-

Posts

5,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by michael mott

-

Galleon by tuciship

michael mott replied to tuciship's topic in - Build logs for subjects built 1501 - 1750

Thinking "Outside of the Barrel" another great way to use heat shrink! Michael -

But I will happily drive in 3700 treenails....... Great job on the rivets Vaddoc, the finished appearance will be worth the time and effort. Michael Michael

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

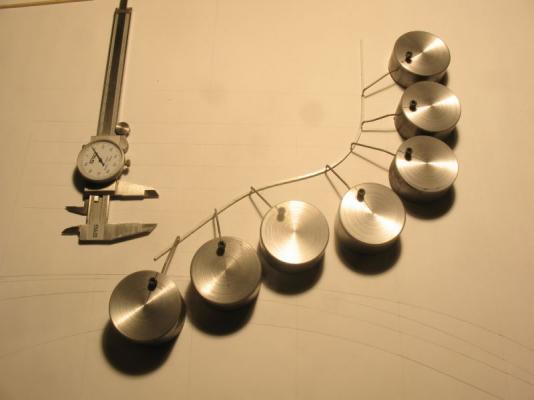

A bit more fiddling with the Carb. First I made a whole new one with a flange at the manifold side. The top air intake also needed to have the adjusting screw added, it was easier to make a new one rather than trying to fix the first one. I "knurled" the edge of the adjusting screw by pressing the head of the 1x72 screw under the edge of a file and rolled it along on a flat surface of MDF then beveled the edged on the lathe. the spring came out of a tiny ball race which I took apart for the springs and balls. Michael

-

Bob I am pretty sure that I will make it look like the one in the real Skipjack as much as possible, which I suppose is a long winded way of saying yes I will paint it green. Most of the Drawings that I print for the engine as I am working on it are printed 2:1, and I am thinking that down the road a smaller boat model with a 1/4 scale engine which would be the same size as my 2:1 prints would make a nice model. Skipjack will be 28 inches so at 1/4 scale something that is say 16 feet long would end up being 38 inches long which is shorter than the pilot cutter hull by 15 inches. Just some idle musings this morning while i am warming up the shop. thanks for all the likes today. Michael

-

I would work on that.... The car would have to live outside of course, quiet, out of the way place, etc, etc. Michael

-

Thanks for the kind thoughts for our Anniversary, I had Atlantic Salmon, and Judy had Lobster, it was great, then cheesecake for dessert. Our lake is starting to break up, it amazes me that 16 days ago people were still driving on the ice, and it looks like we might have open water within a week. Thanks for the likes and comments about the Engine for Skipjack. The more I work on the engine it seems that new bits to make keep jumping out of the woodwork, it is getting closer though. Michael

-

Thanks for all the kind comments and visits they mean a great deal and are very motivating. Just a small update because I am off to dinner with Jude to celebrate our 20th wedding anniversary this evening. The carb is started There are a few more bits yet then it all gets soldered together the main assembly will wind into the manifold and the nut will lock it into the vertical position. Michael

-

Well what a difference that makes Mobbsie. I have been looking at a lot of photographs of Smacks and Bawleys this weekend your new colour scheme looks the ticket. Michael

- 62 replies

-

- harwich bawley

- fishing boat

-

(and 2 more)

Tagged with:

-

Nils your rigging continues to amaze me, Just planning which lines to install first is a mind bender for me. A steady hand a long fine tweezers would be a must. Michael

-

Hello Carl, regarding your comments about the shape of the manifold, I am simply following the shape of the original design. This is the manifold off a 3 HP buffalo Engine I am going to use a vapor carb which is in fact no carb at all see this video I have to admit I am experimenting here and following the concept of using fumes in the same way as the chap in the video. I am also pushing the limits of what might be possible, I don't know. I believe I can make this work, I might have to use butane or Propane, but they require a different set up for feeding the engine, if the vapor doesn't work I will go with the butane. The folk who build a lot of model engines have done a lot of experimenting and I am following some of their ideas regarding the fuel. Thanks for all the fine comments and visits. Michael

-

Patrick, even though the sails are just placeholders their shape gives your incredible model that extra edge! I look forward to seeing how you solve the reinforcement panels. Michael

-

Denis the details just keep adding to the overall effect which is superb. Michael

- 956 replies

-

- andrea gail

- trawler

-

(and 1 more)

Tagged with:

