I used the knurling attachment from Shereline, it gives a good grip and a adds a nice touch. Port side treenailed And draught marks added, they won't be painted red as they should as this might be to distracting. They are just 3 mm, 1/8" high Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

I like it Maybe a little late with my advise, but at this scale you can heat bend small strips of boxwood into the shape of the frames. I used a plug and added the planks first and added the frames afterwards. Working with a plug gives a stable base to add those delicate parts on. Especially in the beginning there is not much structure to keep everything in place. Remco

-

Alan, Cog, I turned the fittings on my lathe, added knurls to finish them off and soldered them to the bars. Cabrapente, thats I nice little tool, I prefer to drill all holes manually as this gives far greater control and precision. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

I hadn't realized the FM antenna would be so large... Se sure looks great and ready to sail off Remco

-

A long overdue update....... I was too busy making decals and flags I planked the port side from the Sheer strake up, this is all the planking I will do on this side except some minor parts I need for the rigging. Next up tree nailing the lot.... Also made new brass knobs on the clamps, as it turned out the wooden ones didn't hold up after I reenforced the bars with nuts. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Congratulations Grant, she turned out beautifully. It was great fun to follow your build, thank you for taking the time to share it with us. Remco

-

The Byrnes Saw "inside and around"

Remcohe replied to nobotch's topic in Modeling tools and Workshop Equipment

Marcus, that are some interesting modifications. "For modifications, i like this one, a simplified version which appeared in NRG journal." Can somebody elaborate on this mod? Remco -

Mayflower by SawdustDave - Finished

Remcohe replied to SawdustDave's topic in - Build logs for subjects built 1751 - 1800

Ok, we'll be visiting Piet next spring, I'll aks the Admiral's permission if we can hit Lumberton during our tour of the South. Remco

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.