-

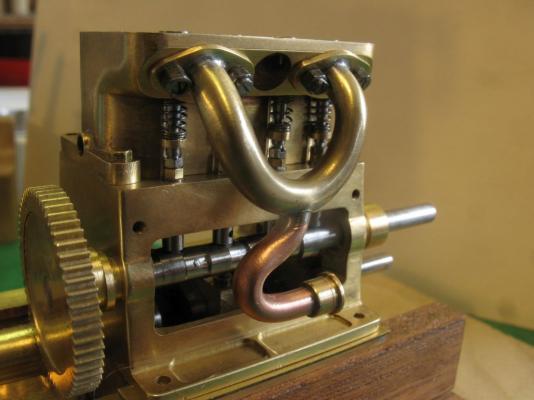

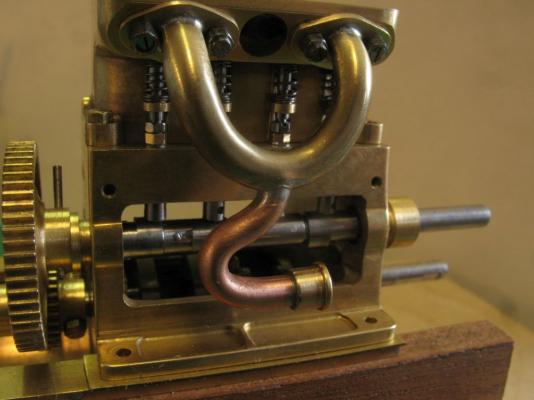

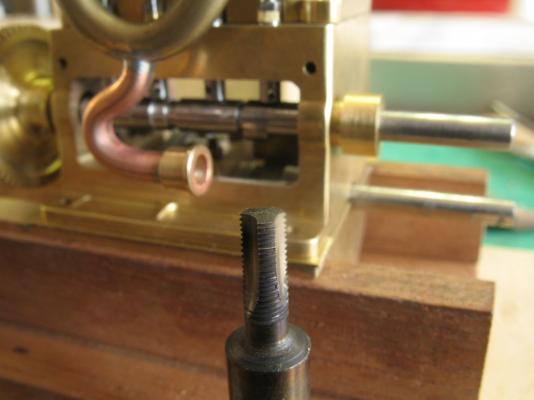

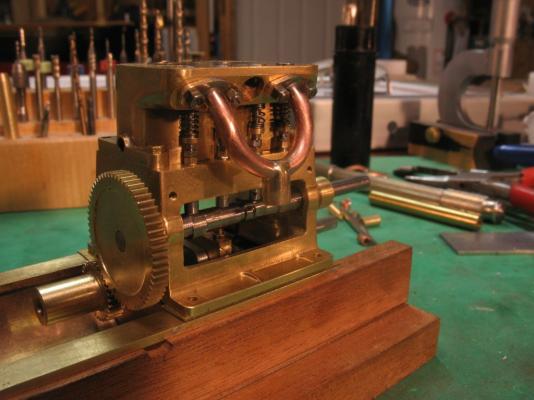

This morning I received a great photo from Roger so then spent most of the rest of the morning learning how to make even tighter loops in the tubing. After a while I got a couple of parts which looked like a good match, I also used a slightly larger diameter tube that was brass so I also needed another pair of flanges (I'm getting faster at making them at least). Soldered them up the same way as the first two times. Drilled a larger hole in the new loop I wanted to ensure that it was all lined up so soldered the bottom piece while it was on the engine. . After lunch I did some more tight loops and get a better bend on the lower part so un-soldered the bottom piece and added the new one with a 5 x 64 threaded coupling Here is the new tap I made it the same way as the other taps. and the final configuration. now I can make the carb Michael

-

Hi Mobbsie, thinking about what John said regarding the strength of the hull, I would be inclined to make them staggered whatever. A good practice is a good practice. It would seem to me that traditional work would follow good practice. Michael

- 62 replies

-

- harwich bawley

- fishing boat

-

(and 2 more)

Tagged with:

-

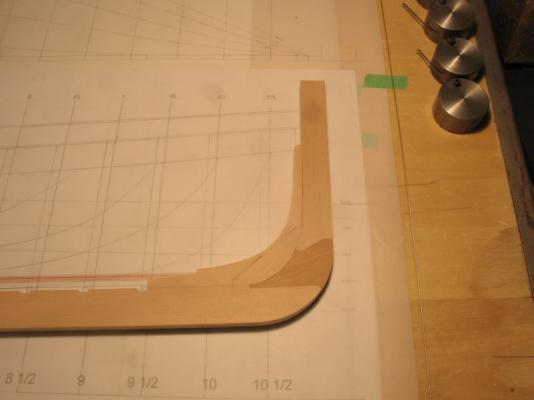

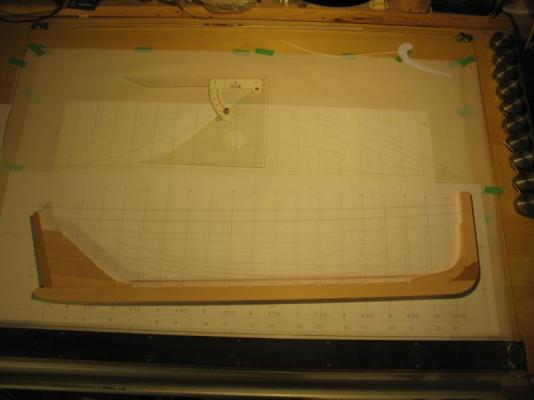

OK you asked I started some drawings based on Ted Penn's lines drawings and have cut the clear fir for the keel I did this a few years ago now and it is waiting for some other things to be finished before I go any further. the first picture shows some drawing Ducks I made to do the drawings. the next shows the overall keel parts. laid over the 1/24th scale drawings next a close up of the stem wood I am not sure about it all at the moment, i might go ahead or not. Michael

- 62 replies

-

- harwich bawley

- fishing boat

-

(and 2 more)

Tagged with:

-

Hi Mobbsie here is a pic of a bawley planking not great but some detail. And here is another they are from this list hope there is something there that will help. Michael

- 62 replies

-

- harwich bawley

- fishing boat

-

(and 2 more)

Tagged with:

-

Thanks everyone for the kind comments and for the visits to my build. I ended up having to make a second inlet manifold that was a bit shorter than the first one, I also made the flanges a little bigger. The brass piece at the bottom is threaded 6x80 for the carb body. I am waiting for Roger to get back to me with some pictures of the manifold side before proceeding. Michael

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.